Innovative Organic Synthesis Methods for Complex Molecule Discovery in Drug Development

This article explores the latest advancements in organic synthesis methodologies that are revolutionizing the discovery and development of complex molecules for biomedical applications.

Innovative Organic Synthesis Methods for Complex Molecule Discovery in Drug Development

Abstract

This article explores the latest advancements in organic synthesis methodologies that are revolutionizing the discovery and development of complex molecules for biomedical applications. Covering foundational strategies, emerging green chemistry techniques, AI-driven optimization, and comparative validation approaches, it provides researchers and drug development professionals with a comprehensive overview of tools enabling more efficient, sustainable, and precise synthesis of biologically active compounds. The content addresses key challenges in synthesizing complex molecular architectures while highlighting practical applications across pharmaceuticals, materials science, and biotechnology.

Core Principles and Emerging Paradigms in Complex Molecule Synthesis

Retrosynthetic Analysis and Strategic Bond Disconnections for Complex Targets

Retrosynthetic analysis is a foundational problem-solving technique in organic chemistry that involves deconstructing a target molecule into progressively simpler precursor structures by applying transforms, the logical reverses of known synthetic reactions [1]. This methodology transforms the planning of complex molecule syntheses from an ad-hoc process into a structured, logical methodology enabling systematic route discovery [1]. Formalized by Nobel Laureate E. J. Corey, this approach begins with the desired target molecule and works backward through hypothetical disconnections until reaching readily available starting materials [2] [1]. The power of retrosynthetic analysis lies in its ability to explore multiple synthetic pathways logically and systematically, comparing them for efficiency, feasibility, and convergence [2]. For complex targets in drug discovery and natural product synthesis, this methodology has become indispensable, reducing molecular complexity through strategic bond disconnections that follow recognized chemical transformations and patterns [3].

Within modern organic synthesis, particularly for complex molecule discovery research, retrosynthetic analysis provides the conceptual framework for designing efficient routes to novel molecular architectures [4] [5]. It serves as the intellectual engine driving synthetic planning in pharmaceutical and agrochemical development, where rapid access to structurally diverse compounds is essential for biological screening [3]. The methodology has evolved from manual application by expert chemists to computer-assisted implementations using artificial intelligence, dramatically accelerating the design of synthetic routes to complex targets [3].

Core Principles and Terminology

Fundamental Concepts

Retrosynthetic analysis operates on several key concepts that form the vocabulary and conceptual toolkit for synthetic planning:

- Target Molecule (TGT): The desired final compound whose synthesis is being planned [2] [1].

- Disconnection: A retrosynthetic step involving the hypothetical breaking of a bond to form two or more synthons, representing the reverse of a synthetic reaction [2].

- Synthon: An idealized fragment resulting from a disconnection, representing a reactivity pattern rather than a stable molecule [2] [1]. Synthons are classified as nucleophilic (donor) or electrophilic (acceptor) based on their electronic character [1].

- Retron: A minimal molecular substructure within the target that enables the application of a specific transform [2] [1].

- Transform: The reverse of a synthetic reaction, forming starting materials from a single product in the retrosynthetic direction [2].

- Synthetic Equivalent: The actual reagent or compound that corresponds to and implements the reactivity of a synthon in the forward synthetic direction [2].

Retrosynthetic Notation

The retrosynthetic process employs specific symbolic notation to distinguish it from forward synthesis. The retrosynthetic arrow (⇒) indicates the transformation from a target to its precursors, distinguishing this conceptual operation from actual synthetic reactions [1]. This notation creates a hierarchical structure where each retrosynthetic step simplifies molecular complexity, ultimately generating a retrosynthetic tree (or EXTGT tree) that maps multiple possible synthetic routes [2] [1].

Table: Core Terminology in Retrosynthetic Analysis

| Term | Definition | Role in Retrosynthesis |

|---|---|---|

| Target Molecule | Desired final compound for synthesis | Starting point for the retrosynthetic analysis |

| Disconnection | Hypothetical bond cleavage | Key operation to simplify molecular structure |

| Synthon | Idealized fragment from disconnection | Represents reactivity pattern for bond formation |

| Transform | Reverse of a known synthetic reaction | Guides the disconnection process logically |

| Retron | Minimal substructure enabling a transform | Identifies where specific disconnections can apply |

| Synthetic Equivalent | Actual reagent implementing synthon reactivity | Bridges idealized synthons with practical reagents |

The Disconnection Approach and Strategic Framework

Disconnection Methodology

The disconnection approach forms the operational core of retrosynthetic analysis, focusing on the imaginary cleavage of strategic bonds in the target molecule to generate simpler synthetic precursors [1]. This methodology systematically reduces molecular complexity by identifying bonds whose disconnection aligns with established synthetic transformations [1]. Valid disconnections must correspond to known and reliable forward synthetic transforms that simplify the target structure by reducing its size, topological complexity, or number of stereocenters [1]. The approach requires the presence of a retron—a structural subunit in the target that matches the transform's requirements—and prioritizes simplicity by favoring convergent pathways over linear ones [1].

Disconnections are classified based on the position of the cleaved bond relative to functional groups. Key classifications include:

- 1,1-Disconnection: Breaks a bond adjacent to a single functional group, such as the reverse of a carbonyl addition where a tertiary alcohol or ketone is cleaved to a carbonyl compound and a carbanionic synthon [1].

- 1,2-Disconnection: Cleaves the bond between two adjacent functional groups or atoms within a functional group, as seen in the retrosynthesis of aldol products from β-hydroxy carbonyl compounds [1].

- 1,3-Disconnection: Involves breaking a bond two or three atoms removed from a functional group, corresponding to reactions like the Michael addition in 1,5-dicarbonyl systems [1].

Heuristic rules guide disconnection choices by emphasizing those that produce stable, commercially available, or easily synthesized synthons [1]. These rules also advise against disconnections that generate strained rings larger than seven members, uncorrectable stereocenters, or unstable intermediates, ensuring the retrosynthetic path remains practical [1].

Strategic Approaches

Multiple strategic frameworks guide the disconnection process, each addressing different aspects of molecular complexity:

Functional Group Strategies: Focus on the manipulation, interconversion, or introduction of functional groups to enable key disconnections or simplify the target [2] [6]. This includes protecting group strategies for temporary masking of reactive functionalities during synthetic sequences [6].

Topological Strategies: Address the overall molecular framework through bond disconnections that fragment rings or chains, prioritizing disconnections that preserve ring structures and avoid creating large, strained ring systems [2] [1].

Stereochemical Strategies: Handle the creation, preservation, or manipulation of chiral centers through stereoselective transforms or disconnections that remove stereochemical complexity [2].

Transform-Based Strategies: Apply specific, powerful transforms to simplify complex structures, though these often require additional steps to establish the necessary retrons in the target [2].

Structure-Goal Strategies: Direct the analysis toward desirable intermediates or key structural motifs that serve as strategic subgoals in the synthetic sequence [2].

Table: Strategic Approaches in Retrosynthetic Analysis

| Strategy Type | Focus Area | Key Considerations |

|---|---|---|

| Functional Group | Reactive sites in the molecule | Interconversion, protection, and strategic placement |

| Topological | Molecular framework and connectivity | Bond disconnections to simplify core structure |

| Stereochemical | Chiral centers and 3D arrangement | Control and simplification of stereochemistry |

| Transform-Based | Application of specific reaction reverses | Requires presence of specific retrons in target |

| Structure-Goal | Targeting key synthetic intermediates | Bidirectional search from target to intermediate |

Practical Implementation and Workflow

Retrosynthetic Process Flow

The implementation of retrosynthetic analysis follows a systematic workflow that transforms complex targets into feasible synthetic plans. The process begins with the target molecule and proceeds through iterative disconnection steps until commercially available starting materials are identified.

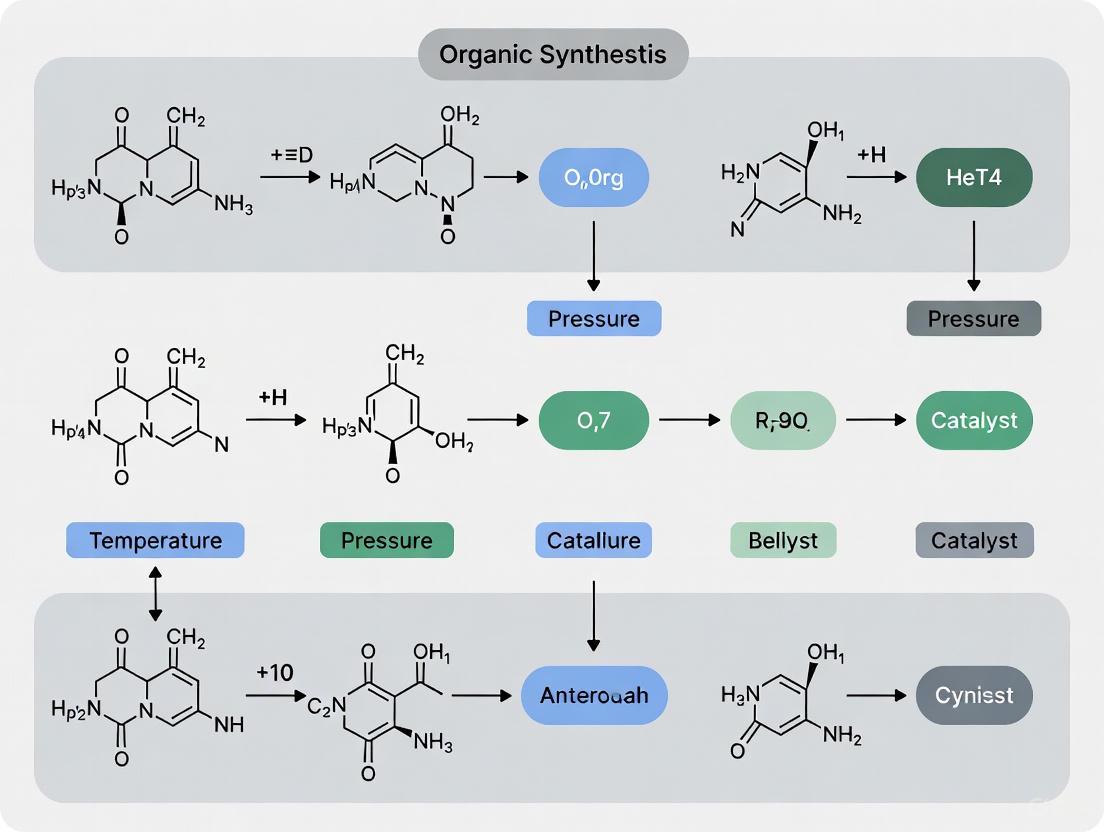

Diagram 1: Retrosynthetic Analysis Workflow. This flowchart illustrates the systematic process of deconstructing a target molecule into simpler precursors through iterative disconnection steps.

Building the Retrosynthetic Tree

The iterative disconnection process generates a retrosynthetic tree (or EXTGT tree), where each node represents a molecular structure and branches denote possible precursors [1]. This tree structure enables chemists to explore and evaluate multiple synthetic pathways, comparing different strategies for efficiency and feasibility [2]. The construction of this tree follows specific hierarchical principles:

- Each disconnection should simplify the molecular structure, reducing size, complexity, or number of stereocenters [1].

- Branching points occur when multiple valid disconnections are possible for a given intermediate [7].

- The tree grows until all terminal nodes (leaves) represent commercially available or easily accessible starting materials [2].

- Pathways are evaluated based on overall yield, step count, convergence, and practicality [7].

The efficiency of synthetic routes derived from retrosynthetic trees varies significantly based on architecture. Convergent syntheses, where multiple branches are synthesized independently then combined, generally offer superior overall yields compared to linear syntheses, where each step depends on the product of the previous one [7]. For a hypothetical 5-step synthesis with 90% yield per step, a linear approach gives 59% overall yield, while a convergent strategy provides 73% overall yield [7].

Research Reagent Solutions for Retrosynthesis Implementation

Successful implementation of retrosynthetic plans requires specific reagents and methodologies to execute the proposed transformations. The following table details essential research reagents and their functions in realizing synthetic routes derived from retrosynthetic analysis.

Table: Essential Research Reagents for Synthetic Implementation

| Reagent/Catalyst | Function in Synthesis | Application Context |

|---|---|---|

| Enzyme Catalysts | Biocatalysis with high selectivity under mild conditions | Synthesis of novel molecular scaffolds through radical mechanisms [4] |

| Photocatalysts | Light absorption to generate reactive species via energy transfer | Photocatalytic activation for multicomponent reactions [4] |

| Grignard Reagents (R-MgX) | Nucleophilic carbon addition to carbonyl groups | Carbon-carbon bond formation for alcohol synthesis [6] [7] |

| TBDMS Chloride | Silylating agent for alcohol protection | Temporary protection of hydroxyl groups during multifunctional synthesis [6] |

| PCC (Pyridinium Chlorochromate) | Selective oxidation of primary alcohols to aldehydes | Functional group interconversion in synthetic sequences [6] |

| Lithium Aluminum Hydride (LiAlHâ‚„) | Powerful reducing agent for carbonyl groups | Reduction of ketones and aldehydes to alcohols [6] |

| Aryne Precursors | Reactive intermediates for C-C bond formation | Efficient construction of complex aromatic structures [8] |

| Fluoride Salts (TBAF) | Desilylation agent for protecting group removal | Deprotection of silyl ethers to regenerate alcohols [6] |

Advanced Methodologies and Emerging Technologies

Innovative Synthetic Approaches

Recent advances in synthetic methodology have expanded the toolbox available for implementing retrosynthetic plans, particularly for complex targets in drug discovery research:

Enzyme-Photocatalyst Cooperativity: Combined photocatalytic and enzymatic catalysis enables novel multicomponent reactions previously inaccessible through either method alone. This approach leverages the efficiency and selectivity of enzymes with the versatility of synthetic catalysts, generating diverse molecular scaffolds with rich stereochemistry [4].

Light-Activated Aryne Chemistry: Modern aryne intermediate generation using low-energy blue light activation eliminates the need for chemical additives, reducing waste and enabling applications under biological conditions previously impossible with traditional methods [8].

Diversity-Oriented Synthesis: Focused on developing structurally diverse molecular libraries for screening, this approach contrasts with target-oriented synthesis by preparing arrays of potential options to increase chances of finding novel bioactive compounds [4].

Computational and AI-Enhanced Retrosynthesis

The field of retrosynthetic analysis has been transformed by computational approaches that augment human expertise:

Computer-Aided Retrosynthesis: Systems like LHASA (Logic and Heuristics Applied to Synthetic Analysis), developed by Corey in the 1970s, automated pathway generation using heuristic rules derived from retrosynthetic principles [1].

AI and Machine Learning: Modern platforms combine rule-based systems with data-driven models, rapidly exploring reaction databases and generating synthetic pathways ranked by criteria like yield, cost, or step count [3]. These tools manage the combinatorial explosion of possible routes that challenges manual analysis [3].

Hybrid Systems: Contemporary platforms balance reliability with innovation by integrating expert-coded rules with algorithmic power, suggesting syntheses aligned with available reagents and green chemistry principles [3].

Diagram 2: Modern AI-Enhanced Retrosynthesis Planning. This diagram illustrates the integration of computational approaches in contemporary retrosynthetic analysis, combining database mining, expert rules, and machine learning to generate optimal synthetic routes.

Applications in Complex Molecule Discovery Research

Pharmaceutical and Natural Product Synthesis

Retrosynthetic analysis provides the foundational framework for synthesizing complex molecules critical to drug discovery and development:

Drug Candidate Synthesis: A viable synthetic route is crucial for transitioning a molecule from theoretical interest to practical medicine, with retrosynthetic planning significantly shortening development timelines by replacing trial-and-error approaches with systematic design [3].

Natural Product Synthesis: Complex natural products with intricate functionalities and stereochemistry have provided challenging targets for developing retrosynthetic concepts [7] [5]. The methodology has been instrumental in the total synthesis of over 100 complex natural products, including prostaglandins, erythronolide B, and ginkgolide B [1].

Molecular Library Generation: For medicinal chemistry, the ability to generate novelty and molecular diversity is particularly important [4]. Retrosynthetic thinking enables combinatorial synthesis of novel molecules that expand accessible chemical space for biological screening [4] [3].

Green Chemistry and Sustainable Synthesis

Modern retrosynthetic analysis incorporates sustainability considerations through:

- Atom Economy Evaluation: Assessing potential routes for material efficiency and waste minimization [3] [5].

- Green Pathway Identification: AI tools help identify eco-friendly syntheses by minimizing steps, replacing toxic reagents, and reducing waste, directly supporting sustainable manufacturing initiatives [3].

- Biocatalytic Integration: Incorporating enzyme-catalyzed steps that operate under mild, environmentally benign conditions aligns with Green Chemistry goals [5].

The strategic disconnection of target molecules remains essential for designing efficient synthetic routes in drug discovery and beyond, emphasizing creativity within a rigorous framework [1]. As synthetic challenges continue to evolve toward increasingly complex targets, retrosynthetic analysis adapts through integration with new methodologies like biocatalysis, photochemistry, and computational planning tools [4] [8] [3]. This ongoing development ensures the continued relevance of retrosynthetic thinking for addressing the synthetic challenges of modern chemical biology and drug discovery research [5].

Modern synthetic organic chemistry is increasingly focused on the precise manipulation of molecular frameworks to enable efficient and versatile transformations across diverse fields, including sustainable synthesis and materials science [9]. Molecular editing, also referred to as skeletal editing, has emerged as a powerful approach that allows for atom-level modifications of molecular cores, facilitating complex transformations while minimizing resource-intensive de novo synthesis [9]. This paradigm shift from traditional peripheral editing—which modifies functional groups without altering the core skeleton—enables direct remodeling of molecular frameworks with unprecedented precision [9].

The conceptualization of "skeletal editing" drew inspiration from CRISPR gene editing, leading to shared terminology such as "editing," "mutations," "transmutations," "deletions," and "insertions" across both fields [9]. This approach has transformative potential across multiple domains: in drug discovery, it enables rapid optimization of lead compounds; in materials science, it allows fine-tuning of electronic, optical, and catalytic properties; and in total synthesis, it introduces retrosynthetic elegance for accessing complex natural products [9].

This technical guide provides an in-depth examination of molecular editing strategies, methodologies, and applications, framed within the context of advancing organic synthesis for complex molecule discovery research.

Core Strategies and Classifications

Skeletal editing encompasses three primary strategies for modifying cyclic compounds, each enabling distinct structural transformations [9]:

- Atom Insertion: Incorporation of new atom(s) into the main skeleton, leading to ring expansion

- Atom Deletion: Removal of one or more atoms, resulting in ring contraction

- Atom Transmutation: Exchange of one or more atoms, altering atom identity without changing ring size

These transformations can be further categorized by the number of atoms involved (single-atom versus multiple-atom editing) and the nature of the atoms being manipulated (carbon, nitrogen, oxygen, etc.) [9]. Single-atom editing has garnered significant attention for its precision in fine-tuning properties for pharmaceuticals and functional materials [9].

Table 1: Classification of Skeletal Editing Strategies

| Editing Strategy | Structural Outcome | Key Applications | Representative Examples |

|---|---|---|---|

| Atom Insertion | Ring expansion | Accessing medium/large rings, altering cavity size | Ciamician–Dennstedt rearrangement, photocatalytic multicomponent reactions |

| Atom Deletion | Ring contraction | Creating strained systems, structural diversification | Contractions via extrusion reactions |

| Atom Transmutation | Heteroatom exchange | Changing electronic properties, bioisosterism | Nitrogen-for-carbon exchanges in heterocycles |

| Multiple-Atom Editing | Significant scaffold reshaping | Generating structural diversity, lead hopping | Ring insertion, fragment replacement |

Experimental Methodologies and Protocols

Ring Expansion Through Carbon Atom Insertion

Carbon atom insertion represents the most extensively studied subclass of ring expansion strategies [9]. The historical Ciamician–Dennstedt rearrangement demonstrates this approach, using dichlorocarbene as an insertive agent to expand pyrrole rings through a cyclopropanation–fragmentation–aromatization pathway [9].

Contemporary Protocol: Photocatalytic Multicomponent Biocatalytic Reactions

Recent advances combine enzymatic catalysis with photocatalysis to achieve unprecedented carbon-carbon bond formations [4]. This hybrid approach leverages the efficiency and selectivity of enzymes with the versatility of synthetic catalysts [4].

Detailed Experimental Workflow:

Catalyst System Preparation:

- Design engineered enzymes capable of accepting photogenerated radical species

- Select organic photocatalysts compatible with enzymatic environments (e.g., xanthone derivatives)

- Establish reaction conditions maintaining both photocatalytic and enzymatic activity

Reaction Setup:

- Conduct reactions under inert atmosphere to protect radical intermediates

- Use blue LED illumination (450-470 nm) to excite photocatalyst

- Maintain temperature control (typically 25-37°C) for optimal enzyme function

- Employ continuous flow conditions to enhance light penetration and reaction efficiency

Multicomponent Assembly:

- Combine substrates bearing diverse functional groups

- Allow photocatalytic generation of radical species

- Enable enzymatic control of stereoselective bond formations

- Achieve convergence of three or more components into single products

Product Characterization:

- Analyze novel scaffolds via LC-MS and NMR spectroscopy

- Determine stereochemistry using chiral HPLC and X-ray crystallography

- Confirm well-defined three-dimensional shapes with rich stereochemistry

This method has generated six distinct molecular scaffolds previously inaccessible through conventional chemical or biological methods, with outstanding enzymatic control over stereochemistry [4].

Light-Actated Aryne Intermediate Generation

A groundbreaking advancement in molecular editing involves the light-activated generation of aryne intermediates without chemical additives [8]. This method replaces traditional thermal activation with low-energy blue light, eliminating significant waste associated with previous approaches [8].

Experimental Protocol:

Precursor Preparation:

- Synthesize carboxylic acid precursors bearing orthogonal protecting groups

- Ensure yellow color indicating light absorption capability

- Characterize precursors using computational analysis (Minnesota Supercomputing Institute)

Photoreaction Setup:

- Use simple aquarium-style blue LED lights (λ = 450-470 nm)

- Conduct reactions under ambient conditions without exclusion of air/moisture

- Employ standard Schlenk techniques or simple round-bottom flasks

Aryne Generation and Trapping:

- Generate aryne intermediates via photochemical activation

- Trap intermediates with diverse reaction partners including nucleophiles, dienes, and carbonyl compounds

- Access myriad aryne derivatives from carboxylic acid precursors

Application Scope:

- Create approximately 40 building blocks for drug discovery

- Apply to biological conditions previously inaccessible

- Enable modification of complex biomolecules (antibody-drug conjugates, DNA-encoded libraries)

This method represents the first major innovation in aryne chemistry since 1983, dramatically expanding applicability in medicinal chemistry and chemical biology [8].

AI-Enhanced Molecular Editing

Artificial intelligence has revolutionized molecular editing through advanced molecular representation methods and multi-modal learning frameworks [10] [11].

MoleculeSTM: Multi-modal Structure-Text Model

This approach jointly learns chemical structures and textual descriptions via contrastive learning, enabling text-based molecule editing with open-vocabulary capability [10].

Implementation Protocol:

Dataset Construction:

- Build PubChemSTM with >280,000 chemical structure-text pairs

- Extract textual descriptions illustrating chemical properties and bioactivities

Model Architecture:

- Chemical structure branch: Transformer on SMILES strings or GNNs on 2D molecular graphs

- Textual description branch: Scientific language models

- Contrastive learning to map representations from both branches to joint space

Text-based Editing:

- Use natural language prompts to specify desired molecular modifications

- Leverage compositionality to handle multi-objective optimization

- Achieve state-of-the-art performance on 20 zero-shot text-based editing tasks

This framework enables researchers to modify molecules using natural language instructions like "make this molecule more water-soluble while maintaining permeability" [10].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Molecular Editing Research

| Reagent/Material | Function | Key Characteristics | Application Examples |

|---|---|---|---|

| Dichlorocarbene Precursors | Insertive agent for carbon atom insertion | Generated from chloroform under strong basic conditions | Ciamician–Dennstedt ring expansion of pyrroles [9] |

| Engineered Biocatalysts | Stereoselective bond formation in complex systems | Reprogrammed substrate specificity, maintained efficiency | Multicomponent reactions for novel scaffolds [4] |

| Organic Photocatalysts | Light absorption and radical generation | Compatible with enzymatic environments, blue-light absorption | Concerted photocatalytic-biocatalytic reactions [4] |

| Carboxylic Acid Precursors | Aryne generation under mild conditions | Yellow color indicating light absorption, stable storage | Light-activated aryne chemistry without additives [8] |

| Blue LED Light Sources | Photochemical activation | Low-energy (450-470 nm), inexpensive, easily scalable | Aryne generation, photocatalytic reactions [8] [4] |

| Functional Group Templates | Guide specific molecular modifications | ElementKG-derived knowledge, standardized patterns | Knowledge graph-enhanced molecular editing [12] |

| 2-Bromo-6-difluoromethoxy-4-fluorophenol | 2-Bromo-6-difluoromethoxy-4-fluorophenol | Bench Chemicals | |

| Cnb-001 | Cnb-001, CAS:1019110-87-2, MF:C27H24N2O4, MW:440.5 g/mol | Chemical Reagent | Bench Chemicals |

Analytical and Validation Methods

Accurately assessing editing efficiency requires sophisticated analytical approaches. Multiple methods have been adapted from genome editing technologies to evaluate molecular editing outcomes [13].

Table 3: Analytical Methods for Assessing Editing Efficiency

| Method | Principle | Key Applications | Advantages | Limitations |

|---|---|---|---|---|

| T7 Endonuclease I Assay | Mismatch cleavage of heteroduplex DNA | Detection of small insertions/deletions | Rapid results, simple implementation | Semi-quantitative, limited sensitivity [13] |

| TIDE/ICE Analysis | Sequence trace decomposition | Quantitative analysis of editing outcomes | More quantitative than T7EI, estimates indel frequencies | Relies on PCR/sequencing quality [13] |

| Droplet Digital PCR | Differential fluorescent probe labeling | Precise quantification of edit frequencies | Highly precise, quantitative, fine discrimination | Requires specific probe design [13] |

| Live-Cell Fluorescent Reporters | Fluorescence activation upon editing | Tracing editing events in cellular context | Live-cell monitoring, flow cytometry compatible | Limited to engineered cells, artificial context [13] |

Computational Integration and Knowledge Enhancement

The KANO framework demonstrates the power of integrating fundamental chemical knowledge through knowledge graphs to enhance molecular editing [12].

ElementKG Construction and Application:

Knowledge Graph Development:

- Build element-oriented knowledge graph (ElementKG) from Periodic Table and functional group data

- Capture class hierarchy, chemical attributes, and element-functional group relationships

- Establish microscopic atomic associations beyond direct chemical bonds

Element-Guided Graph Augmentation:

- Identify element types in molecules and retrieve corresponding entities/relations

- Create augmented molecular graphs preserving chemical semantics

- Establish essential connections between atoms sharing same element type

Contrastive Pre-training:

- Train graph encoder to maximize consistency between original and augmented molecular graphs

- Avoid indiscriminate implantation of external knowledge

- Enhance model understanding of fundamental domain knowledge

Functional Prompt Fine-tuning:

- Generate functional prompts based on ElementKG knowledge

- Bridge gap between pre-training and downstream tasks

- Evoke task-related knowledge in pre-trained model

This approach outperforms state-of-the-art baselines on 14 molecular property prediction datasets while providing chemically sound explanations [12].

Applications in Drug Discovery and Beyond

Scaffold Hopping and Lead Optimization

Molecular editing directly enables scaffold hopping—discovering new core structures while maintaining biological activity—through four main categories [11]:

- Heterocyclic Substitutions: Replacing ring systems with bioisosteric alternatives

- Ring Opening/Closing: Altering ring topology while preserving key pharmacophores

- Peptide Mimicry: Creating non-peptidic scaffolds that mimic peptide function

- Topology-Based Hops: Modifying core connectivity patterns

AI-driven molecular generation methods have transformed scaffold hopping through techniques like variational autoencoders and generative adversarial networks, designing entirely new scaffolds absent from existing chemical libraries [11].

Multi-objective Molecular Optimization

The compositionality attribute of natural language interfaces enables simultaneous optimization of multiple molecular properties [10]. Researchers can craft text prompts like "molecule is soluble in water and has high permeability" to guide molecular transformations that satisfy complex, multi-factorial objectives in lead optimization [10].

Diversity-Oriented Synthesis

The enzymatic multicomponent reaction developed by Yang and collaborators exemplifies how molecular editing enables diversity-oriented synthesis [4]. This approach focuses on generating structurally diverse molecular libraries for screening, contrasting with traditional target-oriented synthesis, and significantly increases chances of finding novel bioactive compounds [4].

Future Perspectives and Challenges

While molecular editing has made remarkable advances, several challenges remain:

- Terminology Standardization: The field lacks consistent terminology, with terms like "insertion," "deletion," "expansion," and "contraction" used inconsistently across studies [9]

- Generalization Limitations: Many methods remain substrate-specific or require extensive optimization for new systems

- Predictive Accuracy: Computational methods still struggle to perfectly predict outcomes of complex molecular edits

- Scalability: Some sophisticated editing approaches face challenges in scaling for industrial applications

Future directions will likely focus on integrating increasingly sophisticated AI models with experimental validation, expanding the toolbox of editing reactions, and developing more standardized frameworks for applying these powerful techniques across chemical space.

Molecular editing represents a paradigm shift in synthetic chemistry, moving beyond peripheral modifications to direct, precise manipulation of molecular cores. As these methods continue to evolve, they promise to accelerate discovery across pharmaceuticals, materials science, and beyond, enabling researchers to precisely sculpt matter at the atomic level with unprecedented control and efficiency.

Late-Stage Functionalization Strategies for Diversifying Complex Intermediates

Late-stage functionalization (LSF) has emerged as a transformative paradigm in modern organic synthesis, enabling direct chemical modification of complex molecules without requiring de novo synthesis. Defined as a "desired, chemical or biochemical, chemoselective transformation on a complex molecule to provide at least one analog in sufficient quantity and purity for a given purpose without needing the addition of a functional group that exclusively serves to enable said transformation," LSF significantly diminishes synthetic effort and provides access to molecules that would otherwise be difficult to obtain [14]. This approach has gained substantial impetus over the past decade, particularly through C–H functionalization methodologies, which have established new retrosynthetic disconnections while improving resource economy [15].

The strategic importance of LSF extends across multiple disciplines, with particularly profound impacts in drug discovery and materials science. In therapeutic development, LSF allows medicinal chemists to rapidly optimize drug candidates by generating diverse analogs from advanced intermediates, thereby accelerating structure-activity relationship (SAR) studies and improving pharmacological properties [16] [15]. The ability to selectively modify complex molecular scaffolds without resorting to lengthy synthetic routes represents a fundamental shift in synthetic planning, making LSF an indispensable tool in the molecular synthesis landscape.

Core Principles and Definitions

Chemoselectivity: The Fundamental Requirement

Chemoselectivity represents the cornerstone of successful LSF applications. This principle demands that transformations occur selectively at the desired site while tolerating the diverse functional groups typically present in complex molecules [17] [14]. High chemoselectivity ensures predictable reaction outcomes and avoids over-functionalization of valuable substrates, which are typically used as limiting reagents in LSF reactions [14]. It is important to distinguish that while all LSF reactions are chemoselective, not every chemoselective reaction qualifies as LSF. True LSF utilizes native functionality without requiring prior installation of directing or activating groups exclusively for enabling the transformation [14].

Site-Selectivity: An Optional but Desired Feature

Site-selectivity (also referred to as positional or regioselectivity) is generally desired but not strictly required for LSF reactions [17] [14]. Site-unselective LSF reactions can provide valuable access to multiple constitutional isomers relevant for biological testing in drug discovery [14]. However, site-selective reactions that independently access each possible isomer are highly desirable as they avoid cumbersome purification procedures and minimize waste production [17]. The discovery of site-selective LSF reactions constitutes an important research objective in synthetic methodology development, with recent advances demonstrating exquisite control over regiochemical outcomes [14] [18].

Classification of LSF Reactions

LSF strategies can be broadly categorized into two main approaches:

- C–H Functionalization: This approach involves direct activation and transformation of C–H bonds, eliminating the need for pre-functionalized starting materials. Every C–H bond functionalization on a complex molecule qualifies as LSF, except when a directing group must be installed specifically to enable the transformation [14].

- Functional Group Manipulation: These transformations modify existing functional groups present in the complex molecule. The distinction between LSF and merely functional-group-tolerant reactions can be subtle, with true LSF utilizing native functionality without artificial modification [14].

Key LSF Methodologies and Experimental Approaches

C–H Borylation for Broad Diversification

C–H borylation has emerged as one of the most versatile strategies for LSF, providing organoboron handles that can be transformed into diverse functional groups through subsequent C–C bond couplings [19]. This approach enables comprehensive SAR studies by facilitating broad structural diversification from a single advanced intermediate. The power of borylation lies in its ability to generate valuable synthetic intermediates that serve as platforms for further elaboration.

Experimental Protocol: High-Throughput Borylation Screening [19]

- Reaction Setup: Screenings are performed in 24-well plates under inert atmosphere using automated liquid handling systems.

- Typical Conditions:

- Substrate: 0.05 mmol scale in 0.2 mL solvent

- Catalyst: Iridium-based catalysts (e.g., [Ir(OMe)COD]â‚‚) with bipyridine ligands

- Boron source: Bâ‚‚pinâ‚‚ (1.5-2.0 equivalents)

- Solvent: Cyclooctane or tert-butyl methyl ether

- Temperature: 80-100°C

- Time: 16-24 hours

- Analysis: Reaction monitoring via LC-MS with automated data analysis pipeline to determine binary (yes/no) reaction outcomes, yields, and regioselectivity.

- Scale-up: Successful conditions identified through screening can be scaled up to produce sufficient material for biological testing or further modification.

Cyclic Iodonium Salt Chemistry

The application of cyclic diaryliodonium salts represents a powerful LSF strategy for constructing complex architectures. This approach enables regioselective functionalization of arene systems through the formation of cyclic iodonium intermediates that undergo diverse atom insertion processes [20].

Experimental Protocol: Regioselective Tetraphenylene Diversification [20]

- Synthesis of Cyclic Iodonium Salt A:

- Substrate: 2,7,10,15-tetra-tert-butyltetraphenylene (5)

- Reagents: Iâ‚‚ (1.2 equiv), m-CPBA (2.2 equiv), TfOH (4.0 equiv)

- Solvent: CHâ‚‚Clâ‚‚

- Conditions: 0°C to room temperature, 12 hours

- Yield: 53%

- Synthesis of Cyclic Iodonium Salt B:

- Substrate: 2,7,10,15-tetranitrotetraphenylene (9)

- Reagents: NaIO₃ (1.1 equiv)

- Solvent: Concentrated Hâ‚‚SOâ‚„

- Conditions: 110°C, 3 hours

- Yield: 62%

- Downstream Functionalization: The resulting cyclic iodonium salts undergo insertion of various atoms (O, N, S) or cross-coupling reactions to generate fused-ring systems including double helical architectures.

Thianthrenation for Site-Selective Aromatic C–H Functionalization

Thianthrenation represents a breakthrough in site-selective aromatic C–H functionalization, enabling the transformation of arenes into aryl sulfonium salts that serve as versatile electrophiles for subsequent transformations [18]. This method is unusual in that it typically produces a single constitutional isomer regardless of substitution pattern or directing groups.

Experimental Protocol: Thianthrenation and Subsequent Functionalization [18]

- Thianthrenation Reaction:

- Reagents: Thianthrene S-oxide, triflic anhydride

- Solvent: Dichloromethane

- Conditions: -78°C to room temperature

- Diversification Reactions:

- Photoredox Catalysis: Enables site-selective late-stage fluorination using aryl sulfonium salts

- Cross-Coupling: Conventional palladium-catalyzed C–C, C–N, C–O, C–S bond formation

- C–H Oxygenation: Conversion to phenols and related oxygenated derivatives

Sequential Multicatalytic C–H Functionalization

Sequential metal catalysis provides an economical and environmentally beneficial approach to polyfunctional biaryl synthesis through complementary multicatalytic sequences [21]. This strategy leverages inherently present functional groups to guide multiple late-stage functionalization steps.

Experimental Protocol: Sequential C–H Halogenation/Arylation/Cross-Coupling [21]

- Step 1 - C–H Halogenation:

- Directing group-assisted metal-catalyzed halogenation

- Catalysts: Pd, Rh, or Ru complexes

- Step 2 - Arylation:

- Transition metal-catalyzed C–H arylation using the halogenated intermediate

- Step 3 - Cross-Coupling:

- Further diversification through Suzuki, Negishi, or related cross-coupling reactions

- Applications: Successfully demonstrated on complex substrates including vismodegib, PH089, diazepam, and azahelicene synthesis

Quantitative Comparison of LSF Methodologies

Table 1: Performance Metrics of Key LSF Strategies

| Methodology | Typical Yield Range | Site-Selectivity | Functional Group Tolerance | Diversification Scope |

|---|---|---|---|---|

| C–H Borylation [19] | Variable (5-95%) | Moderate to High | Broad | Excellent (via boron conversion) |

| Cyclic Iodonium [20] | 32-62% | High (steric/electronic control) | Moderate | Good (atom insertion, coupling) |

| Thianthrenation [18] | 45-85% | Very High | Broad | Excellent (multiple bond formations) |

| Sequential Catalysis [21] | 40-75% | Directed by native FGs | Moderate to Broad | Very Good (stepwise diversification) |

Table 2: Geometric Deep Learning Prediction Accuracy for Borylation [19]

| Prediction Task | Best Model | Performance Metrics | Key Influencing Factors |

|---|---|---|---|

| Reaction Yield | GTNN3DQM | MAE: 4.23%; Pearson r: 0.890 | Substrate structure, conditions |

| Binary Outcome | GTNN3DQM | Balanced Accuracy: 92% (known substrates), 67% (new substrates) | Steric effects, electronic properties |

| Regioselectivity | aGNN3DQM | Classifier F-score: 67% | Steric environment, atomic charges |

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagent Solutions for LSF Experimentation

| Reagent/Catalyst | Function | Application Examples |

|---|---|---|

| Iridium-bipyridine complexes | C–H borylation catalyst | Installing boron handles for diversification [19] |

| Thianthrene S-oxide | Sulfonium salt formation | Site-selective aromatic functionalization [18] |

| Cyclic iodonium salts | Electrophilic linchpins | Atom insertion, fused-ring construction [20] |

| Bâ‚‚pinâ‚‚ | Boron source | Borylation reactions for SAR expansion [19] |

| Palladium-phosphine complexes | Cross-coupling catalysis | C–C, C–N, C–O bond formation from LSF intermediates [18] [21] |

| Photoredox catalysts | Single-electron transfer | Fluorination, other radical-based functionalizations [18] |

| 2-Ethoxy-5-methoxyphenylboronic acid | 2-Ethoxy-5-methoxyphenylboronic Acid|CAS 957065-85-9 | 2-Ethoxy-5-methoxyphenylboronic acid (957065-85-9) is a reagent for Suzuki-Miyaura cross-coupling. This product is for research use only and is not intended for human or veterinary use. |

| Ethyl 3-bromo-5-fluoroisonicotinate | Ethyl 3-bromo-5-fluoroisonicotinate, CAS:1214335-25-7, MF:C8H7BrFNO2, MW:248.05 g/mol | Chemical Reagent |

Implementation Workflows and Decision Pathways

Case Studies in Complex Molecule Diversification

Tetraphenylene Functionalization for Materials Science

The diversification of tetraphenylene scaffolds demonstrates the power of LSF in materials science applications. Through regioselective late-stage iodination followed by atom insertion into cyclic iodonium salts, researchers achieved rapid construction of double helical architectures and potential hole transport materials [20]. This approach leveraged both steric hindrance effects (from tert-butyl groups) and electronic effects (from nitro groups) to control regioselectivity, enabling access to tetraphenylene-based [8 + n] and [n + 8 + n] fused-ring systems with aesthetic architectures.

Drug Molecule Diversification for Property Optimization

LSF has proven particularly valuable in drug discovery campaigns where improving drug-like properties is essential. The application of LSF methodologies to optimize pharmacokinetic properties, metabolic stability, and potency of drug candidates has grown significantly [16]. Case studies where multiple LSF techniques were implemented to generate analog libraries with improved drug-like properties demonstrate the strategic value of this approach in lead optimization [16].

Natural Product Analog Synthesis

The cyanthiwigin natural product core exemplifies the implementation of LSF in natural product diversification [22]. By designing a central molecular scaffold with multiple functional handles, researchers accessed novel oxygenated derivatives through conventional oxidation strategies and modern C–H oxidation methods. This approach generated cyanthiwigin-gagunin "hybrid" molecules combining structural features from different natural product families, highlighting how LSF enables exploration of bioactive chemical space [22].

Emerging Technologies and Future Directions

Integration of Geometric Deep Learning

The combination of geometric deep learning with high-throughput experimentation represents a cutting-edge development in LSF methodology [19]. Graph neural networks (GNNs) and graph transformer neural networks (GTNNs) trained on two-dimensional, three-dimensional, and quantum-mechanically augmented molecular graphs enable accurate prediction of reaction outcomes, yields, and regioselectivity. This digital-experimental hybrid approach accelerates reaction optimization and expands the accessible chemical space for complex molecule diversification.

Photoredox and Electrocatalysis

Photoredox catalysis has emerged as a powerful activation mode for LSF, enabling unique reaction pathways under mild conditions. The application of photoredox methods to aryl sulfonium salt chemistry exemplifies how this approach complements traditional catalytic methods, particularly for challenging transformations such as late-stage fluorination [18]. Similarly, electrosynthesis provides sustainable alternatives for redox transformations in complex molecular settings.

Biocatalytic LSF

Enzyme-mediated functionalization offers exceptional selectivity for LSF applications. The controlled oxidation of remote sp³ C–H bonds in artemisinin via engineered P450 catalysts demonstrates how biocatalysis achieves fine-tuned regio- and stereoselectivity that is challenging with conventional synthetic methods [14]. The integration of biocatalytic steps with synthetic methodologies represents a promising frontier in complex molecule diversification.

Late-stage functionalization strategies have fundamentally transformed the practice of complex molecule synthesis, providing efficient pathways to diverse molecular architectures that would be challenging to access through traditional synthetic approaches. The continued development of increasingly selective, efficient, and predictable LSF methodologies will further empower drug discovery and materials science research. As geometric deep learning and artificial intelligence become more integrated with experimental workflows, the precision and scope of LSF will expand, solidifying its role as an indispensable component of the synthetic chemistry toolkit.

Bioinspired total synthesis represents a foundational concept for designing powerful synthetic strategies by drawing inspiration from nature's biosynthetic pathways [23]. This approach uses the principles of biotic evolution, where organisms survive environmental changes through chemical adaptation, as a blueprint for laboratory synthesis. The core philosophy posits that rather than attempting to surpass nature, synthetic chemists can achieve remarkable efficiency by learning from nature's well-orchestrated processes [23]. Historically, this field gained momentum with seminal works like Robinson's tropinone synthesis in 1917, which demonstrated the rapid assembly of a complex natural product in a cascade manner, mirroring biochemical transformations [23]. In the modern context, bioinspired synthesis aims to rapidly generate molecular complexity from simpler precursors using transformative reactions such as cascades, cycloadditions, and C–H functionalizations, thereby enhancing synthetic efficiency and step-economy [23].

A significant advantage of this approach lies in its capacity to validate proposed biogenetic pathways. While the exact biosynthetic pathway of a natural product is often complex and not fully elucidated, isolating scientists frequently propose plausible pathways based on structural analysis of co-existing natural products [23]. Bioinspired synthesis provides chemical evidence to support these plausible biogenetic pathways by replicating key steps under simple, biomimetic reaction conditions such as acid, base, or visible light catalysis [23]. This synergy between proposed biosynthesis and practical synthesis continues to drive innovation in the field, offering a logical framework for synthesizing structurally intricate natural products that are challenging to access via conventional linear synthesis.

Core Principles and Representative Case Studies

The implementation of bioinspired synthesis can be categorized into several strategic types, including mimicking key cyclization steps, replicating proposed biosynthetic pathways, and mimicking skeletal diversification processes [23]. The following case studies illustrate how these principles are applied to synthesize different classes of natural products, demonstrating the power of this approach to construct complex molecular architectures efficiently.

Case Study 1: Total Synthesis of Chabranol

The diterpenoid chabranol, isolated from soft corals, features a novel bridged skeleton with an oxa-[2.2.1] bridge and two quaternary centers, one at a bridgehead position [23]. Its bioinspired synthesis was designed around a proposed biosynthetic pathway starting from the linear sesquiterpenoid trans-nerolidol [23].

- Proposed Biosynthetic Pathway: The proposed pathway involves dihydroxylation of trans-nerolidol (1) to form triol 2, followed by C–C bond cleavage to yield aldehyde 3. Acidic activation of this aldehyde then triggers a key Prins cyclization with the trisubstituted olefin. This forms a putative tertiary carbocation that is trapped stereoselectively by the chiral alcohol, generating the bicycle 4. Final oxidation of the remaining olefin affords chabranol [23].

- Synthetic Execution and Key Cyclization: The laboratory synthesis convergently constructed the aldehyde precursor 3. Subjecting this aldehyde to conditions mimicking the biosynthetic proposal (activation with a formal silicon cation) successfully triggered the Prins-triggered double cyclization. This key transformation directly furnished the silylated bicycle 9 with sole diastereoselectivity, demonstrating the power of the bioinspired approach to build complexity rapidly [23]. Subsequent redox manipulations and deprotection completed the first total synthesis of chabranol. This synthesis not only provided authentic material to confirm the structure but also offered strong chemical support for the plausibility of the proposed biogenetic pathway [23].

Figure 1: Proposed biosynthetic pathway for chabranol, featuring a key Prins cyclization.

Case Study 2: Total Syntheses of Monocerin-Family Natural Products

Natural products of the monocerin family, such as monocerin and 7-O-demethylmonocerin, are isocoumarin-derived fungal metabolites with broad-spectrum biological activities [23]. Their biosynthesis is proposed to proceed through a para-quinone methide (pQM) intermediate [23].

- Proposed Biosynthetic Pathway: For fusarentin 6-methyl ether, oxidation generates the p-QM intermediate 10. The C10 alcohol then undergoes an intramolecular oxa-Michael addition to this activated system, closing the cis-substituted tetrahydrofuran (THF) ring and yielding 7-O-demethylmonocerin [23]. Monocerin and other analogues are presumed to form from their respective precursors through similar oxidative cyclizations.

- Synthetic Execution and Key Cyclization: The laboratory synthesis commenced with benzaldehyde 11. A sequence involving a Wittig reaction, incorporation of a 1,3-dithiane group (12), and nucleophilic addition to a chiral epoxide (13) constructed the core precursor poised for biomimetic cyclization [23]. The key step in the synthesis mimics the proposed biosynthesis by generating a p-QM intermediate under controlled conditions, which then undergoes an intramolecular oxa-Michael addition to stereoselectively form the complex fused ring system [23]. This use of quinone methide chemistry showcases how bioinspired strategies can leverage reactive intermediates for complexity-generating transformations.

Figure 2: Biomimetic oxidative cyclization via a para-quinone methide intermediate.

Quantitative Comparison of Bioinspired Case Studies

Table 1: Key metrics and strategies in bioinspired total synthesis

| Natural Product | Compound Class | Key Bioinspired Transformation | Complexity Generated | Reported Stereoselectivity |

|---|---|---|---|---|

| Chabranol [23] | Diterpenoid | Prins-triggered double cyclization | Oxa-[2.2.1] bicycle with two quaternary centers | Sole diastereoselectivity |

| Monocerin [23] | Polyketide-derived Isocoumarin | Oxa-Michael addition to para-quinone methide | cis-Fused tetrahydrofuran ring | High stereocontrol (well-defined) |

Experimental Protocols: Key Methodologies

Translating bioinspired strategies into practical synthesis requires carefully designed experimental protocols. This section details a generalized procedure for a key biomimetic cyclization and a modern enzymatic multicomponent reaction.

General Procedure for Biomimetic Prins Cyclization

This procedure is adapted from the synthesis of chabranol, which demonstrates a complexity-generating cationic cyclization [23].

- Precursor Preparation: Synthesize the hydroxy aldehyde precursor (e.g., compound 3) from phenyl sulfide 5 and chiral epoxide 6. This involves coupling under strong basic conditions, followed by a one-pot reduction of the sulfide moiety to generate diol 8. The primary alcohol of diol 8 is then oxidized using Swern oxidation conditions (oxalyl chloride, DMSO, followed by triethylamine) to yield the required hydroxy aldehyde 3 [23].

- Cyclization Reaction:

- In a flame-dried flask under an inert atmosphere (e.g., Nâ‚‚ or Ar), dissolve the hydroxy aldehyde substrate in a dry, aprotic solvent such as dichloromethane (DCM).

- Cool the solution to 0°C.

- Add a Lewis acid or a source of a formal silicon cation (e.g., TMSOTf, TBSOTf) dropwise. The original report used a "formal silicon cation" to activate the aldehyde [23].

- Stir the reaction mixture, allowing it to warm to room temperature slowly, and monitor by thin-layer chromatography (TLC) until completion.

- Work-up and Purification: Upon completion, quench the reaction by careful addition of a saturated aqueous solution of sodium bicarbonate (NaHCO₃). Extract the aqueous layer multiple times with DCM. Combine the organic extracts, dry over an anhydrous drying agent (e.g., MgSO₄ or Na₂SO₄), filter, and concentrate under reduced pressure. Purify the crude residue (e.g., silylated bicycle 9) using flash chromatography on silica gel to obtain the pure cyclized product [23].

General Procedure for Enzymatic Multicomponent Reactions

This procedure is inspired by recent advances in biocatalysis that combine enzymatic efficiency with the versatility of synthetic photocatalysts for diversity-oriented synthesis [4].

- Reaction Setup:

- Prepare a stock solution of the reprogrammed biocatalyst (engineered enzyme) in an appropriate aqueous buffer (e.g., phosphate buffer, pH ~7.5). The enzyme is engineered via directed evolution to function on a wide range of non-natural substrates [4].

- In a reaction vial, combine the enzyme solution, the photocatalyst (e.g., a metal complex or organic dye that absorbs visible light), and the multiple substrate components.

- Photoreaction Execution:

- Seal the vial and place it in a photoreactor equipped with LEDs emitting at the appropriate wavelength (e.g., blue LEDs for 450 nm).

- Initiate the reaction by turning on the light source. The photocatalyst absorbs light to generate reactive species (e.g., radicals) that participate in the enzymatic catalysis cycle, leading to carbon-carbon bond formation [4].

- Maintain constant stirring and temperature control (e.g., 25-30°C) throughout the irradiation period.

- Reaction Work-up:

- After completion, extract the reaction mixture with an organic solvent (e.g., ethyl acetate).

- Dry the combined organic extracts over anhydrous MgSOâ‚„, filter, and concentrate.

- Purify the crude product using flash chromatography to isolate the novel molecular scaffold. This method can generate a library of distinct scaffolds with rich and well-defined stereochemistry, which is invaluable for drug discovery [4].

Figure 3: Workflow for an enzymatic-photocatalytic multicomponent reaction.

Essential Research Reagents and Materials

Table 2: Key reagents and their functions in bioinspired and chemoenzymatic syntheses

| Reagent/Material | Function in Synthesis | Technical Notes |

|---|---|---|

| Chiral Epoxides [23] | Source of stereocenters and oxygen functionality; enables convergent coupling. | Often prepared via Sharpless asymmetric epoxidation for high enantiomeric purity. |

| Lewis Acids (e.g., TMSOTf) [23] | Activates carbonyls (aldehydes) to initiate cationic cyclizations (e.g., Prins reaction). | Requires strict anhydrous conditions and often an inert atmosphere. |

| 1,3-Dithiane [23] | Masked acyl anion equivalent; used for nucleophilic acylation. | Deprotected via oxidative hydrolysis to reveal the carbonyl. |

| Reprogrammed Biocatalysts [4] | Engineered enzymes that catalyze non-natural transformations with high selectivity. | Developed via directed evolution; general for a wide range of substrates. |

| Photocatalysts [4] | Harvests light energy to generate reactive intermediates (e.g., radicals) under mild conditions. | Enables cooperative catalysis with enzymes in multicomponent reactions. |

Emerging Trends and Future Perspectives

The field of bioinspired synthesis is continuously evolving, intersecting with cutting-edge technologies to push the boundaries of complex molecule synthesis. Several emerging trends are shaping its future:

- Diversity-Oriented Synthesis (DOS) via Biocatalysis: There is a growing emphasis on moving biocatalysis beyond large-scale production into discovery chemistry. The integration of enzymes with synthetic catalysts, such as photocatalysts, enables multicomponent reactions that generate structurally diverse and novel molecular scaffolds. This hybrid approach leverages the efficiency and selectivity of enzymes with the versatility of synthetic catalysts, opening doors to combinatorial synthesis of compound libraries for drug screening [4].

- Bioorthogonal Chemistry for In Vivo Applications: Bioorthogonal reactions, which proceed without interfering with native biochemistry, are critical for in vivo imaging, drug delivery, and prodrug activation. The current grand challenge lies in the translation from model systems to humans. This demands synthetic innovation to create reagents with ultra-fast kinetics, minimal toxicity, and optimal pharmacokinetic properties (absorption, distribution, metabolism, excretion) to achieve sufficient reaction yields at clinically relevant concentrations [5].

- Chemoenzymatic and Photobiocatalytic Strategies: The combination of enzymatic and synthetic steps in a single synthetic sequence is becoming increasingly sophisticated. Photobiocatalysis, which utilizes photoexcited states in enzymatic processes, is a particularly promising hybrid strategy. These approaches allow for the installation of complexity via enzymes and subsequent elaboration via synthetic chemistry, or vice versa, thereby expanding access to medicinally relevant natural products and their analogues [5].

- Biomimetic Materials and Metal-Organic Frameworks (MOFs): Inspiration from nature extends to materials science. For instance, short, self-assembling peptides can be designed to mimic enzyme active sites, creating functional biomimetic catalysts [24]. Furthermore, the synthesis of metal-organic frameworks (MOFs) with highly ordered, porous architectures exemplifies how organic synthesis can create tailored environments for applications in drug delivery and biosensing, mimicking the complexity of biological systems [5].

Implementation Guide for Research Programs

For research teams aiming to integrate bioinspired approaches into their workflow, a systematic methodology is crucial for success.

- Target Analysis and Biosynthetic Proposal: Begin with a thorough analysis of the target natural product's structure. Research and propose a plausible biosynthetic pathway, often inferred from the structures of symbiotic metabolites or known biochemical logic. Identify the key complexity-generating step (e.g., a cyclization, rearrangement, or coupling) that could be mimicked in the laboratory [23] [25].

- Retrosynthetic Planning: Use the proposed biosynthetic pathway as a guiding principle for retrosynthetic analysis. Deconstruct the target back to a simpler, achiral, or minimally functionalized precursor that resembles the proposed biosynthetic starting point. Prioritize disconnections that mirror biosynthetic steps [23].

- Reaction Selection and Optimization: Select synthetic methods that mimic the proposed biogenetic transformation. These often include cascade reactions, cycloadditions, or C–H functionalizations performed under mild, biomimetic conditions (e.g., acid/base, visible light) [23]. Be prepared to optimize reaction conditions, solvent systems, and catalysts to achieve high efficiency and stereocontrol.

- Validation and Elucidation: Use the successful execution of the bioinspired synthetic step as chemical evidence to support the initial biosynthetic proposal [23]. Furthermore, the synthesized authentic material can be used to confirm or revise the structural assignment of the natural product, including its absolute configuration, especially when natural samples are scarce [25].

This guide provides a framework for leveraging bioinspired strategies to streamline the synthesis of complex molecules, ultimately accelerating discovery in medicinal chemistry and chemical biology.

The Expanding Toolbox of C–H Activation and Functionalization

The direct conversion of inert carbon-hydrogen (C–H) bonds into functional groups represents one of the most significant paradigm shifts in modern organic synthesis. This approach has transformed retrosynthetic planning by enabling more straightforward, atom-economical, and sustainable routes to complex molecular architectures. Unlike traditional methods that require pre-functionalized substrates, C–H activation and functionalization allows synthetic chemists to bypass unnecessary steps, reducing waste and synthetic time. For researchers in drug development and complex molecule discovery, this methodology offers unprecedented opportunities to accelerate the exploration of chemical space and access novel bioactive compounds. The field has evolved from fundamental organometallic studies to encompass a diverse range of practical applications, with terminology distinguishing between C–H activation (the cleavage of a C–H bond to form a carbon-metal bond) and C–H functionalization (the overall process of replacing a C–H bond with another functional group), the latter typically being preceded by an activation event [26].

The growing importance of C–H functionalization in pharmaceutical research is underscored by its ability to streamline the synthesis and late-stage diversification of active pharmaceutical ingredients (APIs). By enabling direct modification of molecular scaffolds, these methods facilitate rapid structure-activity relationship (SAR) studies and optimization of drug candidates without de novo synthesis. Furthermore, the integration of green chemistry principles—including catalyst recycling, reduced waste generation, and energy-efficient processes—has positioned C–H functionalization as a cornerstone of sustainable molecular synthesis [27] [28]. This technical guide examines the current state of C–H activation methodologies, with particular emphasis on mechanistic insights, practical implementations, and emerging trends that are expanding the synthetic chemist's toolbox for complex molecule discovery.

Fundamental Concepts and Terminology

Mechanisms of C–H Bond Cleavage

The breaking of C–H bonds by transition metals occurs through several well-established mechanistic pathways, though modern understanding recognizes these as existing on a continuum rather than as strictly distinct categories. The classical mechanisms include:

- Oxidative Addition (OA): Common with electron-rich late transition metals, this pathway involves formal insertion of the metal into the C–H bond, increasing the metal's oxidation state by two units. This mechanism is particularly relevant to palladium and nickel catalysis [26].

- Concerted Metalation-Deprotonation (CMD): Also termed Amphiphilic Metal-Ligand Activation (AMLA), this mechanism features a concerted transition state where a base deprotonates the carbon while the metal coordinates to the hydrogen, all without formal oxidation state change. This is the predominant mechanism for many palladium-catalyzed C–H functionalizations [26].

- σ-Bond Metathesis: Typically observed with early transition metals and lanthanides, this concerted process involves a four-centered transition state where the C–H bond and metal-ligand bond are simultaneously broken and formed [26].

- Electrophilic Activation: Characteristic of electron-deficient metal centers, this pathway involves attack on electron-rich C–H bonds, particularly in aromatic systems, with platinum and gold complexes often operating through this mechanism [26].

- 1,2-Addition: Occurs across metal-ligand multiple bonds, commonly with early transition metals [26].

Ess, Goddard, and Periana's computational studies revolutionized the understanding of these mechanisms by demonstrating that they exist on a reactivity continuum governed by the degree of charge transfer between the metal and the C–H bond, rather than being segregated by metal type or oxidation state. The key factors are CT1 (charge transfer from metal dπ-orbital to C–H σ*-orbital) and CT2 (charge transfer from C–H σ-orbital to metal dσ-orbital), which collectively determine whether the mechanism exhibits electrophilic, amphiphilic, or nucleophilic character [26].

Guided versus Innate Selectivity

A critical consideration in C–H functionalization is regiocontrol, which is typically achieved through two complementary approaches:

- Guided C–H Functionalization: Utilizes directing groups (covalently or transiently bound) to steer the metal catalyst to specific C–H bonds through coordination. This approach enables functionalization at otherwise inaccessible positions but requires installation and potential removal of directing groups [29].

- Innate C–H Functionalization: Relies on the inherent steric and electronic properties of the substrate to dictate regioselectivity without external directing forces. Examples include Friedel-Crafts reactions and the functionalization of acidic C–H bonds [29].

The strategic combination of both approaches throughout a synthetic sequence can enable efficient access to complex molecular targets, as demonstrated in total syntheses of natural products like the hapalindole family [29].

Emerging Methodologies and Catalytic Systems

Earth-Abundant Transition Metal Catalysts

While noble metals like palladium, rhodium, and ruthenium have historically dominated C–H functionalization methodology, recent research has focused on developing catalysts based on earth-abundant 3d transition metals. These alternatives offer advantages in cost, toxicity, and sustainability while exhibiting unique reactivity profiles.

Table 1: Earth-Abundant Metals in C–H Functionalization

| Metal | Abundance | Key Advantages | Representative Applications |

|---|---|---|---|

| Manganese | 12th most abundant in Earth's crust (1.9B ton reserves) [30] | Low toxicity, natural abundance, cost-effective, variable oxidation states (I–VII) [30] | C–H alkylation, alkenylation, amidation, annulation reactions [30] |

| Cobalt | ~29 ppm in Earth's crust [30] | Enzymatic relevance (B12), radical reactivity, oxidative stability | C–H hydroxylation, amination, cyclization |

| Nickel | ~84 ppm in Earth's crust | Versatile redox chemistry, complementary to Pd in many transformations | C–H arylation, alkylation, cycloadditions |

| Copper | ~60 ppm in Earth's crust | Biological relevance, utility in oxidative coupling | Arene C–H oxygenation, enolate coupling |

Manganese catalysis has emerged as particularly versatile, with applications spanning various C–H functionalization modes. Mn(I) catalysts such as MnBr(CO)₅ serve as precursors for organomanganese complexes that can operate through isohypsic mechanisms involving cyclomanganation and migratory insertion [30]. Higher oxidation state manganese catalysts (Mn(III)/Mn(IV)) have been employed in electrocatalytic C–H azidation, demonstrating the metal's redox flexibility [30]. The complementary reactivity of manganese catalysts is further illustrated by their ability to catalyze regioselective C–H alkylations where palladium catalysts fail, as demonstrated in the functionalization of azines [30].

Light-Activated and Photocatalytic Approaches

Photochemical strategies have revolutionized C–H functionalization by providing alternative activation pathways that operate under mild conditions. A groundbreaking development comes from the University of Minnesota, where researchers have created a light-activated method for generating aryne intermediates directly from carboxylic acids using low-energy blue light instead of chemical additives [8]. This innovation eliminates stoichiometric waste associated with traditional methods and enables applications in biological contexts that were previously impossible, including modifications of antibody-drug conjugates and DNA-encoded libraries [8].

Concurrently, polar-radical relay processes have been developed for the site-selective functionalization of polymers. In one notable example, a transition metal-free, photoinduced α-C–H amidation of polyethers enables the incorporation of C–N bonds into polymer backbones while suppressing degradation and cross-linking [31]. This method utilizes an alkyl iodide initiator under visible light irradiation to generate radicals that mediate a chain process consisting of hydrogen atom transfer (HAT), halogen atom transfer (XAT), and nucleophilic attack by the amidation reagent [31].

Table 2: Innovative Photochemical C–H Functionalization Methods

| Method | Activation Mode | Key Features | Applications |

|---|---|---|---|

| Blue Light-Induced Aryne Generation [8] | Direct photoexcitation of precursor | Eliminates chemical additives, biocompatible conditions, minimal waste | Synthesis of drug building blocks, bioconjugation |

| Polar-Radical Relay Amidation [31] | Radical chain process initiated by visible light | Transition metal-free, excellent site selectivity, suppresses polymer degradation | Post-functionalization of polyethers, α-amino polyethers |

| Manganese-Electrocatalysis [30] | Electrochemical Mn(III)/Mn(IV) cycling | Oxidant-free, tunable selectivity, scalable | C(sp³)–H azidation, late-stage functionalization |

Quantitative Insights into Catalyst Performance

Rational catalyst design requires quantitative understanding of metal properties. Recent research provides direct experimental comparison between palladium and nickel, explaining palladium's superior performance in C–H activation. Under identical conditions, a palladium complex renders the C–H bond approximately 100,000 times more acidic than its nickel counterpart [32]. This dramatic difference quantifies the empirical observations of palladium's efficiency and suggests strategies for improving nickel catalysts, such as pairing them with stronger bases [32].

Further quantitative insights come from computational studies examining ligand effects on palladium-catalyzed C–H activation. These investigations reveal that σ-donating ligands hinder C–H activation, with retarding effects intensifying as σ-donation strength increases. Conversely, π-accepting ligands facilitate the process, with neutral ligands generally exerting weaker influences than univalent ligands [33]. Such quantitative measurements provide valuable guidelines for catalyst optimization in pharmaceutical applications.

Experimental Protocols and Methodologies

Light-Activated Aryne Generation from Carboxylic Acids

This protocol describes the modern method for generating aryne intermediates using blue light irradiation, developed by the University of Minnesota team [8].

Research Reagent Solutions

Table 3: Essential Reagents for Light-Activated Aryne Generation

| Reagent | Function | Notes |

|---|---|---|

| Carboxylic acid precursor | Aryne precursor | Optimized for o-silylaryl carboxylates |

| Blue LED light source (427 nm) | Reaction activator | Similar to aquarium lighting; low energy |

| Anhydrous solvent | Reaction medium | Must be rigorously dried |

| Reaction partner | Aryne trapping agent | Dienes, heterocycles, nucleophiles |

Detailed Procedure

Preparation of Reaction Mixture: In a dried Schlenk flask under inert atmosphere, combine the carboxylic acid precursor (1.0 equiv) and the reaction partner (1.2-2.0 equiv) in anhydrous solvent (0.1 M concentration).

Degassing: Subject the reaction mixture to three freeze-pump-thaw cycles or sparge with inert gas for 30 minutes to remove oxygen.

Irradiation: Place the reaction vessel at a fixed distance from the blue LED light source (427 nm) and irradiate with stirring for the specified duration (typically 4-24 hours), maintaining temperature at 25-40°C.

Reaction Monitoring: Monitor reaction progress by TLC, GC-MS, or LC-MS until complete consumption of the starting material is observed.

Work-up: Remove the light source and concentrate the reaction mixture under reduced pressure.

Purification: Purify the crude product by flash chromatography on silica gel or recrystallization to obtain the functionalized arene product.

Analysis: Characterize the final product using NMR spectroscopy, mass spectrometry, and comparison with literature data.

Key Advantages and Applications

This photocatalytic method eliminates the need for chemical additives like strong bases or fluoride anions traditionally required for aryne generation, significantly reducing waste and enabling functionalization of complex substrates under mild conditions. The team has developed approximately 40 building blocks for creating drug molecules using this approach, with ongoing work to expand this set further [8]. The methodology is particularly valuable for the synthesis of pharmaceutical precursors and can be applied to biological conditions incompatible with previous methods.

Photoinduced C–H Amidation of Polyethers

This metal-free protocol enables the site-selective incorporation of nitrogen functionality into polyether backbones via a polar-radical relay mechanism [31].

Research Reagent Solutions

Table 4: Essential Reagents for Photoinduced C–H Amidation

| Reagent | Function | Notes |

|---|---|---|

| n-C₄F₉I (5.0 mol%) | Radical initiator | Perfluoroalkyl iodide |

| N-chloro-N-sodio-tert-butylcarbamate | Amidating reagent | Bench-stable chlorocarbamate salt |

| Ethyl acetate (EtOAc) | Solvent | Polar non-protic; optimal for radical relay |

| Blue LED (427 nm) | Light source | Enables photochemical initiation |

Detailed Procedure

Reaction Setup: In a dried glass tube equipped with a magnetic stir bar, combine the polyether substrate (1.0 equiv), N-chloro-N-sodio-tert-butylcarbamate (1.5 equiv), and n-C₄F₉I (0.05 equiv).

Solvent Addition: Add anhydrous ethyl acetate (0.1 M concentration relative to amidating reagent) and stir until all components are fully dissolved.

Degassing: Seal the reaction tube and purge the headspace with inert gas for 15-20 minutes to remove oxygen.

Irradiation: Place the reaction tube in a photoreactor equipped with blue LEDs (427 nm) and irradiate with stirring at room temperature for 12-36 hours.

Mechanistic Monitoring: To track the radical relay process, aliquot small samples for EPR spectroscopy or analyze for TEMPO-adduct formation in control experiments.

Reaction Quenching: After complete conversion (monitored by TLC or NMR), concentrate the reaction mixture under reduced pressure.

Product Isolation: Purify the amidated polymer by precipitation into non-solvent or dialysis, followed by characterization of the α-amino polyether product.

Applications and Scope