Biomimetic Synthesis of Natural Products: Strategies, Advances, and Applications in Drug Discovery

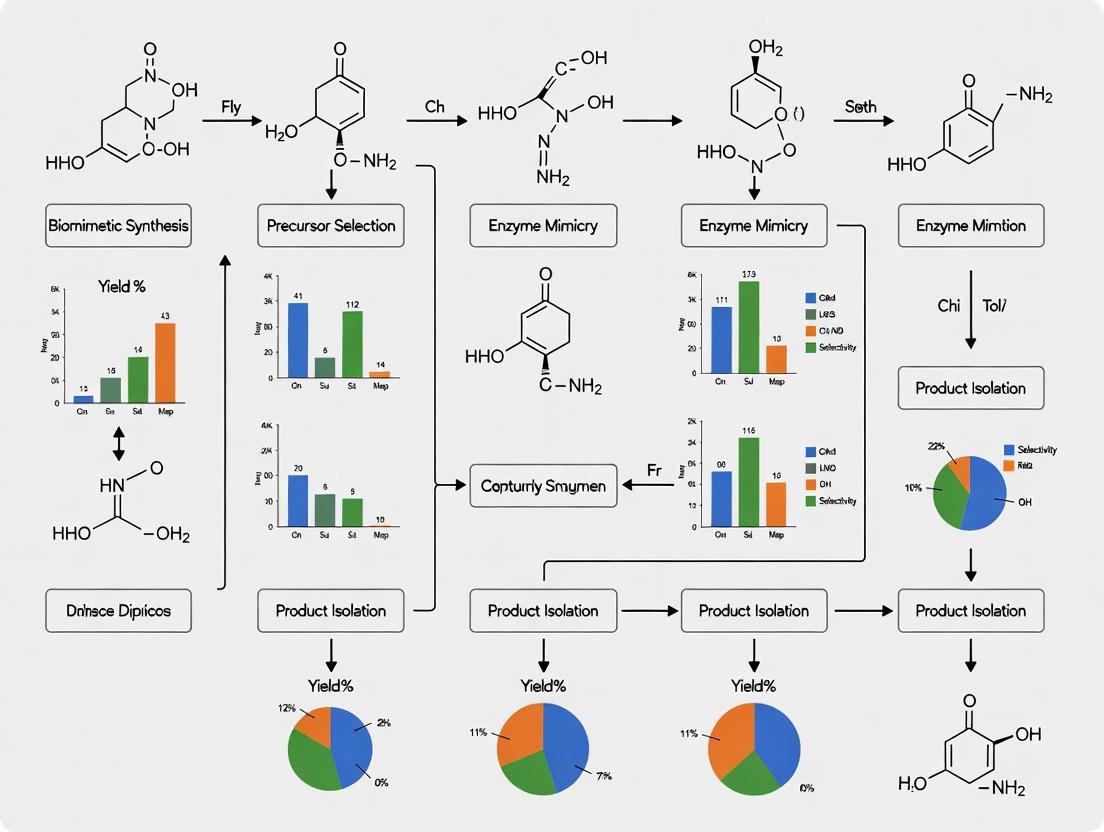

This article provides a comprehensive analysis of biomimetic synthesis, an efficient approach that mimics biosynthetic pathways to produce complex natural products.

Biomimetic Synthesis of Natural Products: Strategies, Advances, and Applications in Drug Discovery

Abstract

This article provides a comprehensive analysis of biomimetic synthesis, an efficient approach that mimics biosynthetic pathways to produce complex natural products. Tailored for researchers, scientists, and drug development professionals, it explores the foundational principles, key methodological strategies like polyene cyclization and oxidative coupling, and practical applications in synthesizing therapeutic agents. The content also addresses common challenges and optimization techniques, compares biomimetic approaches with traditional chemical and biosynthetic methods, and examines future directions integrating AI and sustainable processes for advancing biomedical research and clinical applications.

The Foundations of Biomimetic Synthesis: From Historical Roots to Modern Principles

Biomimetic synthesis is an area of organic chemical synthesis that is specifically biologically inspired, applying inspiration from biogenetic processes to design synthetic strategies that mimic biosynthetic pathways [1] [2] [3]. This approach tests biogenetic hypotheses by executing synthetic reactions that parallel a compound's proposed biosynthesis in nature, or by designing synthetic routes that mimic one or more known enzymatic transformations of an established biosynthetic pathway [1]. The core philosophy is to emulate nature's chemical logic, leveraging the evolutionary optimization that occurs in biological systems to achieve efficient construction of complex molecules, often with significant biological activity [2] [4]. For researchers and drug development professionals, this methodology offers a strategic framework for efficiently accessing structurally intricate natural products that serve as vital scaffolds for drug discovery [2] [3].

The historical foundation of biomimetic synthesis was laid with Sir Robert Robinson's 1917 synthesis of the alkaloid tropinone, which demonstrated the potential of mimicking biological processes to construct complex natural products [1] [2] [4]. Since this pioneering work, the field has evolved substantially, with significant milestones including E.J. Corey's carbenium-mediated cyclization of an engineered linear polyene to produce a tetracyclic steroid ring system, building upon foundational studies by Eschenmoser, Stork, and Johnson on cationic cyclizations of linear polyenes [1]. These early investigations established biomimetic synthesis as a powerful paradigm in organic chemistry, particularly for tackling the complex architectural challenges presented by secondary metabolites.

Table 1: Key Historical Developments in Biomimetic Synthesis

| Year | Researcher | Achievement | Significance |

|---|---|---|---|

| 1917 | Sir Robert Robinson | Synthesis of tropinone [1] [2] | First generally cited example of a biomimetic synthesis [1] |

| 1955-1959 | Stork, Eschenmoser | Studies on polyene cyclizations [1] | Elucidated fundamental principles of stereoselective cyclization |

| 1960s | W.S. Johnson | Continued definition of polyene cyclization requirements [1] | Established parameters for initiating/terminating cyclization and stabilizing carbocations |

| 1990 | Clayton Heathcock | Biomimetic synthesis of proto-daphniphylline [1] | Showcased how biomimetic synthesis simplifies total synthesis of complex alkaloids |

| 1997 | E.J. Corey | Carbenium-mediated cyclization to steroid system [1] | Advanced application of biomimetic cyclization strategies |

In contemporary research, biomimetic synthesis has gained widespread attention from researchers in chemistry, biology, pharmacy, and related fields, underscoring its interdisciplinary impact [3]. It addresses critical challenges in synthesizing structurally complex natural products with significant biological and medicinal importance, offering a highly efficient approach that simplifies synthetic routes to architecturally daunting molecules [1] [3]. As natural product-based drug discovery faces challenges of limited natural abundance and structural complexity, biomimetic strategies provide creative alternatives that emulate nature's own production methods [2] [4].

Core Biomimetic Strategies and Representative Examples

Several key strategies exemplify the biomimetic approach in natural product synthesis, each mirroring a distinct biosynthetic pathway. These strategies enable efficient access to complex molecular architectures that are challenging to produce through conventional synthetic methods.

Biomimetic Polyene Cyclization

The biomimetic polyene cyclization strategy mimics nature's process of creating complex cyclic structures from linear polyene precursors [2] [4]. This approach has been successfully employed in the synthesis of steroids like progesterone and various terpenoid alkaloids, providing critical insights into stereoselective control [2] [4]. In nature, enzyme-controlled cyclizations of polyene precursors such as squalene generate stereodefined polycyclic frameworks with exquisite precision. The biomimetic chemical version of this process aims to replicate this efficiency, often using initiating groups that mimic the biological triggering events to generate carbocationic cascades that form multiple carbon-carbon bonds and stereocenters in a single operation [1].

A landmark application of this strategy was E.J. Corey's carbenium-mediated cyclization of an engineered linear polyene to produce a tetracyclic steroid ring system [1]. This work built upon earlier fundamental studies of cationic cyclizations of linear polyenes by Albert Eschenmoser and Gilbert Stork, and extensive investigations by W.S. Johnson to define the requirements for initiating and terminating the cyclization, and for stabilizing the cationic carbenium group during the process—a function performed by enzymes in natural biosystems [1]. The development of this strategy represents a classic case of chemists learning from and mimicking nature's synthetic efficiency.

Biomimetic Oxidative Coupling

The biomimetic oxidative coupling strategy imitates the natural oxidative joining of phenol or indole units observed in the biosynthesis of many natural products [2] [4]. This approach has been applied in the synthesis of morphine-like molecules and various natural phenolic products, demonstrating its utility for constructing complex dimeric or oligomeric structures [2] [4]. In biological systems, oxidative coupling is often catalyzed by enzymes such as laccases or peroxidases that generate radical species from phenolic substrates, which then dimerize in a regio- and stereoselective manner.

The biomimetic version of this process employs chemical oxidants to achieve similar transformations, often providing rapid access to molecular complexity from simpler precursors. This strategy is particularly valuable for synthesizing complex alkaloids and polyphenolic compounds whose biosynthetic origins involve similar coupling events. The ability to form multiple carbon-carbon bonds simultaneously through controlled radical coupling makes this approach highly efficient for building molecular complexity from relatively simple starting materials.

Biomimetic Diels-Alder Reaction

The biomimetic Diels-Alder reaction strategy is inspired by the natural cycloaddition processes observed in the biosynthesis of certain natural products [2] [4]. This approach has enabled the synthesis of complex polycyclic rings in natural products such as FR182877, providing an efficient method for constructing six-membered rings with controlled stereochemistry [2] [4]. While the existence of natural Diels-Alderases has been debated for decades, increasing evidence supports that certain enzymes do catalyze [4+2] cycloadditions in secondary metabolic pathways.

The biomimetic application of Diels-Alder reactions in total synthesis often involves designing diene and dienophile partners that mirror proposed biosynthetic precursors, then subjecting them to conditions that promote the cycloaddition. This strategy can simultaneously form multiple carbon-carbon bonds and set several stereocenters in a single transformation, making it exceptionally efficient for constructing complex polycyclic frameworks. The intramolecular variant is particularly powerful for generating bridged ring systems that are challenging to access through other methods.

Representative Case: Proto-daphniphylline Synthesis

A particularly elegant example of biomimetic synthesis is Clayton Heathcock's total synthesis of proto-daphniphylline, a precursor in the biosynthesis of alkaloids found in Daphniphyllum macropodum [1]. Based on the proposed biosynthesis from squalene, Heathcock and co-workers developed a remarkably short synthesis from simple starting materials [1]. The key transformation involves cyclization of acyclic dialdehydes (with carbon skeletons analogous to squalene) to form proto-daphniphylline upon treatment with potassium hydroxide, ammonia, and acetic acid [1]. This remarkable single step forms six σ-bonds and five rings, demonstrating the extraordinary efficiency that can be achieved through biomimetic design [1].

The proposed mechanism involves initial formation of a hydroxyldihydropyran intermediate when the dialdehyde starting material is treated with potassium hydroxide, followed by generation of a 2-aza-1,3-diene intermediate from reaction with ammonia [1]. An acid-catalyzed Diels-Alder reaction then forms an intermediate that undergoes further transformation to the final product under the reaction conditions [1]. This synthesis stands as a testament to the power of biomimetic design in simplifying the total synthesis of complex natural products.

Table 2: Key Biomimetic Strategies and Their Applications

| Biomimetic Strategy | Natural Process Mimicked | Representative Applications | Key Features |

|---|---|---|---|

| Polyene Cyclization [2] [4] | Cyclization of linear polyene precursors (e.g., squalene) to form steroidal frameworks [1] | Progesterone, terpenoid alkaloids [2] [4] | Forms multiple rings and stereocenters in a concerted process; carbocationic cascade mechanism |

| Oxidative Coupling [2] [4] | Enzyme-mediated coupling of phenolic or indolic units | Morphine-like molecules, natural phenolic products [2] [4] | Builds complexity through dimerization; often radical-based mechanism |

| Diels-Alder Reaction [2] [4] | Natural [4+2] cycloaddition processes | FR182877 [2] [4] | Simultaneously forms two C-C bonds and one six-membered ring with controlled stereochemistry |

| Alder-ene Reaction [5] | Biosynthetic cyclization through ene mechanism | Phloroglucinol meroterpenoids [5] | Combines alkene migration with cyclization; used in complex meroterpenoid synthesis |

Experimental Protocols: Biomimetic Synthesis of Phloroglucinol Meroterpenoids

This section provides a detailed experimental methodology for the concise biomimetic synthesis of cattleianal and related phloroglucinol meroterpenoids, as reported in recent research [5]. This protocol exemplifies modern approaches to biomimetic synthesis, incorporating both traditional biomimetic principles and contemporary chemical proteomics applications.

Synthetic Procedure

Step 1: Vilsmeier-Haack Diformylation of Phloroglucinol

- Begin with commercial phloroglucinol (10.0 g, 79.3 mmol) dissolved in anhydrous DMF (80 mL) under inert atmosphere [5].

- Cool the solution to 0°C and slowly add phosphorus oxychloride (POCl₃, 16.6 mL, 178 mmol) dropwise with stirring, maintaining the temperature below 5°C [5].

- After addition complete, heat the reaction mixture to 90°C and stir for 16 hours [5].

- Cool the mixture to room temperature and carefully pour onto crushed ice (300 mL) with vigorous stirring [5].

- Adjust pH to approximately 7.0 using saturated sodium hydroxide solution, leading to formation of a yellow precipitate [5].

- Collect the precipitate by vacuum filtration and wash with cold water (3 × 50 mL) to afford crude diformylphloroglucinol (S14) [5].

- Purify by recrystallization from ethanol to yield pure S14 as yellow crystals (78% yield, decagram scale) [5].

Step 2: C-Methylation with Iodomethane

- Dissolve diformylphloroglucinol (S14, 5.0 g, 30.1 mmol) in anhydrous acetone (75 mL) [5].

- Add powdered potassium carbonate (K₂CO₃, 12.5 g, 90.3 mmol) and iodomethane (CH₃I, 5.6 mL, 90.3 mmol) [5].

- Reflux the reaction mixture at 60°C for 12 hours with vigorous stirring [5].

- Monitor reaction progress by TLC (silica gel, hexanes/ethyl acetate 7:3) [5].

- After completion, cool to room temperature and filter to remove inorganic salts [5].

- Concentrate the filtrate under reduced pressure to obtain crude ortho-quinone methide precursor (S18) [5].

- Purify by flash column chromatography (silica gel, hexanes/ethyl acetate gradient) to yield S18 (27% yield) [5].

Step 3: DDQ-Mediated Oxidative Cyclization

- Dissolve ortho-quinone methide precursor (S18, 500 mg, 2.67 mmol) and (−)-β-caryophyllene (1, 547 mg, 2.67 mmol) in anhydrous nitromethane (15 mL) under nitrogen atmosphere [5].

- Add 2,3-dichloro-5,6-dicyano-1,4-benzoquinone (DDQ, 667 mg, 2.94 mmol) in one portion at room temperature [5].

- Stir the reaction mixture at 35°C for 6 hours, monitoring by TLC and LC-MS [5].

- Quench the reaction by adding saturated aqueous sodium thiosulfate solution (20 mL) and stir for 30 minutes [5].

- Extract with dichloromethane (3 × 25 mL), combine organic extracts, and wash with brine (50 mL) [5].

- Dry over anhydrous sodium sulfate, filter, and concentrate under reduced pressure [5].

- Purify the crude product by preparative HPLC (C18 column, methanol/water gradient) to afford (−)-cattleianal as a white solid (11% unoptimized yield, 9:1 d.r.) [5].

Analytical Data Characterization

- (−)-Cattleianal: White solid; Rf = 0.45 (silica gel, hexanes/ethyl acetate 7:3); [α]²⁵D = −15.6 (c = 0.5, CHCl₃); ¹H NMR (500 MHz, CDCl₃) δ 11.32 (s, 1H), 9.65 (s, 1H), 7.10 (s, 1H), 5.20 (s, 1H), 4.85 (s, 1H), 2.90–2.70 (m, 2H), 2.45–2.30 (m, 2H), 2.20 (s, 3H), 2.15–1.90 (m, 6H), 1.75 (s, 3H), 1.60–1.40 (m, 2H), 1.25 (s, 3H), 1.10 (s, 3H), 0.95 (d, J = 6.5 Hz, 3H); ¹³C NMR (125 MHz, CDCl₃) δ 195.6, 188.5, 165.4, 156.2, 150.5, 124.3, 117.8, 110.5, 55.8, 50.2, 42.5, 40.8, 39.5, 38.9, 37.5, 32.6, 30.2, 28.7, 27.5, 25.8, 22.4, 21.5, 19.8; HRMS (ESI-TOF) m/z calcd for C₂₆H₃₇O₄ [M+H]⁺ 413.2692, found 413.2695 [5].

Mechanism of Biomimetic Cyclization

The biomimetic synthesis of cattleianal proceeds through a proposed Alder-ene reaction between β-caryophyllene and an ortho-quinone methide intermediate, generating a mixture of diastereomers that undergo tautomerization and proton transfer to yield the final product [5]. This mechanism mirrors proposed biosynthetic pathways for phloroglucinol meroterpenoids in nature, where similar cyclization events would be enzyme-catalyzed [5]. The synthetic approach successfully mimics this biological process using chemical reagents to promote the key cyclization step.

The Scientist's Toolkit: Essential Research Reagents

Successful execution of biomimetic syntheses requires specific reagents and materials designed to mimic natural processes. The following table details essential research reagent solutions used in the featured biomimetic synthesis of phloroglucinol meroterpenoids and related methodologies.

Table 3: Essential Research Reagents for Biomimetic Synthesis

| Reagent/Material | Function in Biomimetic Synthesis | Specific Example |

|---|---|---|

| Diformylphloroglucinol [5] | Core building block mimicking biosynthetic precursors of phloroglucinol meroterpenoids | Synthesized via Vilsmeier-Haack formylation of phloroglucinol (78% yield) [5] |

| Ortho-quinone methide precursors [5] | Reactive intermediates that participate in cycloaddition reactions mimicking biosynthetic steps | Generated from diformylphloroglucinol via C-methylation with iodomethane [5] |

| Terpene substrates (e.g., β-caryophyllene) [5] | Biological partners for biomimetic cyclization, providing terpenoid architecture | (−)-β-Caryophyllene used in DDQ-mediated oxidative cyclization [5] |

| DDQ (2,3-Dichloro-5,6-dicyano-1,4-benzoquinone) [5] | Oxidizing agent for promoting key biomimetic cyclization steps | Mediates oxidative cyclization between ortho-quinone methide and β-caryophyllene [5] |

| Clickable probes [5] | Chemical probes for target identification and mechanistic studies in chemical proteomics | Synthetic clickable analogues of natural products for proteome-wide reactivity mapping [5] |

| Biomimetic catalysts | Synthetic catalysts designed to mimic enzyme functions | Metal complexes or organocatalysts that replicate enzymatic activation modes |

Current Challenges in Biomimetic Synthesis

Despite significant advances, biomimetic synthesis faces several persistent challenges that limit its broader application. Crafting natural products featuring multiple chiral centers and distinct functional groups necessitates advanced and often complex synthetic techniques [2] [4]. Many biomimetic reactions suffer from low yields or undesired side reactions, which collectively add layers of difficulty for researchers striving to establish reliable synthetic pathways [2] [4]. The scalability of biomimetic transformations presents another considerable obstacle, as converting laboratory-scale successes to industrial-scale applications requires further investigation and innovation [2] [4]. Additionally, accurately hypothesizing and replicating biosynthetic pathways remains challenging, as nature's enzymatic processes often involve transient intermediates and complex regulatory mechanisms that are difficult to replicate in flask-based chemical systems.

Future Directions and Prospects

The future of biomimetic synthesis is brightened by prospects of new technological advancements that can facilitate these processes. The integration of big data analytics and deep learning technologies is gaining traction within the field, offering the ability to optimize synthetic routes and enhance the predictability and reliability of reactions [2] [4]. By integrating modern chemical methods with biological understanding, researchers are likely to boost both efficiency and accessibility for the synthesis of complex natural products and their derivatives [2] [4]. The expanding molecular library created through biomimetic approaches promises to revolutionize drug research, providing novel scaffolds for therapeutic development [2] [4]. Furthermore, the integration of chemical and biological synthesis, along with the development of new strategies, will further enhance the efficiency of natural product production [2]. As these technologies mature, biomimetic synthesis is poised to become an increasingly powerful approach for accessing complex molecular architectures with biological relevance.

Biomimetic synthesis represents a powerful paradigm in organic chemistry that leverages nature's evolutionary optimization to achieve efficient synthesis of complex natural products. By emulating biosynthetic pathways through strategies such as polyene cyclization, oxidative coupling, and biomimetic Diels-Alder reactions, chemists can streamline the synthesis of structurally daunting molecules that are relevant to drug discovery and chemical biology. Despite challenges in stereocontrol, yield optimization, and scalability, the future of the field appears promising with the integration of computational approaches, big data analytics, and deep learning technologies. As research continues to elucidate nature's synthetic strategies, biomimetic approaches will undoubtedly play an increasingly important role in synthesizing complex natural products and expanding the molecular toolbox available for therapeutic development and biological investigation.

The biomimetic synthesis of natural products represents a cornerstone of modern organic chemistry, bridging the disciplines of chemistry, biology, and pharmaceutical science. This approach employs principles from biomimicry, applying inspiration from biogenetic processes to design synthetic strategies that mimic biosynthetic pathways occurring in nature [3] [6]. Natural products, with their remarkable structural and biological diversity, have historically served as vital scaffolds for drug discovery, providing essential templates for developing new medications [2]. However, obtaining sufficient quantities of these compounds from natural sources presents significant challenges due to resource limitations, purification difficulties, and environmental sustainability concerns [7] [2]. Traditional chemical synthesis and biosynthesis methods each present their own limitations, including high reagent costs, environmental unfriendliness, lengthy synthetic routes, and difficulties in modifying complex molecules [6] [2].

Biomimetic synthesis addresses these challenges by emulating nature's efficient biosynthetic pathways, enabling more practical and efficient approaches to constructing complex natural product architectures [6]. This perspective traces the historical evolution of biomimetic synthesis from its seminal achievement in Robinson's 1917 tropinone synthesis to contemporary strategies that continue to push the boundaries of synthetic efficiency and molecular complexity. The field has gained widespread attention from researchers across chemistry, biology, pharmacy, and related disciplines, underscoring its profound interdisciplinary impact and transformative potential for drug discovery [3] [6]. By examining key historical milestones and technical methodologies, this review provides a comprehensive framework for understanding both the theoretical foundations and practical applications of biomimetic synthesis in modern natural product research.

Robinson's Landmark Tropinone Synthesis

Historical Context and Synthetic Challenge

The 1917 total synthesis of tropinone by Sir Robert Robinson stands as a landmark achievement in organic synthesis, representing the dawn of modern biomimetic approaches to natural product construction [8] [6]. This seminal work emerged against a backdrop of significant synthetic challenges in accessing tropane alkaloids, which possess important biological activities and structural complexity. Prior to Robinson's breakthrough, Richard Willstätter had achieved the first synthesis of tropinone in 1901 through a laborious multi-step sequence starting from cycloheptanone [9] [10]. Willstätter's approach required numerous steps to introduce the nitrogen bridge and proceeded with an overall yield of only 0.75%, reflecting the substantial synthetic complexity of this seemingly simple bicyclic molecule [10]. The stark contrast between Willstätter's 21-step synthesis [9] and Robinson's subsequent one-step approach [6] exemplifies the profound impact that strategic innovation can have on synthetic efficiency.

Robinson's synthesis was remarkable not only for its efficiency but also for its prescient biomimetic design, which paralleled proposed biosynthetic pathways [8]. Decades ahead of its time in terms of its retrosynthetic logic and biomimetic approach, this synthesis demonstrated the power of understanding and emulating nature's synthetic strategies [8] [11]. Robinson recognized that organisms likely produced tropinone through a much more direct route than the linear synthetic approaches prevalent in his time, leading him to hypothesize that a one-pot condensation of simple building blocks could replicate this natural process [6] [10]. This elegant combination of retrosynthetic analysis and biogenetic reasoning continues to serve as an inspiration for the development of new and efficient strategies for complex molecule synthesis [8].

Experimental Protocol: Robinson's "Double Mannich" Reaction

Reaction Mechanism and Step-by-Step Procedure

Robinson's synthesis of tropinone employs a double Mannich reaction sequence that can be performed as a one-pot procedure [10]. The following protocol outlines the modern interpretation of this classic transformation:

Starting Materials:

- Succinaldehyde (1,4-butandial)

- Methylamine (CH₃NH₂)

- Calcium acetoacetate (derived from acetonedicarboxylic acid or its equivalent)

Procedure:

- Reaction Setup: In a suitably sized reaction vessel, prepare a solution of succinaldehyde (1.0 equiv) in aqueous medium. The calcium salt of acetoacetate is included as a "buffer" to maintain physiological pH, which has been shown to improve yields [10].

Imine Formation: Add methylamine (1.0 equiv) to the succinaldehyde solution with stirring. The reaction proceeds through nucleophilic addition of methylamine to succinaldehyde, followed by loss of water to create an intermediate imine [10].

First Ring Closure: The imine intermediate undergoes intramolecular addition to the second aldehyde group, resulting in the first ring closure and formation of a bicyclic intermediate [10].

Intermolecular Mannich Reaction: Introduce calcium acetoacetate (1.0 equiv) to the reaction mixture. The enolate of the acetoacetate engages in an intermolecular Mannich reaction with the iminium species [10].

Second Ring Closure and Decarboxylation: New enolate formation followed by intramolecular Mannich reaction facilitates the second ring closure. Subsequent loss of two carboxylic groups via decarboxylation yields the final tropinone product [10].

Reaction Conditions:

- Temperature: Room temperature or mild heating

- Solvent: Aqueous or mixed aqueous-organic system

- pH: Maintained near physiological pH (approximately 7.4) using calcium carbonate buffer

- Reaction Time: Several hours to completion

Purification and Isolation: The crude tropinone can be isolated by extraction with organic solvent and purified through recrystallization or distillation. The original reported yield was 17%, though subsequent optimizations have exceeded 90% yield [10].

Table 1: Key Reagents for Robinson's Tropinone Synthesis

| Reagent | Function | Role in Reaction Mechanism |

|---|---|---|

| Succinaldehyde | Dialehyde component | Provides carbon skeleton for bicyclic ring system through sequential imine formations |

| Methylamine | Amine component | Introduces nitrogen atom and initiates imine/enamine formation sequence |

| Calcium acetoacetate | Dicarbonyl component | Serves as acetone synthetic equivalent; enolate participates in Mannich reactions |

| Calcium carbonate | Buffer | Maintains physiological pH to optimize reaction yield and selectivity |

Significance and Impact on Synthetic Chemistry

Robinson's tropinone synthesis represented a paradigm shift in synthetic strategy, demonstrating that complex natural product skeletons could be efficiently assembled from simple building blocks in a single transformation [8] [6]. This approach stood in stark contrast to the linear, step-wise approaches that dominated synthetic chemistry at the time. The synthesis was particularly remarkable for its biomimetic character, as it mirrored the proposed biosynthetic pathway for tropane alkaloids in plants [10]. This achievement established several important principles that would guide future developments in biomimetic synthesis:

First, it highlighted the value of understanding biosynthetic pathways and applying this knowledge to laboratory synthesis [6]. Second, it demonstrated the power of tandem or cascade reactions, where multiple bond-forming events occur sequentially in a single reaction vessel without isolation of intermediates [10]. Third, it established that molecular complexity could be generated rapidly and efficiently from simple starting materials when the synthetic design paralleled nature's approach [9].

The conceptual framework established by Robinson continues to influence modern synthetic chemistry, particularly in the development of biomimetic strategies for complex natural product synthesis [8] [11]. His work provided the foundation for understanding that "molecular complexity can be used as an indicator of the frontiers of synthesis, since it often causes failures which expose gaps in existing methodology" [9]. This insight continues to drive innovation in synthetic methodology as chemists tackle increasingly complex molecular architectures.

Evolution of Biomimetic Synthesis Strategies

Fundamental Biomimetic Approaches

Following Robinson's pioneering work, the field of biomimetic synthesis has expanded to encompass a diverse toolkit of strategies inspired by biological transformations. These approaches leverage the synthetic efficiency of natural biosynthetic pathways while addressing the unique challenges of laboratory synthesis. Three particularly influential strategies have emerged as cornerstones of modern biomimetic synthesis:

Biomimetic Polyene Cyclization: This strategy mimics nature's approach to constructing complex cyclic terpenoid and steroid skeletons from linear polyene precursors [6] [2]. The process typically involves initiation by an electrophilic source to generate a carbocation that undergoes stereospecific cyclization through a series of carbon-carbon bond formations [6]. The hypothesis proposed by Stork and Burgstahler [6] and Eschenmoser's group [6] in the 1950s on the stereochemical outcomes of polyene cyclization led to successful biomimetic syntheses of steroidal compounds including progesterone and dammaranedienol [6]. These studies profoundly impacted understanding of stereoselective control and the biosynthesis of steroids and terpenoids. In the field of terpenoid alkaloids, Heathcock's one-step biomimetic synthesis of dihydro-proto-daphniphyllines demonstrated that iminium-ion-induced polyene cyclization constitutes a powerful and efficient strategy [6].

Biomimetic Oxidative Coupling: This approach mimics the biogenetic oxidative coupling reactions where phenol or indole units join through oxidative processes [6] [2]. In nature, this strategy generates molecular complexity through the dimerization or oligomerization of simpler phenolic or indolic precursors. Barton's group [6] pioneered the application of this strategy in the 1950s by summarizing structural characteristics of phenolic compounds and proposing reaction rules for site selectivity of phenolic aryl radical coupling. This biomimetic approach has been widely applied in the synthesis of natural products including carpanone, resveratrol tetramers, peshawaraquinone [6], and complex indole alkaloids such as voacalgine A, bipleiophylline, and spiroindimicins [6]. The strategy has proven particularly valuable for constructing the complex architectures of morphine and galantamine, which are believed to arise biosynthetically through phenolic coupling [6] [2].

Biomimetic Diels-Alder Reaction: This strategy emulates the biogenetic Diels-Alder cycloaddition process, where a diene and dienophile react to form a cyclohexene ring, often under mild conditions [6] [2]. These reactions can be catalyzed by metals, acids, or bases, emulating the catalytic environments in nature. For example, Sorensen's group [6] hypothesized that the biosynthesis of the polyketide FR182877, which has excellent anticancer activity, might proceed through successive transannular Diels-Alder reactions. This insight enabled the successful biomimetic synthesis of FR182877's complex polycyclic rings with multiple stereocenters [6]. The biomimetic Diels-Alder approach has proven particularly valuable for constructing complex polycyclic systems with precise stereochemical control in an efficient manner.

Table 2: Comparative Analysis of Major Biomimetic Synthesis Strategies

| Strategy | Key Transformation | Representative Applications | Advantages |

|---|---|---|---|

| Polyene Cyclization | Cation-induced cyclization of polyenes | Steroids (progesterone), terpenoid alkaloids | Rapid complexity generation, excellent stereocontrol |

| Oxidative Coupling | Radical-mediated coupling of phenols/indoles | Morphine, galantamine, carpanone | Efficient dimerization/oligomerization, diverse molecular architectures |

| Diels-Alder Reaction | [4+2] Cycloaddition | FR182877, complex polycyclics | Atom economy, stereospecificity, convergent synthesis |

| Biomimetic Rearrangement | Skeletal reorganization | Various terpenoids and alkaloids | Access to complex skeletons from simpler precursors |

Quantitative Framework for Molecular Complexity

The advancement of biomimetic synthesis strategies has paralleled the development of more sophisticated frameworks for understanding and quantifying molecular complexity. According to Corey, "Molecular complexity can be used as an indicator of the frontiers of synthesis, since it often causes failures which expose gaps in existing methodology" [9]. This perspective has driven the field to develop quantitative approaches to molecular complexity that distinguish between structural complexity (intrinsic to the molecule) and synthetic complexity (extrinsic, dependent on available methods) [9].

The evolution from Willstätter's 21-step synthesis of tropinone to Robinson's one-step approach exemplifies how strategic innovation can dramatically reduce synthetic complexity while addressing the same structural complexity [9]. Modern metrics for quantifying molecular complexity draw from graph theory and information theory, treating molecules as molecular graphs (vertices and edges representing atoms and bonds) or as information-rich systems [9]. These quantitative approaches have become increasingly important in retrosynthetic analysis and synthesis planning, where algorithms prioritize disconnections that maximize reductions in molecular complexity [9].

This conceptual framework reveals that "the most powerful synthetic methods and strategies are those which minimize the synthetic complexity of structurally complex molecules" [9]. The trajectory of biomimetic synthesis represents a continuous effort to bridge the gap between structural and synthetic complexity, enabling more efficient access to nature's most architecturally sophisticated molecules.

Visualization of Biomimetic Synthesis Concepts

Conceptual Evolution of Biomimetic Synthesis

The following diagram illustrates the key conceptual relationships and historical development of biomimetic synthesis strategies:

Strategic Framework for Biomimetic Retrosynthesis

This diagram outlines the strategic decision-making process in planning biomimetic syntheses:

The Scientist's Toolkit: Essential Research Reagents and Materials

The implementation of biomimetic synthesis strategies requires specialized reagents and materials designed to facilitate transformations under mild, physiologically relevant conditions. The following table catalogues essential research tools for executing key biomimetic reactions:

Table 3: Essential Research Reagents for Biomimetic Synthesis

| Reagent/Material | Function | Application Examples |

|---|---|---|

| Acetonedicarboxylic acid | Synthetic equivalent of acetone in Mannich reactions | Robinson's tropinone synthesis, double Mannich reactions |

| Calcium carbonate buffer | pH maintenance in aqueous biomimetic reactions | Tropinone synthesis at physiological pH |

| Enzyme-mimetic catalysts | Biomimetic catalysts mimicking natural enzymes | Laccase-mimetic copper complexes for oxidative coupling |

| Chiral phosphoric acids | Enantioselective control in biomimetic cyclizations | Asymmetric polyene cyclizations, desymmetrization reactions |

| Oxidizing agents (alloxan/ascorbic acid) | Aerobic oxidative halogenation mimicking flavin-dependent halogenases | Biomimetic bromination and iodination reactions |

| NADPH cofactor analogs | Biomimetic reducing agents for carbonyl reduction | Tropinone reductase mimetics for stereoselective reduction |

| Polyene precursors | Linear substrates for biomimetic cyclization | Steroid and terpenoid synthesis via polyene cyclization |

| Phenolic dimerization substrates | Monomers for oxidative coupling reactions | Synthesis of dimeric alkaloids and phenolic natural products |

Current Challenges and Future Perspectives

Despite significant advances, biomimetic synthesis continues to face several formidable challenges that represent opportunities for future innovation. The synthesis of natural products featuring multiple chiral centers and unique functional groups demands increasingly sophisticated techniques for stereochemical control [2]. Many biomimetic reactions suffer from low yields or competing side reactions, complicating the development of efficient synthetic routes from readily accessible starting materials [2]. Perhaps most significantly, the transition from laboratory-scale success to industrial-scale production presents substantial hurdles in process chemistry, including cost efficiency, reproducibility, and environmental sustainability [2].

The future of biomimetic synthesis appears bright, with several promising directions emerging. The integration of chemical and biological synthesis approaches continues to advance, enabling more efficient production of complex natural products and their analogues [6] [2]. The emergence of big data analytics and deep learning technologies offers unprecedented opportunities for optimizing synthetic routes and improving reaction predictability [2] [4]. These computational approaches can help identify new biomimetic strategies and guide the development of more efficient synthetic sequences. Additionally, the continued discovery and characterization of novel biosynthetic pathways in nature provides fresh inspiration for biomimetic approaches, creating a virtuous cycle of innovation [7] [12].

As the field progresses, biomimetic synthesis is poised to make increasingly significant contributions to drug discovery and development. By enabling efficient access to complex natural products and their analogues, biomimetic strategies expand the molecular library available for pharmaceutical research [3] [4]. This expansion is particularly valuable in the pursuit of novel therapeutic agents for challenging disease targets, where natural product scaffolds often provide unique bioactivity profiles. The continued evolution of biomimetic synthesis promises to enhance our fundamental understanding of both chemical reactivity and biological pathways, ultimately advancing the frontiers of synthetic chemistry and drug discovery.

The biomimetic synthesis of natural products represents a powerful paradigm in synthetic chemistry, strategically employing biogenetic hypotheses—proposed explanations for how organisms biosynthesize compounds—to design efficient synthetic routes. This approach addresses critical challenges in synthesizing structurally complex natural products with significant biological and medicinal importance by mimicking nature's inherent biosynthetic logic. This whitepaper delineates the core principles linking biogenetic theory to synthetic execution, providing researchers and drug development professionals with advanced strategies, detailed experimental methodologies, and a modern toolkit for applying these concepts. By framing synthetic design within the context of biosynthetic pathways, biomimetic synthesis enhances efficiency, enables access to molecular complexity, and unlocks novel therapeutic agents, thereby bridging the disciplines of chemistry, biology, and pharmacy.

Natural products, with their remarkable structural and biological diversity, have historically served as a vital bridge between chemistry, the life sciences, and medicine, providing essential scaffolds for drug discovery [3] [6]. A scientific hypothesis is a foundational element of the scientific method, constituting a testable statement proposing a potential explanation for natural phenomena [13]. In the context of natural product biosynthesis, a biogenetic hypothesis is a specific type of scientific hypothesis that proposes a tentative explanation for the biosynthetic pathway through which an organism produces a given natural product [14] [6]. It suggests that the complex architecture of a natural molecule arises from a logical sequence of biochemical transformations, often from simpler, readily available biosynthetic building blocks within the organism.

Biomimetic synthesis is the practical application of this concept, employing principles from biomimicry to design synthetic strategies that imitate these proposed biosynthetic processes [3] [15]. The seminal work of Robinson in 1917, with the one-step synthesis of tropinone via a Mannich reaction, is considered the dawn of this field, as it validated a biosynthetic hypothesis and demonstrated the potential of biomimetic synthesis to construct complex molecules with remarkable efficiency [6]. This strategy has since evolved into a disciplined approach that links chemical synthesis and natural biosynthesis, enabling the development of new concepts, strategies, and methods for synthesizing structurally intricate natural products [6].

Table 1: Core Concepts in Biomimetic Synthesis

| Concept | Definition | Role in Synthetic Design |

|---|---|---|

| Biogenetic Hypothesis | A proposed explanation for the biosynthetic pathway of a natural product within an organism [14] [6]. | Provides the foundational logic and blueprint for designing a synthetic route. |

| Biomimetic Synthesis | A synthetic approach that mimics proposed or known biogenetic processes [3] [15]. | Translates the biogenetic blueprint into practical laboratory reactions and sequences. |

| Bioinspired Synthesis | A broader term for strategies loosely inspired by, but not strictly mimicking, biological principles [14]. | Allows for creative adaptation of nature's strategies using modern synthetic tools. |

The transformative potential of this approach lies in its ability to address long-standing challenges in natural product synthesis, such as cumbersome synthetic routes, poor overall yields, and difficulties in controlling stereochemistry [6]. By learning from and emulating nature's synthetic prowess, chemists can achieve rapid assembly of molecular complexity, often through cascade reactions that form multiple bonds and stereocenters in a single operation [14].

Core Biomimetic Strategies and Reaction Mechanisms

Several key biomimetic strategies have been developed and refined, each based on a class of biogenetic reactions hypothesized to occur in nature. These strategies form the core tactical arsenal for the synthetic chemist employing a biomimetic approach.

Biomimetic Polyene Cyclization

This strategy mimics the biogenetic process where linear polyene precursors undergo concerted, stereospecific cyclization to form complex polycyclic structures, such as those found in steroids and terpenoids [6]. The hypothesis concerning the stereochemical outcomes of these cyclizations, advanced by Stork, Eschenmoser, and others, was pivotal in guiding successful synthetic efforts [6].

- Mechanistic Insight: The reaction is typically initiated by the formation of a carbocation, which triggers a cascade of ring-forming steps. The stereochemistry is controlled by the conformation of the polyene chain and the mediating influence of the template.

- Synthetic Utility: This strategy allows for the one-step construction of intricate carbon skeletons with multiple stereocenters. Heathcock's one-step biomimetic synthesis of dihydro-proto-daphniphyllines using an iminium-ion-induced polyene cyclization is a classic example of its power and efficiency [6].

Biomimetic Oxidative Coupling

This approach emulates nature's strategy of joining simple phenolic or indole subunits through oxidative processes to generate complex dimers or higher oligomers [6]. Barton's early work on the site-selectivity of phenolic aryl radical coupling laid the groundwork for this strategy [6].

- Mechanistic Insight: Oxidation of a phenol generates a phenoxyl radical, which can undergo radical-radical coupling or attack another electron-rich aromatic system. The specific regiochemical outcome is governed by the spin density distribution of the radical intermediate.

- Synthetic Utility: It provides efficient access to a wide array of natural product families, including bisindole alkaloids (e.g., voacalgine A, bipleiophylline) and complex polyphenols (e.g., resveratrol tetramers) [6].

Biomimetic Diels-Alder Reaction

The Diels-Alder (DA) cycloaddition is a widely proposed transformation in biosynthesis, where a diene and a dienophile combine to form a six-membered ring [6]. The biomimetic strategy seeks to replicate this efficient, atom-economical process in the laboratory.

- Mechanistic Insight: The reaction proceeds via a concerted [4+2] cycloaddition, often predicted to be stereospecific. In a biosynthetic context, it may be catalyzed by enzymes (Diels-Alderases).

- Synthetic Utility: This strategy is invaluable for constructing complex polycyclic ring systems with defined stereochemistry. Sorensen's biomimetic synthesis of FR182877, which features successive transannular DA reactions to build its complex architecture, is a prime illustration of its application [6].

Table 2: Key Biomimetic Strategies and Their Applications

| Biomimetic Strategy | Postulated Biogenetic Role | Representative Natural Products Synthesized |

|---|---|---|

| Polyene Cyclization | Formation of steroid and terpenoid skeletons from linear isoprenoid precursors [6]. | Progesterone, Dammaranedienol, Daphniphyllum Alkaloids [6] |

| Oxidative Coupling | Dimerization/Oligomerization of phenolic or indolic monomers to generate molecular complexity [6]. | Carpanone, Morphine-related compounds, Voacalgine A, Bipleiophylline [6] |

| Diels-Alder Reaction | [4+2] Cycloaddition to form complex polycyclic systems in a single step [6]. | FR182877, various pyran-containing metabolites [6] |

Experimental Protocols: From Hypothesis to Synthesis

The following detailed protocols illustrate how a biogenetic hypothesis is translated into a practical synthetic workflow, providing a roadmap for researchers.

Protocol: Bioinspired Total Synthesis of Chabranol via Prins-Triggered Double Cyclization

This protocol is based on the work detailed in [14], which sought to validate a proposed biosynthetic pathway for the terpenoid natural product chabranol.

1. Biogenetic Hypothesis: The authors proposed that the linear sesquiterpenoid trans-nerolidol undergoes dihydroxylation and C–C bond cleavage to form an aldehyde intermediate. This aldehyde is then activated in nature by an acid to trigger a key Prins cyclization with a trisubstituted olefin, culminating in trapping by a tertiary alcohol to form the oxa-[2.2.1] bridged bicycle [14].

2. Synthetic Design & Execution:

- Step 1: Synthesis of Aldehyde Precursor 3. Instead of starting from trans-nerolidol, a convergent coupling approach was employed.

- Phenyl sulfide 5 (derived from geranyl bromide) was coupled with chiral epoxide 6 (prepared via Sharpless epoxidation) under strong basic conditions.

- The resulting intermediate 7 was reduced with sodium to furnish diol 8.

- The primary alcohol of 8 was oxidized using Swern oxidation to yield the key hydroxy aldehyde precursor 3.

- Step 2: Biomimetic Prins Double Cyclization. This step directly tests the core biogenetic hypothesis.

- Hydroxy aldehyde 3 was activated with a silylating agent (e.g., TMSOTf), generating a formal silicon cation.

- This activation triggered a Prins cyclization with the olefin, followed by termination through nucleophilic attack by the tertiary alcohol.

- The reaction proceeded with sole diastereoselectivity to afford silylated bicycle 9, directly mimicking the proposed biosynthetic step.

- Step 3: Late-Stage Functionalization. The remaining olefin in 9 was manipulated through redox reactions and deprotection to yield the final product, chabranol. The structure was confirmed by X-ray diffraction analysis [14].

Protocol: Biomimetic Oxidative Cyclization in Monocerin-Family Products

This protocol, derived from [14], focuses on a hypothesized oxidative cyclization to form the cis-fused tetrahydrofuran (THF) ring in isocoumarin natural products.

1. Biogenetic Hypothesis: It was postulated that the THF ring in compounds like monocerin is formed through a benzylic oxidation to generate a para-quinone methide (pQM) intermediate. The C10 alcohol then undergoes an intramolecular oxa-Michael addition to close the THF ring [14].

2. Synthetic Design & Execution:

- Step 1: Assembly of the Isocoumarin Precursor.

- Benzaldehyde 11 was subjected to a Wittig reaction with MOMPPh3Cl and LDA to install a methyl enol ether.

- This was converted to 1,3-dithiane 12.

- A nucleophilic addition to a chiral epoxide 13 and subsequent oxidative hydrolysis of the dithiane assembled the core chain.

- Step 2: Probing the Biomimetic Oxidative Cyclization.

- With the linear precursor in hand, conditions were screened to effect the oxidation/cyclization cascade.

- The key transformation involved treating the precursor with an oxidizing agent (e.g., DDQ, MnO2, or under photoredox conditions) to generate the pQM intermediate in situ.

- The pQM intermediate spontaneously underwent the hypothesized intramolecular oxa-Michael addition, cyclizing to form the THF ring and yielding 7-O-demethylmonocerin or its analogues.

- This successful transformation provided strong chemical evidence supporting the plausibility of the proposed biosynthetic pathway [14].

Visualization of the Biomimetic Synthesis Workflow

The following diagram illustrates the core logical and experimental workflow that connects a biogenetic hypothesis to the final synthesis of a natural product, integrating the strategies and protocols discussed.

Diagram 1: The Biomimetic Synthesis Workflow from Hypothesis to Application.

The Scientist's Toolkit: Essential Reagents and Materials

The successful execution of biomimetic syntheses relies on a curated set of reagents, catalysts, and analytical tools. This toolkit enables the key transformations required to mimic biosynthetic pathways.

Table 3: Research Reagent Solutions for Biomimetic Synthesis

| Reagent/Category | Function in Biomimetic Synthesis | Specific Examples / Notes |

|---|---|---|

| Chiral Epoxides & Building Blocks | Serve as stereodefined precursors to install chiral centers in complex molecular skeletons [14]. | Epoxide 6 in chabranol synthesis; often prepared via Sharpless Asymmetric Epoxidation for high enantiomeric purity [14]. |

| Oxidizing Agents | Generate reactive intermediates for key biomimetic steps, such as para-quinone methides (pQM) for oxidative cyclization [14]. | DDQ (Dichlorodicyanobenzoquinone), MnO₂; also modern photoredox catalysts for tunable, radical-based oxidation [14] [16]. |

| Lewis & Brønsted Acids | Activate carbonyls and other functional groups to initiate cationic cyclization cascades, mimicking enzymatic acid catalysis [14] [6]. | TMSOTf (Trimethylsilyl triflate) used in Prins cyclization for chabranol; enzymatic environments are mimicked by mild acids or metal salts [14]. |

| Silylating Agents | Protect hydroxyl groups and can be used to generate reactive silyl cations that mediate key cyclization steps [14]. | TBS-Cl (tert-butyldimethylsilyl chloride) for protection; TMSOTf for in situ generation of reactive electrophiles [14]. |

| Cross-Coupling Catalysts | Form carbon-carbon bonds between complex fragments, enabling modular and convergent synthesis of biomimetic precursors [16]. | Palladium catalysts (e.g., Pd(PPh₃)₄, Pd₂(dba)₃) for Suzuki, Stille, and Negishi reactions; essential for building polyene chains [16]. |

The strategic link between biogenetic hypotheses and synthetic design remains a cornerstone of modern natural product synthesis. This biomimetic approach, which uses nature's proposed blueprints as a guide, consistently demonstrates its power in achieving the efficient and stereocontrolled construction of complex molecular architectures that are often intractable through traditional linear synthesis.

Looking forward, the field is poised for transformation through integration with emerging technologies. The use of big data and deep learning is anticipated to optimize synthetic routes and improve the predictability of complex biomimetic transformations [15]. Furthermore, the synergy between chemical synthesis and synthetic biology will continue to deepen [17] [18]. Advances in genome mining and metabolic engineering allow for the discovery of new biosynthetic gene clusters and the production of complex natural product analogues in microbial hosts, providing both inspiration and starting materials for biomimetic chemistry [17]. This interdisciplinary convergence, coupled with automated synthesis platforms and AI-assisted retrosynthesis planning [16], will undoubtedly accelerate the discovery and development of novel therapeutic agents derived from or inspired by natural products, solidifying the critical role of biomimetic principles in the future of pharmaceutical research and development.

Biomimetic synthesis, the practice of imitating nature's strategies to construct complex molecules and materials, has emerged as a transformative approach in scientific research and drug development. By emulating the efficiency, sustainability, and structural complexity achieved by biological systems, this field addresses critical challenges in traditional synthetic methodologies. This whitepaper provides a technical examination of the core advantages of biomimetic synthesis, supported by quantitative data and detailed experimental protocols. Framed within contemporary research on natural product strategies, it offers researchers and drug development professionals a comprehensive guide to the principles, applications, and forward-looking techniques that are defining the next generation of synthetic design.

Natural products have long been a cornerstone of drug discovery, providing essential molecular scaffolds for new therapeutics [2]. However, their traditional synthesis is often hampered by resource limitations, high reagent costs, environmental concerns, and difficulties in modifying complex structures [2]. Biomimetic synthesis presents a paradigm shift, drawing inspiration from billions of years of evolutionary optimization. It moves beyond simple morphological mimicry to embed nature's functional principles—hierarchical organization, adaptive behavior, and resource efficiency—into engineered synthetic processes [19].

This approach is grounded in the observation that biological systems achieve extraordinary functionality not through material excess but through intelligent, multi-scale organization [19]. This whitepaper deconstructs the key advantages of biomimetic synthesis into three core pillars: efficiency in chemical steps and energy use, enhanced sustainability through greener processes and materials, and the ability to navigate and construct immense structural complexity. The subsequent sections will dissect these principles with technical rigor, providing a framework for their application in modern research and development.

Core Principles and Quantitative Advantages

The superiority of biomimetic synthesis is evident in its ability to achieve more with less. By adopting nature's blueprints, researchers can bypass lengthy synthetic routes, reduce environmental impact, and access architectures that are otherwise intractable. The following quantitative comparison and analysis illustrate these advantages unequivocally.

Table 1: Quantitative Comparison of Traditional vs. Biomimetic Synthesis

| Characteristic | Traditional Chemical Synthesis | Biomimetic Synthesis | Key Biomimetic Example |

|---|---|---|---|

| Step Efficiency | Often requires 20-30 steps for complex natural products [2] | Mimics nature's concise pathways (e.g., 1-5 key steps) [2] | Biomimetic polyene cyclization constructs complex rings in a single step [2]. |

| Material Efficiency | Relies on high material consumption for structural integrity [19] | Achieves performance through hierarchical organization, not material excess [19] | Nacre's "brick-and-mortar" structure provides exceptional toughness from weak constituents [19]. |

| Stereochemical Control | Often requires protecting groups and chiral auxiliaries | Employs inherent stereochemical guidance from biomimetic precursors | Biomimetic Diels-Alder reactions achieve precise stereocontrol seen in natural products like FR182877 [2]. |

| Environmental Impact | Frequently uses toxic solvents, high energy, and generates waste | Utilizes milder conditions and aims for atom economy | Enzyme immobilization in COFs under mild aqueous conditions [20]. |

Analysis of Advantages

- Efficiency: Biomimetic strategies are inherently concise. For instance, the biomimetic polyene cyclization strategy mirrors nature's process for building complex cyclic structures like steroids and terpenoid alkaloids from linear precursors, dramatically reducing the number of synthetic steps required and providing superior stereoselective control [2]. This efficiency translates directly into reduced time and cost for producing target molecules.

- Sustainability: The paradigm of "hierarchical structuring" and "material economy" observed in systems like spider silk and bone informs a more sustainable manufacturing ethos [19]. Biomimetic Additive Manufacturing (BAM) focuses on creating structures that are "optimized for load-bearing with minimal material use," directly reducing waste and resource consumption [19].

- Structural Complexity: Nature excels at building molecules with multiple chiral centers and unique functional groups. Biomimetic synthesis meets this challenge by using strategies that pre-organize reactants or template transitions states, as seen in the biomimetic oxidative coupling strategy for synthesizing morphine-like molecules [2]. This allows for the practical construction of intricate architectures that are essential for biological activity.

Experimental Protocols: Biomimetic Synthesis in Action

To translate these principles into practice, detailed and reproducible methodologies are essential. The following protocol exemplifies a cutting-edge biomimetic approach for enzyme immobilization, highlighting the interplay between structure and function.

Protocol: Biomimetic Synthesis of Vesicular Covalent Organic Frameworks (COFs) for Enzyme Immobilization

This protocol details the synthesis of morphology-controlled COFs using Gemini surfactants as biomimetic templates, enabling robust in-situ enzyme encapsulation under mild conditions [20].

1. Hypothesis and Objective

- Hypothesis: Cationic Gemini surfactants can mimic phospholipid bilaries to serve as dynamic soft templates for COF self-assembly, creating a robust biomimetic interface for enzyme immobilization.

- Objective: To synthesize vesicular (v-TpPa-COF) or lamellar (l-TpPa-COF) frameworks under mild aqueous conditions for enhancing enzyme stability and activity.

2. Materials and Reagents Table 2: Research Reagent Solutions for Vesicular COF Synthesis

| Reagent / Material | Function / Role in Experiment | Critical Parameters & Notes |

|---|---|---|

| 1,3,5-triformylphloroglucinol (Tp) | Monomer for COF formation (Knot) | Purity >98%; stored desiccated at -20°C. |

| p-phenylenediamine (Pa) | Monomer for COF formation (Linker) | Purity >98%; stored desiccated at -20°C. |

| C16-2-16 Gemini Surfactant | Biomimetic template & phase-transfer catalyst | Critical Packing Parameter (CPP) ~1/2-1 for vesicle formation [20]. |

| Polyvinyl Alcohol (PVA) | Stabilizing agent | Molecular weight 85,000-124,000; optimal concentration prevents aggregation. |

| Dichloromethane (DCM) | Organic solvent (for O/W system) | Anhydrous grade; forms vesicular morphology with C16-2-16. |

| o-Dichlorobenzene/Chloroform (3:2) | Organic solvent (for W/O system) | Anhydrous grade; specific ratio required for optimal vesicle morphology. |

3. Step-by-Step Procedure

- Step 1: Surfactant Solution Preparation. Dissolve the C16-2-16 Gemini surfactant in deionized water at a concentration of 1 mg mL⁻¹. For the oil-in-water (O/W) system, use water as the continuous phase. For the water-in-oil (W/O) system, prepare the organic phase with o-dichlorobenzene and chloroform in a 3:2 ratio.

- Step 2: Monomer Addition and Stabilization. Add the Tp monomer to the organic phase and the Pa monomer to the aqueous phase. Introduce PVA as a stabilizer at its optimal concentration to the aqueous phase to form protective layers around droplets and prevent coalescence.

- Step 3: Polymerization and Self-Assembly. Combine the two phases under vigorous stirring at 25°C. The Gemini surfactant will act as a phase-transfer catalyst, facilitating the reaction at the interface and self-assembling into micelles. The polymerization to form TpPa-COF is typically complete within 10 minutes.

- Step 4: In-Situ Enzyme Immobilization (Optional). To immobilize an enzyme, include it in the aqueous phase prior to combination. The enzyme's charge will interact with the charged surfactant, participating in the micelle transformation and becoming encapsulated within the forming COF structure.

- Step 5: Product Isolation. Recover the resulting COF product by centrifugation, and wash thoroughly with water and ethanol to remove any residual surfactants or monomers. Dry the product under vacuum.

4. Critical Experimental Parameters

- Temperature: Maintain at 25°C to ensure enzyme integrity and controlled self-assembly.

- Surfactant CPP: The morphology is dictated by the surfactant's CPP. C16-2-16 (CPP between 1/2 and 1) yields vesicular COFs, while C16Py-2-Py16 (CPP ≈ 1) yields lamellar structures [20].

- Solvent System: The interface is critical. Vesicular morphology in the O/W system is only achieved with DCM as the organic phase.

- Stabilizer Choice: PVA is superior to PVP and carboxymethyl cellulose, resulting in higher specific surface area and enhanced COF crystallinity.

Emerging Frontiers and Advanced Techniques

The field of biomimetic synthesis is dynamically evolving, integrating advanced manufacturing and computational technologies to push the boundaries of what is possible.

Biomimetic Additive Manufacturing (BAM)

BAM combines biomimicry with the flexibility of 3D printing to create structures with unprecedented performance. It focuses on emulating the functional adaptation and hierarchical organization of biological systems like nacre, spider silk, and bone [19]. This approach moves beyond geometric replication to embed multifunctionality and responsiveness directly into printed structures. Key advances include:

- 4D Printing: Creating materials that change shape or function over time in response to environmental stimuli, inspired by dynamic systems like pinecones [19].

- Soft Robotics: Engineering compliant and adaptive robotic systems using bioinspired material architectures [19].

- Structural Optimization: Using algorithms to generate load-optimized, lightweight forms that mimic the growth patterns of trees or the porous architecture of bone, leading to significant material savings [19].

The Role of Computational Design

The integration of big data and deep learning technologies is poised to revolutionize biomimetic synthesis [2]. Machine learning models can analyze vast datasets of known natural products and synthetic pathways to:

- Predict viable biomimetic routes for unknown or complex natural products.

- Optimize synthetic conditions to improve yields and reduce side reactions.

- Accelerate the design of new biomimetic materials and molecules by simulating their properties and formation processes.

Biomimetic synthesis represents a fundamental shift in synthetic strategy, one that is increasingly critical for addressing the complex challenges of modern drug discovery and materials science. Its core advantages—unparalleled efficiency, inherent sustainability, and mastery over structural complexity—are not merely incremental improvements but transformative qualities that redefine the limits of synthetic design. As evidenced by the detailed protocols and quantitative data, this field has moved from conceptual admiration of nature to practical, high-yield application.

The future of biomimetic synthesis lies in the deeper integration of interdisciplinary expertise—from chemistry and biology to materials science and artificial intelligence. By continuing to learn from and emulate nature's simple yet powerful principles, researchers and drug developers can create the next generation of high-performance, sustainable, and complex molecular and material solutions. The frameworks and techniques outlined in this whitepaper provide a foundational toolkit for advancing this promising frontier.

Biomimetic Chemistry as a New Frontier in Synthetic Methodology

Biomimetic chemistry, which draws inspiration from the efficiency and selectivity of biological processes, is emerging as a transformative frontier in the development of novel synthetic methodologies. This approach leverages billions of years of evolutionary optimization to create practical and sustainable laboratory syntheses, particularly for complex natural products with bioactive properties. By mimicking the sophisticated strategies employed by enzymes and biological pathways, chemists can achieve remarkable regio- and stereoselectivity under mild conditions, bypassing the need for extensive protecting group manipulations or harsh reagents. This whitepaper examines the core principles, cutting-edge methodologies, and experimental protocols underpinning biomimetic synthesis, with a specific focus on its application in natural product synthesis and drug development. We provide a detailed analysis of a recent breakthrough in 1,2-amino migration via photoredox catalysis as a representative case study, alongside essential resources for implementing these strategies in research settings.

Synthetic organic chemists continually draw inspiration from biocatalytic processes to innovate beyond existing catalytic platforms [21]. Biomimetic synthesis imitates the biosynthetic processes occurring in nature to design synthetic strategies for natural products, offering a promising alternative to traditional chemical synthesis and biosynthesis methods, which often face challenges such as high reagent costs, environmental unfriendliness, and limitations in modifying complex molecules [2]. This field dates back to the late 19th century, with Robinson’s synthesis of tropinone in 1917 representing a significant early milestone [2].

The fundamental premise of biomimetic chemistry lies in its ability to translate biological principles into engineering and design solutions [22]. Where nature uses enzyme-catalyzed reactions to construct complex molecular architectures with perfect stereocontrol, biomimetic chemistry aims to develop simplified, practical synthetic equivalents that capture the essence of these biological transformations. This approach has become particularly valuable for constructing natural products with optical activities, unusual structural characteristics such as spiro-ring systems, or quaternary carbon atoms [7]. The biomimetic approach provides a unified method for synthesizing bioactive skeletal products, facilitating laboratory synthesis of natural compounds with complicated structures [7].

Core Principles and Biomimetic Strategies

Biomimetic strategies in organic synthesis are characterized by several unifying principles that distinguish them from traditional synthetic approaches. These principles include the emulation of biosynthetic pathways, the use of biologically plausible reactive intermediates, and the implementation of cascade reactions that mimic the efficiency of enzymatic transformations.

Key Biomimetic Reaction Archetypes

Several key reaction archetypes frequently appear in biomimetic synthesis, each inspired by observed biological processes:

- Biomimetic Polyene Cyclization: This strategy mimics the natural process of creating complex cyclic structures from polyene precursors and has been used to synthesize steroids like progesterone and terpenoid alkaloids, providing insights into stereoselective control [2].

- Biomimetic Oxidative Coupling: This approach imitates the oxidative joining of phenol or indole units and has been applied in the synthesis of morphine-like molecules and natural phenolic products [2].

- Biomimetic Diels-Alder Reaction: Inspired by the natural cycloaddition process, this strategy has enabled the synthesis of complex polycyclic rings in natural products such as FR182877 [2].

- Photocycloaddition and Radical Reactions: These methods mimic radical-based biological mechanisms and have been employed in the synthesis of various complex natural products [7].

Table 1: Fundamental Biomimetic Reaction Strategies and Their Applications

| Strategy | Biological Inspiration | Synthetic Application | Key Feature |

|---|---|---|---|

| Polyene Cyclization | Steroid biosynthesis | Synthesis of steroids, terpenoid alkaloids | Stereoselective cyclization |

| Oxidative Coupling | Lignin and alkaloid biosynthesis | Morphine-like molecules, phenolic products | C-C and C-O bond formation |

| Diels-Alder Reaction | Biosynthetic cycloadditions | Complex polycyclic rings | Pericyclic ring formation |

| Radical Reactions | Enzyme-mediated radical processes | Various complex natural products | Functional group tolerance |

The Functional Group Migration Principle

A particularly innovative biomimetic strategy involves functional group (FG) migratory transformation, which differs from conventional FG transformation that does not involve positional movement within the molecular skeleton (ipso-transformation) [21]. In FG migratory transformation, a functional group moves position along the molecular skeleton, serving as a flexible strategy for molecular modification, especially for the late-stage functionalization of highly complex molecules [21].

This approach is exceptionally valuable for interconverting late-stage regioisomers, which often exhibit distinct properties including bioactivities [21]. In medicinal chemistry, synthesizing structurally related regioisomers typically requires de novo route planning, which is often time- and resource-consuming. A late-stage FG migratory transformation enables the generation of multiple related regioisomers from one existing isomer in a single operation [21].

Case Study: Biomimetic 1,2-Amino Migration via Photoredox Catalysis

A recent groundbreaking example of biomimetic chemistry is the development of a 1,2-amino migration strategy inspired by enzymatic processes, accomplished through the synergistic combination of biocatalytic mechanism and photoredox catalysis [21].

Biological Inspiration and Reaction Design

The biological inspiration for this transformation comes from enzyme-catalyzed 1,2-amino migration, which plays a vital role in various biochemical processes, including the biosynthesis of l-β-lysine [21]. Specifically, the interconversion of l-α-lysine to l-β-lysine is facilitated by lysine 2,3-aminomutase (LAM) in conjunction with pyridoxal 5′-phosphate (PLP) as a co-enzyme [21]. However, due to enzyme specificity, this natural reaction is only applicable to β-lysine synthesis with essentially no substrate scope.

The biomimetic reaction design emulates this naturally occurring process to achieve the modular synthesis of β-amino acids by utilizing visible-light catalysis (Figure 1). In this catalysis process, photocatalytically generated free-radical intermediates from feedstock chemicals are intercepted by α-vinyl-aldimine esters derived from the condensation of α-vinyl-α-amino acids and arylaldehydes, resulting in the formation of the γ-functionalized-β-radical of α-amino-acid derivatives [21].

In the key migration step, as proposed and further chemically validated by Frey et al. [21], an azacyclopropyl carbinyl radical arises through an analogous 3-exo-trig cyclization of the corresponding alkyl radical onto an imine group, followed by rearrangement to generate the product-related γ-functionalized-α-radical of β-amino-acid derivatives [21]. Finally, a facile reduction followed by acidic work-up regenerates the photocatalyst and releases the product, γ-functionalized-β-amino acids.

Reaction Optimization and Scope

The investigation commenced with a focus on the 1,2-amino migration of α-vinyl-aldimine esters using sodium trifluoromethanesulfinate (CF₃SO₂Na) as a model reactant [21]. The presence of fluorine-containing arylaldehydes proved pivotal for the success of this reaction, likely due to their strong electron-withdrawing properties, which enhance the electrophilicity of the resulting imines to facilitate the effective trapping of the free-radical intermediates [21].

Table 2: Optimization of Photocatalyst and Reaction Conditions for 1,2-Amino Migration

| Entry | Arylaldehyde | Photocatalyst | Yield (%) | d.r. |

|---|---|---|---|---|

| 1 | 3,5-Bis(trifluoromethyl)benzaldehyde | 4CzIPN | 45 | - |

| 2 | 2,4,6-Trifluorobenzaldehyde | 4CzIPN | 40 | - |

| 3 | 2,6-Difluorobenzaldehyde | 4CzIPN | 38 | - |

| 4 | 4-Nitrobenzaldehyde | 4CzIPN | Trace | - |

| 5 | 3,5-Bis(trifluoromethyl)benzaldehyde | Ir(dtbbpy)(ppy)₂PF₆ | 79 | - |

| 6 | 3,5-Bis(trifluoromethyl)benzaldehyde | None | 0 | - |

| 7 | 3,5-Bis(trifluoromethyl)benzaldehyde | Ir(dtbbpy)(ppy)₂PF₆ (dark) | 0 | - |

| 8 | 3,5-Bis(trifluoromethyl)benzaldehyde | Ir(dtbbpy)(ppy)₂PF₆ (3 mol%) | 88 | 6.1:1 |

Initial experiments using 3,5-bis(trifluoromethyl)benzaldehyde with 4CzIPN photocatalyst yielded the product in 45% yield [21]. Optimization revealed that Ir(dtbbpy)(ppy)₂PF₆ significantly improved the reaction efficiency (79% yield), with further enhancement to 88% yield and 6.1:1 d.r. when using 3 mol% of this photocatalyst [21]. Control experiments confirmed the indispensable roles of both photocatalyst and light for the reaction to proceed [21].

The reaction scope was extensively evaluated, demonstrating exclusive chemo- and regioselectivity across a diverse range of natural α-amino-acid derivatives, including α-Leu-OMe, α-Val-OMe, α-Ala-OMe, and α-Phg-OMe, which reacted efficiently with CF₃SO₂Na to afford the corresponding γ-CF₃-β-amino acids in 69-83% yield [21]. The method also tolerated more complex amino acids including α-Tyr(Me)-OMe, α-Glu-OMe, α-Asp-OMe, and α-Ser(tBu)-OMe derivatives, providing the desired products in satisfactory yields (44-73%) [21]. Unnatural α-amino-acid derivatives also proved amenable to the reaction, showcasing the protocol's versatility in modifying unnatural α-amino acids (41-74% yield) [21].

Experimental Protocols: Key Methodologies

General Procedure for Biomimetic 1,2-Amino Migration

Materials:

- α-Vinyl-aldimine ester (0.2 mmol)

- Radical precursor (e.g., CF₃SO₂Na, 0.24 mmol)

- Ir(dtbbpy)(ppy)₂PF₆ (3 mol%)

- K₃PO₄ (0.4 mmol)

- 3,5-Bis(trifluoromethyl)benzaldehyde (0.24 mmol)

- Anhydrous MeCN (2.0 mL)

Procedure:

- Add α-vinyl-aldimine ester, radical precursor, K₃PO₄, and 3,5-bis(trifluoromethyl)benzaldehyde to a dried reaction vial.

- Evacuate and purge the vial with nitrogen gas three times.

- Add anhydrous MeCN and Ir(dtbbpy)(ppy)₂PF₆ under a nitrogen atmosphere.

- Stir the reaction mixture at room temperature for 24 hours under irradiation with 34W blue LEDs.

- Monitor reaction progress by TLC or LC-MS.

- Upon completion, concentrate the mixture under reduced pressure.

- Purify the crude product by flash column chromatography on silica gel to afford the desired γ-substituted β-amino acid.

Note: All manipulations should be performed under inert atmosphere when necessary. The reaction is sensitive to oxygen and moisture, which can quench the photocatalytic cycle.

Preparation of α-Vinyl-Aldimine Ester Substrates

α-Vinyl-aldimine esters are prepared through condensation of α-vinyl-α-amino acids with appropriate arylaldehydes:

Materials:

- α-Vinyl-α-amino acid derivative (1.0 equiv)

- Arylaldehyde (1.2 equiv)

- Molecular sieves (4Å)

- Anhydrous dichloromethane or toluene

Procedure:

- Suspend activated molecular sieves in anhydrous solvent.

- Add α-vinyl-α-amino acid derivative and arylaldehyde.

- Stir the mixture at room temperature or reflux under inert atmosphere.

- Monitor reaction progress by TLC or NMR.

- Filter to remove molecular sieves and concentrate under reduced pressure.

- Purify by recrystallization or column chromatography if necessary.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful implementation of biomimetic methodologies requires specific reagents and materials optimized for these transformations. The following toolkit outlines essential components for biomimetic 1,2-amino migration and related reactions.

Table 3: Essential Research Reagent Solutions for Biomimetic Photoredox Reactions

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Ir(dtbbpy)(ppy)₂PF₆ | Photoredox catalyst | 3 mol% loading; enables radical generation via single-electron transfer |

| 4CzIPN | Organic photocatalyst | Metal-free alternative; useful for certain substrate classes |

| 3,5-Bis(trifluoromethyl)benzaldehyde | Electrophilic imine formation | Enhances electrophilicity of resulting imines for radical trapping |

| CF₃SO₂Na (Langlois' reagent) | Trifluoromethyl radical precursor | Bench-stable solid; source of CF₃ group |

- Additional Radical Precursors: PhSO₂-Na (phenylsulfonyl), MeS-SMe (methylthio), Ph₂P(O)-H (phosphinyl), Ph-Br (phenyl) [21]

- Base: K₃PO₄ (2.0 equiv) - facilitates radical generation and maintains reaction pH

- Solvent: Anhydrous MeCN - optimal for photoredox reactions; dissolves reactants while transmitting visible light

Current Challenges and Future Perspectives