Decoding Light-Driven Catalysis: The Ultrafast Mechanism and Biotech Promise of Fatty Acid Photodecarboxylase (FAP)

This article provides a comprehensive analysis of the catalytic mechanism and emerging applications of Fatty Acid Photodecarboxylase (FAP), a recently discovered flavin-dependent photoenzyme.

Decoding Light-Driven Catalysis: The Ultrafast Mechanism and Biotech Promise of Fatty Acid Photodecarboxylase (FAP)

Abstract

This article provides a comprehensive analysis of the catalytic mechanism and emerging applications of Fatty Acid Photodecarboxylase (FAP), a recently discovered flavin-dependent photoenzyme. Targeting researchers and biotech professionals, it first explores the foundational photocycle, detailing the ultrafast electron transfer and radical intermediate dynamics that enable light-driven hydrocarbon synthesis. The discussion then progresses to methodological approaches for studying FAP and its potential in sustainable biotechnology and synthetic chemistry. Subsequently, it addresses key challenges in enzyme engineering and reaction optimization for practical deployment. Finally, the article validates the proposed mechanism through comparative analysis with traditional decarboxylation catalysts and discusses future research directions for harnessing this unique photo-biocatalyst in biomedicine and green chemistry.

Unveiling the Blue Light Switch: Foundational Principles of the FAP Photocycle

Discovery and Natural Role of Fatty Acid Photodecarboxylase

The discovery of fatty acid photodecarboxylase (FAP) represents a paradigm shift in photobiology and enzymology, fundamentally challenging the long-held thesis that biological photoreceptors are exclusively based on metallo- or polyene-chromophores. This in-depth guide frames this discovery within the broader mechanistic thesis of FAP research: understanding how a single, unmodified flavin cofactor harnesses blue light to catalyze the challenging decarboxylation of fatty acids, a reaction of significant biotechnological and potentially therapeutic interest.

Prior to FAP's identification, biological decarboxylation of fatty acids was known to require complex multi-step enzymatic pathways (e.g., the ubiquitin-like enzyme OleTJE P450 peroxidase) or high-energy input. The discovery of a light-dependent, single-enzyme system provided a novel, energetically efficient mechanistic blueprint. The core thesis of ongoing FAP research now revolves around elucidating the precise photophysical and chemical steps, from photon absorption to carbon-carbon bond cleavage, and defining its physiological role in algal photoprotection and lipid metabolism.

Discovery and Natural Physiological Role

FAP was first discovered and characterized in 2017 in the microalga Chlorella variabilis NC64A. Genomic analysis identified a candidate gene belonging to the "glucose-methanol-choline (GMC) oxidoreductase" superfamily but with unique features. Heterologous expression and biochemical assays confirmed its light-dependent activity.

Natural Role: In its native algal context, FAP is proposed to function as a photoprotective metabolic valve and a component of a lipid remodeling system.

- Photoprotection & ROS Mitigation: Under high light stress, photosynthetic organisms produce excess reducing equivalents and reactive oxygen species (ROS). By decarboxylating free fatty acids (potentially released from damaged membranes), FAP consumes a substrate and generates alkanes/alkenes. This process may act as an electron sink, helping to manage the cellular redox state and mitigate oxidative damage.

- Membrane Lipid Homeostasis: FAP operates on C16-C20 saturated and unsaturated free fatty acids. The resulting hydrocarbons may be excreted, volatilized, or potentially incorporated into complex lipids, suggesting a role in dynamic lipid turnover and membrane adaptation.

Table 1: Key Discovery Milestones and Natural Substrate Profile of FAP

| Aspect | Key Finding | Significance |

|---|---|---|

| Discovery Year | 2017 (Sorigué et al., Science) | First report of a light-dependent, flavin-based decarboxylase. |

| Source Organism | Chlorella variabilis NC64A (photosynthetic microalga) | Indicates an evolutionary adaptation to light-rich environments. |

| Protein Family | GMC oxidoreductase superfamily (but distinct) | Suggests divergent evolution from oxidoreductases to a photodecarboxylase. |

| Natural Substrates | C16:0 (palmitic), C18:0 (stearic), C18:1 (oleic) fatty acids. | Points to a role in general fatty acid metabolism, not a specialized pathway. |

| Primary Products | C15 (pentadecane) from C16:0, C17 (heptadecane) from C18:0, etc. | Generation of hydrocarbons with potential biological and biotech applications. |

| Cellular Location | Associated with the chloroplast (predicted) | Links activity to the photosynthetic compartment and its metabolic byproducts. |

Core Mechanism: A Stepwise Thesis

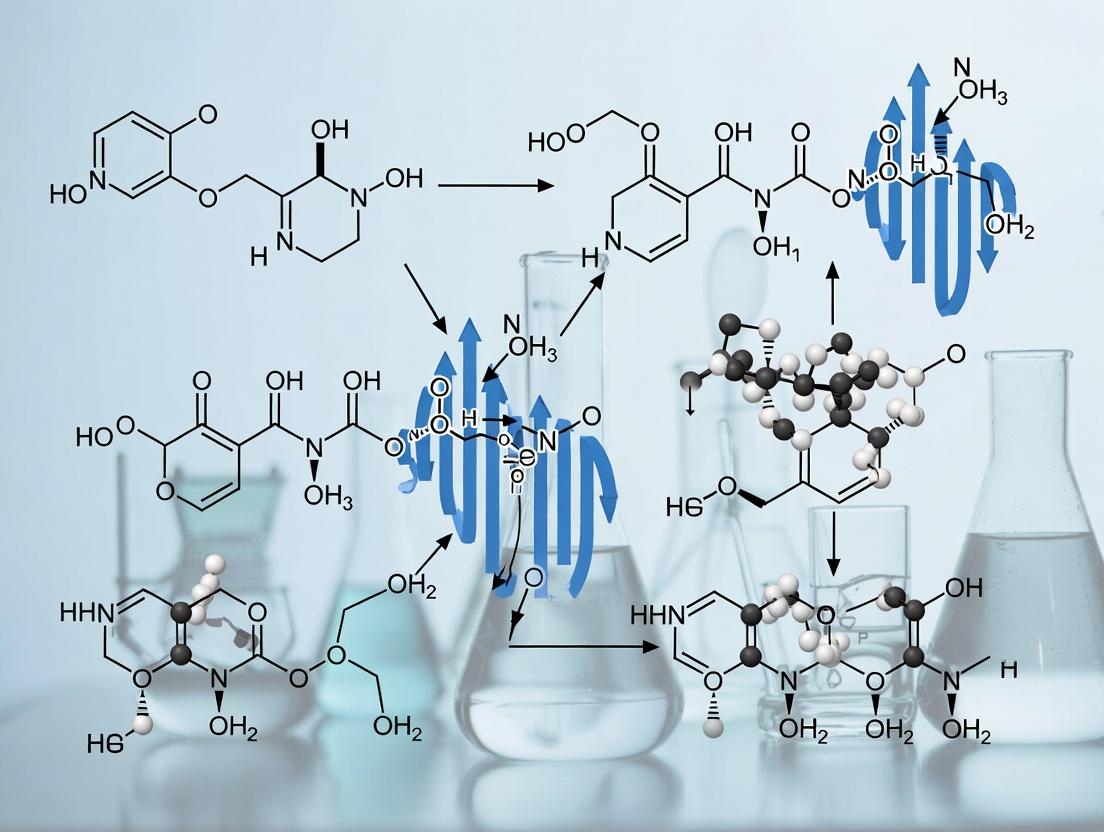

The prevailing mechanistic thesis for FAP catalysis involves a sequential, light-triggered process. The following diagram outlines this proposed pathway.

Diagram Title: Proposed Photocatalytic Cycle of FAP

Mechanistic Steps:

- Photon Absorption & Flavins's Role: The resting state contains an oxidized FAD non-covalently bound. Absorption of a blue photon (~450 nm) by FAD leads to its excitation.

- Electron Transfer: The excited flavin (FAD) acts as a strong oxidant. The current thesis proposes a direct single electron transfer (SET) from the carboxylate group of the bound fatty acid substrate to the flavin, generating a transient fatty acid carboxyl radical and a reduced, anionic flavin semiquinone (FADH•⁻).

- Decarboxylation: The unstable fatty acid carboxyl radical rapidly loses CO₂, forming a carbon-centered alkyl radical (R•).

- Hydrogen Atom Transfer (HAT): The alkyl radical abstracts a hydrogen atom from a key conserved glutamate residue (Glu367 in C. variabilis) within the active site. This quenches the radical, yielding the final alkane product and regenerating a flavin neutral semiquinone (FADH•).

- Reset: The FADH• is re-oxidized to complete the catalytic cycle, likely involving a solvent proton and possibly oxygen in some conditions.

Key Experimental Protocols

Protocol: Recombinant FAP Expression and Purification

Aim: To produce active, purified FAP for in vitro studies.

- Gene Cloning: The FAP gene (e.g., from C. variabilis) is codon-optimized and cloned into an expression vector (e.g., pET series) with an N- or C-terminal affinity tag (His₆, Strep-tag).

- Heterologous Expression: The plasmid is transformed into E. coli BL21(DE3). Cells are grown in LB medium at 37°C to OD₆₀₀ ~0.6-0.8. Protein expression is induced with isopropyl β-d-1-thiogalactopyranoside (IPTG, typically 0.2-0.5 mM) and incubated for 16-20 hours at 18-20°C (to improve folding and flavin incorporation).

- Cell Lysis and Clarification: Cells are harvested by centrifugation, resuspended in lysis buffer (e.g., 50 mM Tris-HCl pH 8.0, 300 mM NaCl, 20 mM imidazole, plus protease inhibitors), and lysed by sonication or high-pressure homogenization. The lysate is clarified by centrifugation at >20,000 x g.

- Affinity Chromatography: The supernatant is applied to a nickel-nitrilotriacetic acid (Ni-NTA) agarose column pre-equilibrated with lysis buffer. The column is washed with 10-20 column volumes of wash buffer (increased imidazole to 40-50 mM). Protein is eluted with elution buffer (250-300 mM imidazole).

- Buffer Exchange and Storage: The eluted protein is desalted into storage buffer (e.g., 50 mM HEPES pH 7.5, 150 mM NaCl) using a PD-10 column or dialysis. Glycerol is added to 10% (v/v), and aliquots are flash-frozen in liquid nitrogen and stored at -80°C.

Protocol:In VitroPhotodecarboxylase Activity Assay (GC-MS based)

Aim: To quantitatively measure FAP activity on a specific fatty acid substrate.

- Reaction Setup: In a clear, low-protein-binding microtube, mix:

- 50-100 µL reaction buffer (e.g., 100 mM phosphate buffer, pH 7.5).

- Purified FAP (final concentration 1-10 µM).

- Fatty acid substrate (e.g., palmitic acid, final concentration 0.1-1 mM), delivered from a stock solution in ethanol or complexed with cyclodextrin.

- Optional: An internal standard (e.g., deuterated alkane) for quantification.

- Illumination: Place the open tube or a sealed quartz cuvette under a controlled blue light source (e.g., LED array at 450 nm, ~10-50 mW/cm²). Perform parallel control reactions in identical tubes kept in complete darkness. Incubate for a defined time (seconds to minutes) at room temperature.

- Extraction: Stop the reaction by adding an organic solvent (e.g., 200 µL hexane or chloroform). Vortex vigorously for 1-2 minutes. Centrifuge to separate phases.

- Analysis: Recover the organic (upper) phase and analyze by Gas Chromatography-Mass Spectrometry (GC-MS). Use a non-polar capillary column (e.g., DB-5). Identify the hydrocarbon product by its retention time and mass spectrum compared to an authentic standard.

- Quantification: Integrate peak areas. Calculate product formation rate using the internal standard calibration curve.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Reagents for FAP Research

| Reagent/Material | Function/Description | Key Application |

|---|---|---|

| Codon-Optimized FAP Gene | Synthetic gene for optimal expression in E. coli or other hosts. | Recombinant protein production. |

| pET Expression Vectors | High-copy number plasmids with T7 promoter for controlled protein expression. | Cloning and overexpression of FAP. |

| E. coli BL21(DE3) | Robust expression strain deficient in proteases, carrying T7 RNA polymerase gene. | Host for recombinant FAP production. |

| Isopropyl β-d-1-thiogalactopyranoside (IPTG) | Molecular mimic of allolactose, induces T7 RNA polymerase expression. | Induction of FAP protein expression. |

| Nickel-NTA Agarose | Affinity resin that chelates Ni²⁺ ions, binding to polyhistidine tags. | One-step purification of His-tagged FAP. |

| Fatty Acid Substrates (C12-C20) | Native and non-native saturated/unsaturated fatty acids (e.g., palmitic, oleic acid). | Activity assays and substrate scope determination. |

| Methyl-β-Cyclodextrin | Oligosaccharide used to solubilize hydrophobic fatty acids in aqueous buffers. | Preparation of substrate stocks for in vitro assays. |

| Blue LED Light Source (450 nm) | Provides controlled, monochromatic illumination for photoactivation. | Essential for triggering FAP catalysis in experiments. |

| Deuterated Alkane Internal Standards | Chemically identical, isotopically labeled products (e.g., pentadecane-d₃₂). | Enables precise quantification of reaction products via GC-MS. |

Quantitative Data on FAP Activity and Properties

Table 3: Kinetic and Biophysical Parameters of FAP (Representative Data)

| Parameter | Value / Observation | Experimental Conditions / Notes |

|---|---|---|

| Optimal pH | ~7.5 - 8.5 | Activity assay in phosphate/HEPES buffers. |

| Action Spectrum Peak | ~450 nm (Blue Light) | Correlates with FAD absorption maximum. |

| Apparent Kₘ (for Palmitate) | ~50 - 200 µM | Varies with enzyme source, assay conditions, and light intensity. |

| Turnover Frequency (kcat) | ~80 - 200 s⁻¹ | Under saturating light and substrate; highlights remarkable speed. |

| Quantum Yield (Φ) | ~0.8 - 1.0 | Suggests near-perfect efficiency per absorbed photon. |

| Thermal Stability (Tm) | ~45-50°C | Determined by differential scanning fluorimetry (DSF). |

| Oxygen Sensitivity | Activity inhibited by O₂; optimal under anaerobic or micro-aerobic conditions. | O₂ competes with substrate for electrons/radicals. |

| Cofactor | Non-covalently bound FAD | Identified by HPLC analysis of denatured protein. |

This whitepaper provides a detailed architectural analysis of the flavin cofactor’s role within the enzyme-substrate complex, framed explicitly within the ongoing research on the mechanism of fatty acid photodecarboxylase (FAP). FAP, a light-dependent enzyme, utilizes a flavin adenine dinucleotide (FAD) cofactor to catalyze the decarboxylation of fatty acids into alkanes, a reaction of significant interest for renewable biofuel production and drug development targeting related oxidoreductases. Understanding the precise spatial, electronic, and dynamic relationship between the flavin and the bound fatty acid substrate is the central thesis driving current mechanistic investigations. This guide deconstructs this complex, serving as a technical foundation for researchers aiming to elucidate catalytic pathways or design inhibitors.

Architectural Anatomy of the Flavin Cofactor

The FAD cofactor is the photochemical and redox heart of FAP. Its architecture within the enzyme’s active site dictates function.

2.1 Chemical and Electronic Structure: The isoalloxazine ring system of FAD is the primary chromophore and redox center. Its electronic states—ground state (FADox), singlet excited state (¹FAD*), and semiquinone (FADH•) or hydroquinone (FADH⁻) reduced forms—are manipulated by light and proton-coupled electron transfer (PCET) events.

2.2 Positioning and Non-Covalent Interactions: In FAP, crystallographic data shows the isoalloxazine ring is buried within a dedicated pocket, positioned parallel to the alkyl chain of the fatty acid substrate. Key interactions include:

- π-Stacking with substrate and aromatic residues.

- Hydrogen Bonding via the N(5) and C(4)=O positions to specific amino acids (e.g., a conserved glutamine) and often, a water network.

- Van der Waals Contacts along the hydrophobic alkyl tail.

Architecture of the Enzyme-Substrate Complex in FAP

The fatty acid substrate (e.g., C16-C22) binds in a tunnel extending from the solvent to the flavin. The architecture ensures precise alignment for catalysis.

3.1 Substrate Binding Tunnel: A hydrophobic channel guides the alkyl chain. The carboxylic acid headgroup is anchored near the flavin N(5)/C(4)a region via electrostatic interactions, often with a arginine or lysine residue, positioning it for decarboxylation.

3.2 Critical Distances and Orientations: The catalytic efficiency is governed by nanoscale spatial parameters.

Table 1: Key Geometric Parameters in the FAP FAD-Substrate Complex (Representative Data)

| Parameter | Typical Distance/Orientation | Experimental Method | Functional Significance |

|---|---|---|---|

| Cα of substrate (C1) to Flavin N5 | ~3.5 - 4.5 Å | X-ray Crystallography, QM/MM | Dictates electron transfer feasibility post-decarboxylation. |

| Dihedral angle between isoalloxazine and alkyl chain | ~0-30° | X-ray Crystallography | Maximizes orbital overlap for electron transfer. |

| Distance to proposed proton donor (e.g., Cys/His) | ~3.5 - 5.0 Å | X-ray Crystallography, Mutagenesis | Critical for the final protonation step to form alkane. |

Detailed Experimental Protocols for Architectural Analysis

4.1 Protocol: Time-Resolved Absorption Spectroscopy for Flavin States

Objective: To kinetically resolve the formation and decay of flavin intermediates (e.g., ¹FAD*, FADH•) during the FAP photocycle.

- Sample Preparation: Purify FAP enzyme in assay buffer (e.g., 50 mM Tris-HCl, pH 8.0, 150 mM NaCl). Pre-mix with saturating substrate (e.g., palmitic acid) under anaerobic conditions (glove box) if studying reductive steps.

- Laser Excitation: Use a pulsed laser (e.g., 450 nm, 100 fs-10 ns pulse width) to selectively excite the flavin.

- Probe Beam: Pass a broad-spectrum white light continuum probe (350-750 nm) through the sample collinear with the pump laser.

- Detection: Use a multichannel spectrometer and CCD detector to record time-delayed absorption spectra (delay times from ps to ms).

- Analysis: Global fitting of spectral changes to derive species-associated difference spectra and kinetic lifetimes.

4.2 Protocol: Crystallization of the FAP-Substrate Analog Complex Objective: To obtain high-resolution structural data of the enzyme-substrate-cofactor architecture.

- Protein & Ligand: Express and purify his-tagged FAP. Pre-incubate with a non-hydrolyzable substrate analog (e.g., a C18 fatty acid with a methyl ester or thioether headgroup) at 2:1 molar ratio.

- Crystallization Screen: Use commercial sparse-matrix screens (e.g., Hampton Research) in sitting-drop vapor diffusion plates. Mix 1 µL protein-ligand complex (10-15 mg/mL) with 1 µL reservoir solution.

- Optimization: Based on initial hits, optimize around conditions containing PEG smears (e.g., PEG 3350) and buffers like HEPES or MES (pH 6.5-7.5). Include 1-5% additive screens.

- Cryo-Protection: Soak crystals briefly in reservoir solution supplemented with 20-25% glycerol or ethylene glycol before flash-cooling in liquid nitrogen.

- Data Collection & Refinement: Collect data at a synchrotron microfocus beamline. Solve structure by molecular replacement using apo-FAP coordinates (PDB: 6T4F). Model ligand and water molecules into clear

Fo-Fcelectron density.

Visualizing the Catalytic and Experimental Architecture

Diagram 1: FAP Photocatalytic Pathway (98 chars)

Diagram 2: Transient Absorption Experiment Workflow (99 chars)

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions for FAP Architecture Studies

| Reagent/Material | Function & Rationale | Example/Supplier |

|---|---|---|

| FAP Wild-type & Mutant Proteins | Structural and mechanistic studies require pure, active enzyme. Site-directed mutants probe key residues. | Heterologous expression in E. coli or yeast; purify via His-tag/Ni-NTA. |

| Fatty Acid Substrates & Analogs | Native substrates (C12-C22) and non-decarboxylatable analogs (e.g., methyl esters, ω-fluoro) for trapping complexes. | Sigma-Aldrich, Cayman Chemical. |

| Anaerobic Chamber/Glove Box | Essential for studying redox intermediates of flavin (FADH•, FADH⁻) without oxygen interference. | Coy Laboratory Products, MBraun. |

| Time-Resolved Spectrometer | For laser flash photolysis to track ultrafast flavin photocycle kinetics (ps-ms). | Edinburgh Instruments LP980, home-built systems. |

| Crystallization Sparse-Matrix Kits | Initial screening for growing protein-ligand co-crystals. | Hampton Research Index, JCSG Core Suites. |

| Synchrotron Beamline Access | Source of high-intensity X-rays for collecting diffraction data from micro-crystals. | ESRF, APS, DESY facilities. |

| Cryo-Protectants | To prevent ice crystal formation during vitrification of crystals for cryo-crystallography. | Glycerol, Ethylene Glycol. |

| Molecular Graphics Software | For building, refining, and analyzing the atomic model of the complex. | Coot, PyMOL, ChimeraX. |

The mechanism of fatty acid photodecarboxylase (FAP) represents a paradigm shift in enzymatic photocatalysis, combining light harvesting with C-C bond cleavage. At the core of this mechanism lies the photocycle initiation, governed by ultrafast electron transfer (ET) dynamics from a photoexcited flavin adenine dinucleotide (FAD) cofactor to the fatty acid substrate. Understanding these femtosecond-to-picosecond timescale events is critical for elucidating the complete catalytic cycle and for leveraging FAP in biotechnology and drug development, such as in the light-triggered release of bioactive molecules or synthesis of hydrocarbons.

Theoretical Framework: Key Steps in FAP Photocycle Initiation

The primary photochemical reaction in FAP involves the decarboxylation of a fatty acid (e.g., C12) to yield an alkane or alkene. The initiation sequence is:

- Photon Absorption: Blue light (≈450 nm) photoexcites the FAD cofactor to its singlet excited state (

FAD*). - Ultrafast Electron Transfer: An electron is transferred from

FAD*to the fatty acid carboxylate, forming a charge-separated state: FAD•⁺ + R-COO•⁻. - Decarboxylation & Back-ET: The carboxylate radical rapidly decarboxylates to yield a carbon-centered alkyl radical (R•) and CO₂. This is followed by back-electron transfer from the flavin semiquinone (FADH•) to the alkyl radical, yielding the final alkane product and regenerating ground-state FAD.

The efficiency of the overall reaction is dictated by the competition between productive forward ET/decarboxylation and unproductive charge recombination from the initial ion pair.

Quantitative Data on Ultrafast Dynamics

Recent time-resolved spectroscopic studies have quantified the electron transfer kinetics in FAP. The data below summarizes key rate constants and time constants.

Table 1: Ultrafast Kinetic Parameters in FAP Photocycle Initiation

| Process | Time Constant (Femtoseconds, fs) | Rate Constant (s⁻¹) | Quantum Yield (Approx.) | Experimental Method |

|---|---|---|---|---|

| FAD* Formation (Excitation) | <50 fs | >2.0 x 10¹³ | - | Femtosecond Transient Absorption (fs-TA) |

| Forward Electron Transfer (FAD* → Substrate) | 200 - 500 fs | 2.0 - 5.0 x 10¹² | - | fs-TA, Ultrafast Fluorescence |

| Charge Recombination (Initial Pair) | 5 - 20 ps | 5.0 - 20 x 10¹⁰ | - | fs-TA |

| Carboxylate Radical Decarboxylation | ~2.3 ns | ~4.3 x 10⁸ | ~0.85 (C12 substrate) | fs-TA, Nanosecond TA |

| Productive Back Electron Transfer | ~4 ns | ~2.5 x 10⁸ | - | Nanosecond TA, EPR |

| Unproductive Charge Recombination | Sub-ps to ps | >1 x 10¹² | - | fs-TA |

Table 2: Spectral Signatures of Key Intermediates

| Intermediate | Characteristic Absorption Peaks | Lifetime (Primary) |

|---|---|---|

| FAD (Ground State) | ~375 nm, ~450 nm | Stable |

| FAD (Singlet Excited, FAD*) | ~550-750 nm (broad) | <500 fs |

| FAD⁺• (Flavin Radical Cation) | ~362 nm, ~500-700 nm (broad) | ~3-5 ps |

| R-COO•⁻ (Substrate Radical) | ~350-380 nm | <2.3 ns |

| FADH• (Flavin Semiquinone) | ~580 nm, ~620 nm | Nanoseconds |

Experimental Protocols for Studying Ultrafast ET

Femtosecond Transient Absorption Spectroscopy (Primary Method)

Objective: To resolve the formation and decay of electronic excited states and radical intermediates on femtosecond to nanosecond timescales.

Protocol:

- Sample Preparation: Purified FAP enzyme (e.g., from Chlorella variabilis NC64A) in reaction buffer (e.g., 50 mM HEPES, pH 7.5) is mixed with saturating concentrations of substrate (e.g., 1 mM C12 fatty acid). Sample is circulated through a flow cell (path length 1-2 mm) to prevent photodamage.

- Pump-Probe Setup: A Ti:Sapphire oscillator/amplifier system generates ~100 fs pulses at 800 nm.

- Pump Pulse: A portion is frequency-doubled (400 nm) or used to generate a tunable pulse (e.g., 450 nm) via an optical parametric amplifier (OPA) to selectively excite the FAD cofactor.

- Probe Pulse: A white light continuum (450-800 nm) is generated by focusing a portion of the 800 nm beam onto a sapphire or CaF₂ crystal.

- Data Acquisition: The pump pulse is delayed relative to the probe pulse using a mechanical translation stage. The change in optical density (ΔOD) of the sample is measured across the probe spectrum at each delay time (from -1 ps to several ns). Typically, 10,000-100,000 laser shots are averaged per delay.

- Global & Target Analysis: ΔOD data matrices are analyzed using global fitting algorithms to extract evolution-associated difference spectra (EADS) and their lifetimes, mapping the kinetic model.

Time-Resolved Fluorescence Upconversion

Objective: To specifically monitor the decay of the FAD singlet excited state with ultra-high time resolution (<100 fs).

Protocol:

- Sample: Identical to 4.1.

- Setup: The fluorescence emitted from the sample after 450 nm excitation is collected and focused into a nonlinear crystal (e.g., BBO) together with a time-delayed "gate" pulse (800 nm). Sum-frequency generation (upconversion) occurs only when the fluorescence and gate pulse overlap in time, effectively mapping fluorescence intensity vs. pump-gate delay.

- Analysis: The decay curve at the FAD emission maximum (~550 nm) is fitted to extract the lifetime of FAD*, which is quenched upon ET.

Visualization of Pathways and Workflows

Diagram 1: FAP Photocycle Initiation & ET Pathways

Diagram 2: Femtosecond Transient Absorption Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for FAP Ultrafast Dynamics Studies

| Item | Function & Specification | Example/Supplier |

|---|---|---|

| Recombinant FAP Enzyme | Catalytic protein with native FAD cofactor. High purity (>95%) is critical for artifact-free spectroscopy. | Heterologously expressed in E. coli with His-tag, purified via Ni-NTA and size-exclusion chromatography. |

| Fatty Acid Substrates | Decarboxylation reactants. Saturated chains (C12-C18) are common. Deuterated forms used for mechanistic probing. | Palmitic acid (C16), Lauric acid (C12); from Sigma-Aldrich, Cambridge Isotopes. |

| Ultrafast Laser System | Generates femtosecond light pulses for pump-probe experiments. Core of the time-resolved setup. | Ti:Sapphire amplified laser (e.g., Spectra-Physics Solstice Ace) with OPA (e.g., TOPAS Prime). |

| White Light Continuum Generator | Produces broad-spectrum probe light. Material defines spectral range. | Sapphire crystal (450-800 nm) or CaF₂ (UV-vis). |

| Fast Spectrometer & Detector | Disperses probe light and records intensity with high temporal and spectral resolution. | CCD array spectrometer (e.g., Princeton Instruments) or fast photodiode array. |

| Circulating Flow System | Preserves sample integrity by moving fresh volume into the beam path for each shot. | Peristaltic pump with tubing and custom or commercial flow cell (e.g., Harrick). |

| Anaerobic Chamber/Glovebox | For preparing samples without oxygen, which can quench radicals and interfere with kinetics. | Coy Labs, MBraun. |

| Global Analysis Software | Deconvolutes complex time-spectral data into kinetic components. | Glotaran, OPTIMUS, home-built MATLAB/Python scripts. |

Within the mechanistic study of Fatty Acid Photodecarboxylase (FAP), the direct observation of transient carbonyloxy (acyloxy) and alkyl radicals is paramount. These intermediates, central to the enzyme's unique light-driven decarboxylation, are notoriously short-lived. This whitepaper provides an in-depth technical guide on contemporary strategies to capture and characterize these radical species, detailing experimental protocols, spectroscopic techniques, and analytical methodologies tailored for FAP research.

Fatty Acid Photodecarboxylase (FAP) utilizes a flavin adenine dinucleotide (FAD) cofactor and blue light to catalyze the decarboxylation of fatty acids to alkanes. The prevailing mechanism involves light-induced electron transfer from the fatty acid substrate to the excited FAD, leading to subsequent decarboxylation and radical formation. The carbonyloxy radical (RCOO•) is the immediate product of decarboxylation, which rapidly fragments to yield a CO₂ molecule and a terminal alkyl radical (R•). This alkyl radical is ultimately quenched to form the alkane product. Direct experimental evidence for these radicals has been challenging, making their capture a critical frontier in enzymology and mechanistic photobiology.

Core Methodologies for Radical Trapping and Characterization

Time-Resolved Spectroscopic Techniques

Protocol: Femtosecond Transient Absorption Spectroscopy (fs-TAS)

- Objective: To observe the formation and decay kinetics of primary photoproducts and radical intermediates on sub-picosecond to nanosecond timescales.

- Procedure:

- Purified FAP (with FAD cofactor) is mixed with substrate (e.g., C12 fatty acid) in an anaerobic buffer (e.g., 50 mM Tris-HCl, pH 8.0).

- The solution is flowed through a capillary cell to prevent photodamage.

- A femtosecond pump pulse (typically 450 nm to excite FAD) is directed at the sample.

- A broad-spectrum white-light continuum probe pulse, delayed by a mechanically controlled optical delay line, interrogates the sample at time points from -1 ps to several nanoseconds.

- Differential absorption (ΔA) spectra are recorded across UV-Vis-NIR ranges.

- Global and target analysis is performed to decompose the data into evolution-associated difference spectra (EADS), identifying spectral signatures of FAD excited states, FAD radical, and carbon-centered radicals.

Protocol: Electron Paramagnetic Resonance (EPR) Spectroscopy with Spin Traps

- Objective: To provide definitive identification of radical species through their characteristic spin signatures.

- Procedure:

- Sample Preparation: FAP reaction mixtures are prepared in buffer with the addition of a spin trap (e.g., PBN (α-Phenyl-N-tert-butylnitrone) or DMPO (5,5-Dimethyl-1-pyrroline N-oxide)) at 50-100 mM concentration.

- Photoirradiation: The sample is loaded into a quartz EPR tube and irradiated directly within the EPR cavity using a fiber-coupled 450 nm LED.

- Measurement: Continuous-wave X-band EPR spectra are recorded at cryogenic temperatures (e.g., 77 K) to stabilize intermediates, or at room temperature with rapid freezing. Spectra are simulated to assign hyperfine coupling constants to specific radical adducts (e.g., PBN-alkyl adduct).

Computational & Isotope-Labeling Approaches

Protocol: Stopped-Flow Rapid-Freeze Quench EPR

- Objective: To trap intermediates at specific, short time points after reaction initiation.

- Procedure:

- Two syringes, one containing FAP enzyme and the other containing substrate, are loaded into a stopped-flow apparatus.

- Upon mixing, the solution is ejected through a nozzle and sprayed into an isopentane bath cooled by liquid N₂ (~130 K), freezing the reaction at defined ages (milliseconds to seconds).

- The frozen powder is packed into an EPR tube under liquid N₂.

- High-resolution pulsed EPR techniques (e.g., ESEEM, HYSCORE) are performed, often using ¹³C- or ²H-labeled substrates (e.g., 1-¹³C fatty acid) to identify radical structure and environment through hyperfine interactions.

Protocol: Isotope-Sensitive Transient Kinetics

- Objective: To confirm the identity of intermediates by their kinetic isotope effects (KIE).

- Procedure:

- Reaction kinetics are measured using fs-TAS or ns-Laser Flash Photolysis with two separate substrates: a natural abundance fatty acid and a deuterium-labeled analog (e.g., labeled at the α- or β-positions).

- The decay kinetics of the FAD radical (a proxy for the radical quenching step) or the rise kinetics of product are compared.

- A significant KIE (e.g., kH/kD > 2) indicates C-H bond cleavage is rate-limiting in the step involving the alkyl radical intermediate.

Key Data and Findings

Table 1: Spectral Signatures of Key Intermediates in FAP

| Intermediate | Probable Formation Time | Characteristic Spectral Feature (Technique) | Assignment Confirmation |

|---|---|---|---|

| FAD Singlet Excited State | < 1 ps | Absorption max ~600-700 nm (fs-TAS) | Fluorescence upconversion |

| FAD Radical (FAD•⁻) | ~30 ps | Broad absorption ~500-700 nm, bleach at 450 nm (fs-TAS) | Comparison to chemically reduced FAD |

| Carbonyloxy Radical (RCOO•) | ~100 ps - 1 ns | Weak, transient feature ~350-400 nm (fs-TAS) | Computed TD-DFT spectra; substrate dependence |

| Alkyl Radical (R•) | 1 ns - 10 µs | Weak UV absorption; distinct EPR signal (EPR/fs-TAS) | Spin trapping with PBN; KIE studies |

| Alkane Product | > 10 µs | GC-MS detection | Comparison to authentic standard |

Table 2: Essential Research Reagent Solutions for FAP Radical Studies

| Reagent / Material | Function & Rationale |

|---|---|

| Anaerobic Sealed Cuvette Systems | Maintains anoxic conditions critical for stabilizing radical states and preventing O₂ quenching. |

| Deuterated Fatty Acid Substrates (e.g., d₃₃-C16) | Allows mechanistic probing via Kinetic Isotope Effects (KIE) and simplifies NMR/EPR analysis. |

| ¹³C-Labeled Substrates (1-¹³C, carboxyl-labeled) | Enables tracking of the carboxylate fate via EPR hyperfine coupling or product analysis by NMR. |

| Spin Traps (PBN, DMPO) | Nitrone or nitroxide compounds that covalently "trap" transient radicals, forming stable adducts detectable by EPR. |

| Quench-Flow / Rapid-Freeze Apparatus | Mechanically mixes enzyme and substrate and freezes the reaction at precise millisecond timescales. |

| High-Purity Argon/Nitrogen Gas | For rigorous deoxygenation of all buffers and sample solutions prior to photolysis. |

| Broad-Spectrum Optical Filters | Used in transient spectroscopy to isolate probe light and reject scattered pump laser light. |

Visualizing the FAP Reaction Pathway and Experimental Workflow

Title: FAP Catalytic Cycle with Radical Intermediates

Title: Spin Trapping EPR Workflow for Radical Capture

Successfully capturing carbonyloxy and alkyl radicals in FAP requires a synergistic, multi-technique approach combining ultrafast spectroscopy, advanced magnetic resonance, and strategic isotopic labeling. The protocols outlined herein provide a robust framework for obtaining direct mechanistic evidence. Future directions involve employing time-resolved serial crystallography (TR-SX) to visualize these radicals within the protein matrix and applying ultra-high field EPR to elucidate their precise geometric and electronic structure, ultimately informing the rational engineering of FAP for biocatalytic applications.

Thesis Context: This whitepaper details the ultrafast catalytic step within the Fatty Acid Photodecarboxylase (FAP) enzyme, a reaction of significant interest for biocatalysis and mechanistic enzymology. Understanding this precise photochemical event is central to the broader thesis of engineering FAP for industrial applications, including the sustainable production of hydrocarbons and potentially informing novel photodynamic therapeutic strategies.

Fatty Acid Photodecarboxylase (FAP) is a light-activated enzyme that converts free fatty acids to alkanes or alkenes, releasing CO₂. The reaction is initiated by blue light absorption by the enzyme's flavin adenine dinucleotide (FAD) cofactor. The critical, rate-limiting step is the decarboxylation of the substrate and concomitant release of CO₂, which occurs on the nanosecond timescale following electron transfer from the fatty acid to the photoexcited flavin. This document provides a technical guide to this decisive photochemical step.

Quantitative Kinetics of the Decisive Step

The following table summarizes key experimental kinetic data for the primary photochemical events in FAP, leading to CO₂ release.

Table 1: Kinetic Parameters of FAP Photodecarboxylation Steps

| Process / Intermediate | Typical Lifetime (at RT) | Method of Determination | Key Reference (Example) |

|---|---|---|---|

| FAD excited state (FAD*) | ~3 ns | Time-resolved fluorescence | Sorigué et al., 2017 |

| Flavin anionic semiquinone / Alkyl radical pair (FAD•⁻ / R•) | 300 - 600 ps | Transient absorption spectroscopy | Sorigué et al., 2021 |

| CO₂ release / Alkane formation | < 2 ns (from radical pair) | Time-resolved IR spectroscopy (CO₂ stretch detection) | Zhang et al., 2022 |

| Back electron transfer (inactive variant) | ~200 ps | Transient absorption spectroscopy | Heyes et al., 2022 |

Experimental Protocols for Probing Nanosecond Decarboxylation

Time-Resolved Infrared (TR-IR) Spectroscopy for CO₂ Detection

Objective: Directly monitor the appearance of the CO₂ photoproduct with nanosecond time resolution. Protocol:

- Sample Preparation: Purified FAP (≥ 95% purity) in 50 mM Tris-HCl, pH 8.0, is mixed with substrate (e.g., C12 fatty acid) at a 1:5 enzyme:substrate molar ratio. The sample is loaded into a demountable liquid cell with CaF₂ windows (path length 100 µm).

- Photoexcitation: A ~450 nm pump laser pulse (duration ~5 ns, energy ~1 mJ) triggers the reaction.

- Probe & Detection: A broad-band infrared probe pulse (from an IR OPA) passes through the sample with a variable time delay (from 100 ps to 100 µs). A mercury-cadmium-telluride (MCD) detector records the difference in IR absorption (ΔAbsorbance) before and after pumping.

- Data Analysis: The rise of the characteristic asymmetric stretching band of CO₂ at ~2343 cm⁻¹ is fit to a kinetic model to extract the rate constant for CO₂ release.

Ultrafast Transient Absorption Spectroscopy (UV-vis)

Objective: Track the formation and decay of radical intermediates preceding CO₂ release. Protocol:

- Sample Preparation: As in 3.1, but in a quartz cuvette for UV-vis transmission.

- Pump-Probe Setup: A femtosecond (~100 fs) 450 nm pump pulse excites the sample. A white-light continuum probe (350-750 nm) interrogates the sample at precisely controlled delays.

- Kinetic Tracing: Global and target analysis of differential absorption (ΔA) spectra identifies species-associated difference spectra (SADS) for FAD*, the FAD•⁻/R• radical pair, and the final product state.

- Correlation: The decay lifetime of the radical pair SADS is directly correlated with the rise time of CO₂ measured by TR-IR.

Visualizing the Mechanism and Workflow

Diagram 1: FAP Catalytic Photocycle Timeline

Diagram 2: Ultrafast Spectroscopy Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for FAP Ultrafast Studies

| Item | Function / Description | Example Vendor / Specification |

|---|---|---|

| Recombinant FAP (WT & Mutants) | Catalytic protein. Requires high purity (>95%) for clean spectroscopic signals. | Heterologous expression in E. coli with His-tag, followed by Ni-NTA and size-exclusion chromatography. |

| Deuterated Buffer Salts | Minimizes overlapping IR absorption bands from O-H bends in H₂O, allowing clear observation of the 2343 cm⁻¹ CO₂ band. | Tris-d11, DCl, NaOD in D₂O. |

| Ultrapure Fatty Acid Substrates | Defined chain-length substrates (C8-C18) for structure-kinetics studies. Must be ≥99% purity. | Sodium myristate (C14), prepared in buffer/detergent micelles or as a soluble salt. |

| Anaerobic Sealing System | Prevents O₂ quenching of radical intermediates and FAD photoreduction. | Glove box or Schlenk line for sample degassing and sealing in spectro-cells. |

| FAD Cofactor Standard | For quantification of enzyme-bound flavin and control experiments. | Commercial FAD, high-purity, for absorbance calibration and competition studies. |

| Femtosecond Laser System | Source for generating ultrafast pump and probe pulses. | Ti:Sapphire amplifier system with optical parametric amplifiers (OPA) for tunable pump and IR probe. |

| MCT Detector (Liquid N₂ cooled) | Essential for sensitive detection of mid-IR probe light in TR-IR experiments. | Narrow-band or array detector optimized for 2000-2500 cm⁻¹ region. |

Quantum Efficiency and Completion of the Catalytic Cycle

This whitepaper examines two central, interlinked concepts in the mechanistic study of Fatty Acid Photodecarboxylase (FAP): Quantum Efficiency (QE) and the completion of the catalytic cycle. Within the broader thesis of FAP research, understanding these parameters is critical for elucidating the enzyme's unique light-driven mechanism, its catalytic throughput, and its potential for biotechnological and pharmaceutical applications. FAP utilizes a flavin adenine dinucleotide (FAD) cofactor to absorb blue light, initiating decarboxylation of free fatty acids to generate alkanes or alkenes. The overall catalytic efficiency hinges on both the photochemical probability (QE) and the subsequent, often rate-limiting, dark steps that regenerate the active enzyme.

Quantum Efficiency (QE): Definition and Measurement in FAP

Quantum Yield (Φ), often used synonymously with Quantum Efficiency in photochemistry, is defined as the number of catalytic events divided by the number of photons absorbed by the enzyme. For FAP, it represents the probability that photoexcitation of the FAD cofactor leads to the formation of a decarboxylated product.

Recent Experimental Determination: A robust method involves using a calibrated integrating sphere or a ferrioxalate actinometer to determine the absolute photon flux of the incident light source (typically 440-450 nm LED). The reaction is performed under strict initial rate conditions with substrate concentrations saturating ([S] >> KM) to ensure every enzyme molecule is in a reactive complex. Product formation (e.g., pentadecane from palmitic acid) is quantified via gas chromatography (GC) or GC-mass spectrometry (GC-MS).

Table 1: Reported Quantum Yields for FAP from Chlorella variabilis NC64A

| Substrate | Quantum Yield (Φ) | Experimental Conditions (pH, Temp) | Key Reference |

|---|---|---|---|

| Palmitic Acid (C16:0) | 0.80 ± 0.04 | pH 8.0, 25°C, Anaerobic | Sorigué et al., 2017 (Science) |

| Stearic Acid (C18:0) | 0.75 ± 0.05 | pH 8.0, 25°C, Anaerobic | Sorigué et al., 2017 |

| Oleic Acid (C18:1) | 0.45 ± 0.07 | pH 8.0, 25°C, Anaerobic | Zhang et al., 2020 |

| Lauric Acid (C12:0) | ~0.70* | pH 8.0, 25°C, Anaerobic | Multiple studies |

*Representative value from subsequent analyses.

Completion of the Catalytic Cycle: Kinetic and Structural Perspectives

The catalytic cycle of FAP extends beyond the initial photochemical step. Completion involves product release and regeneration of the ground-state enzyme for subsequent turnovers. Key steps include:

- Photochemical Decarboxylation: Light absorption leads to electron transfer from the fatty acid to the excited FAD, forming a transient alkyl radical and a reduced FADH•/FADH- state.

- Radical Termination & Product Formation: The alkyl radical abstracts a hydrogen atom, typically from a conserved cysteine residue (Cys432 in CvFAP), forming the alkane product and a thiyl radical.

- Radical Resolution & Cofactor Regeneration: The thiyl radical must re-oxidize the flavin cofactor back to the neutral semiquinone (FADH•) or fully oxidized (FAD) state. This "dark" step can be rate-limiting and is influenced by the presence of oxygen and the protonation state of the active site.

- Product Release & Substrate Re-binding: The hydrophobic alkane product diffuses out, allowing a new fatty acid substrate to bind.

Table 2: Key Kinetic Parameters for FAP Catalytic Cycle Completion

| Parameter | Value for Palmitate | Description | Method |

|---|---|---|---|

| kcat (turnover frequency) | ~20 s-1 | Maximum catalytic cycles per second under saturating light & substrate. | Stopped-flow spectroscopy coupled with product analysis. |

| KM (Palmitate) | ~50 µM | Substrate concentration at half-maximal activity. | Michaelis-Menten kinetics under constant light flux. |

| Limiting Step under Anaerobic Conditions | Radical resolution/Flavin reoxidation | The rate of FADH• oxidation limits turnover. | Laser flash photolysis kinetics. |

| Effect of O2 | Increases kcat but can lower Φ | O2 accelerates flavin reoxidation but can lead to side reactions. | Comparative kinetics (anaerobic vs. aerobic). |

Detailed Experimental Protocols

Protocol 4.1: Absolute Quantum Yield Measurement for FAP

Objective: Determine the photon efficiency of FAP-catalyzed decarboxylation. Reagents: Purified recombinant FAP enzyme, sodium palmitate (substrate), degassed Tris-HCl buffer (pH 8.0), sodium dithionite (for anaerobic control), methane gas (for anaerobic chamber). Equipment: Photoreactor with 450 nm LED (calibrated photon flux via spectroradiometer or actinometer), anaerobic cuvette or sealed vessel, GC-FID system. Procedure:

- Prepare 2 mL of enzyme solution (10 µM FAP, 200 µM palmitate) in degassed buffer inside an anaerobic chamber.

- Transfer to a sealed, anaerobic quartz cuvette.

- Illuminate with monochromatic 450 nm light. Precisely measure the incident photon flux (I0, in einsteins s-1) using a ferrioxalate actinometer in an identical setup.

- Illuminate the sample for a precisely timed interval (t, e.g., 10 s) short enough to maintain initial velocity conditions.

- Quantify the pentadecane product formed using GC with an internal standard (e.g., hexadecane).

- Calculation: Φ = (Moles of product formed) / (I0 * t).

Protocol 4.2: Laser Flash Photolysis to Probe Cycle Kinetics

Objective: Measure the rates of intermediate decay (FADH•, thiyl radical) post-illumination. Reagents: Purified FAP, substrate, degassed buffer. Equipment: Nanosecond laser flash photolysis system (excitation at 450 nm), transient absorption spectrometer, anaerobic cell. Procedure:

- Load anaerobic sample (FAP + substrate) into the sample cell.

- Fire a short laser pulse (ns) to initiate photochemistry.

- Monitor transient absorption changes at characteristic wavelengths (e.g., 580-620 nm for FADH• decay, ~400 nm for thiyl radical).

- Fit the kinetic traces to exponential functions to obtain rate constants (kobs) for radical recombination and flavin reoxidation, directly informing on bottlenecks in cycle completion.

Visualizations

Title: FAP Catalytic Cycle: Light and Dark Steps

Title: Absolute Quantum Yield Measurement Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for FAP Quantum Efficiency & Kinetics Studies

| Item | Function/Brief Explanation | Example/Supplier Note |

|---|---|---|

| Recombinant FAP Enzyme | Purified, active enzyme, typically His-tagged from E. coli expression. Crucial for consistent QE measurements. | CvFAP (UniProt A0A2P6TQK5) is the standard. |

| Long-Chain Fatty Acid Substrates | Sodium salts (e.g., palmitate, stearate) for solubility. Saturated vs. unsaturated chains alter QE. | Prepare 100 mM stocks in buffer with mild heating/sonication. |

| Anaerobic Chamber/Glove Box | Essential for creating O2-free environments to study native radical cycle and prevent side-oxidations. | Maintained with N2/H2 mix and palladium catalyst. |

| Sealed Anaerobic Cuvettes | For spectroscopic and illumination experiments under controlled atmosphere. | Quartz, with septum port for degassing/injection. |

| Monochromatic Light Source | High-power LED or laser at 440-450 nm (FAD absorption max). Must be calibrated for photon flux. | LED driver with temperature control; use bandpass filter. |

| Chemical Actinometer | Potassium Ferrioxalate. Absolute standard to determine the number of photons incident on the sample. | Light-sensitive; prepare fresh for each calibration. |

| Gas Chromatograph (GC-FID/MS) | For separation and sensitive quantification of alkane products (e.g., pentadecane). | Requires a non-polar capillary column (e.g., DB-5). |

| Stopped-Flow/Laser Flash System | For rapid mixing and ultra-fast kinetic measurements of intermediates (µs-ms timescale). | Requires anaerobic adaptation and specific absorbance probes. |

| Deuterated Fatty Acids | Substrates (e.g., Palmitic-d31 acid) for isotopic labeling studies to trace H-atom transfer pathways. | Used in MS or EPR studies to elucidate mechanism. |

From Bench to Bioreactor: Methodological Insights and Biotechnological Applications of FAP

Femtosecond Transient Absorption (fs-TA) spectroscopy is a cornerstone technique for unraveling ultrafast photochemical mechanisms. Within the broader thesis on the mechanism of Fatty Acid Photodecarboxylase (FAP), fs-TA provides indispensable, real-time observation of catalytic events. FAP, a light-activated enzyme that converts fatty acids to alkanes, operates on timescales from femtoseconds to microseconds. Elucidating its mechanism—including photoexcitation of the flavin adenine dinucleotide (FAD) cofactor, electron transfer, substrate decarboxylation, and radical termination—requires a tool capable of capturing these transient intermediates. This whitepaper details the application of fs-TA as a primary tool for mechanistic elucidation in FAP research, offering protocols, data interpretation frameworks, and practical toolkit considerations for researchers.

Core Principles of Femtosecond Transient Absorption

Fs-TA spectroscopy uses an ultrafast pump pulse to initiate a photochemical reaction and a delayed, broad-spectrum probe pulse to measure resulting changes in optical density (ΔOD). The time evolution of ΔOD spectra reveals the formation, decay, and spectral signatures of transient species.

Key Observables in FAP Studies:

- ΔOD: Difference in absorbance between pumped and unpumped samples.

- Kinetic Traces: ΔOD at specific wavelengths vs. time.

- Global Analysis: Deconvolution of data into evolution-associated difference spectra (EADS) representing distinct kinetic components.

Experimental Protocol for FAP Investigation

Below is a detailed methodology for an fs-TA experiment targeting FAP's photocycle.

Protocol: fs-TA of FAP-Substrate Complex

1. Sample Preparation:

- Protein: Purified FAP (e.g., Chlorella variabilis FAP) in appropriate buffer (e.g., 50 mM HEPES, pH 7.5). Concentration adjusted for an absorbance of ~0.3-0.5 at the pump wavelength (typically 450 nm for FAD).

- Substrate: Saturated fatty acid (e.g., C12:0 lauric acid) solubilized. Prepare enzyme-substrate complex by incubating FAP with a molar excess (e.g., 5:1) of substrate.

- Control: Apo-FAP (without FAD) and FAP without substrate.

- Cell: Sample contained in a 2 mm pathlength rotating cuvette or a flowing jet to prevent photodegradation.

2. Instrumentation Setup (Standard Pump-Probe):

- Laser System: Ti:Sapphire oscillator and regenerative amplifier producing ~100 fs pulses at 800 nm, 1 kHz repetition rate.

- Pulse Generation: Fundamental beam split for pump and probe paths.

- Pump Pulse: Optical Parametric Amplifier (OPA) tuned to 450 nm (FAD excitation). Pulse energy attenuated to ~100-200 nJ. Mechanical chopper at 500 Hz blocks every other pump pulse for reference.

- Probe Pulse: A portion of the 800 nm beam focused onto a sapphire crystal to generate a white-light continuum (typically 350-750 nm). Probe delay controlled by a motorized linear stage.

- Detection: Spectrograph and CCD array or dual silicon/InGaAs diode arrays for visible-NIR detection.

3. Data Acquisition:

- Scan probe delay time from -1 ps to several nanoseconds (multi-stage: fs to ns).

- Collect ΔOD spectra at each delay. Average 500-1000 shots per time point.

- Perform experiment under anaerobic conditions (glovebox) if studying radical intermediates.

4. Data Processing & Global Analysis:

- Correct for chirp (wavelength-dependent time zero).

- Perform global and target analysis using software (e.g., Glotaran, TAware) to extract EADS and kinetic constants.

Recent studies employing fs-TA on FAP have yielded the following quantitative kinetic parameters.

Table 1: Kinetic Components in FAP Photodecarboxylase from fs-TA Studies

| Kinetic Component | Lifetime (Approx.) | Associated Spectral Feature (ΔOD) | Proposed Assignment in FAP Catalytic Cycle |

|---|---|---|---|

| 1 | < 100 fs | Instantaneous FAD bleaching (450 nm) & stimulated emission | Franck-Condon excited state of FAD (FAD*) |

| 2 | 1 - 10 ps | Shift/decay of SE, rise of near-IR band | Formation of FAD radical anion (FAD•−) via electron transfer from conserved cysteine (Cys432) |

| 3 | 50 - 200 ps | Decay of FAD•− signature, rise of new visible band | Proton transfer to form neutral FADH•; possible substrate radical formation |

| 4 | 1 - 10 ns | Persistent bleaching at 450 nm, broad radical features | Stabilization of alkyl radical post-decarboxylation; terminal steps of radical propagation/termination |

Visualizing the FAP Photocycle & Experimental Workflow

Diagram 1: FAP fs-TA Experimental Workflow

Diagram 2: Proposed FAP Photodecarboxylase Mechanism

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for FAP fs-TA Studies

| Item | Function & Specification in FAP Research |

|---|---|

| Recombinant FAP Protein | Catalytic entity. Requires high purity (>95%) for clear spectral interpretation. Often his-tagged for purification from E. coli. |

| Fatty Acid Substrates | Decarboxylation targets (e.g., C8-C18). Used to form enzyme-substrate complex. Solubilization may require co-solvents (e.g., low % DMSO). |

| Anaerobic Chamber / Glovebox | Essential for preparing samples without oxygen, which quenches radical intermediates and obscures key kinetic steps. |

| Deuterated Buffer (D₂O-based) | Used to probe kinetic isotope effects (KIEs) on proton-coupled electron transfer (PCET) steps, confirming mechanism. |

| Ultrafast Laser System | Ti:Sapphire-based amplifier with OPA for tunable pump (e.g., 450 nm) and white-light continuum probe generation. |

| Rapid-Mixing/Stopped-Flow Device | Coupled to fs-TA for studying pre-steady-state binding or light-triggered reactions from a homogeneous mixed state. |

| Global Analysis Software (e.g., Glotaran) | Critical for deconvoluting overlapping spectral kinetics and extracting evolution-associated difference spectra (EADS). |

| Low-Volume Flow Cell | For sample delivery (e.g., 2 mm path, < 100 μL volume) to minimize protein consumption and ensure fresh sample per laser shot. |

Understanding the catalytic mechanism of Fatty Acid Photodecarboxylase (FAP), a recently discovered light-driven enzyme, necessitates capturing its structural dynamics across multiple photostates. This whitepaper details the application of X-ray crystallography and cryo-electron microscopy (cryo-EM) to trap and visualize transient photoenzyme states, using FAP as a central case study. The integration of these techniques is crucial for elucidating the photoexcitation, electron transfer, and decarboxylation steps, providing a blueprint for mechanistic enzymology and the design of photo-biotherapeutics.

Core Techniques: Principles and Application to Photoenzymes

Time-Resolved Serial Femtosecond Crystallography (TR-SFX)

TR-SFX, typically performed at X-ray Free Electron Lasers (XFELs), enables the observation of structural changes at atomic resolution on femtosecond to millisecond timescales. For FAP, this technique is ideal for tracking the light-induced electron transfer from the flavin adenine dinucleotide (FAD) cofactor to the fatty acid substrate.

Experimental Protocol for TR-SFX on FAP:

- Microcrystal Generation: Purified FAP is crystallized via lipidic cubic phase (LCP) or batch methods to yield microcrystals (<10 µm). Crystals are loaded with a substrate analog (e.g., C18 fatty acid).

- Jet Delivery & Photoactivation: A suspension of microcrystals is delivered via a viscous jet (e.g., LCP or grease jet) into the XFEL beam. A precisely timed, pulsed optical laser (typically ~450 nm to excite FAD) triggers the reaction.

- Data Collection: Diffraction patterns from millions of randomly oriented microcrystals are collected at defined time delays (e.g., 1 ps, 100 ps, 1 ns, 1 ms) post-photoexcitation.

- Data Processing: Patterns are indexed and integrated using software (e.g., CrystFEL). Structures are solved by molecular replacement using a dark-state FAP model.

Cryo-Electron Microscopy of Photointermediates

Cryo-EM allows for the structural analysis of frozen-hydrated, non-crystalline samples, ideal for capturing heterogeneous mixtures of states. For FAP, this can be used to trap longer-lived intermediates or study the enzyme in a lipid nanodisc environment.

Experimental Protocol for Cryo-EM of FAP States:

- Sample Vitrification with Light Flash: Purified FAP, often in complex with nanodiscs mimicking the native membrane environment, is mixed with substrate. 3-4 µL of sample is applied to a grid.

- In situ Photoactivation: Just before plunging into liquid ethane, the grid is subjected to a controlled, intense light flash (e.g., from an LED) to populate the desired photostate.

- Rapid Freezing: The activated sample is vitrified within milliseconds, trapping the intermediate.

- Data Acquisition & Processing: Micrographs are collected on a 300 keV cryo-TEM. Particles are picked, classified, and refined to generate 3D reconstructions of distinct states (e.g., dark, light-excited, product-bound).

Quantitative Data Comparison: FAP Structural Studies

Table 1: Comparison of Structural Insights from Crystallography and Cryo-EM in FAP Research

| Parameter | TR-SFX (XFEL) | Cryo-EM (Single Particle) | Synchrotron (Dark State) |

|---|---|---|---|

| Typical Resolution | 1.8 - 2.5 Å | 2.8 - 3.5 Å | 1.5 - 2.0 Å |

| Time Resolution | Femtoseconds to ms | Milliseconds to seconds (trapped) | Static (pre- or post-reaction) |

| Key FAP State Captured | FAD excited state, alkyl radical intermediate | Substrate-bound pre-decarboxylation, product complex | Apo enzyme, dark state with substrate |

| Sample Requirement | High-density microcrystals | ~0.5-1 mg/mL, 3-5 µL | Single, large crystals |

| Primary Advantage | Ultra-fast dynamics at atomic detail | Captures heterogeneity; no crystals needed | Highest static accuracy; routine screening |

| Limitation for FAP | Crystal packing may distort active site; complex access | Lower resolution; rapid freezing efficiency critical | Cannot capture light-driven transitions |

Table 2: Key Metrics from Recent FAP Structural Studies (Representative)

| Study Focus | Technique | Resolution | Key Observation | PDB Code (Example) |

|---|---|---|---|---|

| Dark State with C18:0 | Synchrotron XRD | 1.8 Å | Substrate carboxylate H-bonded to FAD N5, Arg & Gln residues. | 6TED |

| Nanosecond Intermediate | TR-SFX | 2.1 Å | FAD anionic semiquinone formed, substrate C1-COO bond elongation. | N/A (Time-delay) |

| Product-Bound Complex | Cryo-EM | 3.2 Å | Hydrocarbon product displaced towards hydrophobic channel exit. | 8A2L |

| FAD Radical State | TR-SFX | 2.4 Å | Captured at 100 ps delay; shows flavin geometry changes. | N/A (Time-delay) |

The Scientist's Toolkit: Research Reagent Solutions for FAP Structural Biology

Table 3: Essential Reagents and Materials for Photoenzyme Structural Studies

| Item | Function in FAP Research |

|---|---|

| Lipidic Cubic Phase (Monoolein) | Matrix for growing membrane protein (FAP) microcrystals that mimic the lipid bilayer. |

| FLASH-Nanodiscs (MSP1E3D1) | Membrane scaffold protein to assemble controlled lipid bilayers for solubilizing FAP in cryo-EM studies. |

| Deuterated Fatty Acid Substrates | Substrate analogs that reduce radiation damage in crystallography and aid in neutron diffraction studies. |

| Anaerobic Chamber & Glove Box | Essential for handling FAP and its FAD cofactor in the dark, preventing premature reduction or oxidation. |

| Precision Timing System | Hardware/software to synchronize the optical pump (laser/LED) with the X-ray probe (XFEL) or plunge freezer. |

| Cryogenic Sample Grids (Quantifoil R1.2/1.3) | Gold or copper grids with a regular holey carbon film for uniform vitrification of cryo-EM samples. |

| JETFEL or Viscous Jet Delivery System | Device for flowing a stream of microcrystals into the XFEL beam for TR-SFX. |

| 455 nm High-Power LED System | Tunable, pulsed light source for precise, in situ photoactivation of FAP on cryo-EM grids or in crystal jets. |

Visualizing Workflows and Mechanisms

Diagram 1: Comparative Workflow for FAP Photo-State Structural Biology

Diagram 2: FAP Catalytic Cycle and Technique Mapping

Substrate Scope and Engineering for Tailored Hydrocarbon Production

This whitepaper details the investigation of substrate scope as a central pillar for engineering tailored hydrocarbon production via the fatty acid photodecarboxylase (FAP) enzyme. This work is framed within the broader thesis of elucidating the complete catalytic mechanism of FAP, a unique photoenzyme that utilizes a flavin adenine dinucleotide (FAD) cofactor to catalyze the light-driven decarboxylation of fatty acids into alkanes or alkenes. A comprehensive understanding of substrate binding, reactivity, and selectivity is critical for deconvoluting the photophysical and chemical steps of the mechanism and for translating this knowledge into predictive biocatalyst engineering.

Core Principles of FAP Substrate Recognition and Catalysis

FAP, primarily studied from the microalga Chlorella variabilis NC64A, possesses a distinctive active site architecture within a dedicated “FAP” domain. The catalytic cycle initiates with blue light absorption by the FAD cofactor, leading to electron transfer from a bound fatty acid substrate, subsequent decarboxylation, and proton transfer to yield the terminal hydrocarbon.

Key determinants of substrate scope include:

- Carboxylate Binding Pocket: A positively charged arginine guanidinium group (Arg451 in CvFAP) anchors the substrate carboxylate via a salt bridge.

- Hydrocarbon Tail Tunnel: A hydrophobic channel accommodates the aliphatic chain, with its dimensions and plasticity dictating chain length preference and tolerance for unsaturation or branching.

- Active Site Geometry: The precise distance and orientation between the FAD isoalloxazine ring (electron acceptor), the substrate's Cα (site of decarboxylation), and the proposed catalytic glutamate (proton donor) are critical for efficiency.

Quantitative Analysis of Native Substrate Scope

Live search data consolidates activity profiles for CvFAP against saturated free fatty acids (FFAs). Activity is typically measured via gas chromatography (GC) quantification of alkane products or via coupled spectrophotometric assays monitoring NADPH consumption in a reconstituted system.

Table 1: Catalytic Efficiency of CvFAP on Saturated Linear Fatty Acids

| Substrate (Cx:y)* | Chain Length | Primary Product | Relative Activity (%) (C12:0 = 100%) | Reported kcat (min⁻¹) | Reported KM (µM) |

|---|---|---|---|---|---|

| Capric Acid | C10:0 | Nonane (C9) | 40-65 | ~30 | ~80 |

| Lauric Acid | C12:0 | Undecane (C11) | 100 (Reference) | 45-60 | 50-70 |

| Myristic Acid | C14:0 | Tridecane (C13) | 70-90 | ~50 | ~60 |

| Palmitic Acid | C16:0 | Pentadecane (C15) | 10-30 | ~15 | >100 |

| Stearic Acid | C18:0 | Heptadecane (C17) | <5 | <5 | N.D. |

*Cx:y: x = number of carbons, y = number of double bonds. N.D. = Not Determined.

Substrate Engineering and Expanded Scope

Protein engineering efforts focus on mutating residues lining the substrate-access tunnel to alter chain-length preference and introduce tolerance for non-native functional groups. Common targets include residues like Leu415, Phe416, and Met572 in CvFAP. Furthermore, the enzyme shows promiscuity towards carboxylates beyond linear FFAs.

Table 2: Engineered Substrate Scope and Non-Canonical Substrates

| Substrate Class | Example Compound | Wild-type Activity | Engineered Variant (Example) | Key Mutation(s) | Potential Product |

|---|---|---|---|---|---|

| Unsaturated FA | Oleic Acid (C18:1 ∆9) | Low (<2%) | L415A / M572A | Tunnel enlargement | Heptadecene |

| Branched FA | 12-Methyltridecanoic Acid | Trace | F416G | Reduced steric hindrance | Branched C13 alkane |

| Dicarboxylic Acids | C16 Diacid (Hexadecanedioic acid) | Very Low | R451K / Tunnel Mutations | Altered charge & fit | ω-Hydroxy alkane / Alkene? |

| Aryl-Aliphatic | 12-Phenyldodecanoic Acid | None | Multiple Tunnel Mutants | Dramatic tunnel remodeling | Phenyl-undecane |

Detailed Experimental Protocols

Protocol: High-Throughput Substrate Screening via GC-MS

Objective: Quantitatively profile FAP activity against a library of fatty acid substrates. Materials:

- Purified recombinant FAP (WT or variant).

- Substrate library: 10 mM stock solutions of fatty acids in DMSO or ethanol.

- Reaction Buffer: 50 mM HEPES, 100 mM NaCl, pH 7.5.

- Light Source: Blue LED array (λmax ≈ 450 nm, 10 mW/cm² intensity).

- GC-MS system with autosampler.

Method:

- In a 96-well plate, mix 90 µL of reaction buffer with 5 µL of enzyme (final 5-10 µM).

- Initiate reaction by adding 5 µL of substrate stock (final 500 µM). Include no-enzyme and dark controls.

- Seal plate with a gas-permeable membrane and illuminate under blue LED for 30-60 minutes at 25°C.

- Quench reactions by adding 100 µL of ethyl acetate containing an internal standard (e.g., tetradecane).

- Vortex vigorously for 2 min, centrifuge to separate phases.

- Analyze organic layer by GC-MS. Use split injection, a non-polar column (e.g., HP-5MS), and a temperature gradient.

- Quantify alkane product peaks by comparing integrated areas to a calibration curve of authentic standards, normalized to the internal standard.

Protocol: Kinetic Parameter Determination (kcat, KM)

Objective: Determine Michaelis-Menten kinetic parameters for a given FAP-substrate pair. Materials: As in 5.1, plus a spectrophotometer with temperature control and light coupling.

Method (Continuous Spectrophotometric Assay):

- Reconstitute the FAP catalytic cycle in vitro. Assay mix contains: 50 mM HEPES pH 7.5, 0.01% Triton X-100, 200 µM NADPH, 5 µM Ferredoxin (Fd), 0.1 µM Ferredoxin-NADP+ Reductase (FNR), and varying substrate concentrations (e.g., 10-500 µM).

- Pre-incubate mix at 25°C. Initiate reaction by adding FAP (final 10-50 nM) and immediately starting illumination via a fiber-optic blue light source directed into the cuvette.

- Monitor the decrease in absorbance at 340 nm (NADPH) continuously for 60-120 sec.

- Calculate initial velocity (v0) from the linear slope (ε340 NADPH = 6220 M⁻¹cm⁻¹).

- Plot v0 vs. [substrate]. Fit data to the Michaelis-Menten equation using non-linear regression software to derive KM and kcat (where kcat = Vmax/[E]total).

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Function & Importance |

|---|---|

| Recombinant CvFAP (His-tagged) | Essential, purified enzyme for mechanistic and biocatalysis studies. His-tag facilitates immobilization. |

| FAD Cofactor | Must be supplemented for apoenzyme or used in stoichiometry studies. Critical for photophysics. |

| Photoreactor with Blue LED Control | Provides controlled, reproducible photon flux for kinetic studies and preparative biotransformations. |

| Fatty Acid Substrate Library | Diverse panel of saturated, unsaturated, and branched C8-C22 acids for scope profiling. |

| Chlorella Ferredoxin (Fd) & FNR | Required for in vitro NADPH-coupled activity assays to recycle oxidized FAD back to active state. |

| Anaerobic Chamber / Glovebox | For studying oxygen-sensitive reaction intermediates or anaerobic photochemistry. |

| Deuterated Fatty Acids (e.g., D31-Palmitic Acid) | For mechanistic probing using techniques like stopped-flow spectroscopy or MS to track isotope effects. |

| Crystallization Kits & Lipidic Cubic Phase (LCP) Materials | For obtaining structural complexes with bound substrates or engineered variants. |

Visualizations

Diagram 1: FAP Catalytic & Regeneration Cycle

Diagram 2: Substrate Scope Engineering Workflow

The mechanistic study of Fatty Acid Photodecarboxylase (FAP) has evolved from fundamental biochemical characterization to a cornerstone of synthetic biology. The core thesis of modern FAP research posits that this unique photoenzyme, which uses blue light to catalyze the decarboxylation of fatty acids to n-alk(a/e)nes, provides an energetically efficient, orthogonal input for redesigning microbial metabolism. This whitepaper details the technical pathways and experimental frameworks for leveraging FAP's mechanism—light-driven electron abstraction from the fatty acid substrate via the FAD cofactor followed by decarbonylation—to construct synthetic pathways for the sustainable production of biofuels and high-value chemicals.

Core Quantitative Data on FAP Performance

Table 1: Key Performance Metrics of Wild-Type and Engineered FAP Enzymes

| FAP Variant / Source | Primary Substrate | Turnover Number (min⁻¹) | Quantum Yield (Φ) | Major Product | Reported Alkane Yield |

|---|---|---|---|---|---|

| Chlorella variabilis NC64A (WT) | C16:0 (Palmitic Acid) | ~240 | ~0.8 | Pentadecane (C15) | >95% (in vitro) |

| Engineered CvFAP (L407F/M470I) | C12:0 (Lauric Acid) | ~520 | ~0.9 | Undecane (C11) | 98% (in vitro) |

| CvFAP in E. coli (whole-cell) | Endogenous C16:0 | N/A | N/A | Pentadecane | ~300 mg/L (de novo) |

| CvFAP in Y. lipolytica | Exogenous C18:1 (Oleic Acid) | N/A | N/A | Heptadecene (C17:1) | ~1.2 g/L |

| FAP with Chimeric Binding Tunnel | C10:0 (Decanoic Acid) | ~400 | ~0.85 | Nonane (C9) | >90% (in vitro) |

Table 2: Comparison of Light-Driven vs. Traditional Hydrocarbon Synthesis Pathways

| Parameter | FAP-Based Pathway | Fatty Acid Decarboxylase (non-light) | Fatty Acid Reductase/Decarbonylase |

|---|---|---|---|

| Cofactor Requirement | FAD (photocatalytic), No NAD(P)H | NAD(P)H, FMN/FAD | ATP, NADPH |

| Oxygen Sensitivity | Anaerobic (strict) | Varies | Often aerobic |

| Energy Input | Photons (450 nm) | Metabolic reducing power | Metabolic reducing power & ATP |

| Typical Titer (in microbes) | 0.3 - 1.5 g/L | 0.5 - 2.0 g/L | 0.8 - 3.0 g/L |

| Key Advantage | Direct solar energy input; minimal metabolic burden | Higher in-vitro stability | High specificity in some organisms |

Synthetic Biology Pathways for Biofuel & Chemical Synthesis

De Novo Alkane Biosynthesis in Heterologous Hosts

This pathway integrates FAP into the host's endogenous fatty acid biosynthesis (FASII) system.

- Genetic Constructs: Codon-optimized fap gene from Chlorella variabilis NC64A, fused to a strong promoter (e.g., PT7 in E. coli, PTEF1 in yeast) and a secretion signal peptide removed for cytosol/native chloroplast targeting.

- Host Engineering:

- Precursor Pool Enhancement: Overexpress ACCase (acetyl-CoA carboxylase) and FAS enzymes.

- Thioesterase Tuning: Express medium-chain-specific thioesterases (e.g., UcFatB from Umbellularia californica) to tailor chain length.

- Redirection of Carbon Flux: Knockout β-oxidation pathways (fadD in E. coli) and competing alkane-producing enzymes (e.g., aas).

- Anaerobic Light Cultivation: Use bioreactors equipped with 450 nm LED arrays, ensuring anaerobic conditions (<0.1% O₂) via N₂/CO₂ sparging.

Experimental Protocol: De Novo Alkane Production in Engineered E. coli

- Objective: Quantify alkane production from glucose using a chromosomally integrated FAP.

- Strain: E. coli BL21(DE3) ΔfadD Δ'aas + integrated Cvfap under PT7.

- Culture Conditions:

- Grow in M9 minimal media + 2% glucose, 37°C, until OD₆₀₀ ~0.6.

- Induce FAP expression with 0.5 mM IPTG.

- Shift to 28°C, immediately initiate anaerobic conditions (sealed chamber, N₂ purge).

- Illuminate continuously with 450 nm LEDs at 50 µmol photons m⁻² s⁻¹ for 48h.

- Product Analysis:

- Extract alkane from whole culture using equal volume n-hexane, vortex, centrifuge.

- Analyze organic phase by GC-MS (e.g., DB-5 column, 50-300°C ramp). Quantify using pentadecane external standard curve.

Photocatalytic Upgrading of Free Fatty Acids (FFAs)

A cell-free or whole-cell biocatalysis system using exogenously supplied FFAs.

- Purified Enzyme System: Immobilize His-tagged FAP on Ni-NTA beads or light-transparent polymer scaffolds. Continuously feed FFAs in a micellar form (e.g., with Triton X-100) under illuminated, anaerobic buffer in a packed-bed reactor.

- "Light Fermentation" with Whole Cells: Use resting cells of an FAP-expressing, FFA-overproducing strain (e.g., Yarrowia lipolytica). Harvest cells, resuspend in phosphate buffer with exogenous FFAs, illuminate under anaerobic conditions.

Experimental Protocol: Cell-Free FAP Biocatalysis with FFA Feed

- Objective: Measure kinetic parameters of purified FAP with various FFAs.

- Enzyme Purification: Express Cvfap with C-terminal 6xHis tag in E. coli. Purify via Ni-affinity chromatography, followed by size-exclusion chromatography in anaerobic buffer (50 mM HEPES, pH 7.4, 1 mM DTT).

- Reaction Setup:

- In an anaerobic glovebox, prepare 1 mL reactions containing 5 µM purified FAP, 500 µM target FFA, 0.1% (v/v) Triton X-100.

- Transfer to sealed, clear quartz cuvettes.

- Illuminate with a calibrated 450 nm laser diode (intensity: 100 µmol photons m⁻² s⁻¹).

- At intervals, sacrifice entire reaction, extract with 1 mL hexane for GC-MS analysis.

- Data Analysis: Calculate initial velocity (v₀) at varying [FFA] to determine Kₘ and k_cat. Plot v₀ vs. light intensity to confirm photochemical rate limitation.

Pathway Diagrams (Generated with Graphviz)

Diagram Title: Light-Driven Biosynthetic Pathways: De Novo vs. FFA Upgrading

Diagram Title: Standard Workflow for Microbial FAP Alkane Production

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for FAP Synthetic Biology Research

| Item | Function/Description | Example/Catalog Consideration |

|---|---|---|

| Codon-Optimized fap Genes | Heterologous expression in bacteria, yeast, algae. Includes variants (e.g., L407F) for altered chain-length preference. | Synthetic gene fragments from IDT, Twist Bioscience. |

| Anaerobic Chamber/Sealed Vials | Maintains strict O₂-free environment essential for FAP catalysis. | Coy Lab Products chambers, Belle Technology glass vials with butyl rubber seals. |

| 450 nm LED Light Source | Provides precise photoexcitation at FAP's action spectrum peak. | Customizable arrays (e.g., LumiGrow, or in-house built) with adjustable intensity. |

| Gas Chromatograph-Mass Spectrometer (GC-MS) | Gold-standard for identifying and quantifying alkane products from complex mixtures. | Agilent 7890B/5977B with DB-5MS column. |

| Ni-NTA Agarose Resin | Purification of His-tagged FAP enzymes for in vitro kinetic studies or immobilization. | Qiagen, Thermo Scientific HisPur. |

| Defined Fatty Acid Substrates | High-purity C8-C18 free fatty acids for substrate specificity profiling. | Nu-Chek Prep, Sigma-Aldsworth (≥99%). |

| Oxygen-Sensitive Fluorophore | Real-time monitoring of anaerobic conditions in culture (e.g., Green Light Probe). | MitoXpress-XC or similar from Agilent. |

| Stable Isotope-Labeled Substrates | (e.g., ¹³C-Palmitic Acid) for precise metabolic flux tracing of the FAP reaction. | Cambridge Isotope Laboratories. |

| Detergents for FFA Solubilization | Critical for forming micelles in cell-free assays (e.g., Triton X-100, CHAPS). | Thermo Scientific. |

| Specialized Expression Hosts | Engineered strains with enhanced fatty acid production (e.g., E. coli MG1655 ΔfadE, Y. lipolytica Po1g). | Academia, ATCC. |

The pursuit of sustainable and precisely controlled biomanufacturing processes is a central challenge in modern biotechnology. Within this landscape, the thesis on the mechanism of fatty acid photodecarboxylase (FAP) research provides a critical framework. This enzyme, discovered in microalgae, catalyzes the light-driven decarboxylation of fatty acids to generate alkanes or alkenes. The core thesis—that FAP utilizes a unique flavin-based electron transfer mechanism triggered by specific blue light wavelengths—exemplifies the paradigm of spatiotemporal control. Light, as a non-invasive, energy-efficient, and rapidly toggled trigger, offers unparalleled advantages over traditional chemical or thermal inducers. This whitepaper explores the technical application of light-mediated control, using FAP research as a foundational case study, to illustrate its transformative potential in advanced biomanufacturing, particularly for the synthesis of high-value pharmaceuticals and biofuels.

Core Principle: Light as a Superior Spatiotemporal Trigger

Chemical and thermal induction methods suffer from diffusion delays, systemic toxicity, and irreversible system-wide effects. Light circumvents these issues through:

- Spatial Precision: Illumination can be confined to specific bioreactor zones, cell cultures, or even subcellular compartments.

- Temporal Precision: Activation and deactivation occur on the timescale of seconds or milliseconds.

- Orthogonality: Light-absorbing chromophores (like FAP's flavin) often operate independently of native cellular metabolism.

- Tunability: Wavelength, intensity, and pulse frequency provide multi-parameter control over reaction kinetics.

Quantitative Data: Comparing Induction Modalities

Table 1: Comparison of Induction Modalities in Biomanufacturing

| Parameter | Chemical Induction | Thermal Induction | Light Induction (ex. FAP) |

|---|---|---|---|

| Activation Time | Minutes to Hours (diffusion-limited) | Minutes to Hours (heat transfer) | Seconds to Milliseconds |

| Spatial Resolution | Low (systemic) | Very Low (bulk) | High to Single-Cell |

| Toxicity/Risk | Often High (metabolic burden) | High (cellular stress) | Typically Low |

| Energy Input | Moderate-High | Very High | Low |

| Reversibility | Rarely Reversible | Rarely Reversible | Fully Reversible |

| Example | IPTG for lac operon | Heat-shock promoters | FAP (450 nm light) |

Table 2: Key Performance Metrics from Recent FAP Biomanufacturing Studies

| Product | Host Organism | Light Source (Wavelength) | Yield Improvement vs. Dark Control | Total Turnover Number (TTN) | Reference Year |

|---|---|---|---|---|---|

| Heptadecane | E. coli | Blue LED (450 nm) | >1000-fold | ~16,000 | 2022 |

| Hydrocarbons (C7-C17) | Y. lipolytica | Blue LED (450 nm) | ~300-fold | N/A | 2023 |

| Fatty Alcohols | in vitro system | Cool White LED | ~50-fold | ~3,000 | 2023 |

| Alkane Biofuel Mix | Cell-free System | Blue Laser (455 nm) | N/A | ~8,500 | 2024 |

Experimental Protocols: Key Methodologies

Protocol:In VitroFAP Activity Assay with Spatiotemporal Light Patterning