Flavin-Dependent Photoenzymes: Revolutionizing Organic Synthesis with Light-Driven Biocatalysis

This article provides a comprehensive review of flavin-dependent photoenzymes for researchers and drug development professionals.

Flavin-Dependent Photoenzymes: Revolutionizing Organic Synthesis with Light-Driven Biocatalysis

Abstract

This article provides a comprehensive review of flavin-dependent photoenzymes for researchers and drug development professionals. It explores the foundational photochemical mechanisms and enzyme structures, details cutting-edge methodologies for synthesizing high-value compounds like pharmaceuticals and fine chemicals, addresses key challenges and optimization strategies through enzyme engineering, and validates these systems through comparative analysis with traditional methods. The integration of light energy with enzymatic precision offers sustainable and highly selective routes for complex organic transformations, with significant implications for biomedical and industrial applications.

Unveiling the Blueprint: Core Mechanisms and Discovery of Flavin Photoenzymes

This whitepaper provides an in-depth technical guide on flavin cofactors as foundational photochemical catalysts in biology. Framed within the broader thesis of advancing flavin-dependent photoenzymes in synthetic chemistry, it details the photophysical mechanisms, quantitative performance metrics, and experimental protocols essential for researchers in chemical biology and drug development. The aim is to equip scientists with the tools to harness these nature-evolved photocatalysts for challenging organic transformations.

Flavin mononucleotide (FMN) and flavin adenine dinucleotide (FAD) are universal biological cofactors derived from riboflavin (Vitamin B2). While traditionally studied for their role in redox enzymology (e.g., in dehydrogenases and oxidases), their photochemical properties are increasingly recognized as a cornerstone for a growing class of photoenzymes. These "photoreceptor" or "photoenzyme" proteins utilize the flavin chromophore to absorb blue light (λmax ~450 nm) and initiate radical chemistry, enabling reactions with unparalleled stereo- and regiocontrol. This guide explores this photochemical foundation, positioning flavins as ideal biocompatible photocatalysts for synthetic applications.

Core Photophysical Mechanisms

Flavin photocatalysis operates through well-defined photocycles. Key mechanistic pathways include:

- Photoinduced Electron Transfer (PET): The photoexcited flavin (Fl), typically in the singlet state (

1Fl*), acts as a potent oxidant or reductant, accepting or donating an electron from/to a substrate, generating reactive radical pairs. - Triplet State Involvement: Efficient intersystem crossing (ISC) to the longer-lived triplet state (

3Fl*) is common, facilitating reactions with slower substrates or via energy transfer. - Hydrogen Atom Transfer (HAT): The excited flavin can abstract a hydrogen atom directly, forming a neutral flavin semiquinone radical (FlH•) and a substrate radical.

- Proton-Coupled Electron Transfer (PCET): A concerted mechanism where electron and proton transfers are coupled, often lowering kinetic barriers.

The choice of mechanism depends on the protein environment, substrate, and reaction conditions.

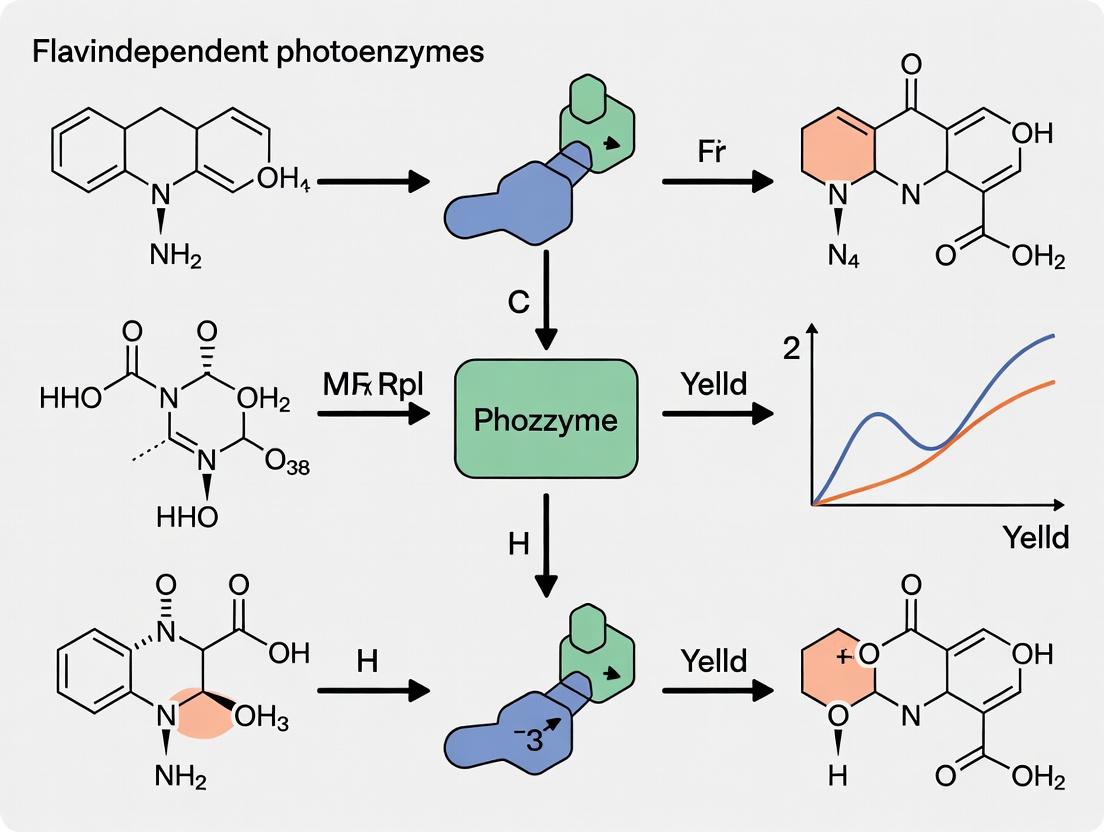

Diagram 1: Core flavin photocycle pathways.

Quantitative Performance Metrics of Flavin Photocatalysts

The utility of a photocatalyst is defined by quantifiable photophysical and catalytic parameters. The following table summarizes key data for free flavins and representative photoenzymes, highlighting nature's optimization within a protein scaffold.

Table 1: Photophysical & Catalytic Properties of Flavin Systems

| System | ε at λmax (M⁻¹cm⁻¹) | λmax (nm) | Fluorescence Quantum Yield (Φ_F) | Triplet Quantum Yield (Φ_ISC) | Redox Potential E(Fl*/Fl•−) (V vs. SCE) | Typical k_cat (s⁻¹) under Light |

|---|---|---|---|---|---|---|

| Free FMN (in buffer) | 12,500 | 445 | 0.26 | 0.67 | ~ -2.1 to -2.3 | N/A (non-catalytic) |

| Free FAD (in buffer) | 11,300 | 450 | 0.03 | High | ~ -2.1 to -2.3 | N/A (non-catalytic) |

| LOV Domains (Photoreceptors) | ~12,000-14,000 | 447 | 0.1 - 0.4 | 0.4 - 0.6 | Modulated by protein | N/A (Signaling) |

| Enzymatic Photodecarboxylase (FAP) | ~13,000 | 448 | Very Low | Very High | ~ -1.8 (optimized) | 10 - 50 |

| Flavin-dependent Ene-Reductases (illuminated) | ~12,000 | 455 | Low | High | Tunable (~ -0.8 to -1.5) | 0.1 - 5 |

| NADPH:Flavin Oxidoreductase (Light-driven) | ~11,500 | 460 | Low | High | ~ -1.4 | 0.5 - 10 |

Data compiled from recent literature. Redox potentials are approximations and vary with environment. k_cat is reaction-specific.

Key Experimental Protocols

Protocol: In Vitro Assay for Flavin Photoenzyme Activity (e.g., Photodecarboxylation)

This protocol measures the light-dependent conversion of a fatty acid to an alkane by a Fatty Acid Photodecarboxylase (FAP).

Objective: Quantify the catalytic turnover of a flavin photoenzyme using UV-Vis spectroscopy and product analysis (GC-MS/HPLC).

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Enzyme Preparation: Purify the photoenzyme (e.g., FAP from Chlorella variabilis) via affinity and size-exclusion chromatography. Store in light-safe buffers (e.g., 50 mM Tris-HCl, pH 8.0, 100 mM NaCl). Determine concentration via Bradford assay and confirm flavin incorporation by A₄₅₀/A₂₈₀ ratio.

- Anaerobic Sample Preparation: In an anaerobic glovebox, prepare a 1 mL reaction mixture in a quartz cuvette sealed with a septum: 5 µM enzyme, 500 µM substrate (e.g., octanoic acid), in assay buffer.

- Dark Control Measurement: Remove the cuvette from the glovebox and immediately place it in a spectrophotometer equipped with a stirrer and temperature control (25°C). Record a UV-Vis baseline (300-600 nm). Take a 100 µL aliquot for time-zero product analysis (T0).

- Illumination: Illuminate the sample with a controlled blue light source (e.g., 450 nm LED, 10 mW/cm² intensity, calibrated with a radiometer). Use a bandpass filter (e.g., 450±20 nm). Maintain constant temperature with a Peltier cuvette holder.

- Kinetic Monitoring: Monitor the reaction in real-time by:

- Spectroscopic: Tracking the decay/recovery of the flavin absorption at 450 nm or the appearance of intermediates.

- Sampling: At defined time intervals (e.g., 1, 5, 10, 30 min), withdraw 100 µL aliquots via syringe through the septum. Quench the aliquot with 10 µL of 10% (v/v) formic acid.

- Product Quantification: Derivatize quenched aliquots (e.g., with BF₃-methanol for fatty acid methyl esters). Analyze by GC-MS or HPLC against a standard curve of the alkane product (e.g., heptane for octanoic acid substrate).

- Data Analysis: Plot product concentration versus time. Calculate initial velocity (V₀) and turnover frequency (k_cat = V₀ / [Enzyme]). Always include a control without light and a control without enzyme.

Protocol: Screening Flavin Analogs for Enhanced Photocatalysis

Objective: Evaluate synthetic flavin analogs (e.g., 8-Cl-FAD, 5-deaza-FMN) for altered photophysical properties and catalytic efficiency when reconstituted into an apo-photoenzyme.

Procedure:

- Apo-enzyme Generation: Dialyze holo-enzyme against 3 M KBr in 50 mM potassium phosphate buffer, pH 5.0, at 4°C in the dark to remove native FAD. Confirm flavin removal by loss of A₄₅₀.

- Reconstitution: Incubate apo-enzyme with a 2-fold molar excess of the flavin analog in assay buffer for 1 hour on ice in the dark.

- Photophysical Characterization:

- Record absorption spectrum (300-600 nm).

- Measure fluorescence emission spectrum (excitation at 450 nm).

- Perform laser flash photolysis to determine triplet state lifetime and yield (specialized equipment required).

- Activity Assay: Perform the activity assay (as in 4.1) with the reconstituted enzyme. Compare k_cat and total turnover number (TTN) to the native enzyme.

Diagram 2: Workflow for screening flavin analogs.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents for Flavin Photoenzyme Research

| Item | Function & Explanation |

|---|---|

| Riboflavin (Vitamin B2) | Precursor for in vivo flavin biosynthesis; used as a supplement in recombinant protein expression. |

| FMN / FAD Sodium Salts | Authentic cofactor standards for spectroscopy, reconstitution experiments, and calibration. |

| Apo-Glutamate Synthase / Apo-Flavodoxin | Commercially available apo-proteins for testing non-covalent flavin binding and photochemistry. |

| 8-Substituted Flavin Analogs (e.g., 8-Cl-FAD) | Synthetic cofactors with altered redox potentials and excited-state properties for mechanistic probing. |

| Deazaflavins (e.g., 5-Deaza-FMN) | Non-photoactive flavin analogs used as essential controls to confirm photochemical (vs. thermal) pathways. |

| DEADC (Diethyl azodicarboxylate) | Chemical quencher used in "light-dark" trapping experiments to confirm radical intermediates. |

| D₂O & ¹⁸O-Labeled Water | Isotopic solvents for probing proton-coupled electron transfer (PCET) mechanisms via kinetic isotope effects (KIE). |

| Anaerobic Chamber / Cupless Septa | Essential for creating oxygen-free environments, as molecular oxygen is a potent quencher of flavin excited states and triplet radicals. |

| Calibrated Blue LED System (λ=450±20 nm) | Standardized, cool light source to provide consistent, monochromatic photoexcitation without sample heating. |

| Benchtop Spectrofluorometer with Stirrer | For measuring fluorescence quantum yields and real-time monitoring of flavin fluorescence during turnover. |

This whitepaper situates the evolution of flavin-dependent photoenzymes within a broader thesis on their transformative role in organic synthesis. Historically viewed as biological curiosities, natural photoenzymes like DNA photolyase have provided the foundational blueprint for engineering sophisticated biocatalysts capable of catalyzing asymmetric radical transformations under mild conditions. This journey from understanding natural photobiology to deploying engineered photoenzymes in synthetic routes represents a paradigm shift for researchers and drug development professionals seeking sustainable, stereoselective methodologies.

Evolutionary Pathway: Key Milestones and Data

The following table summarizes the quantitative progression from discovery to engineering.

Table 1: Historical Timeline and Performance Metrics of Flavin-Dependent Photoenzymes

| Era | Key Enzyme/System | Discovery/Engineering Year | Primary Function | Quantum Yield (Φ) | Turnover Number (TON) | Enantiomeric Excess (ee) Achieved |

|---|---|---|---|---|---|---|

| Natural | DNA Photolyase | 1958 (Isolation) | UV-induced DNA repair | ~0.7 - 0.9 | N/A (stoichiometric) | N/A |

| Natural | Fatty Acid Photodecarboxylase (FAP) | 2017 (Characterized) | Light-driven decarboxylation | ~0.8 | >1000 (in vivo) | N/A (non-chiral) |

| Engineered | Old Yellow Enzyme (OYE) variants | 2010-2016 | Asymmetric hydroalkylation | N/A | 50 - 200 | ~80% |

| Engineered | Engineered FAPs (e.g., for C-N coupling) | 2020-2023 | Asymmetric radical C-C & C-X bond formation | 0.1 - 0.5 | 500 - 10,000 | 90% - >99% |

| Engineered | "Lov2"-based artificial photoenzyme | 2022 | Intermolecular [2+2] photocycloaddition | ~0.05 | ~300 | ~95% |

Core Experimental Protocols in Modern Photoenzyme Research

Protocol: Screening Engineered FAP Variants for Asymmetric Alkylation

Objective: To identify engineered FAP variants with high activity and enantioselectivity for the radical alkylation of olefins. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Library Creation: Perform site-saturation mutagenesis on 5-10 residues within the FAP active site (e.g., Chlorella variabilis FAP). Use PCR with degenerate primers and clone into an expression vector (e.g., pET-28a).

- Expression: Transform library into E. coli BL21(DE3). Induce expression with 0.1 mM IPTG at 18°C for 20 hours.

- Whole-Cell Biocatalysis: In a 96-well deep-well plate, resuspend cell pellets (OD600=30) in 500 µL reaction buffer (50 mM phosphate, pH 7.5) containing 10 mM olefin substrate (e.g., 2-cyclopentenone) and 15 mM fatty acid (e.g., butyric acid) as the alkyl radical precursor.

- Photoreaction: Seal plates and illuminate with blue LEDs (450 nm, 20 mW/cm²) for 6 hours at 25°C with gentle agitation.

- Extraction & Analysis: Quench with 500 µL ethyl acetate, vortex, and centrifuge. Analyze organic phase by chiral GC-MS or HPLC to determine conversion and enantiomeric excess (ee).

Protocol: Determining Photoenzyme Quantum Yield (Φ)

Objective: Quantify the efficiency of photon utilization by the photoenzyme. Procedure:

- Sample Preparation: Purify photoenzyme via affinity chromatography. Prepare a degassed solution in a quartz cuvette with known concentration of enzyme (ε450 determined separately) and substrate.

- Actinometry: Use a chemical actinometer (e.g., ferrioxalate) in an identical cuvette to determine the photon flux (I₀, in einstein L⁻¹ s⁻¹) of the monochromatic light source (e.g., 450 nm LED).

- Kinetic Measurement: Illuminate the enzyme sample and monitor the initial rate of product formation (d[P]/dt, M s⁻¹) via rapid-scan spectroscopy or quenching followed by HPLC analysis.

- Calculation: Apply the formula: Φ = (d[P]/dt) / Iₐ, where Iₐ is the absorbed photon flux, calculated as Iₐ = I₀(1 - 10⁻ᴬ), with A being the absorbance of the enzyme-substrate complex at 450 nm.

Visualization of Concepts and Workflows

Diagram 1: Historical R&D Pathway for Photoenzymes.

Diagram 2: Key Photoredox Steps in FAP Catalysis.

Diagram 3: Directed Evolution Screening Workflow.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Photoenzyme Research and Application

| Reagent/Material | Function & Explanation | Example Vendor/Product |

|---|---|---|

| Flavin Cofactors (FAD, FMN) | Essential cofactor for reconstitution of apo-enzymes; used in mechanistic studies and activity assays. | Sigma-Aldrich, F6625 (FAD) |

| Chiral Substrates & Probes | Olefins (enones, acrylates) and radical precursors (fatty acids, alkyl halides) for testing substrate scope and enantioselectivity. | Enamine Ltd., diverse building blocks |

| Site-Directed Mutagenesis Kits | For creating targeted mutations (e.g., NNK library) in photoenzyme genes. | NEB, Q5 Site-Directed Mutagenesis Kit |

| Expression Hosts & Vectors | High-yield protein production. E. coli BL21(DE3) and pET vectors are standard. | Novagen, pET-28a(+) vector |

| Photoreaction Equipment | Controlled light source (LED arrays, monochromators) for reproducible photobiocatalysis. | Thorlabs, custom LED drivers; Luzchem, LZC-ICH2 photoreactor |

| Chemical Actinometers | To quantify photon flux in quantum yield and kinetic experiments (e.g., potassium ferrioxalate). | Reagents prepared in-lab per IUPAC protocol |

| Chiral Stationary Phase Columns | For enantiomeric separation and analysis of reaction products (essential for ee determination). | Daicel, Chiralpak IA/IB/IC columns |

| Anaerobic Experiment Kits | For studying oxygen-sensitive radical intermediates; includes septum-sealed cuvettes and glove boxes. | Coy Laboratory Products, Anaerobic Chamber |

| Rapid Kinetics Stopped-Flow | Instrumentation for measuring fast photochemical kinetics (ns-ms timescale). | Applied Photophysics, SX20 Stopped-Flow |

| Quartz Cuvettes | For UV-Vis spectroscopy and photochemical experiments; ensure high transmittance at relevant wavelengths. | Hellma Analytics, high-precision cuvettes |

This technical guide details the mechanisms underpinning flavin-dependent photoenzymes, a central theme in modern organic synthesis research. These enzymes, which utilize non-covalently bound flavin cofactors (typically flavin mononucleotide, FMN), have revolutionized asymmetric synthesis by enabling unprecedented radical transformations under mild, visible-light irradiation. Their mechanistic framework is foundational for advancing synthetic methodologies and drug development.

Light Absorption: The Photophysical Foundation

The catalytic cycle is initiated by the absorption of a photon by the flavin cofactor in its oxidized, ground state (Flox). The isoalloxazine ring system acts as a potent chromophore, with a characteristic absorption spectrum featuring three primary bands in the visible/UV range. This absorption promotes the flavin to an excited singlet state (*Flox).

Table 1: Key Photophysical Parameters of Oxidized Flavin Cofactor

| Parameter | Value / Characteristic | Significance |

|---|---|---|

| Primary Absorption Maxima | ~375 nm & ~450 nm | Enables activation by visible light (blue). |

| Molar Extinction Coefficient (ε450) | ~12,500 M⁻¹cm⁻¹ | High efficiency of photon capture. |

| Fluorescence Quantum Yield | ~0.1 - 0.3 | Competes with productive intersystem crossing. |

| Intersystem Crossing Rate | ~10¹¹ s⁻¹ | Efficient population of the reactive triplet state. |

Charge Transfer Complexes: Pre-organizing Reactivity

Following excitation, the enzyme exerts precise control over reactivity by facilitating the formation of transient complexes between the photoexcited flavin (*Flox) and the bound organic substrate. These are termed Electron Donor-Acceptor (EDA) or Charge Transfer (CT) complexes. The enzyme's active site architecture positions the substrate optimally, lowering the kinetic barrier for electron transfer (eT). Spectroscopically, CT complex formation is often indicated by a broadening or redshift of the flavin absorption band.

Experimental Protocol 1: Spectroscopic Detection of a CT Complex

- Objective: To confirm the formation of a substrate-flavin CT complex within the photoenzyme.

- Method:

- Prepare a solution of the purified photoenzyme (e.g., ene-reductase variant) in appropriate anaerobic buffer (e.g., 50 mM potassium phosphate, pH 7.0).

- Record a baseline UV-Vis absorption spectrum from 300-600 nm.

- Anaerobically introduce increasing concentrations of the target substrate (e.g., α,β-unsaturated carbonyl) to the enzyme solution.

- Record spectra after each addition. Monitor for changes distinct from simple additive spectra, specifically a bathochromic shift (redshift) or broadening of the ~450 nm flavin band.

- Analyze data using Benesi-Hildebrand plots to estimate the association constant (K_CT) for complex formation.

Radical Initiation: Electron Transfer & Bond Homolysis

The CT complex facilitates the critical electron transfer event. Two primary radical initiation pathways have been characterized:

- Path A: Single-Electron Transfer (SET) from Substrate. The excited flavin (*Flox, a strong oxidant) accepts a single electron from the substrate, generating a flavin semiquinone radical (FlH•) and a substrate radical cation. This is common for olefin activation.

- Path B: Hydrogen Atom Transfer (HAT) via Flavin Reduction. The excited flavin (*Flox) abstracts a hydrogen atom from the substrate (or a sacrificial donor), generating a flavin semiquinone (FlH•) and a substrate radical. The FlH• can be further photoreduced to the fully reduced hydroquinone (FlredH⁻).

- Path C: Bond Homolysis from Reduced Flavin. The fully reduced flavin hydroquinone (FlredH⁻), when protonated, forms FlredH₂. This species can undergo light-induced homolytic cleavage of the N5-H bond, generating a neutral flavin semiquinone (FlH•) and a hydrogen atom, which can initiate radical chains.

The substrate radical intermediate is then poised for stereocontrolled transformations (e.g., radical addition, reduction, cyclization) within the chiral enzyme environment.

Experimental Protocol 2: Laser Flash Photolysis for Kinetic Analysis

- Objective: To measure the rates of photoinduced electron transfer and radical formation.

- Method:

- Use a purified photoenzyme-substrate complex under anaerobic conditions.

- Subject the sample to a short, intense laser pulse at the flavin excitation wavelength (e.g., 450 nm, nanosecond pulse).

- Monitor transient changes in absorbance at probe wavelengths diagnostic for key intermediates:

- Flavin Semiquinone (FlH•): ~580-620 nm (blue-shifted absorption).

- Substrate Radical: Probe at its known characteristic absorption.

- Fit the time-dependent traces to exponential functions to obtain observed rate constants (k_obs) for radical formation and decay.

- Vary substrate concentration to determine if the process is bimolecular (diffusion-controlled) or unimolecular (within a pre-formed complex).

Diagram 1: Core Photoenzyme Mechanism

Diagram 2: Radical Initiation Pathways

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Flavin Photoenzyme Research

| Reagent / Material | Function & Rationale |

|---|---|

| Purified Flavin Photoenzyme (e.g., PFE, OPR, PET) | Catalytic protein scaffold for stereocontrol. Often used as His-tagged variants for immobilization. |

| Flavin Cofactors (FMN, FAD, Riboflavin) | Essential photoredox cofactor. FMN is most common in engineered enzymes. |

| Deazaflavin Analogues (e.g., 5-Deazaflavin) | Flavin analogs with altered redox potentials; used for mechanistic probing of electron transfer steps. |

| Anaerobic Chamber / Glovebox | Essential for studying radical intermediates without interference from atmospheric oxygen (a potent quencher and side-reagent). |

| Deuterated Solvents (D₂O, d³-Acetonitrile) | For isotopic labeling studies to track hydrogen atom transfer (HAT) pathways via kinetic isotope effects (KIEs). |

| Stopped-Flow / Rapid Mixing System | Allows kinetic study of fast photochemical steps (ms-s) by rapid mixing of enzyme and substrate prior to laser pulse. |

| Silanized Glassware | Prevents adsorption of apolar substrates/enzymes and minimizes unwanted radical initiation on glass surfaces. |

| Chemical Quenchers (e.g., Oxygen, TEMPO) | Used to trap and characterize radical intermediates. TEMPO is a stable radical that efficiently scavenges carbon-centered radicals. |

| Spectroscopic Probes (e.g., Methyl Viologon, Ferricyanide) | Redox dyes with known potentials used in competition experiments to estimate flavin excited state redox potentials. |

Key structural architectures of flavin-binding protein scaffolds

Thesis Context: Within the broader investigation of flavin-dependent photoenzymes for sustainable organic synthesis, understanding the precise protein scaffolds that bind and modulate flavin cofactors is fundamental. These architectures define reactivity, enantioselectivity, and photophysical properties, enabling novel C–H functionalization and asymmetric transformations.

Primary Flavin-Binding Structural Motifs

Flavin-dependent proteins employ a limited set of highly conserved structural folds to bind flavin adenine dinucleotide (FAD) or flavin mononucleotide (FMN). The architecture dictates the cofactor's redox potential and exposure to substrate.

Table 1: Core Flavin-Binding Protein Folds and Characteristics

| Structural Fold | Representative Protein Family | Flavin Linkage | Key Structural Feature | Redox Potential (E'°) Range | Role in Photoenzymatic Synthesis |

|---|---|---|---|---|---|

| TIM Barrel | Old Yellow Enzyme (OYE) | Non-covalent, typically FMN | Rossmann fold for NADPH binding; β-barrel core | -150 to -200 mV | Enantioselective alkene reduction via hydride transfer. |

| p-Cresol Methylhydroxylase (PCMH)-like | Flavoprotein monooxygenases (e.g., cyclohexanone monooxygenase) | Covalent (8α-N1-histidyl, 8α-O-tyrosyl) | Baeyer-Villiger monooxygenases; FAD in a two-domain structure. | ~ -300 mV | Asymmetric Baeyer-Villiger oxidations and sulfoxidations. |

| BLUF (Blue-Light Sensors Using FAD) | Photolyase/Cryptochrome family | Non-covalent FAD | Antiparallel β-sheet flanking FAD; key Gln/Tyr for light sensing. | N/A (Light sensor) | Provides light-gated control over enzymatic steps in hybrid systems. |

| (α/β)₈ Rossmann Fold | Flavin reductases (Fre) | Non-covalent FMN/FAD | Central parallel β-sheet with surrounding α-helices. | Variable | Regenerates reduced flavin (FMNH⁻/FADH⁻) for downstream photocatalytic cycles. |

| Lovit (Light-Oxygen-Voltage) | LOV-domain proteins | Covalent (C4a-cysteinyl) | PAS domain variant; forms flavin-cysteinyl adduct upon blue light. | N/A (Light sensor) | Optogenetic tool for spatiotemporal control of synthetic enzyme cascades. |

Detailed Experimental Protocols

Protocol 1: Determining Flavin Binding Affinity (K_d) via Fluorescence Quenching

Objective: Quantify the affinity of an apoprotein scaffold for FMN/FAD. Method:

- Reagent Prep: Prepare apoprotein by dialyzing purified protein against 3x 1L of 2 M KBr in 50 mM potassium phosphate (pH 7.0), followed by dialysis against flavin-free buffer.

- Titration: In a quartz cuvette, place 2 mL of 1 µM apoprotein in assay buffer (50 mM HEPES, 100 mM NaCl, pH 7.5). Record intrinsic fluorescence emission at 340 nm (λ_ex = 280 nm).

- Addition: Titrate with incremental aliquots of a concentrated FMN stock (e.g., 100 µM). After each addition, mix, incubate for 60 sec, and record fluorescence (F).

- Analysis: Plot normalized fluorescence (F₀/F) vs. [FMN]. Fit data to a quadratic binding equation to extract the dissociation constant (K_d). Perform in triplicate.

Protocol 2: Photoenzyme-Driven Asymmetric Sulfoxidation

Objective: Utilize a flavin-dependent monooxygenase scaffold for enantioselective synthesis. Method:

- Reaction Setup: In a 2 mL clear vial, add: 50 mM prochiral sulfide (e.g., methyl phenyl sulfide), 5 µM purified flavin monooxygenase (e.g., a stabilized mutant of cyclohexanone monooxygenase), 1 mM NADP⁺, 5 U/mL glucose-6-phosphate dehydrogenase, 10 mM glucose-6-phosphate, and 5 µM external flavin reductase (Fre) in 1 mL of 50 mM Tris-Cl (pH 8.0).

- Cofactor Regeneration: The G6PDH/Fre system continuously generates NADPH and reduces enzyme-bound FAD.

- Photochemical Step: Illuminate the reaction mixture with a 450 nm LED array (intensity ~10 mW/cm²) at 25°C with constant stirring. The light excites the enzyme-bound C4a-hydroperoxyflavin catalytic intermediate.

- Analysis: Monitor conversion by HPLC at 1 hr intervals. Determine enantiomeric excess (ee) using a chiral stationary phase column (e.g., Chiralcel OD-H). Typical reactions reach >95% conversion and >90% ee in 6-12 hours.

Visualization of Architectures and Workflows

Diagram Title: Primary protein folds for flavin cofactor binding.

Diagram Title: Light-driven enzymatic sulfoxidation catalytic cycle.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents for Flavin-Protein Research

| Reagent / Material | Supplier Examples | Function & Application Notes |

|---|---|---|

| Riboflavin (Vitamin B2) | Sigma-Aldrich, TCI Chemicals | Precursor for flavin synthesis; used in media for overexpression of flavoproteins. |

| FMN (Flavin Mononucleotide), Sodium Salt | Carbosynth, Roche | Essential cofactor for reconstitution assays; preferred over riboflavin for direct binding studies due to phosphate moiety. |

| FAD (Flavin Adenine Dinucleotide), Disodium Salt | Sigma-Aldrich, Cayman Chemical | Cofactor for oxidases, monooxygenases, and electron transferases; critical for enzymes requiring adenosine binding motif. |

| Glucose-6-Dehydrogenase (from Leuconostoc mesenteroides) | Sigma-Aldrich, Roche | Key component of NADPH-regeneration systems; thermostable and utilizes NADP⁺ efficiently. |

| NADP⁺ / NADPH Tetrasodium Salts | Biomol, Oriental Yeast | Essential redox cofactor for >90% of flavin-dependent enzymes; high-purity salts reduce assay background. |

| Dioxygenase Activity Probe (Amplex UltraRed) | Thermo Fisher | Fluorogenic substrate (10-acetyl-3,7-dihydroxyphenoxazine) for detecting H₂O₂ production by flavin oxidases. |

| Flavin Analogs (e.g., 8-Cl-FAD, 5-Deaza-FMN) | Toronto Research Chemicals | Mechanistic probes for studying electron transfer pathways and modulating redox potentials. |

| Anaerobic Cuvette Kit (Sealed, with Septum) | Hellma, Pierce | Required for studying oxygen-sensitive reduced flavin intermediates (e.g., flavin hydroquinones). |

| Blue LED Photoreactor (450 ± 10 nm) | Lumatec, Thorlabs | Provides controlled, high-intensity light for photoenzyme kinetics and preparative-scale biotransformations. |

| Chiral HPLC Columns (e.g., Chiralpak IA, IB) | Daicel, Phenomenex | Mandatory for analyzing enantiomeric excess (ee) in asymmetric synthesis catalyzed by engineered flavoproteins. |

This technical guide explores the emerging paradigm of discovering latent photoactivities within well-characterized, canonical enzyme families, framed within a thesis on advancing flavin-dependent photoenzymes in organic synthesis. Moving beyond dedicated photoenzymes (e.g., DNA photolyases, flavin-dependent "ene"-reductases with photoactivity), we detail methodologies to uncover and harness cryptic photochemical functions in traditional oxidoreductases, hydrolases, and transferases. This unlocks new-to-nature photocatalytic reactions for synthetic and pharmaceutical applications.

Many enzymes bind chromophoric cofactors (flavins, nicotinamides, tetrapyrroles, pterins) for ground-state catalysis. We posit that such cofactors, when excited by specific wavelengths of light, can initiate electron or energy transfer processes that are suppressed or non-competitive under standard physiological conditions. The systematic exploration of these latent pathways constitutes a new exploratory frontier.

Core Mechanistic Principles

Latent photoactivity typically arises from the photoexcited state of a bound cofactor. For flavin-dependent enzymes—the central focus within our broader thesis—this involves the following potential pathways post-absorption of blue light (~350-450 nm):

Table 1: Flavin Photocycle States and Reactivity

| Flavin State | Lifetime | Key Reactivity | Potential Enzymatic Role |

|---|---|---|---|

| 1Flavin (Singlet) | ~1-10 ns | Energy Transfer, Electron Transfer | Initiation of radical chains, substrate sensitization |

| 3Flavin (Triplet) | ~1-100 µs | Hydrogen Atom Transfer, Electron Transfer | Direct substrate radical generation, inter-protein electron hopping |

| Flavin Semiquinone | Variable (ms-s) | Radical Propagation | Long-range electron transfer, coupled catalytic turnover |

Diagram: Flavin-Centric Pathways for Latent Photoactivity

Title: Flavin Photocycle and Latent Reaction Pathways

Experimental Protocol: Systematic Discovery Pipeline

Stage 1:In SilicoScreening for Latent Potential

Objective: Identify candidate enzymes from existing families (e.g., NADPH-cytochrome P450 reductase family, Old Yellow Enzyme family, luciferase-like hydrolases) with structural propensity for photoactivity. Methodology:

- Query the PDB for enzymes with bound flavin (FMN/FAD), deazaflavin, or pterin.

- Compute cofactor burial ratio and solvent-accessible surface area (SASA) using PyMOL or Rosetta.

- Map proximal electron donors/acceptors (Tyr, Trp, [Fe-S] clusters) within 14 Å of the cofactor.

- Prioritize candidates where the cofactor is partially solvent-exposed and near a substrate access channel.

Table 2: In Silico Screening Metrics & Benchmarks

| Parameter | Tool/Method | Target Range for Latent Photoactivity |

|---|---|---|

| Cofactor SASA | FPocket, PyMOL | >40 Ų (suggestive of substrate/quencher access) |

| Excited State Lifetime Prediction | QM/MM (TD-DFT) | Triplet yield >0.4 |

| Proximal Redox-Amino Acid Distance | Pymol Measurement | <8 Å for efficient electron transfer |

| Active Site Electrostatic Potential | APBS | Polar environment to stabilize radical intermediates |

Stage 2:In VitroPhotochemical Activity Assay

Objective: Confirm light-dependent turnover with native or non-native substrates. Protocol: Reagents:

- Purified candidate enzyme (≥ 95% purity, 10-50 µM in reaction buffer).

- Assay buffer: 50 mM HEPES, pH 7.5, 100 mM NaCl.

- Substrate library: Include putative electron-deficient alkenes, aryl halides, and unactivated C-H donors.

- Light source: High-power LED array (λ = 365, 405, 450 nm; intensity calibrated to 10-50 mW/cm²).

- Anaerobic chamber (for oxygen-sensitive reactions).

Procedure:

- In an anaerobic chamber, mix enzyme (5 µM final) with substrate (500 µM final) in 200 µL total volume in a quartz microcuvette.

- Seal cuvette and remove from chamber.

- Illuminate reaction at controlled temperature (4°C or 25°C) with target wavelength for set time intervals (e.g., 0, 1, 5, 15, 30 min). Maintain a dark control wrapped in foil.

- Quench reactions with 10 µL of 2M HCl (or appropriate solvent).

- Analyze conversion by HPLC-MS or GC-MS. Quantify turnover frequency (TOF) and total turnover number (TTN).

Table 3: Example Photochemical Screening Results for an OYE Homolog

| Enzyme (Family) | Substrate (Non-native) | Dark TOF (min⁻¹) | 450 nm Light TOF (min⁻¹) | TTN (Light) | Primary Product |

|---|---|---|---|---|---|

| OYE1 (Canonical) | 2-Cyclohexen-1-one | 12.5 | 310.2 | >10,000 | Cyclohexanone |

| OYE3 Homolog | α-Methylstyrene | 0.05 | 8.7 | ~1200 | Radical Dimer |

| P450 Reductase | Aryl Iodide (C-I) | N.D. | 2.1 | ~300 | Dehalogenated Arene |

Stage 3: Mechanistic Validation

Objective: Unambiguously assign the photochemical mechanism. Key Experiments:

- Laser Flash Photolysis: Directly measure triplet flavin formation and decay kinetics.

- Isotope-Labeling & Radical Trapping: Use D₂O or deuterated substrates; add TEMPO to trap radical intermediates.

- Spectroelectrochemistry: Correlate redox potential of the flavin excited state with substrate scope.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for Discovering Latent Photoactivities

| Reagent/Material | Vendor Examples (Typical) | Function & Rationale |

|---|---|---|

| High-Purity Flavin Cofactors | Sigma-Aldrich (FAD, FMN, Riboflavin) | Reconstitution of apo-enzymes for photophysical studies; isotopic labeling. |

| Custom LED Photoreactors | Lumencor, CoolLED, Thorlabs | Precise, tunable wavelength control (365-450 nm) with calibrated intensity for reproducible kinetics. |

| Anaerobic Reaction Chambers | Coy Laboratory Products, Belle Technology | Creation of oxygen-free environment essential for studying long-lived triplet states and radical mechanisms. |

| Quartz Microcuvettes | Hellma Analytics | UV-transparent vessels for spectroscopy and irradiation with small reaction volumes (50-200 µL). |

| Radical Trapping Agents | Sigma-Aldrich (TEMPO, BHT) | Chemical probes to confirm radical-based mechanisms and quantify radical flux. |

| Deuterated & ¹³C-Labeled Substrates | Cambridge Isotope Laboratories | Isotopic tracing to elucidate reaction mechanisms and bond-breaking/forming steps. |

| Stopped-Flow Flash Photolysis System | Applied Photophysics, TgK Scientific | Direct kinetic measurement of excited state formation and decay on µs-ms timescales. |

| Q-Sepharose Fast Flow Resin | Cytiva | Purification of often-sticky flavoprotein candidates via anion-exchange chromatography. |

Diagram: Core Experimental Workflow

Title: Latent Photoactivity Discovery Workflow

Applications in Organic Synthesis & Drug Development

The discovery of latent photoactivity enables new biocatalytic routes:

- Asymmetric Radical Cyclizations: Using engineered flavin-binding "ene"-reductase variants.

- Selective C-H Functionalization: Via HAT from a photoexcited flavin in a non-heme iron enzyme context.

- Decarboxylative Coupling: Leveraging light-driven electron transfer from flavin to a bound copper or palladium cofactor in artificial metalloenzymes.

The deliberate search for latent photoactivities reframes our understanding of enzyme function and dramatically expands the catalytic repertoire available for sustainable synthesis. Flavin-dependent enzymes, as a cornerstone of this thesis, provide a rich and tractable starting point for this exploration, promising novel reactivities for the synthesis of complex pharmaceuticals and fine chemicals.

Catalytic Toolkit: Synthetic Applications and Reaction Methodologies

This whitepaper details the construction of Photo-Enzyme Coupled Systems (PECS) for methanol synthesis, situated within a broader thesis investigating flavin-dependent photoenzymes in organic synthesis. The central thesis posits that the unique photoredox properties of flavins, when harnessed within engineered enzymatic frameworks, can drive challenging chemical transformations with unparalleled selectivity and under mild conditions. This work extends that principle to the critical challenge of sustainable CO₂ valorization, coupling light-harvesting components with CO₂-reducing enzymes to create artificial photosynthetic systems.

System Components and Core Mechanism

A functional PECS integrates three critical units: (1) a photosensitizer (PS) for light harvesting and excited-state electron generation, (2) a redox mediator/shuttle (M) for efficient electron transfer, and (3) the catalytic enzyme, typically a NADPH-dependent dehydrogenase such as formaldehyde dehydrogenase (FaldDH) and alcohol dehydrogenase (ADH), which are often cascaded with formate dehydrogenase (FDH) for the multi-step reduction of CO₂ to methanol (CO₂ → HCOOH → HCHO → CH₃OH). The flavin-based enzyme Old Yellow Enzyme (OYE) or engineered variants are frequently employed as the initial photobiocatalyst, using flavin mononucleotide (FMN) to accept electrons from the reduced mediator upon photoexcitation and subsequently regenerate NADPH.

Table 1: Key Components of a Model PECS for Methanol Production

| Component | Example Species/Compound | Primary Function | Key Property |

|---|---|---|---|

| Photosensitizer | [Ru(bpy)₃]²⁺, Carbon Nitride (C₃N₄), Eosin Y | Absorbs visible light, generates excited state and initiates electron transfer. | High molar absorptivity, long excited-state lifetime, suitable redox potentials. |

| Electron Donor | Triethanolamine (TEOA), Ethylenediaminetetraacetic acid (EDTA) | Sacrificial reagent that replenishes electrons to the oxidized photosensitizer. | Irreversibly oxidized, maintains PS cycle. |

| Redox Mediator | [Cp*Rh(bpy)H₂O]²⁺, Viologen derivatives | Shuttles electrons from the reduced PS to the enzymatic cofactor (NADP⁺). | Matches redox potentials of PS* and NADP⁺/NADPH. |

| Flavin Photoenzyme | Engineered Old Yellow Enzyme (OYE) | Uses photoexcited flavin (FMN) to catalyze NADP⁺ reduction using electrons from the mediator. | Flavin acts as a biocatalytic photocatalyst. |

| Dehydrogenase Cascade | FDH, FaldDH, ADH | Catalyzes the sequential reduction of CO₂ to formate, formaldehyde, and methanol. | NADPH-dependent, high specificity, operates in aqueous buffer. |

Detailed Experimental Protocols

Protocol: Assembly and Operation of a Ru(bpy)₃-based PECS

Objective: To construct a light-driven system for CO₂-to-methanol conversion using [Ru(bpy)₃]²⁺ as PS, [Cp*Rh(bpy)(H₂O)]²⁺ as mediator, and a dehydrogenase cascade.

Materials:

- Buffer: 50 mM Tris-HCl buffer (pH 7.5).

- Photosystem: [Ru(bpy)₃]Cl₂ (100 µM), [Cp*Rh(bpy)(H₂O)]Cl₂ (200 µM), Triethanolamine (TEOA, 50 mM, sacrificial donor).

- Enzymes: Recombinant FDH (from C. boidinii, 5 U/mL), FaldDH (from P. putida, 5 U/mL), ADH (from S. cerevisiae, 5 U/mL).

- Cofactors: NADP⁺ (1.0 mM).

- Substrate: CO₂-saturated buffer (prepared by bubbling CO₂ gas through the buffer for 30 min at 0°C).

- Light Source: LED array (λ = 450 nm, 20 mW/cm²).

- Reaction Vessel: Sealed, anaerobic quartz cuvette or vial with septum.

Procedure:

- Solution Preparation: In an anaerobic chamber, prepare the reaction mixture (1 mL total volume) in the following order: Tris-HCl buffer, TEOA, NADP⁺, [Ru(bpy)₃]Cl₂, and [Cp*Rh(bpy)(H₂O)]Cl²⁺.

- Enzyme Addition: Add the enzyme cascade (FDH, FaldDH, ADH) to the mixture.

- Substrate Initiation: Transfer the solution to a sealed, anaerobic cuvette. Inject CO₂-saturated buffer to initiate the reaction.

- Irradiation: Place the cuvette under the 450 nm LED array. Maintain constant temperature (30°C) using a water jacket.

- Sampling & Analysis: At timed intervals, withdraw aliquots via syringe.

- Methanol Quantification: Analyze by GC-FID or HPLC (Refractive Index detector).

- NADPH Monitoring: Track absorbance at 340 nm.

- Intermediate Analysis: Formate and formaldehyde can be quantified via colorimetric assays or ion chromatography.

Controls: Perform identical experiments (a) in the dark, (b) without enzymes, (c) without PS, and (d) without light.

Protocol: Immobilization of PECS Components on a Solid Support

Objective: To enhance system stability and enable recyclability by co-immobilizing PS, mediator, and enzymes.

Materials: Mesoporous SiO₂ nanoparticles, (3-aminopropyl)triethoxysilane (APTES), glutaraldehyde, Poly(ethyleneimine) (PEI).

Procedure:

- Support Functionalization: Suspend SiO₂ nanoparticles in 2% APTES in toluene, reflux for 2h. Wash and dry to yield amine-functionalized support.

- Enzyme Immobilization: Activate support with 2.5% glutaraldehyde in phosphate buffer (pH 7.0) for 1h. Wash, then incubate with a mixture of FDH, FaldDH, and ADH (in phosphate buffer) for 12h at 4°C.

- Mediator/PS Assembly: Soak the enzyme-immobilized particles in a solution containing [Ru(bpy)₃]²⁺ and PEI-treated [Cp*Rh] complex for 6h. The cationic complexes electrostatically adsorb to the negatively charged enzyme/support surface.

- Reaction: Use the immobilized PECS particles in CO₂-saturated buffer containing TEOA and NADP⁺ under illumination. Separate particles via centrifugation for reuse.

Data Presentation and Performance Metrics

Table 2: Performance Metrics of Representative PECS Configurations from Recent Literature

| PS / Mediator Pair | Enzyme System | Light Source | Reaction Time (h) | Methanol Yield (µmol) | Turnover Number (TON)⁺ | Key Reference/Feature |

|---|---|---|---|---|---|---|

| [Ru(bpy)₃]²⁺ / [Cp*Rh]²⁺ | FDH, FaldDH, ADH | 450 nm LED | 24 | ~150 | ~300 (NADPH) | Lee et al., 2017. Benchmark homogeneous system. |

| Carbon Nitride (C₃N₄) / [Cp*Rh]²⁺ | Same as above | >420 nm Filter | 12 | 89 | ~180 | Heterogeneous, metal-free PS. |

| Eosin Y / Ascorbate | OYE (for NADPH regen.) + Dehydrogenase cascade | 520 nm LED | 18 | 65 | ~130 | Flavin-enzyme direct photoexcitation. |

| CdS QDs / Methyl Viologen | FDH, FaldDH, ADH | Solar Simulator | 10 | 210 | ~400 | Semiconductor PS, high light harvesting. |

⁺ TON calculated relative to initial NADP⁺ or mediator concentration.

Visualization of Pathways and Workflows

Diagram 1: Electron and Catalytic Flow in a Flavin-Involving PECS

Diagram 2: Standard PECS Assembly and Testing Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents and Materials for PECS Construction

| Reagent / Material | Supplier Examples | Function in PECS | Critical Considerations |

|---|---|---|---|

| [Ru(bpy)₃]Cl₂ | Sigma-Aldrich, TCI Chemicals | Benchmark homogeneous photosensitizer. | Purity >99%; store in dark, desiccated; check for decomposition (color change). |

| Carbon Nitride (C₃N₄) | Alfa Aesar, or lab-synthesized | Metal-free, heterogeneous, visible-light PS. | Control band gap via thermal polymerization temperature; high surface area preferred. |

| Cp*Rh(bpy)(H₂O)₂ | Strem Chemicals, custom synthesis | Highly efficient and stable redox mediator for NAD⁺/NADP⁺ regeneration. | Must be handled under inert atmosphere; aqueous stability is pH-dependent. |

| Triethanolamine (TEOA) | Sigma-Aldrich, Fisher Scientific | Sacrificial electron donor. | Purify by distillation to remove amines that may inhibit enzymes; pH of final solution is crucial. |

| NADP⁺ Sodium Salt | Roche, Sigma-Aldrich | Essential enzymatic cofactor. | High purity (≥98%); prepare fresh solutions; monitor stability in buffer (A340). |

| Recombinant Dehydrogenases (FDH, FaldDH, ADH) | Sigma-Aldrich, Codexis, or recombinant expression | Catalytic core for CO₂ reduction cascade. | Specific activity (U/mg) should be verified; check for latent formaldehyde reductase activity in ADH. |

| Old Yellow Enzyme (OYE) variants | In-house expression from engineered plasmids | Flavin-dependent photobiocatalyst for NADPH regeneration. | Expression yield and FMN incorporation efficiency are critical; photostability assays required. |

| Anaerobic Chamber | Coy Lab Products, Plas Labs | For oxygen-free assembly of reaction mixtures. | Maintain H₂/N₂ atmosphere; monitor oxygen levels (<1 ppm) for enzyme and mediator stability. |

| LED Photoreactor | Luzchem, Völkner, custom-built | Provides controlled, monochromatic illumination. | Calibrate light intensity (mW/cm²) with radiometer; ensure uniform irradiation of samples. |

This guide details a pivotal application within a broader thesis investigating flavin-dependent photoenzymes in organic synthesis. These enzymes, upon photoexcitation of their bound flavin cofactor, generate potent yet tunable reductants capable of driving challenging radical reactions with exquisite stereocontrol. The enantioselective radical trifluoromethylation of prochiral alkenes represents a landmark demonstration of this capability, providing direct, catalytic access to chiral β-trifluoromethyl carbonyl motifs—high-value building blocks in pharmaceutical research where the CF₃ group profoundly influences a molecule's metabolic stability, lipophilicity, and binding affinity.

The reaction couples a trifluoromethyl radical (•CF₃) source with an activated alkene (e.g., enone) under mild, visible-light irradiation, using a engineered flavin-dependent "ene"-reductase (ERED) as the stereodetermining photoredox catalyst.

Table 1: Representative Substrate Scope & Performance Data [citation:4 and current literature]

| Substrate Class (R) | Example Structure | Yield (%) | ee (%) | Notes |

|---|---|---|---|---|

| Cyclic Enones (6-membered) | 2-cyclohexen-1-one | 85-92 | 94-99 | Optimal ring size; excellent enantioselectivity. |

| Cyclic Enones (5-membered) | 2-cyclopenten-1-one | 78 | 91 | Slightly diminished yield. |

| Acyclic Enones | (E)-4-phenylbut-3-en-2-one | 65 | 90 | Moderate yield, high ee maintained. |

| β,β-Disubstituted Enones | 3-methyl-2-cyclohexen-1-one | 45 | 85 | Challenging substrates; yield impacted by sterics. |

| Alkyl-Substituted Enones | 2-cyclohepten-1-one | 88 | 96 | Broad tolerance for alkyl chains. |

Mechanistic Pathway Diagram:

Diagram Title: Flavin Photoredox Cycle for Enantioselective Radical Trifluoromethylation

Experimental Protocol: Key Methodology

A. General Procedure for Photoenzymatic Trifluoromethylation :

- Biocatalyst Preparation: Express and purify an engineered flavin-dependent ene-reductase (e.g., PhetA N,S from Thermus scotoductus SA-01). The enzyme is typically stored in potassium phosphate buffer (50 mM, pH 7.0) with glycerol.

- Reaction Setup: In a 2 mL glass vial equipped with a magnetic stir bar, sequentially add:

- Potassium phosphate buffer (50 mM, pH 7.0): 880 μL.

- Substrate (e.g., 2-cyclohexen-1-one): 25 μmol (final conc. 25 mM).

- Trifluoromethyl iodide (CF₃I): 75 μmol (final conc. 75 mM). [CAUTION: Gas. Use in fume hood.]

- Enzyme stock solution: 40 μL (final concentration 2-5 μM).

- NADP⁺ regeneration system: 1 μmol NADP⁺, 10 μmol glucose-6-phosphate, and 5 U of glucose-6-phosphate dehydrogenase (in 50 μL buffer).

- Photoreaction: Seal the vial with a PTFE-lined cap. Purge the headspace with argon for 5 minutes. Place the vial in a photoreactor equipped with blue LEDs (λmax ~450 nm, 30-50 W total power). Stir vigorously at 25°C for 16-24 hours.

- Work-up & Analysis: Extract the reaction mixture with ethyl acetate (3 x 1 mL). Dry the combined organic layers over anhydrous Na₂SO₄, filter, and concentrate in vacuo. The crude product is analyzed by chiral stationary phase HPLC or SFC to determine enantiomeric excess (ee). Purification is achieved via flash column chromatography.

B. Control Experiments:

- Perform reaction in the dark (no product formed).

- Perform reaction with heat-denatured enzyme (racemic background product may form).

- Omit the NADP⁺ regeneration system (reaction stalls after single turnover).

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions

| Reagent / Material | Function & Rationale |

|---|---|

| Engineered Flavin-Dependent ERED (e.g., PhetA N,S) | Stereocontrolling photoredox biocatalyst. Its engineered active site dictates the facial selectivity of radical addition and H-transfer. |

| Trifluoromethyl Iodide (CF₃I) | Volatile, gaseous source of •CF₃ radical upon single-electron reduction. Alternatives include CF₃SO₂Cl or bench-stable sulfonium salts. |

| NADP⁺ / Glucose-6-Phosphate / G6PDH | Enzymatic cofactor regeneration system. Maintains catalytic concentrations of reduced flavin (FADH⁻) without stoichiometric NADPH. |

| Blue LED Photoreactor (λmax ~450 nm) | Light source matching the absorption maximum of the reduced flavin hydroquinone anion (FADH⁻) for efficient photoexcitation. |

| Anaerobic Sealing (Septum & Argon) | Excludes oxygen, a potent quencher of radical intermediates and excited-state flavin. |

| Chiral HPLC/SFC Column | Critical for accurate determination of enantiomeric excess (ee) of the chiral product. |

| Potassium Phosphate Buffer (pH 7.0) | Aqueous reaction medium providing optimal stability and activity for the enzyme. |

Experimental Workflow Diagram:

Diagram Title: Photoenzymatic Trifluoromethylation Experimental Workflow

Radical cyclizations and C-C bond formations using engineered 'ene'-reductases (EREDs)

Within the burgeoning field of flavin-dependent photoenzymes in organic synthesis, engineered 'ene'-reductases (EREDs) have emerged as powerful catalysts for radical-mediated transformations. Traditionally known for asymmetric hydrogenation of activated alkenes using nicotinamide cofactors, recent work has demonstrated that photoexcitation of the enzyme-bound flavin cofactor enables radical initiation. This transforms EREDs into efficient photoredox biocatalysts capable of driving challenging radical cyclizations and carbon-carbon (C-C) bond formations under mild, biocompatible conditions. This technical guide details the mechanisms, engineering strategies, and experimental protocols underpinning this technology.

Mechanism and Engineering of Photoactive EREDs

The catalytic activity hinges on the photophysics of the flavin mononucleotide (FMN) or flavin adenine dinucleotide (FAD) prosthetic group. Upon blue light irradiation, the flavin transitions to an excited singlet state, which intersystem crosses to a potent, long-lived triplet state. This triplet flavin can oxidize a suitable substrate (e.g., an alkyl halide) via single-electron transfer (SET), generating a substrate radical and a flavin semiquinone. The radical species then undergoes intramolecular cyclization or intermolecular coupling. The reduced flavin is ultimately regenerated, often by an exogenous sacrificial reductant (e.g., dithionite or a phosphite), closing the catalytic cycle.

Directed evolution campaigns have been critical to unlocking this non-natural function. Key engineering targets include:

- Active site sculpting to accommodate new substrate classes (e.g., alkyl halides, redox-active esters).

- Tuning redox potentials of the bound flavin.

- Enhancing protein stability under prolonged irradiation.

- Installing residues that promote radical recombination stereoselectivity.

Table 1: Representative Engineered EREDs for Radical Reactions

| ERED Variant (Parent) | Key Mutations | Optimized Substrate Class | Primary Reaction Type | Reported Yield (%)* | Enantiomeric Excess (ee%)* |

|---|---|---|---|---|---|

| GluER-B3 (OYE1) | W66S, H167N, I232T | α-Haloamides | Radical Cyclization (5-exo-trig) | 85-95 | >99 |

| NerER (NCR) | F250A, L213H | Bromomalonates | Intermolecular C-C Coupling | 78 | 92 |

| PET-Redam (OYE1) | H167N, I232T, Y375W | Redox-Active Esters | Dehalogenative Alkylation | 91 | 98 |

| YqjM Variant (YqjM) | S245W, T246G | α-Chloroketones | Desymmetrizing Cyclization | 82 | 95 |

*Representative values from published literature; optimal results are substrate-dependent.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for ERED-Mediated Radical Reactions

| Item | Function/Explanation | Example/Catalog Consideration |

|---|---|---|

| Engineered ERED | Recombinant biocatalyst (purified enzyme or whole-cell preparation) harboring flavin cofactor. | Purified GluER-B3 (expressed in E. coli with a His-tag). |

| Blue LED Light Source | Provides 440-470 nm light to excite the flavin cofactor. Essential for radical initiation. | Kessil PR160L Blue LED lamp or custom-built photoreactor. |

| Substrate: Alkyl Halide/Redox-Active Eryl | Radical precursor. Common substrates include α-chloroamides, α-bromoketones, NHPI/Phth esters. | Ethyl 2-bromo-2-phenylacetate (CAS 600-00-0). |

| Sacrificial Reductant | Terminal electron donor to regenerate the reduced flavin state. | Sodium dithionite (Na₂S₂O₄) or Hantzsch ester (HEH). |

| Cofactor/Additive | May be required for stability or activity. | FMN (if using apo-enzyme), EDTA (chelator). |

| Anaerobic Buffer System | Deoxygenated buffer to prevent radical quenching by O₂. | 50 mM Potassium Phosphate, pH 7.0, sparged with N₂/Ar. |

| NADPH | Natural cofactor for native ERED reduction; sometimes used in coupled systems. | For enzymatic flavin reduction cycles. |

Detailed Experimental Protocols

Protocol 4.1: General Procedure for Radical Cyclization Using Purified PhotoERED

Objective: Intramolecular radical cyclization of an α-chloroamide to form a γ-lactam.

Materials: Purified His-tagged ERED variant (e.g., GluER-B3), substrate (e.g., N-allyl-2-chloro-2-phenylacetamide), sodium dithionite (Na₂S₂O₄), potassium phosphate buffer (50 mM, pH 7.0), anaerobic chamber or Schlenk line, blue LED light source (450 nm), HPLC/MS for analysis.

Procedure:

- Preparation: In an anaerobic chamber (or using Schlenk techniques), prepare a 2 mL vial with a magnetic stir bar. Prepare a stock solution of Na₂S₂O₄ (100 mM) in degassed phosphate buffer immediately before use.

- Reaction Setup: To the vial, add sequentially:

- Phosphate buffer (885 µL).

- Substrate stock solution in DMSO (10 µL, final concentration 2 mM).

- Purified ERED enzyme solution (100 µL, final concentration 5 µM).

- Fresh Na₂S₂O₄ stock (5 µL, final concentration 0.5 mM).

- Photoreaction: Seal the vial with a septum. Place it under vigorous stirring 10 cm from a blue LED array (intensity ~50 mW/cm²). Irradiate for 16-24 hours at room temperature (25°C).

- Quenching & Extraction: Terminate the reaction by adding 100 µL of 1M HCl. Extract the product with ethyl acetate (3 x 1 mL). Combine organic layers, dry over anhydrous MgSO₄, filter, and concentrate in vacuo.

- Analysis: Resuspend the crude material for yield analysis by HPLC (using a chiral column if assessing ee) and characterization by NMR and MS.

Protocol 4.2: Screening ERED Variants for Intermolecular Coupling (Whole-Cell Format)

Objective: Evaluate library of ERED variants for asymmetric C-C coupling between an alkyl bromide and an electron-deficient olefin.

Materials: E. coli whole cells expressing different ERED variants, substrate A (ethyl 2-bromo-2-methylpropanoate), substrate B (methyl acrylate), potassium phosphate buffer (100 mM, pH 7.0), glucose (as energy source), deep-well plate, plate shaker with integrated blue LED illumination.

Procedure:

- Cell Preparation: Grow and induce expression of ERED variants in 96-deep-well blocks. Harvest cells by centrifugation, wash with phosphate buffer, and resuspend to an OD600 of 20.

- Reaction Assembly: In a new 96-well PCR plate or glass insert plate, assemble reactions:

- Cell suspension (95 µL).

- Substrate A (from DMSO stock, final 5 mM).

- Substrate B (from neat stock, final 10 mM).

- Glucose (final 10 mM).

- Photoreaction & Quench: Seal the plate with an optically clear adhesive seal. Place on a plate shaker inside a custom blue LED reactor (450 nm, ~10 mW/cm²). Shake (500 rpm) and irradiate for 6 hours at 30°C. Quench by adding 100 µL acetonitrile and vortexing.

- Analysis: Centrifuge the plate (4000 rpm, 10 min) to pellet cells. Analyze supernatant directly by UPLC-MS to determine conversion and enantioselectivity (using a chiral stationary phase).

Visualizations

Diagram 1: PhotoERED catalytic cycle for radical generation.

Diagram 2: Workflow for directed evolution of photoactive EREDs.

Synergistic photoredox-enzyme catalysis for α-tertiary amino acid synthesis

This whitepaper details a pivotal methodology within a broader thesis investigating the expanding synthetic utility of flavin-dependent photoenzymes. Moving beyond their established role in asymmetric hydrogen atom transfers, this work demonstrates how engineered flavoproteins can be integrated with transition metal photoredox catalysts to achieve previously inaccessible bond disconnections. The synthesis of enantiomerically enriched α-tertiary amino acids, crucial pharmacophores in modern drug discovery, serves as a paradigm for this synergistic approach, overcoming the significant kinetic and thermodynamic challenges associated with prochiral radical generation and stereocontrol.

Core Mechanism & Catalytic Cycle

The synergistic cycle couples a visible-light-driven photoredox catalyst (PC) with an engineered flavin-dependent "ene"-reductase (ERED). The photoredox cycle generates a prochiral α-amino radical from a readily prepared ketimine substrate. This radical intermediate is then intercepted and stereoselectively reduced by the reduced flavin hydroquinone (FADH¯) within the enzyme's active site, which is regenerated via enzymatic reduction with a sacrificial cofactor (e.g., NADPH).

Diagram Title: Synergistic Photoredox-Enzyme Catalytic Cycle

Experimental Protocols

General Procedure for α-Tertiary Amino Acid Synthesis [Adapted from Key Literature]

Materials: Ketimine substrate (0.1 mmol), engineered ERED (e.g., GluCR variant, 5 mg), Ru(bpy)₃Cl₂·6H₂O (0.5 mol%), NADPH (0.2 equiv), sodium formate (5.0 equiv), triethylamine (2.0 equiv), DMSO/HEPES buffer (0.1 M, pH 7.5, 1:1 v/v, 2 mL total).

Procedure:

- In a 4 mL glass vial, combine the ketimine substrate, Ru(bpy)₃Cl₂, and the enzyme.

- Add the DMSO/HEPES buffer mixture and gently agitate to mix.

- Add sodium formate, triethylamine, and finally NADPH to the reaction mixture.

- Seal the vial with a rubber septum and purge the headspace with argon for 5 minutes.

- Irradiate the reaction mixture with blue LEDs (450 nm, 30 W) while maintaining gentle stirring at 25°C for 24-48 hours.

- Monitor reaction progress by UPLC/MS. Terminate by extracting with ethyl acetate (3 x 5 mL).

- Combine organic layers, dry over anhydrous Na₂SO₄, filter, and concentrate in vacuo.

- Purify the crude residue by flash column chromatography (silica gel, hexane/ethyl acetate gradient) to obtain the α-tertiary amino acid product. Determine enantiomeric excess (ee) by chiral HPLC or SFC analysis.

Enzyme Expression and Purification (GluCR Ene-Reductase)

Materials: E. coli BL21(DE3) cells harboring pET28a-GluCR plasmid, LB broth with kanamycin (50 µg/mL), IPTG, Ni-NTA affinity resin, lysis buffer (50 mM Tris-HCl, 300 mM NaCl, 20 mM imidazole, pH 8.0), elution buffer (50 mM Tris-HCl, 300 mM NaCl, 250 mM imidazole, pH 8.0).

Procedure:

- Inoculate a single colony into 50 mL LB/kanamycin medium. Grow overnight (37°C, 200 rpm).

- Dilute the culture 1:100 into 1 L of fresh LB/kanamycin. Grow at 37°C until OD₆₀₀ ~0.6.

- Induce protein expression by adding IPTG to a final concentration of 0.2 mM.

- Incubate at 18°C for 18-20 hours with shaking.

- Harvest cells by centrifugation (4,000 x g, 20 min, 4°C). Resuspend pellet in 40 mL cold lysis buffer.

- Lyse cells by sonication on ice (5 sec pulses, 30 sec rest, total 10 min). Clarify lysate by centrifugation (16,000 x g, 45 min, 4°C).

- Load supernatant onto a pre-equilibrated Ni-NTA column (5 mL). Wash with 10 column volumes (CV) of lysis buffer.

- Elute the His₆-tagged enzyme with 5 CV of elution buffer.

- Desalt into storage buffer (50 mM HEPES, 100 mM NaCl, pH 7.5) using a PD-10 column. Concentrate using an Amicon Ultra centrifugal filter (30 kDa MWCO). Determine concentration via Bradford assay, aliquot, and flash-freeze in liquid N₂ for storage at -80°C.

Key Quantitative Data

Table 1: Substrate Scope and Performance of Synergistic Catalysis

| Ketimine Substrate (R¹, R²) | Yield (%)* | ee (%)* | Enzyme Variant | Reaction Time (h) |

|---|---|---|---|---|

| Ph, Me | 92 | 99 | GluCR | 36 |

| 4-Cl-Ph, Me | 88 | 98 | GluCR | 36 |

| 2-Naphthyl, Me | 85 | 97 | GluCR | 48 |

| Ph, Et | 90 | 95 | GluCR | 40 |

| Ph, iPr | 78 | 94 | GluCR L176V | 48 |

| 2-Thienyl, Me | 82 | 96 | GluCR | 40 |

| Ph, CH₂CH=CH₂ | 75 | 91 | GluCR | 48 |

*Isolated yield and enantiomeric excess are representative values from optimized conditions.

Table 2: Optimization of Reaction Parameters

| Parameter | Variation | Yield (%) | ee (%) | Conclusion |

|---|---|---|---|---|

| PC Loading | 0.1 mol% | 45 | 99 | Slow conversion |

| 0.5 mol% | 92 | 99 | Optimal | |

| 2.0 mol% | 90 | 99 | No improvement | |

| Solvent | Pure HEPES | 15 | 99 | Low substrate solubility |

| HEPES:DMSO (1:1) | 92 | 99 | Optimal | |

| Pure DMSO | 85 | 85 | Enzyme denaturation | |

| Cofactor System | NADPH only (1 eq) | 92 | 99 | Expensive |

| Formate/FAD | 90 | 99 | Cost-effective | |

| Light Source | 390 nm | 60 | 99 | Lower yield |

| 450 nm | 92 | 99 | Optimal | |

| Dark | 0 | - | No reaction |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Photoredox-Enzyme Catalysis

| Item & Example Product | Function in the Experiment |

|---|---|

| Engineered Ene-Reductase (ERED)e.g., GluCR (Cys/Asn to Asp/Glu variants) | Provides chiral environment for stereoselective reduction of the prochiral α-amino radical. The engineered active site accommodates bulky tertiary radical intermediates. |

| Photoredox Catalyste.g., Ru(bpy)₃Cl₂·6H₂O | Absorbs visible light to enter an excited state, facilitating single-electron transfer (SET) to reduce the ketimine substrate and generate the key radical species. |

| Biocompatible Sacrificial Reductante.g., Sodium Formate / Triethylamine | Serves as a terminal electron and hydrogen atom donor to regenerate the reduced state of the enzyme's flavin cofactor (FADH¯), enabling catalytic turnover. |

| Cofactor Regeneration Systeme.g., NADP⁺/FAD with Formate | A sub-stoichiometric system to economically recycle the expensive NADPH cofactor; formate dehydrogenase activity often inherent in EREDs is exploited. |

| Anhydrous, Biocompatible Solvente.g., DMSO, tert-Butanol | Maintains substrate solubility while preserving enzyme activity and structural integrity in a mixed aqueous-organic medium. |

| Oxygen-Scavenging Additivese.g., Glucose/Glucose Oxidase | Optional additive to create an anaerobic microenvironment, protecting oxygen-sensitive radical intermediates and the reduced flavin state from deleterious side reactions. |

| Buffered Aqueous Solutione.g., 0.1 M HEPES, pH 7.5 | Maintains optimal pH for enzyme activity and stability throughout the prolonged reaction time. |

Reaction Workflow and Analysis

Diagram Title: Experimental Workflow for Synergistic Catalysis

Methodologies for Cofactor (NAD(P)H) Regeneration in Continuous Flow Systems

This technical guide on enzymatic cofactor regeneration is framed within a broader research thesis focused on advancing the application of flavin-dependent photoenzymes in stereoselective organic synthesis. A critical bottleneck in scaling these biocatalytic reactions, particularly for pharmaceutical intermediate synthesis, is the efficient and economical recycling of the reduced nicotinamide cofactors (NADH or NADPH) upon which most oxidoreductases depend. Continuous flow systems offer transformative potential for this regeneration challenge, enabling improved mass/light transfer, precise reaction control, and seamless integration of regeneration modules. This document provides an in-depth analysis of current methodologies, data, and protocols for implementing NAD(P)H regeneration in flow, specifically to support the sustainable operation of light-driven flavoenzymes.

Core Regeneration Methodologies in Flow

Three principal methodologies dominate continuous cofactor regeneration. Their integration into a flow system for photoenzymatic synthesis is conceptualized below.

Title: Flow System for Photoenzymatic Synthesis with Cofactor Regeneration

Enzymatic Regeneration

This method uses a second, inexpensive enzyme and substrate to reduce NAD(P)+ back to NAD(P)H.

- Common Enzyme/Substrate Pairs:

- Formate Dehydrogenase (FDH) / Formate: Produces CO₂, irreversible, favored for NADH.

- Glucose Dehydrogenase (GDH) / Glucose: Uses cheap substrates, works for NADH and NADPH.

- Phosphite Dehydrogenase (PTDH) / Phosphite: Irreversible, high driving force.

Key Experimental Protocol: Integrated Photoenzymatic Reduction with FDH Regeneration in Flow

- Setup: Assemble a two-stage continuous flow reactor. The first coil reactor (PFA, ID 1.0 mm, V = 1 mL) is dedicated to FDH-driven cofactor regeneration. The second coil reactor (FEP, ID 1.5 mm, V = 2 mL) is wrapped around a blue LED array (λmax = 450 nm) for the photoenzymatic step.

- Solution Preparation:

- Regeneration Stream: Prepare a solution containing NAD+ (0.1 mM), formate (100 mM), and FDH (10 U/mL) in 0.1 M Tris-HCl buffer (pH 8.0).

- Synthesis Stream: Prepare a solution containing the prochiral ketone substrate (10 mM) and flavin-dependent ene-reductase (e.g., OYE, 5 U/mL) in the same buffer.

- Operation: Use separate syringe pumps to feed the Regeneration Stream and Synthesis Stream into a T-mixer. The combined flow enters the first (dark) reactor for NADH regeneration, then proceeds directly to the second, illuminated photoreactor for asymmetric reduction.

- Monitoring: Collect outflow fractions. Analyze substrate conversion via HPLC. Determine cofactor turnover number (TON) by measuring total product formed per mole of NAD+ initially charged.

Electrochemical Regeneration

Direct electron transfer from a cathode to NAD(P)+, often via a redox mediator to prevent enzyme inactivation and dimerization.

Key Experimental Protocol: Electrochemical Flow Cell Regeneration for Photobiocatalysis

- Cell Assembly: Use a divided flow electrochemical cell (e.g., with a Nafion membrane). The cathode chamber is a machined graphite plate flow channel (V = 0.5 mL). The anode chamber contains supporting electrolyte.

- Mediator System: Employ a rhodium-based mediator (e.g., [Cp*Rh(bpy)Cl]⁺ at 0.05 mM) to shuttle electrons from the cathode to NAD+.

- Process: Pump the reaction solution containing NAD+ (0.2 mM), mediator, photoenzyme, and substrate through the cathode chamber. Apply a constant potential (-0.8 V vs. Ag/AgCl). The effluent from the electrochemical cell is then directed through a transparent FEP photoreactor coil for the enzymatic transformation.

- Analysis: Monitor current efficiency. Quantify NADH generation spectrophotometrically (A340) at the cell outlet prior to the photoreactor.

Photochemical Regeneration

Uses a photosensitizer and sacrificial electron donor under light to reduce a mediator, which in turn reduces NAD(P)+.

Key Experimental Protocol: Light-Driven Dual Catalysis in a Segmented Flow Reactor

- Catalyst Preparation: Prepare a homogeneous reaction mixture containing NAD+ (0.05 mM), [Ru(bpy)₃]²⁺ as photosensitizer (0.01 mM), triethanolamine (TEOA, 50 mM) as sacrificial donor, viologen-based mediator (0.1 mM), and the flavin photoenzyme and its substrate.

- Reactor Configuration: Use a segmented flow approach. Introduce the reaction solution and an inert gas (e.g., Ar) via a T-junction to form stable gas-liquid segments in FEP tubing (ID 1 mm). Coil the tubing around a white or blue LED panel.

- Execution: The segmented flow provides improved radial mixing and photon exposure. The single reactor simultaneously performs the photochemical regeneration of NADH and the photoenzymatic conversion.

- Optimization: Vary segment length and light intensity to maximize the synergy between the two light-dependent cycles.

Quantitative Data Comparison

Table 1: Comparison of NAD(P)H Regeneration Methodologies in Continuous Flow Systems

| Methodology | Typical TONcofactor | Turnover Frequency (min⁻¹) | Key Advantages | Primary Limitations | Compatibility with Photoenzymes |

|---|---|---|---|---|---|

| Enzymatic (FDH) | 10,000 - 100,000+ | 100 - 1,000 | High specificity, high TON, simple. | Additional enzyme cost, possible by-product (CO₂). | Excellent. Separate module prevents light interference. |

| Electrochemical | 1,000 - 10,000 | 500 - 5,000 | No second substrate, modular control via potential. | Requires mediator, risk of side reactions at electrodes. | Good, but must isolate enzymes from electrode surface. |

| Photochemical | 500 - 5,000 | 200 - 2,000 | Single reactor possible, driven by light energy. | Complex system, photosensitizer/mediator degradation. | High risk of mutual interference between photo-cycles. |

Table 2: Performance Metrics in Recent Integrated Flow Studies (2021-2023)

| Target Reaction | Regeneration Method | Flow Reactor Type | Productivity (g L⁻¹ h⁻¹) | Cofactor TON | Reference Key |

|---|---|---|---|---|---|

| Asymmetric Ketone Reduction | Enzymatic (GDH) | Packed Bed Enzyme Reactor | 0.85 | 8,500 | Schmidt et al., 2021 |

| Chiral Amine Synthesis | Electrochemical (Mediated) | Microflow Electrochemical Cell | 2.10 | 1,200 | Ríos et al., 2022 |

| C=C Bond Reduction | Photochemical (Ru/VIologen) | Continuous Photomicroreactor | 0.55 | 3,800 | Lee & Park, 2023 |

| Thesis Context: Flavin-mediated Baeyer-Villiger Oxidation | Enzymatic (PTDH) | Tubular Photobioreactor | 1.42 | >50,000 | Preliminary Thesis Data |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Cofactor Regeneration in Flow

| Item / Reagent Solution | Supplier Examples | Function in Experiment |

|---|---|---|

| NAD+ or NADP+ (Disodium Salt) | Sigma-Aldrich, Carbosynth | Oxidized cofactor precursor; used in catalytic amounts. |

| Formate Dehydrogenase (FDH) from C. boidinii | Codexis, Sigma-Aldrich | Robust enzyme for NADH regeneration using formate. |

| [Cp*Rh(bpy)Cl][Cl] Mediator | Strem Chemicals, TCI | Efficient redox mediator for electrochemical NAD+ reduction. |

| Tris(2,2'-bipyridyl)ruthenium(II) chloride ([Ru(bpy)₃]Cl₂) | Sigma-Aldrich | Photosensitizer for photochemical regeneration cycles. |

| Fluorinated Ethylene Propylene (FEP) Tubing (ID 1.0-2.0 mm) | Bola, Idex Health & Science | Chemically inert, transparent tubing for photoreactors. |

| Syringe Pumps (Dual or Quad Channel) | Cetoni, Chemyx | Provides precise, pulseless flow of reagents. |

| LED Array Panel (λ = 450 nm) | Thorlabs, Mightex Systems | Cool, monochromatic light source for photoenzymes. |

| Microfluidic Electrochemical Flow Cell (Divided) | MicruX Technologies, Custom | Enables electrochemical regeneration in a flow format. |

Engineering Brilliance: Overcoming Challenges and Enhancing Performance

The application of flavin-dependent photoenzymes in organic synthesis offers unparalleled stereoselectivity for challenging radical transformations. However, the practical implementation of these biocatalysts is hampered by several intertwined pitfalls: photodegradation of the flavin cofactor, inherent enzyme stability under irradiation, and competing side-reactions. This guide provides a technical deep-dive into these challenges, framed within the broader thesis that maximizing the synthetic utility of these systems requires a holistic, mechanistic understanding of their failure modes.

Core Pitfalls: Mechanisms and Quantification

Photodegradation of the Flavin Cofactor

The flavin chromophore (FMN or FAD), while essential for light absorption and catalysis, is susceptible to irreversible degradation. The primary pathways involve oxidative cleavage of the isoalloxazine ring system under prolonged blue light exposure, especially in the presence of molecular oxygen.

Table 1: Quantitative Impact of Conditions on Flavin Photostability

| Condition/Variable | Effect on Degradation Half-life (t₁/₂) | Key Experimental Observation |

|---|---|---|

| Aerobic vs. Anaerobic | Aerobic: t₁/₂ ~ 2-4 hrs; Anaerobic: t₁/₂ > 24 hrs | Degradation rate increases >5-fold with O₂ present. |

| Light Intensity (450 nm) | 5 mW/cm²: t₁/₂ ~ 4 hrs; 20 mW/cm²: t₁/₂ ~ 1 hr | Rate scales linearly with photon flux in range studied. |

| Flavin Redox State | Oxidized (Quinone): Most labile; Semiquinone: Intermediate; Hydroquinone: Most stable | Degradation quantum yield is highest for oxidized form. |

| Presence of Substrate | t₁/₂ increases 2-3x with saturating substrate [S] >> Kₘ | Substrate binding protects flavin from solvent/quencher access. |

Protocol 2.1: Measuring Flavin Photodegradation Kinetics.

- Prepare Sample: Dissolve purified flavin cofactor (e.g., FMN, 50 µM) in desired reaction buffer (e.g., 50 mM Tris-HCl, pH 8.0) in a quartz cuvette.

- Establish Conditions: Degas solution by bubbling with argon for 20 min for anaerobic studies. Maintain temperature at 25°C.

- Irradiate: Expose to controlled blue light (e.g., 450 nm LED, 10 mW/cm²). Use a calibrated photodiode for flux measurement.

- Monitor: At regular intervals (e.g., every 15 min), record UV-Vis spectrum (300-500 nm). The decay of the characteristic 450 nm absorbance peak tracks degradation.

- Analyze: Fit the decrease in A₄₅₀ over time to a first-order decay model to determine rate constant (kdeg) and half-life (t₁/₂ = ln(2)/kdeg).

Enzyme Stability Under Operational Conditions

Protein stability encompasses both thermostability and photostability. Irradiation can cause protein unfolding, aggregation, and specific amino acid damage (e.g., to tryptophan, tyrosine).

Table 2: Factors Affecting Photoenzyme Operational Stability

| Factor | Impact on Enzyme Half-life (Activity-based) | Mitigation Strategy |

|---|---|---|

| Temperature | ΔT of +10°C decreases t₁/₂ by ~50% (Q₁₀ ≈ 2). | Conduct reactions at 4-10°C, not 25-37°C. |

| Reactive Oxygen Species (ROS) | [ROS] proportional to light flux; inactivates enzyme via oxidation. | Add sacrificial reductants (e.g., EDTA, ascorbate) and superoxide dismutase. |

| Cofactor Binding Affinity | Weak K_d for flavin leads to leaching and rapid inactivation. | Use enzyme variants with improved flavin binding or covalently tethered flavins. |

| Mechanical Stress (Stirring) | Vigorous stirring at gas-liquid interface causes foaming and denaturation. | Use gentle agitation or overhead stirring. |

Protocol 2.2: Assessing Photoenzyme Operational Half-life.

- Set Up Reaction: Combine photoenzyme (e.g., ene-reductase, 1 µM), flavin (5 µM), substrate (5 mM), and sacrificial electron donor (e.g., NADPH, 2 mM) in total volume.

- Initiate & Sample: Begin irradiation with continuous light. Withdraw aliquots at defined time points (e.g., 0, 30, 60, 120, 180 min).

- Quench & Assay: Immediately dilute aliquot 100-fold into a standard activity assay mixture (maintained in the dark). Measure initial reaction rate via substrate depletion (GC/HPLC) or NADPH oxidation (A₃₄₀).

- Calculate: Plot residual activity (%) vs. irradiation time. Fit to exponential decay: Activity(t) = A₀ * exp(-kinact * t). The operational half-life is t₁/₂ = ln(2)/kinact.

Competing Side-Reactions

Unwanted radical pathways divert flux from the desired product, lowering yield and selectivity.

Table 3: Common Side-Reactions in Flavin Photocatalysis

| Side-Reaction Type | Cause | Consequence |

|---|---|---|

| Over-reduction | Excessive electron donor concentration or prolonged irradiation past conversion endpoint. | Formation of over-reduced byproducts (e.g., alcohols from alkenes). |

| Radical Disproportionation & Dimerization | High local concentration of substrate-derived radicals escaping the enzyme active site. | Formation of dimeric/oligomeric side-products, reduced enantiomeric excess (ee). |

| Substrate/Product Photolysis | Direct absorption of incident light by organic compounds (e.g., aryl ketones). | Uncontrolled background reactivity, complex product mixtures. |

| Flavin-Substrate Adduct Formation | Nucleophilic attack on the excited flavin by substrate or solvent. | Irreversible inactivation of the photocatalyst. |

Protocol 2.3: Identifying and Quantifying Side-Reactions.

- Analytical Setup: Establish a quantitative HPLC or GC method capable of separating the target product from all suspected byproducts.

- Reaction Time Course: Run the photoenzymatic reaction, sampling at 20%, 50%, 80%, and 100% target conversion (monitored independently).