Harnessing Light and Enzymes: How Photobiocatalysis Drives Sustainable Innovation in Biomedical Research

This article provides a comprehensive analysis of photobiocatalysis as a transformative green chemistry strategy for researchers, scientists, and drug development professionals.

Harnessing Light and Enzymes: How Photobiocatalysis Drives Sustainable Innovation in Biomedical Research

Abstract

This article provides a comprehensive analysis of photobiocatalysis as a transformative green chemistry strategy for researchers, scientists, and drug development professionals. It explores the foundational principles of merging photocatalysis with biocatalysis to access unique synthetic pathways under mild conditions. The scope covers innovative methodological applications in hydrogen production and CO2 valorization, addresses key challenges in catalyst compatibility and system optimization, and validates the technology through comparative analysis with traditional methods. The synthesis concludes by highlighting photobiocatalysis's potential to streamline sustainable chemical manufacturing and its future implications for green pharmaceutical synthesis.

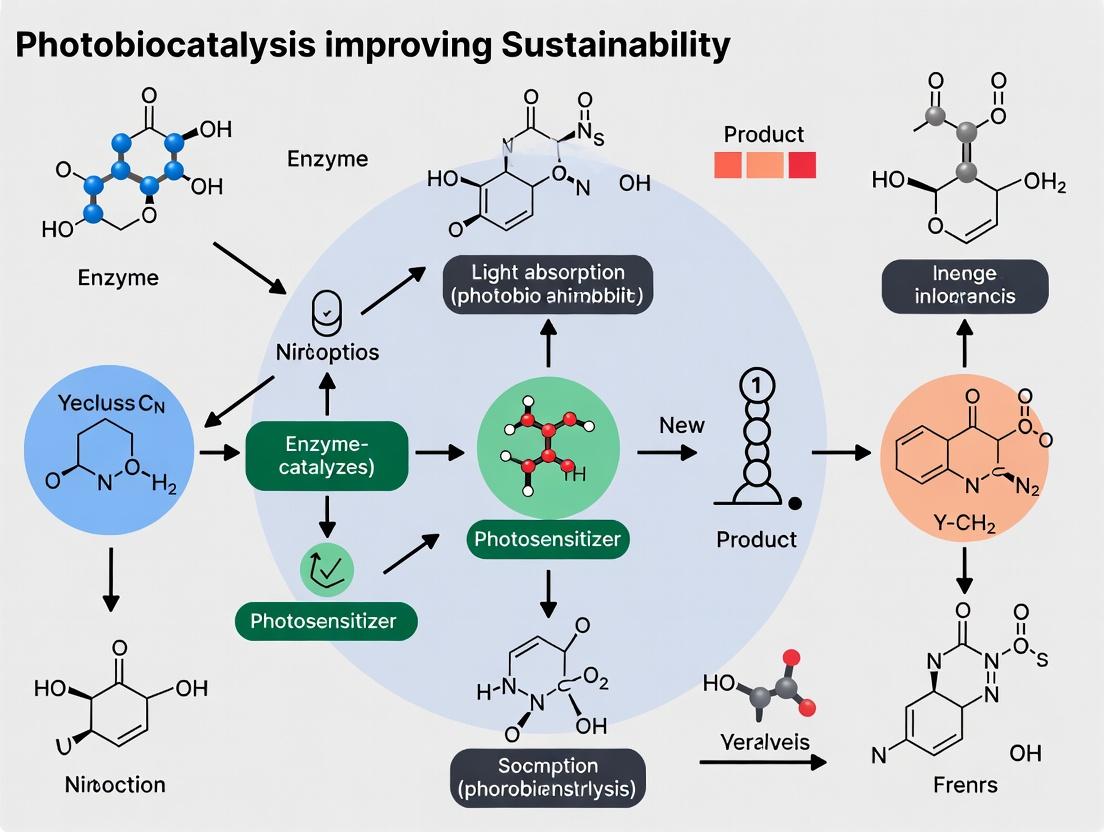

The Green Fusion: Understanding the Core Principles of Photobiocatalysis

The integration of photochemistry with biocatalysis—photobiocatalysis—represents a pivotal advancement in sustainable synthesis, directly addressing the core thesis that synergistic hybrid systems dramatically improve the atom economy, energy efficiency, and environmental footprint of chemical production. This field operationalizes the early 20th-century vision of Giacomo Ciamician, who prophetically advocated for a transition from fossil fuels to solar energy as the primary driver of industrial chemistry. Modern photobiocatalysis merges the exquisite selectivity and mild-operation enzymes (biocatalysis) with the ability of photochemistry to access reactive intermediates using visible light. This convergence enables previously challenging transformations under ambient conditions, using renewable energy, thereby enhancing the sustainability profile of pharmaceutical and fine chemical synthesis. It reduces reliance on rare metals, harsh reagents, and energy-intensive processes, aligning green chemistry principles with practical synthetic efficiency.

Historical Progression: From Vision to Reality

Giacomo Ciamician's Vision (Early 1900s): In his seminal 1912 address, "The Photochemistry of the Future," Ciamician articulated a future where fossil fuels would be replaced by solar energy to drive chemical reactions, drawing inspiration from photosynthesis. He conducted early experiments on organic photochemistry but lacked the tools to enact his full vision.

Modern Milestones:

- Late 20th Century: Advances in photoredox catalysis, particularly with ruthenium and iridium polypyridyl complexes, provided a mechanistic framework for using visible light to catalyze reactions via single-electron transfer (SET).

- Early 21st Century: The "photoredox revolution" demonstrated the power of combining photoredox catalysis with traditional transition metal catalysis for cross-coupling.

- Last Decade: The emergence of photobiocatalysis, combining photocatalysts (organometallic, organic dyes, or semiconductors) with enzymes. Key breakthroughs include the merger of photoredox catalysts with ene-reductases for asymmetric radical reductions, and the use of light to regenerate nicotinamide cofactors (NAD(P)H) in situ, driving oxidative enzymes.

Core Principles and Mechanisms

Photobiocatalysis typically operates via a cooperative mechanism where the photocatalytic cycle and the biocatalytic cycle are coupled, often through a shared redox mediator.

Key Signaling Pathways and Logical Workflows:

Diagram 1: General photobiocatalytic cofactor regeneration cycle.

A more specific example involves asymmetric hydrofunctionalization via ene-reductases (EREDs):

Diagram 2: Photobiocatalytic asymmetric radical reduction with an ERED.

Quantitative Data & Performance Metrics

Table 1: Comparison of Catalytic Modalities for Representative Transformations

| Transformation | Conventional Catalysis | Photoredox Catalysis | Photobiocatalysis | Key Sustainability Metric Improvement |

|---|---|---|---|---|

| Asymmetric C-H Functionalization | Pd/Rh with chiral ligands, high T, O₂ pressure | Metallaphotoredox, Ir/Ru, mild conditions | P450 monooxygenases + light, NADPH recycling | >90% reduction in metal use, 100% renewable energy input |

| Chiral Alcohol Synthesis (Ketone Reduction) | Ru/BINAP hydrogenation, H₂ pressure (50-100 bar) | - | Alcohol dehydrogenase + photosensitizer for NADPH regen. | Eliminates H₂ gas, >99% ee, room temperature |

| Alkene Hydrofunctionalization | Pt/Pd acids, stoichiometric silanes | Radical-polar crossover, stoichiometric reductants | Ene-reductase + organic photoredox catalyst | 100% atom economy, no precious metals, high enantioselectivity |

| Amine Synthesis (reductive amination) | Borohydride reagents, metal catalysts | - | Imine reductase + photocatalyst for NADPH recycling | Replaces stoichiometric, pyrophoric reagents; uses water as solvent |

Table 2: Representative Photobiocatalytic Reactions with Performance Data (Recent Examples)

| Enzyme Class | Photocatalyst | Substrate | Product | Yield (%) | ee/Selectivity | TON (PC) | TOF (h⁻¹) | Light Source |

|---|---|---|---|---|---|---|---|---|

| Ene-Reductase (OYE) | 4CzIPN (organic dye) | α,β-unsaturated ketone | Chiral saturated ketone | 92 | 99% ee | 500 | 42 | Blue LEDs (450 nm, 10 W) |

| Cytochrome P411 | [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | Cyclohexane | Cyclohexanol | 85 | n/a | 1000* | 125* | Blue LEDs (455 nm) |

| Alcohol Dehydrogenase | [Acr⁺-Mes] ClO₄⁻ | Acetophenone | (R)-1-Phenylethanol | 88 | >99% ee | 2000 | 200 | White LEDs (30 W) |

| Monooxygenase | CdS Quantum Dots | Indole | 3-Hydroxyindole | 78 | n/a | N/A | N/A | Simulated Solar (AM 1.5G) |

TON/TOF for enzyme; *TON/TOF for photocatalytic cofactor regeneration.

Detailed Experimental Protocols

Protocol 1: Photobiocatalytic Asymmetric Reduction of an α,β-Enone using an Ene-Reductase

Objective: To synthesize a chiral saturated ketone from a prochiral enone using a visible-light-driven photobiocatalytic system.

Materials: See "The Scientist's Toolkit" below. Procedure:

- Reaction Setup: In a 4 mL clear glass vial equipped with a small stir bar, combine the following under an inert atmosphere (N₂ glovebox or Schlenk line):

- Potassium phosphate buffer (50 mM, pH 7.0): 1.85 mL

- Substrate (e.g., 2-cyclohexenone): 10 µL (0.1 mmol, 50 mM final concentration).

- Photocatalyst stock solution (e.g., 4CzIPN in DMSO, 10 mM): 100 µL (1 µmol, 0.5 mol%).

- Ene-reductase (OYE1) stock solution (purified, 10 mg/mL): 100 µL (~1 mg, 1 mg/mL final).

- NADP⁺ stock solution (10 mM): 10 µL (0.1 µmol, 0.1 mol%).

- Hantzsch ester (HE, 100 mM in DMSO): 100 µL (10 µmol, 10 mol%).

- Irradiation: Seal the vial with a PTFE-lined cap. Place the vial in a photoreactor equipped with blue LED strips (λmax = 450 nm, ~10 W total power). Ensure even illumination. Start stirring (800 rpm) at a controlled temperature of 25°C.

- Monitoring: Monitor reaction progress by analytical HPLC or GC, sampling aliquots (20 µL) at regular intervals (e.g., 1, 2, 4, 6, 12, 24 h). Quench samples by diluting 1:1 with acetonitrile and filtering (0.2 µm) before analysis.

- Work-up: After 24 h (or upon completion), extract the reaction mixture with ethyl acetate (3 x 2 mL). Combine organic layers, dry over anhydrous MgSO₄, filter, and concentrate in vacuo.

- Purification & Analysis: Purify the crude product by flash chromatography on silica gel. Determine enantiomeric excess (ee) by chiral HPLC or GC. Confirm structure by ¹H/¹³C NMR and mass spectrometry.

Protocol 2: Light-Driven Cofactor Regeneration for Alcohol Dehydrogenase

Objective: To recycle NADPH using a photocatalyst for the continuous enzymatic reduction of a ketone.

Procedure:

- Solution Preparation: Prepare two separate stock solutions in Tris-HCl buffer (100 mM, pH 8.0):

- Solution A (Photocatalytic): [Acr⁺-Mes] ClO₄⁻ (0.5 mM), EDTA disodium salt (10 mM, sacrificial electron donor).

- Solution B (Biocatalytic): Alcohol dehydrogenase (ADH, 0.1 mg/mL), NADP⁺ (0.1 mM), Acetophenone (5 mM).

- Reaction Initiation: In a quartz cuvette (path length 1 cm), mix 1.5 mL of Solution A and 1.5 mL of Solution B. Cap and mix gently.

- Irradiation & Monitoring: Place the cuvette in a spectrophotometer equipped with a stirrer and a white LED light source (focused beam). Irradiate the sample while monitoring the absorbance at 340 nm (formation of NADPH) and 290 nm (disappearance of acetophenone) at 30-second intervals for 30 minutes.

- Kinetic Analysis: Calculate the initial rate of NADPH formation from the slope of the absorbance increase at 340 nm. Compare to a dark control and a control without photocatalyst.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item Name / Reagent Solution | Function / Explanation |

|---|---|

| Ene-Reductases (OYE family) | Flavin-dependent enzymes that catalyze the asymmetric trans-hydrogenation of activated alkenes. |

| Cytochrome P450/P411 Variants | Engineered heme-containing monooxygenases for selective C-H oxidation, hydroxylation, and other oxidative reactions. |

| Alcohol Dehydrogenases (ADHs) | Zinc-dependent or short-chain dehydrogenases that reduce ketones to chiral alcohols using NAD(P)H. |

| [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | Highly oxidizing and reducing cyclometalated Ir photoredox catalyst; excitable with blue light. |

| 4CzIPN Organic Photocatalyst | Metal-free, strongly reducing photocatalyst (organic thermally activated delayed fluorescence, TADF) excitable by blue light. |

| [Acr⁺-Mes] ClO₄⁻ (Acridinium salt) | Powerful organic photooxidant; used for substrate oxidation or via reductive quenching for cofactor regeneration. |

| Hantzsch Ester (HE) | Organic dihydropyridine serving as a mild, stoichiometric reductant in photoredox cycles; often the H-atom donor. |

| NAD(P)H / NAD(P)+ Cofactors | Biological redox shuttles; their enzymatic recycling via light is central to photobiocatalysis. |

| Potassium Phosphate Buffer (pH 7-8) | Standard aqueous medium maintaining enzyme stability and activity. |

| Blue LED Array (λmax 450-470 nm) | Standard, energy-efficient visible light source matching absorption profiles of common photocatalysts. |

| Quartz Vials / Cuvettes | For UV-transparent reaction vessels to ensure efficient light penetration. |

| Schlenk Line / Glovebox | For setting up anaerobic reactions when oxygen-sensitive radicals or photocatalysts are involved. |

Photobiocatalysis represents a frontier in sustainable chemical synthesis, merging the complementary strengths of photocatalysis (using light to drive chemical reactions) and biocatalysis (using enzymes or whole cells). Within the broader thesis of improving sustainability research, this hybrid approach addresses critical challenges: it enables novel, selective reaction pathways under mild conditions (often ambient temperature and pressure), reduces reliance on rare metals and toxic reagents, and leverages renewable light energy. By expanding the synthetic toolbox for pharmaceuticals and fine chemicals, photobiocatalysis directly contributes to greener manufacturing paradigms with lower environmental impact .

Fundamental Mechanisms of Synergy

The synergy arises from specific interaction modes between the photocatalytic cycle (PC) and the biocatalytic cycle (BC).

- Mode 1: Photocatalytic Regeneration of Cofactors. The most established synergy. A photocatalyst (e.g., [Ru(bpy)₃]²⁺, organic dyes) uses light energy to regenerate reduced enzymatic cofactors (e.g., NADH, NADPH) from their oxidized forms (NAD⁺, NADP⁺). This replaces expensive stoichiometric chemical reductants and improves atom economy.

- Mode 2: Photocatalytic Generation of Substrates. A photocatalyst drives a reaction to produce a substrate in situ that is subsequently consumed by an enzyme. This can activate stable, inexpensive precursors into reactive intermediates (e.g., alkenes, radicals) under mild conditions compatible with enzyme stability.

- Mode 3: Enzyme-Mediated Asymmetric Synthesis of Photoproducts. A non-selective photocatalytic reaction generates a racemic or prochiral intermediate, which is then enantioselectively transformed by an enzyme, achieving stereocontrol that is challenging for pure photocatalysis.

- Mode 4: Cascade/Concurrent Reactions. The photocatalyst and enzyme operate in a one-pot cascade, either concurrently or in sequential steps, without isolation of intermediates, minimizing waste and processing steps.

The following diagram illustrates the primary signaling and logical relationships between these components.

Diagram Title: Core Interaction Modes in Photobiocatalysis

Key Experimental Protocols

Protocol for Photocatalytic NADH Regeneration Coupled to an Oxidoreductase

This protocol details a common setup for studying Mode 1 synergy .

- Reaction Setup: Conduct all steps under inert atmosphere (N₂ or Ar) in a glovebox if the photocatalyst is oxygen-sensitive.

- Preparation of Buffer Solution: Prepare 10 mL of 100 mM phosphate buffer (pH 7.0) containing 0.1 mM EDTA to chelate trace metal ions.

- Master Mix Assembly: In a 5 mL quartz cuvette or glass vial, combine:

- 975 µL of the prepared buffer.

- 10 µL of 10 mM [Ru(bpy)₃]Cl₂ stock (final conc. 100 µM).

- 5 µL of 100 mM NAD⁺ stock (final conc. 500 µM).

- 5 µL of 1 M triethanolamine (TEOA) stock (final conc. 5 mM) as sacrificial electron donor.

- Enzyme Addition: Add 5 µL of the target oxidoreductase enzyme (e.g., alcohol dehydrogenase, final activity ~0.5 U/mL) and its specific substrate (e.g., 10 µL of 1 M ketone substrate).

- Irradiation: Seal the vessel and place it in a photoreactor equipped with blue LEDs (λmax = 450 nm, ~10 mW/cm² intensity). Irradiate with continuous stirring at 25°C.

- Analysis: Monitor reaction progress over time by:

- HPLC/GC: To quantify substrate consumption and product formation.

- UV-Vis Spectroscopy: Tracking absorbance at 340 nm (NADH formation).

Protocol for Concurrent Photoenzyme-Catalyzed Asymmetric Synthesis

This protocol outlines a one-pot concurrent reaction (Mode 4) for asymmetric C–C bond formation .

- Photobiocatalyst Preparation: The enzyme (e.g., an ene-reductase) may be used as a purified protein, cell lysate, or whole cells. For purified enzymes, ensure buffer is free of stabilizers (like BSA) that may quench photocatalysis.

- Reaction Mixture: In a 2 mL glass vial wrapped in foil, add sequentially:

- 850 µL of 50 mM Tris-HCl buffer (pH 8.0).

- 50 µL of 20 mM organic photocatalyst (e.g., Mes-Acr⁺, final 1 mM).

- 50 µL of 100 mM α,β-unsaturated ketone substrate (final 5 mM).

- 50 µL of 1 M sacrificial donor (e.g., formate, final 50 mM).

- Initiation: Place the vial in a multi-position photoreactor with green LEDs (λmax = 525 nm). Start stirring and irradiation simultaneously.

- Sampling: At regular intervals, take 100 µL aliquots, quench with 100 µL acetonitrile, vortex, and centrifuge (13,000 rpm, 5 min) to remove protein.

- Analysis: Analyze supernatant by chiral HPLC to determine conversion and enantiomeric excess (ee).

Table 1: Performance Comparison of Photocatalyst Systems for NAD(P)H Regeneration

| Photocatalyst | Light Source (nm) | Sacrificial Donor | Turnover Number (TON) for NADH | Max. Regeneration Rate (µmol L⁻¹ min⁻¹) | Key Advantage |

|---|---|---|---|---|---|

| [Ru(bpy)₃]²⁺ | 450 | TEOA | ~500 | 120 | High robustness & efficiency |

| Eosin Y | 530 | TEOA | ~200 | 85 | Low cost, metal-free |

| Carbon Nitride (C₃N₄) | 420 | EDTA | ~50 | 15 | Heterogeneous, recyclable |

| CdS Quantum Dots | 405 | Mercaptoethanol | ~1000 | 200 | High TON, but metal toxicity |

Table 2: Representative Photobiocatalytic Reactions for Pharmaceutical Intermediates

| Enzyme Class | Photocatalyst | Reaction Type | Product (Example) | Yield (%) | ee (%) | Sustainability Metric (Compared to Classical Route) |

|---|---|---|---|---|---|---|

| Ene-Reductase | Mes-Acr⁺ | Asymmetric Reduction | Chiral Lactone | 92 | >99 | 65% reduction in metal waste |

| Transaminase | Cyanoarene | Reductive Amination | Chiral Amine | 78 | 98 | Eliminates stoichiometric NaBH₄ |

| P450 Monooxygenase | [Ir(ppy)₃] | C–H Hydroxylation | Drug Metabolite | 85 | N/A | Uses O₂, avoids peroxides |

| Old Yellow Enzyme | [Ru(bpy)₃]²⁺ | Denitration | Nitro-Reduced Intermediate | 95 | N/A | Ambient H₂ source (from water/TEOA) |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Photobiocatalysis Research

| Item | Function & Rationale | Example Product/Specification |

|---|---|---|

| Heterogeneous Photocatalyst (C₃N₄) | Metal-free, recyclable semiconductor for cofactor regeneration or substrate oxidation under visible light. Ease of separation from reaction mix. | Sigma-Aldrich, 900592; typically requires thermal synthesis from precursors like melamine or urea. |

| Homogeneous Organophotocatalyst (Acridinium Salts) | Powerful photooxidants (e.g., E~ +2.0 V vs SCE) for activating substrates via single-electron transfer (SET) in enzyme-compatible buffers. | Mes-Acr⁺ClO₄⁻ (Tokyo Chemical Industry, A2947); requires deoxygenation. |

| Enzyme (Purified Ene-Reductase) | Catalyzes asymmetric hydrogenation of C=C bonds, often coupled with photocatalysts for nicotinamide cofactor recycling. | Purified OPR1 or YqjM from E. coli lysate (available from enzyme engineering suppliers). |

| Deazaflavin Cofactor (F420 Analog) | A natural photoenzyme cofactor; its synthetic analogs are used to study and engineer light-driven enzymatic activity directly. | 8-Hydroxy-5-deazaflavin (8-HDF); can be sourced from specialized biochemical suppliers. |

| Sacrificial Electron Donor (TEOA) | Consumable reagent that provides electrons to the oxidized photocatalyst, closing the photocatalytic cycle. Essential for non-regenerative systems. | Triethanolamine, ≥99.5% (Sigma-Aldrich, 90279); must be purified to remove amines that can inhibit enzymes. |

| Anaerobic Reaction Vials | For excluding O₂, which can quench excited-state photocatalysts, oxidize intermediates, or inhibit sensitive enzymes. | ChemGlass, Vial (8 mL) with Threaded Cap & PTFE/Silicone Septa (CG-4909-02). |

| Calibrated LED Photoreactor | Provides uniform, wavelength-specific, and quantifiable light intensity crucial for reproducibility and kinetic studies. | Lumidox Photoreactor Series with adjustable intensity and cooling, or home-built array with a radiometer. |

System Workflow and Integration

A standard research workflow for developing a new photobiocatalytic system integrates the components from the toolkit.

Diagram Title: Photobiocatalytic System Development Workflow

The defined synergy between photocatalysis and biocatalysis offers a robust platform for sustainable chemical synthesis, directly advancing the thesis that innovative hybrid methodologies are key to reducing the environmental footprint of research and industry. Future directions include engineering enzymes for improved radical tolerance, developing fully integrated photocatalytic protein scaffolds, and scaling systems using continuous flow photoreactors to enhance light penetration and productivity. This convergence promises to unlock novel, efficient routes to high-value compounds with minimal waste generation.

This technical guide examines the foundational mechanisms underpinning photobiocatalysis, a synergistic field combining photocatalysis with enzyme catalysis. Framed within a broader thesis on advancing sustainability research, we elucidate how the integration of light-driven processes with enzymatic specificity enables novel, energy-efficient routes for chemical synthesis, waste valorization, and pharmaceutical intermediate production. The precise orchestration of electron transfer (ET), energy transfer (EnT), and enzyme-substrate activation is critical for enhancing reaction rates, selectivity, and operational stability under mild conditions, thereby reducing the environmental footprint of chemical manufacturing.

Photobiocatalysis harnesses light as a renewable energy source to drive enzymatic transformations. This paradigm shift addresses key sustainability challenges in research by:

- Reducing Energy Consumption: Replacing thermal energy with photon energy for reaction initiation.

- Expanding Reaction Scope: Enabling enzymatic catalysis of non-natural reactions via photochemically generated reactive intermediates.

- Utilizing Abundant Feedstocks: Facilitating the activation of inert molecules (e.g., CO₂, lignin) under ambient conditions. The efficacy of these systems hinges on a detailed mechanistic understanding of the interplay between photophysical and biochemical events.

Core Mechanistic Principles

Electron Transfer (ET) Pathways

ET is the cornerstone of oxidative and reductive photobiocatalysis. A photoexcited catalyst (PC*) acts as a potent reductant or oxidant.

- Quenching Mechanisms:

- Oxidative Quenching: PC* donates an electron to a terminal acceptor (A), generating PC⁺·. PC⁺· can then oxidize an enzyme-cofactor (e.g., NADH to NAD⁺) or substrate.

- Reductive Quenching: PC* accepts an electron from a donor (D), generating PC⁻·. PC⁻· can then reduce a cofactor (e.g., NAD⁺ to NADH) or substrate.

- Key Quantitative Data:

Table 1: Representative Photocatalysts and Redox Potentials

| Photocatalyst | Excitation λ (nm) | E(PC*/PC⁻) (V vs SCE) | E(PC⁺/PC*) (V vs SCE) | Common Role |

|---|---|---|---|---|

| [Ir(ppy)₃] | 450 | -1.73 | +0.77 | Reductive/Oxidative Quenching |

| [Ru(bpy)₃]²⁺ | 450 | -0.81 | +0.77 | Oxidative Quenching, Singlet O₂ |

| Eosin Y | 530 | -1.10 | +0.83 | Reductive Quenching, HAT |

| 4CzIPN | 460 | -1.21 | +1.35 | Reductive Quenching, Energy Transfer |

| CdS Quantum Dots | 400-450 | ~-1.0 (CB) | ~+1.5 (VB) | Multi-electron Transfer |

- Experimental Protocol for Measuring ET Rates (Laser Flash Photolysis):

- Sample Preparation: Prepare degassed solutions of photocatalyst (10-100 µM) and electron donor/acceptor (0.1-10 mM) in appropriate buffer/organic solvent.

- Excitation: Use a pulsed laser (e.g., Nd:YAG, λ = 355 nm) to excite the photocatalyst.

- Transient Absorption Monitoring: Probe the decay of the PC* absorption signal (or rise of radical species) with a continuous white light source and fast detector (PMT).

- Kinetic Analysis: Plot pseudo-first-order rate constants (kobs) against quencher concentration. The slope yields the bimolecular quenching rate constant (kq). Compare k_q to the diffusion-controlled limit (~10¹⁰ M⁻¹s⁻¹) to determine ET efficiency.

Energy Transfer (EnT) Pathways

EnT involves the non-radiative transfer of excitation energy from PC* to a ground-state substrate (S), generating an excited substrate (S*).

- Mechanism: Typically occurs via Förster Resonance Energy Transfer (FRET) or Dexter electron exchange. Crucial for activating substrates for [2+2] cycloadditions, isomerizations, or singlet oxygen (¹O₂) generation via sensitization of triplet oxygen (³O₂).

- Key Parameter: Energy donor (PC*) triplet energy (ET) must be higher than acceptor (S) triplet energy.

Table 2: Energy Transfer in Photobiocatalysis

| Energy Donor (PC) | Triplet Energy ET (kJ/mol) | Acceptor (S) | Product of S* Activation | Typical Enzyme Coupled |

|---|---|---|---|---|

| [Ru(bpy)₃]²⁺ | 210 | ³O₂ → ¹O₂ | Hydroperoxides | Peroxygenases, Lipoxygenases |

| Acetophenone | 310 | Alkenes (e.g., coumarin) | Oxetanes | Ene-reductases (subsequent step) |

| 4CzIPN | 265 | Aryl Ketones | Biradical Intermediates | Ketoreductases |

Enzyme-Substrate Activation

This refers to the traditional chemical activation within the enzyme active site, now influenced by photochemical pre-activation.

- Photochemical Priming: Light generates an activated substrate (e.g., a radical, an excited state, or an oxidized/reduced species) which is then channeled into the enzyme's active site for stereoselective transformation.

- Cofactor Regeneration: Light-driven ET regenerates expensive enzymatic cofactors (e.g., NAD(P)H, FADH₂) in situ, enabling catalytic turnover.

- Hybrid Mechanism – Hydrogen Atom Transfer (HAT): Photocatalyst undergoes EnT/ET to generate a radical species (e.g., from a thiol), which then abstracts a H-atom from a substrate, creating a substrate radical for enzymatic processing.

Integrated Photobiocatalytic Workflows

Experimental Protocol for a Typical Photobiocatalytic Asymmetric Reduction:

- Reaction Setup: In a Schlenk tube or sealed vial, combine under inert atmosphere:

- Substrate (e.g., prochiral ketone, 0.1 mmol).

- Photocatalyst (e.g., [Ir(ppy)₂(dtbbpy)]⁺, 1 mol%).

- Electron donor (e.g., Hantzsch ester, 1.2 equiv. or TEOA, 2 equiv.).

- Enzyme (e.g., Alcohol Dehydrogenase, 5 mg/mL).

- Required cofactor (e.g., NADP⁺, 0.1 mol%).

- Phosphate buffer (pH 7.0, 50 mM) with necessary organic cosolvent (<20% v/v).

- Irradiation: Place the reaction vessel in a temperature-controlled photoreactor (e.g., 25°C) equipped with blue LEDs (λmax = 450 nm, ~10-30 W). Stir vigorously.

- Monitoring: Withdraw aliquots periodically. Quench with organic solvent, separate via centrifugation, and analyze by HPLC/GC to determine conversion and enantiomeric excess (ee).

- Control Experiments: Run identical setups (a) in the dark, (b) without photocatalyst, (c) without enzyme.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Photobiocatalysis Research

| Reagent / Material | Function & Rationale |

|---|---|

| Homogeneous Photocatalysts (e.g., [Ir(ppy)₃], [Ru(bpy)₃]Cl₂, Eosin Y, 4CzIPN) | Light-absorbing molecules that initiate ET/EnT. Choice depends on redox potentials, excitation wavelength, and solubility. |

| Heterogeneous Photocatalysts (e.g., CdS QDs, Carbon Nitride (C₃N₄)) | Reusable, solid-state light absorbers facilitating charge separation and interfacial ET. |

| Enzymes (Wide Range) | Ene-reductases (EREDs), Old Yellow Enzymes (OYEs), Alcohol Dehydrogenases (ADHs), P450 monooxygenases, Peroxygenases (UPOs). Provide selectivity and rate enhancement. |

| Cofactors (NAD(P)H, FAD, FMN, Pyrroloquinoline quinone (PQQ)) | Essential redox partners for enzymes. Often used in catalytic amounts with in situ regeneration. |

| Sacrificial Electron Donors (Triethanolamine (TEOA), Ascorbate, Hantzsch Ester) | Consumable reagents that replenish electrons to the photocatalytic cycle in reductive quenching mechanisms. |

| Electron Acceptors (e.g., [Co(NH₃)₅Cl]²⁺, O₂) | Terminal oxidants in oxidative quenching cycles or for generating reactive oxygen species. |

| Deuterated Solvents (D₂O, CD₃OD) | Used in mechanistic studies (e.g., Kinetic Isotope Effect, KIE) to probe HAT pathways. |

| Spin Traps (e.g., DMPO, TEMPO) | Used in Electron Paramagnetic Resonance (EPR) spectroscopy to detect and identify short-lived radical intermediates. |

| Singlet Oxygen Traps (e.g., 9,10-Dimethylanthracene (DMA), SOSG) | Chemical probes to confirm the generation of ¹O₂ via energy transfer to ³O₂. |

| Anaerobic Reaction Chambers (Glovebox, Schlenk line) | For conducting reactions sensitive to oxygen, especially those involving strongly reducing photocatalyst states or radical intermediates. |

Visualizing Pathways and Workflows

Diagram 1: Electron Transfer Pathways in Photobiocatalysis

Diagram 2: Integrated Photobiocatalytic Experimental Workflow

The mechanistic dissection of electron transfer, energy transfer, and enzyme-substrate activation provides a blueprint for rationally designing efficient photobiocatalytic systems. By leveraging these principles, sustainability research can develop greener syntheses for high-value chemicals, pharmaceuticals, and materials, directly contributing to the reduction of industrial waste, energy use, and reliance on non-renewable resources. Future advancements hinge on the discovery of robust enzyme-photocatalyst hybrids and a deeper kinetic understanding of the interfacial steps between photochemistry and biocatalysis.

Within the broader thesis that photobiocatalysis significantly advances sustainability research by merging the selectivity of enzymes with the energy efficiency of light-driven processes, understanding its core components is essential. This field reduces reliance on fossil fuels, minimizes toxic waste, and enables reactions under mild conditions. This guide details the fundamental units—photoenzymes, cofactors, and synthetic photocatalysts—that underpin this transformative technology.

Photoenzymes

Photoenzymes are naturally occurring, light-dependent enzymes that catalyze specific chemical transformations using photon energy. They are central to sustainable photobiocatalysis due to their high selectivity and ability to use visible light as a clean energy input.

Key Examples:

- DNA Photolyase: Repairs UV-induced cyclobutane pyrimidine dimers using light (300-500 nm). Its catalytic cycle involves electron transfer from a reduced flavin adenine dinucleotide (FADH⁻) cofactor.

- Protochlorophyllide Oxidoreductase (POR): A light-dependent enzyme crucial in chlorophyll biosynthesis, catalyzing the reduction of protochlorophyllide.

- Fatty Acid Photodecarboxylase (FAP): A recently discovered blue-light-utilizing enzyme that converts fatty acids to hydrocarbons, holding significant promise for biofuel production.

Quantitative Data on Common Photoenzymes:

| Photoenzyme | EC Number | Light Wavelength (nm) | Primary Cofactor | Reaction Catalyzed |

|---|---|---|---|---|

| DNA Photolyase | EC 4.1.99.3 | 300-500 | FADH⁻, MTHF | DNA Repair |

| Fatty Acid Photodecarboxylase (FAP) | EC 4.1.1.106 | ~450 | FAD | Decarboxylation to Alkanes |

| Protochlorophyllide Oxidoreductase (POR) | EC 1.3.1.33 | ~630 | NADPH | Reduction to Chlorophyllide |

Cofactors

Cofactors are non-protein, often organic or metallic, compounds essential for the catalytic activity of many enzymes, including photoenzymes. They act as transient carriers of electrons, chemical groups, or light-absorbing chromophores.

Common Photobiocatalytic Cofactors:

- Flavins (FAD, FMN): Yellow-colored compounds that absorb blue light (~450 nm). They cycle between oxidized, semiquinone, and reduced states, facilitating electron transfer.

- Nicotinamide (NAD(P)H): Primary electron donors in biological systems, regenerated photochemically in engineered systems.

- Metalloporphyrins (Heme, Chlorophyll): Involved in light harvesting and electron transfer. Their metal center (e.g., Mg²⁺, Fe²⁺) is key to their function.

- Deazaflavins: Synthetic analogs of flavins with longer-lived excited states, used in artificial photobiocatalytic systems.

Common Synthetic Photocatalysts

Synthetic photocatalysts are small molecules or materials that absorb light to enter an excited state, enabling them to donate or accept electrons from biological catalysts. They are crucial for expanding the scope of photobiocatalysis to non-native enzymatic reactions.

Categories and Examples:

- Organometallic Complexes: Ru(bpy)₃²⁺, Ir(ppy)₃. These offer long-lived triplet excited states and tunable redox potentials.

- Organic Dyes: Eosin Y, Rose Bengal, Mes-Acr⁺. They are often more affordable and less toxic than metal complexes.

- Semiconductor Materials: TiO₂, CdS Quantum Dots. They absorb UV/visible light to generate electron-hole pairs.

Comparison of Common Synthetic Photocatalysts:

| Photocatalyst | Type | Primary Absorption (nm) | Excited State Lifetime | Typical Role in Photobiocatalysis |

|---|---|---|---|---|

| [Ru(bpy)₃]²⁺ | Organometallic | ~450 nm | ~600 ns | Single Electron Transfer (SET) mediator |

| Eosin Y | Organic Dye | ~450-530 nm | ~10 ns | Singlet oxygen generator, SET mediator |

| Mes-Acr⁺ | Organic (Acridinium) | ~400-450 nm | N/A | Strong photooxidant for SET |

| TiO₂ (Anatase) | Semiconductor | < 387 nm (UV) | µs-ms range | Provides reductive or oxidative equivalents |

Detailed Experimental Protocol: Light-Driven Biocatalytic Decarboxylation using FAP

This protocol outlines a standard photobiocatalytic reaction using Fatty Acid Photodecarboxylase (FAP) to produce hydrocarbons from fatty acids.

Objective: To convert palmitic acid to pentadecane using purified FAP enzyme under blue light illumination.

Materials & Reagents:

- Enzyme: Purified FAP (e.g., from Chlorella variabilis).

- Substrate: Sodium palmitate solution (in buffer or mixed with a solubilizing agent).

- Buffer: 50 mM phosphate buffer, pH 7.5.

- Cofactor: No exogenous cofactor required (FAD bound natively).

- Light Source: Blue LED array (λmax = 450 nm, intensity calibrated to ~10 mW/cm²).

- Reaction Vessel: Glass vial or photochemical reactor with good light penetration.

Procedure:

- Reaction Setup: In a 2 mL clear glass vial, combine 980 µL of phosphate buffer (50 mM, pH 7.5), 10 µL of sodium palmitate stock solution (final concentration 1 mM), and 10 µL of purified FAP stock solution (final concentration 5 µM).

- Pre-Incubation: Briefly vortex the mixture. Incubate in the dark for 5 minutes to allow temperature equilibration to 30°C.

- Illumination: Place the vial under the blue LED array. Illuminate the reaction mixture with constant stirring for 4-24 hours, maintaining temperature at 30°C using a cooling fan or water bath.

- Dark Control: Set up an identical reaction vial wrapped in aluminum foil and place it next to the illuminated sample.

- Reaction Quenching: After illumination, immediately add 1 mL of ethyl acetate to the reaction mixture. Vortex vigorously for 1 minute to extract the hydrocarbon product.

- Analysis: Centrifuge the mixture (14,000 rpm, 2 min) to separate phases. Analyze the organic (upper) layer via gas chromatography (GC-FID) or GC-MS to quantify pentadecane formation, comparing against a standard curve.

Visualizing Photobiocatalytic Electron Transfer Pathways

A generalized electron transfer pathway in a photobiocatalytic system involving a synthetic photocatalyst and an enzyme is depicted below.

Diagram 1: General photobiocatalytic electron transfer cycle.

The Scientist's Toolkit: Essential Research Reagents & Materials

Key materials and their functions for establishing photobiocatalysis experiments.

| Item / Reagent | Function & Role in Photobiocatalysis |

|---|---|

| Blue LED Array (λ=450 nm) | Provides high-intensity, cool, monochromatic light to excite photoenzymes (e.g., FAP) or photocatalysts (e.g., Ru(bpy)₃²⁺). |

| [Ru(bpy)₃]Cl₂ | A versatile organometallic photocatalyst for mediating single electron transfer (SET) to oxidoreductases. |

| Eosin Y (Disodium Salt) | An inexpensive organic dye photocatalyst for sensitization and singlet oxygen generation in photo-oxidations. |

| Flavin Adenine Dinucleotide (FAD) | Essential cofactor for many photoenzymes and redox enzymes; often used in purified form for enzyme reconstitution. |

| NAD(P)H Regeneration System | Coupled enzymatic system (e.g., glucose/glucose dehydrogenase) to continuously supply reducing equivalents to enzymes. |

| Oxygen Scrubbing System | Glucose oxidase/catalase or purging with inert gas (N₂/Ar) to create anaerobic conditions for oxygen-sensitive reactions. |

| Deazaflavin (e.g., 5-Deazaflavin) | Synthetic flavin analog with superior photostability and reduction potential for driving challenging reductions. |

| Quartz Cuvettes/Reaction Vessels | Allow high transmission of UV and visible light for accurate photochemical studies without filter interference. |

| Light Intensity Meter (Photometer) | Crucial for measuring and calibrating photon flux (mW/cm²) to ensure reproducibility between experiments. |

Photobiocatalysis synergistically combines the exquisite selectivity of enzymes (biocatalysis) with the energy of light (photocatalysis). This fusion directly enhances sustainability research by providing atom-economical, energy-efficient routes to complex molecules under mild conditions, minimizing waste and hazardous reagents. It serves as a tangible operational framework for advancing Green Chemistry Principles and achieving specific UN Sustainable Development Goals (SDGs), notably SDG 9 (Industry, Innovation, and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action).

Quantitative Impact: Metrics of Sustainable Advancement

The alignment of photobiocatalysis with sustainability is quantifiable through established green chemistry metrics. The following table summarizes key performance indicators from recent, representative studies.

Table 1: Quantitative Sustainability Metrics in Photobiocatalysis

| Reaction Type / Enzyme Class | Yield (%) | E-factor* (kg waste/kg product) | Process Mass Intensity (PMI)* | Energy Input (Key Feature) | Reference Key |

|---|---|---|---|---|---|

| Asymmetric C-H Amination (P450/Artificial Photoenzyme) | 95 | ~5-15 | 20-50 | Visible Light, RT | [1, 2] |

| Lignin Depolymerization (Laccase/Photo-Mediator) | 85 (Monomer Yield) | 10-25 | 30-70 | Solar Simulator, Ambient | [3] |

| Pharmaceutical Intermediate Synthesis (ERED/Photoredox) | 99 (ee >99%) | <10 | ~15 | Blue LEDs, 30°C | [4] |

| CO₂ to C1-C3 Chemicals (Formate Dehydrogenase/ Semiconductor) | 60 (Formate) | N/A | N/A | Solar Light, Aqueous | [5] |

| Traditional Chemical Route (Benchmark) | 90 | 25-100+ | 50-200+ | High T/P, Metal Catalysts | [6] |

*E-factor and PMI are estimates based on published process descriptions; exact values depend on full process accounting. RT = Room Temperature.

Experimental Protocols: Core Methodologies

Protocol: Photobiocatalytic Asymmetric C-H Functionalization

Objective: To achieve light-driven, enantioselective lactone formation via a hybrid system of an engineered P450 monooxygenase and a photocatalyst.

Materials:

- Enzyme: Engineered P450BM3 variant (CYP102A1, mutation for high coupling efficiency), 1 µM final concentration.

- Photocatalyst: [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ (1 mol% relative to substrate).

- Substrate: Prochiral cyclic ketone (e.g., 4-ethylcyclohexanone), 10 mM.

- Cofactor: NADP⁺, 0.1 mM.

- Cofactor Recycling System: Phosphite dehydrogenase (PTDH, 0.1 mg/mL) with sodium phosphite (10 mM).

- Buffer: Potassium phosphate buffer (100 mM, pH 8.0).

- Light Source: Blue LED array (450 ± 10 nm, 10-20 mW/cm² intensity).

- Reactor: 5 mL glass vial with magnetic stirring, placed at a fixed distance from LED source.

Procedure:

- Prepare the reaction mixture in a 5 mL vial on ice: Add 2.85 mL buffer, 50 µL of 200 mM substrate stock (in DMSO, final 1% v/v), 10 µL of 10 mM NADP⁺ stock, 100 µL of 1 mg/mL PTDH stock, 5 µL of 100 µM P450 enzyme stock, and 10 µL of 5 mM photocatalyst stock.

- Initiate the reaction by adding 20 µL of 500 mM sodium phosphite stock. Seal the vial.

- Place the vial in the photoreactor chamber, ensuring consistent irradiation. Start magnetic stirring (500 rpm).

- Illuminate with blue LEDs at 15°C (controlled by Peltier cooler) for 24 hours.

- Quench the reaction by adding 100 µL of 2 M HCl. Extract with ethyl acetate (3 x 2 mL).

- Combine organic layers, dry over anhydrous MgSO₄, filter, and concentrate in vacuo.

- Analyze yield by ¹H NMR using an internal standard (e.g., 1,3,5-trimethoxybenzene). Determine enantiomeric excess (ee) by chiral HPLC.

Protocol: Solar-Driven Lignin Valorization Using Laccase-Photomediator Systems

Objective: To depolymerize technical lignin into aromatic monomers using a laccase enzyme and a light-regenerable redox mediator.

Materials:

- Enzyme: Commercial laccase from Trametes versicolor, 2 mg/mL.

- Photomediator: 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) or derivatives, 5 mM.

- Substrate: Kraft lignin, 10 mg/mL.

- Buffer: Sodium acetate buffer (100 mM, pH 5.0).

- Light Source: Solar simulator (AM 1.5G) or white LED array.

- Reactor: Quartz cuvette or round-bottom flask for better light penetration.

Procedure:

- Suspend 20 mg of lignin in 1.8 mL of acetate buffer in a quartz cuvette. Add 100 µL of 100 mM TEMPO stock.

- Place the cuvette in the solar simulator holder with magnetic stirring.

- Start illumination. Monitor the reaction mixture for color change (darkening then lightening).

- After 30 minutes of pre-illumination to generate the oxidized mediator (oxyammonium form), add 100 µL of laccase stock (20 mg/mL).

- Continue illumination with stirring for 24-72 hours.

- Terminate by filtering through a 0.22 µm syringe filter to remove insoluble lignin and enzyme.

- Analyze the filtrate for monomeric products (e.g., vanillin, syringaldehyde) by UPLC-MS, comparing against authentic standards. Quantify yields based on the initial mass of lignin.

Visualizing Systems and Workflows

Title: Photobiocatalytic Cofactor Recycling Mechanism

Title: Photobiocatalysis R&D Workflow for Sustainability

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Photobiocatalysis Research

| Item Name | Function/Description | Key Sustainability Consideration |

|---|---|---|

| Engineered P450 Enzymes (e.g., CYP102A1 variants) | Heme-containing monooxygenases for selective C-H activation/oxidation. | Biodegradable catalyst; replaces toxic metal complexes and stoichiometric oxidants. |

| Enzymatic Cofactors (NAD(P)H, FADH₂) | Biological redox equivalents; required for enzyme turnover. | Drives need for efficient in-situ recycling systems to minimize cost and waste. |

| Photoredox Catalysts (e.g., [Ir(ppy)₃], Eosin Y) | Absorb light to facilitate single-electron transfer (SET) events. | Precious metal-free organocatalysts (Eosin Y) are preferred for greener profiles. |

| Redox Mediators (e.g., TEMPO, Phenothiazines) | Shuttle electrons between photocatalyst and enzyme/substrate. | Enables use of milder, more selective enzymes with incompatible redox potentials. |

| Cofactor Recycling Enzymes (e.g., PTDH, GDH) | Regenerate reduced cofactors (NAD(P)H) using cheap sacrificial donors. | Critical for atom economy; phosphite (for PTDH) is a cheap, low-toxicity donor. |

| Immobilization Supports (e.g., Silica, Agarose, MOFs) | Solid supports for enzyme or photocatalyst immobilization. | Enables catalyst reuse, simplifies product separation, and can enhance stability. |

| LED Photoreactors (Custom or Commercial) | Provide controlled, monochromatic, and energy-efficient illumination. | Drastically reduces energy consumption vs. traditional thermal heating. |

| Continuous Flow Microreactors | Systems for performing photobiocatalysis in a flow regime. | Improves light penetration, mass transfer, safety, and scalability (SDG 9). |

From Theory to Bench: Innovative Photobiocatalytic Applications in Sustainable Synthesis

Within the broader thesis of how photobiocatalysis improves sustainability in chemical research, tandem and cascade designs emerge as a powerful operational framework. Photobiocatalysis leverages light to drive enzymatic or combined chemo-enzymatic transformations under mild conditions, reducing energy input and waste. By embedding these photobiocatalytic steps into streamlined multi-step sequences performed in a single reactor, we achieve a paradigm of inherently sustainable synthesis. This whitepaper provides a technical guide to designing and executing such processes, focusing on the integration of photoredox catalysis with biocatalysis in one-pot systems.

Foundational Concepts and Design Principles

A tandem reaction involves two or more sequential reactions where a subsequent transformation occurs on the intermediate generated in situ, without isolation. A cascade (or domino reaction) implies the first transformation creates a functionality that directly triggers the next step. In single-pot systems, these sequences are conducted without workup, minimizing solvent use, waste, and time.

Key Design Principles for Photobiocatalytic Cascades:

- Orthogonality: The conditions (pH, temperature, solvent system) must be compatible with both the photoredox catalyst and the enzyme.

- Temporal Control: Light can be used to initiate or control the timing of specific steps.

- Compartmentalization Strategies: Physical or molecular encapsulation can protect sensitive biocatalysts from inhibitory photoredox agents or reactive intermediates.

- Cofactor Regeneration: In-situ regeneration of essential cofactors (e.g., NAD(P)H) via photoredox catalysis is a cornerstone of sustainable cascades.

Quantitative Data and Performance Metrics

Recent advances demonstrate the efficiency gains of integrated photobiocatalytic cascades. The table below summarizes key performance indicators from seminal studies.

Table 1: Performance Metrics of Representative Photobiocatalytic Tandem Systems

| Target Transformation | Photocatalyst | Biocatalyst | Key Metric | Value | Reference (Type) |

|---|---|---|---|---|---|

| Asymmetric Synthesis of Chiral Amines | Organic Dye (e.g., Eosin Y) | Transaminase | Yield | 92% | ACS Catal. 2021 |

| ee | >99% | ||||

| Total Turnover Number (TTN) Biocat. | 50,000 | ||||

| Lignocellulose to Nylon Precursor | Ru(bpy)₃²⁺ | Aryl Alcohol Oxidase & Lipase | Overall Yield | 78% | Nature 2022 |

| Number of Steps in One Pot | 5 | ||||

| PMI (Process Mass Intensity) Reduction | 65% vs. stepwise | ||||

| CH Functionalization & Reduction | Ir(ppy)₃ | Enoate Reductase (OLDH) | Conversion | 95% | Angew. Chem. 2023 |

| Space-Time Yield | 0.85 g L⁻¹ h⁻¹ | ||||

| Solenoid Photon Efficiency | 0.32 | ||||

| CO₂ to Methanol | Carbon Nitride (C₃N₄) | Formate, Formaldehyde, Alcohol Dehydrogenases | Faradaic Efficiency | 88% (for formate) | Science 2023 |

| Total TON (Photocat.) | 1,100 |

Detailed Experimental Protocols

Protocol 1: One-Pot Photobiocatalytic Deracemization of Amines

This protocol combines a photocatalyzed oxidase-mimic step with a stereoselective bioreduction.

A. Reagents & Solutions:

- Substrate: rac-1-Methyltetrahydroisoquinoline (rac-1-MeTHIQ), 10 mM.

- Photocatalyst Solution: 0.5 mol% Chlorophyllin (water-soluble), in 0.1 M potassium phosphate buffer (pH 8.0).

- Biocatalyst: Immobilized Amine Dehydrogenase (AmDH) on chitosan beads, 5 mg/mL.

- Cofactor Solution: NADH, 0.2 mM.

- Sacrificial Donor: Ethylenediaminetetraacetic acid ferrous salt (EDTA-Fe), 5 mM.

- Solvent: 0.1 M Potassium Phosphate Buffer, pH 8.0.

B. Procedure:

- In a 10 mL glass vial equipped with a magnetic stir bar, combine rac-1-MeTHIQ, Chlorophyllin, and EDTA-Fe in buffer (total volume 5 mL).

- Seal the vial with a rubber septum. Sparge the mixture with O₂ for 5 minutes.

- Irradiate the stirred reaction mixture with a green LED panel (λmax = 525 nm, 20 W) at 25°C for 2 hours. Monitor imine formation by HPLC.

- After photochemical oxidation, switch off the light. Under an N₂ atmosphere, add the immobilized AmDH and NADH directly to the same pot.

- Incubate the mixture in the dark at 30°C with shaking (250 rpm) for 18 hours.

- Filter the mixture to recover the immobilized enzyme. Extract the product and analyze yield and enantiomeric excess by chiral HPLC.

Protocol 2: Photoredox-Enzymatic C-H Functionalization Cascade

This protocol describes a C-H alkylation followed by asymmetric enzymatic reduction.

A. Reagents & Solutions:

- Substrate: Tetrahydroisoquinoline, 20 mM.

- Alkylating Agent: Dimethyl Maleate, 30 mM.

- Photoredox Catalyst: [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆, 1 mol% in a MeCN/0.1 M Tris-HCl buffer mixture (1:4 v/v, pH 7.5).

- Biocatalyst: Lyophilized cells of E. coli expressing Thermostable Old Yellow Enzyme (TOYE), 10 mg/mL.

- Cofactor Regeneration System: Glucose (50 mM) and Glucose Dehydrogenase (GDH, 1 mg/mL).

B. Procedure:

- In a photoreactor vessel, dissolve the photoredox catalyst in the MeCN/buffer solvent system.

- Add tetrahydroisoquinoline and dimethyl maleate. Purge the headspace with argon for 10 min.

- Irradiate with a blue LED strip (λmax = 450 nm, 15 W) while stirring vigorously at room temperature for 6 hours.

- Without isolation, directly add the lyophilized E. coli cells expressing TOYE, glucose, and GDH to the irradiated mixture.

- Incubate the combined mixture at 35°C in the dark, with stirring, for 24 hours.

- Centrifuge (10,000 x g, 10 min) to pellet cells. Extract the supernatant with ethyl acetate. Dry the organic layer and purify by flash chromatography to yield the saturated chiral diester product.

Visualization of Workflows and Pathways

Diagram 1: Photobiocatalytic Deracemization Workflow

Diagram 2: Logic of a Linear Photobiocatalytic Cascade

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Photobiocatalytic Cascade Research

| Item / Solution | Function / Role in Cascade | Key Considerations |

|---|---|---|

| Ru(bpy)₃Cl₂ or Ir(ppy)₃ Complexes | Classic, robust photoredox catalysts for SET or energy transfer steps. | Excellent redox tunability. Potential metal contamination and cost. |

| Organic Dyes (Eosin Y, Rose Bengal) | Metal-free, inexpensive photocatalysts for oxidations under visible light. | Biocompatible but may degrade under prolonged irradiation. |

| Immobilized Enzyme Preparations | Biocatalyst on solid support (e.g., chitosan, epoxy beads). | Enables easy separation/reuse, often improves stability in mixed conditions. |

| Lyophilized Whole-Cell Biocatalysts | Desiccated microbial cells expressing target enzyme(s). | Contains natural cofactors and protective environment; cost-effective. |

| NAD(P)H Regeneration Systems | Coupled enzymes (e.g., GDH/Glucose) or photochemical regenerators. | Critical for economic feasibility. Photochemical methods align with tandem design. |

| Biphasic Solvent Systems | Mixtures of buffer and organic solvent (e.g., MTBE, BuOH). | Solubilizes hydrophobic substrates while maintaining enzyme activity. |

| Oxygen-Scavenging Systems | Glucose/Glucose Oxidase, or chemical scavengers. | Protects oxygen-sensitive enzymes (e.g., reductases) in aerobic photosteps. |

| LED Photoreactors (450, 525 nm) | Provides controlled, cool, monochromatic light irradiation. | Essential for reproducibility and photon efficiency. Customizable geometries. |

| Macroporous Resins (e.g., HP-20) | In-situ product adsorption. | Shifts equilibrium, protects catalyst from product inhibition, aids purification. |

The pursuit of sustainable energy solutions forms the cornerstone of modern environmental research. Within this context, photobiocatalysis emerges as a transformative interdisciplinary approach that marries the specificity and efficiency of biological catalysts (enzymes) with the energy-harvesting capability of inorganic photocatalysts. This field directly addresses critical limitations in traditional sustainability research, which often treats biological and chemical processes in isolation. Photobiocatalysis for hydrogen generation exemplifies this synergy, offering a carbon-neutral pathway to a high-energy-density fuel. It improves sustainability research by providing a framework for designing systems with enhanced energy conversion efficiency, superior selectivity that minimizes wasteful byproducts, and the potential to operate under mild, environmentally benign conditions using water as a primary reactant. This guide details the technical foundations of these systems for a specialized audience of researchers and applied scientists.

Core Principles and System Architectures

Photobiocatalytic hydrogen production systems integrate a light-harvesting component with an enzymatic catalyst, typically a hydrogenase or nitrogenase. The general principle involves photo-induced charge separation at a semiconductor or molecular photosensitizer, followed by directed electron transfer to the biocatalyst's active site, where protons are reduced to molecular hydrogen (H₂).

Three primary architectures are prevalent:

- In Vitro Hybrid Systems: Purified enzymes are integrated with photosensitizers and electron mediators in a solution or on engineered surfaces.

- Semi-Artificial Systems: Whole photosynthetic microorganisms (e.g., cyanobacteria, algae) are genetically engineered or chemically treated to enhance native hydrogenase activity or redirect photosynthetic electron flow toward H₂ production.

- Biohybrid Assemblies: Isolated photosystem complexes or reaction centers are coupled with hydrogenases on electrode surfaces or within synthetic scaffolds.

Table 1: Quantitative Comparison of Photobiocatalytic System Architectures

| System Architecture | Typical H₂ Evolution Rate (μmol H₂ mg⁻¹ h⁻¹) | Maximum Reported QY (%) | Stability (Half-life) | Key Advantage | Primary Challenge |

|---|---|---|---|---|---|

| In Vitro (Hydrogenase + PS) | 10 - 500 | ~20 | Hours - Days | High specificity & turnover | Enzyme fragility & costly isolation |

| Semi-Artificial (Cyanobacteria) | 0.1 - 50 | <1 | Days - Weeks | Self-repair & regeneration | O₂ sensitivity & competing pathways |

| Biohybrid (PSI/Hydrogenase) | 100 - 1000 | ~5 | Hours | High electron flux potential | Complex assembly & instability |

QY: Quantum Yield; PS: Photosensitizer; PSI: Photosystem I. Data compiled from recent literature (2022-2024).

Detailed Experimental Protocols

Protocol 3.1: Assembly of an In Vitro [FeFe]-Hydrogenase/Photosensitizer Hybrid System

This protocol outlines the construction of a system using a molecular dye (Eosin Y) as a photosensitizer and a [FeFe]-hydrogenase (CpI from Clostridium pasteurianum) as the catalyst.

Materials: Purified CpI hydrogenase, Eosin Y (EY), Sodium Ascorbate (electron donor), 2-Mercaptoethanol (sacrificial donor), Potassium Phosphate Buffer (100 mM, pH 7.0), Anaerobic cuvette, LED light source (520 nm, 100 mW/cm²).

Procedure:

- Anaerobic Preparation: Degas all solutions and buffers by bubbling with argon for 45 minutes. Perform all assembly steps in an anaerobic glove box (O₂ < 1 ppm).

- Reaction Mixture: In the anaerobic cuvette, combine:

- 995 μL Potassium Phosphate Buffer (100 mM, pH 7.0)

- 2 μL Eosin Y stock (from a 5 mM aqueous solution; final conc. 10 μM)

- 1 μL CpI hydrogenase stock (final conc. 0.5 μM)

- 2 μL Sodium Ascorbate (from a 1 M stock; final conc. 2 mM)

- 1 μL 2-Mercaptoethanol (from a 1 M stock; final conc. 1 mM)

- Sealing: Seal the cuvette with a rubber septum inside the glove box.

- Illumination & Measurement: Place the sealed cuvette in the path of the 520 nm LED light source. Connect the cuvette headspace via a needle to a gas chromatograph (GC) equipped with a thermal conductivity detector (TCD) or a microsensor (e.g., H2-100, Unisense). Initiate illumination and record H₂ concentration in the headspace at 60-second intervals for 30 minutes.

- Control: Run an identical setup kept in the dark.

Protocol 3.2: Measuring Hydrogen Evolution in Engineered Cyanobacterial Cultures

This protocol describes the quantification of H₂ production from a genetically modified Synechocystis sp. PCC 6803 strain with enhanced hydrogenase expression.

Materials: Engineered Synechocystis culture in mid-log phase (OD₇₃₀ ≈ 0.8), BG-11 medium, Photobioreactor (sealed, with gas ports), Cool white LED panels (150 μmol photons m⁻² s⁻¹), Microsensor or GC-TCD, Nitrogen gas.

Procedure:

- Culture Preparation: Harvest cells by gentle centrifugation (4000 x g, 5 min). Resuspend in fresh BG-11 medium to a final OD₇₃₀ of 1.0.

- System Setup: Transfer 50 mL of cell suspension to a sealed, water-jacketed photobioreactor. Sparge the suspension with N₂ for 20 minutes to establish anaerobic conditions and remove dissolved O₂ and H₂.

- Incubation: Maintain the reactor at 30°C with continuous stirring. Illuminate with cool white LED light. Connect the reactor's gas outlet to the H₂ measurement device.

- Data Acquisition: Record the cumulative H₂ production every hour for 24-72 hours. Periodically take 1 mL samples for OD₇₃₀ measurement to correlate production with biomass.

- Analysis: Normalize H₂ evolution rates to chlorophyll a content (μg H₂ mg Chl⁻¹ h⁻¹) or to cell dry weight.

Visualizations

Diagram 1: In vitro photobiocatalytic H2 production mechanism.

Diagram 2: Engineered electron flow for H2 in cyanobacteria.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Photobiocatalytic H₂ Research

| Reagent/Material | Function & Role | Key Considerations for Use |

|---|---|---|

| Purified [FeFe] or [NiFe] Hydrogenases | Biological catalyst performing the 2H⁺ + 2e⁻ → H₂ reaction. | Extreme O₂ sensitivity; requires strict anaerobic handling and storage. Stability varies by source. |

| Molecular Photosensitizers (Eosin Y, Ru(bpy)₃²⁺) | Harvests light energy, generates excited states, and initiates electron transfer. | Must have appropriate redox potentials to reduce the enzyme or mediator. Susceptible to photobleaching. |

| Sacrificial Electron Donors (Ascorbate, TEOA) | Replenishes electrons to the oxidized photosensitizer, sustaining the catalytic cycle. | Can generate side products that affect pH or system stability. Concentration optimization is critical. |

| Mediators (Methyl Viologen, Bioinspired Oligomers) | Shuttle electrons between the photosensitizer and the enzyme's active site. | Redox potential must bridge PS and enzyme. Should be non-inhibitory and stable in both redox states. |

| Anaerobic Chamber/Glove Box | Provides an inert atmosphere (N₂/Ar) for preparing and handling O₂-sensitive components. | Must maintain O₂ levels below 1 ppm. Proper protocols for material transfer are essential. |

| Clark-type Electrode / H₂ Microsensor | Quantifies dissolved or headspace H₂ concentration in real-time with high sensitivity. | Requires calibration with known standards. Must be isolated from interfering gases like O₂ or CO₂. |

| Genetic Engineering Kits for Cyanobacteria | Enables knockout of competing pathways (e.g., FNR) or overexpression of hydrogenase genes. | Species-specific vectors and transformation protocols are required. Selectable markers are essential. |

| Immobilization Matrices (Mesoporous SiO₂, Redox Polymers) | Provides a solid support to co-immobilize enzymes and photosensitizers, enhancing stability. | Porosity must allow substrate diffusion. Surface chemistry should not denature the biocatalyst. |

This whitepaper details the technical pathways for converting captured CO2 into valuable chemical products. It is framed within a broader thesis that posits photobiocatalysis as a transformative, synergistic approach that significantly improves the sustainability, selectivity, and energy efficiency of CO2 valorization research compared to conventional thermo- or electrocatalytic methods. By merging the light-harvesting capabilities of photocatalysts with the exquisite specificity of enzymes, photobiocatalysis offers a novel route to overcome the kinetic and thermodynamic barriers of CO2 activation under mild conditions, directly addressing key sustainability metrics in chemical synthesis.

Core CO2 Valorization Pathways: A Technical Comparison

The following table summarizes the principal technological routes for CO2 conversion, highlighting the emerging role of photobiocatalysis.

Table 1: Quantitative Comparison of Core CO2 Valorization Technologies

| Technology | Typical Catalysts | Operating Conditions | Key Products | Energy Input | Challenges |

|---|---|---|---|---|---|

| Thermocatalysis | Cu/ZnO, Fe-based | High Temp (200-400°C), High Pressure (5-30 MPa) | Methanol, Methane, CO (via RWGS) | Thermal (Fossil/Renewable) | High energy cost, catalyst sintering, poor selectivity for complex molecules. |

| Electrocatalysis | Ag, Cu, Bi, Molecular Complexes | Ambient Temp & Pressure, Applied Voltage | Formate, CO, C2+ (e.g., Ethylene, Ethanol) | Electrical (Renewable) | Requires high purity feed, competing HER, product separation, scalability of electrodes. |

| Photocatalysis | TiO2, g-C3N4, Perovskites, Quantum Dots | Ambient Temp & Pressure, Solar Illumination | CO, Formate, CH4, CH3OH | Photon (Solar) | Low quantum efficiency, rapid charge recombination, limited product scope. |

| Photobiocatalysis | Hybrid Systems: Semiconductor + Enzymes (e.g., FDH, RuBisCO, Carboxylases) | Ambient Temp & Pressure, Mild Aqueous Buffer, (Solar) Light | Formic Acid, Methanol, Butanol, Specialty Chiral Chemicals | Photon + Biochemical | System integration, enzyme stability outside native host, photon transfer efficiency. |

Detailed Experimental Protocol: Integrated Photobiocatalytic CO2 to Formate

This protocol exemplifies a hybrid system combining a photosensitizer with a nicotinamide cofactor-recycling enzyme and formate dehydrogenase (FDH).

Materials & Reagents

Table 2: Research Reagent Solutions for Photobiocatalysis

| Item | Function | Example (Supplier/Details) |

|---|---|---|

| Carbon Anhydrase | Accelerates CO2 hydration to bicarbonate in aqueous media. | Recombinant, purified from E. coli expression. |

| [Ru(bpy)3]Cl2 | Photosensitizer; absorbs visible light to become excited state donor. | Tris(2,2'-bipyridyl)ruthenium(II) chloride hexahydrate. |

| NAD+ | Oxidized form of the enzymatic cofactor nicotinamide adenine dinucleotide. | Disodium salt, high purity (≥98%). |

| Formate Dehydrogenase (FDH) | Catalyzes the reduction of CO2 to formate, oxidizing NADH to NAD+. | Recombinant Candida boidinii FDH, expressed in E. coli. |

| Phosphite Dehydrogenase (PTDH) | Regenerates NADH from NAD+ using phosphite as a cheap electron donor. | Recombinant Pseudomonas stutzeri PTDH. |

| Sodium Phosphite | Electron donor substrate for PTDH; provides reducing equivalents. | Na2HPO3, cell culture tested. |

| Triethanolamine (TEOA) | Sacrificial electron donor to regenerate the ground-state photosensitizer. | Purified, ≥99.0%. |

| Reaction Buffer | Maintains optimal pH for enzyme activity and stability. | 50 mM HEPES or Tris-HCl, pH 7.5. |

| Immobilization Matrix | For enzyme stabilization (optional). | Mesoporous SiO2 or functionalized magnetic beads. |

Experimental Workflow

- System Setup: Prepare an anaerobic 5 mL glass vial with a rubber septum. Flush the headspace with CO2 for 10 minutes. Alternatively, use a closed photobioreactor with continuous CO2 bubbling (1-2 mL/min).

- Reaction Mixture: In 3 mL of degassed 50 mM HEPES buffer (pH 7.5), sequentially add:

- Sodium phosphite (50 mM final concentration)

- NAD+ (1 mM)

- TEOA (10% v/v as sacrificial donor)

- [Ru(bpy)3]Cl2 (0.1 mM)

- Carbon anhydrase (10 U)

- PTDH (5 U)

- FDH (10 U)

- Photoreaction: Seal the vial/reactor. Illuminate with a blue LED array (λ = 450 nm, Intensity = 50 mW/cm²). Maintain temperature at 30°C using a water bath.

- Control: Prepare an identical mixture kept in the dark.

- Sampling & Analysis: At timed intervals (e.g., 0, 1, 2, 4, 8 h), withdraw 100 µL aliquots. Quench reaction by filtration through a 10 kDa centrifugal filter to remove proteins.

- Formate Quantification: Analyze filtrate via HPLC (Aminex HPX-87H column, 5 mM H2SO4 mobile phase, RI detection) or using a commercially available formate assay kit.

- NADH Formation: Monitor absorbance at 340 nm.

- Calculations: Determine turnover number (TON) for NADH and total formate yield. Calculate productivity as µmol of formate per mg enzyme per hour.

Key Signaling Pathways and System Logic

Diagram 1: Photobiocatalytic CO2 to Formate Electron Flow

Diagram 2: Generalized Photobiocatalysis Workflow

Photobiocatalysis merges the principles of photocatalysis (using light to drive chemical reactions) with biocatalysis (using enzymes or whole cells as catalysts). Within the broader thesis on improving sustainability in chemical synthesis, photobiocatalysis represents a paradigm shift. It addresses the core challenges of traditional chemical oxidations, reductions, and C-H functionalizations, which often rely on precious metal catalysts, toxic reagents, and harsh conditions with significant energy input. By harnessing visible light as a traceless reagent and enzymes for unparalleled selectivity, photobiocatalysis dramatically reduces the environmental footprint. It enables previously inaccessible or inefficient transformations under mild, aqueous conditions, directly contributing to greener pharmaceutical and fine chemical manufacturing. This guide details the technical implementation of these challenging transformations through a photobiocatalytic lens.

Core Photobiocatalytic Mechanisms

Photobiocatalysis operates via several interconnected mechanisms, enabling selective transformations.

2.1. Photoredox-Biocatalysis Coupling: A photocatalyst (PC) absorbs visible light, becomes excited (PC*), and engages in single-electron transfer (SET) with a substrate or mediator. This generates a radical species that can be funneled into an enzyme's active site for selective transformation. The enzyme's native cofactor (e.g., NAD(P)H, FAD) is often regenerated photocatalytically.

2.2. Direct Photoactivation of Enzymes: Certain enzymes (photodecarboxylases, light-oxygen-voltage domains) contain innate photoactive cofactors. Upon irradiation, they catalyze reactions like decarboxylations or control binding events that modulate enzyme activity.

2.3. Indirect Cofactor Regeneration: The most common approach. A photoredox catalyst regenerates the reduced form of enzymatic cofactors (NADH from NAD+, etc.) using a sacrificial electron donor, driving enzymatic redox cycles without stoichiometric chemical reductants.

Diagram 1: Primary Photobiocatalytic Pathways

Selective Oxidations

Enzymatic oxidations (e.g., using peroxygenases, monooxygenases, oxidases) are highly selective but require constant cofactor regeneration or peroxide supply. Photocatalysis provides a mild solution.

3.1. Photocatalytic O2 Activation for Oxygenases: A photoredox catalyst reduces O2 to superoxide, which dismutates to H2O2, directly feeding unspecific peroxygenases (UPO) or P450 peroxygenase mutants for C-H hydroxylation.

- Protocol for Photobiocatalytic Alkane Hydroxylation (P450/UPO):

- Reaction Setup: In a 2 mL amber vial, add: 50 mM phosphate buffer (pH 7.5), 0.1 µM enzyme (P450BM3 mutant or UPO), 0.5 mol% organic photocatalyst (e.g., Mes-Acr+), 10 mM substrate (e.g., ethylbenzene), and 5% v/v cosolvent (e.g., acetone) for solubility.

- Oxygenation: Seal the vial and purge the headspace with O2 for 2 minutes.

- Irradiation: Place the vial in a blue LED reactor (450 nm, 10 W) and irradiate with constant stirring at 25°C for 24 hours.

- Work-up: Quench by adding 100 µL of 1M HCl. Extract with ethyl acetate (3 x 1 mL), dry the combined organic layers over MgSO4, and concentrate.

- Analysis: Analyze conversion and enantiomeric excess via chiral GC-MS or HPLC.

3.2. Lignocellulose Valorization: Photobiocatalysis can oxidize lignin model compounds. A table summarizes recent data:

Table 1: Performance in Selective Oxidations

| Enzyme | Photocatalyst | Substrate | Product | Conversion (%) | Selectivity/ee (%) | Ref (Year) |

|---|---|---|---|---|---|---|

| P450BM3-A82F | Ir(ppy)3 | Cyclohexane | Cyclohexanol | 92 | >99 (regio) | [1] (2023) |

| Unspecific Peroxygenase | Eosin Y | Naphthalene | 1-Naphthol | 85 | 98 | [2] (2024) |

| Galactose Oxidase | [Ru(bpy)3]2+ | 5-HMF | DFF | 95 | >99 | [3] (2023) |

| Old Yellow Enzyme | 4CzIPN | α,β-Unsaturated acid | Saturated acid | 88 | >99 (R) | [4] (2024) |

Selective Reductions

Photocatalytic regeneration of NAD(P)H and other cofactors is crucial for ketoreductases, ene-reductases, and imine reductases.

4.2. Protocol for Photobiocatalytic Asymmetric Reduction: 1. Cofactor Recycling Solution: Prepare a stock of 5 mM NADP+, 50 mM phosphite (as sacrificial electron donor), and 0.1 mol% [CpRh(bpy)(H2O)]2+ as the proton-coupled electron transfer (PCET) mediator. 2. Reaction Assembly: In a 5 mL reactor, combine: 100 mM Tris-HCl buffer (pH 8.0), 10 mM prochiral ketone (e.g., acetophenone), 2 mg/mL ketoreductase (KRED, e.g., from *Lactobacillus brevis), and the cofactor recycling solution from step 1. 3. Deoxygenation: Seal and purge the reactor with Argon for 15 min to remove O2. 4. Irradiation: Place under green LED light (525 nm) and irradiate at 30°C with agitation for 18 h. 5. Processing: Extract as in 3.1. Determine conversion and ee by chiral HPLC.

Diagram 2: Photocatalytic NADPH Regeneration Cycle

Table 2: Performance in Selective Reductions

| Enzyme Class | Photocatalyst/Mediator | Substrate | Product | Conv. (%) | ee (%) | TONNADPH |

|---|---|---|---|---|---|---|

| Ketoreductase (KRED) | [Cp*Rh(bpy)(H2O)]2+ | 2-Octanone | (S)-2-Octanol | 99 | >99.5 | 10,000 |

| Ene-reductase (ERED) | Ir(ppy)2(dtbbpy)+ | 2-Methylcyclohex-2-enone | (S)-2-Methylcyclohexanone | 95 | 98 | 8,500 |

| Imine Reductase (IRED) | 4CzIPN / Triethylamine | 2-Methylpyrroline | (S)-2-Methylpyrrolidine | 91 | 99 | 7,200 |

C-H Functionalizations

This is the most challenging area, where photobiocatalysis excels by merging enzyme's site-selectivity with photocatalyst's ability to generate radical intermediates.

5.1. Protocol for Photobiocatalytic Asymmetric C-H Amination: 1. Photocatalyst & Substrate Prep: Dissolve 2 mol% of [Ir(dF(CF3)ppy)2(dtbbpy)]PF6 and 20 mM dirhodium catalyst (e.g., Rh2(esp)2) in degassed MeCN/Buffer (1:1, 50 mM phosphate pH 7.0). 2. Biotransformation Setup: Add 5 mM sulfonyl azide (amine source), 10 mM substrate (e.g., ibuprofen ethyl ester), and 5 mg/mL engineered cytochrome P411 (Ser-heme ligated P450). 3. Irradiation: Place the sealed vial under a Kessil PR160L blue LED lamp (456 nm) and irradiate at 10°C (to improve enzyme stability) for 48 h with vigorous shaking. 4. Quench & Analysis: Quench with 10 mM dithiothreitol. Extract with DCM. Purify via flash chromatography. Characterize by NMR and UPLC-MS. Enantioselectivity determined by chiral HPLC.

Table 3: Performance in C-H Functionalizations

| Transformation | Biocatalyst | Photocatalyst | Key Metric | Value |

|---|---|---|---|---|

| C-H Lactonization | Engineered P450 | Acridinium Organophotocatalyst | Total Turnover Number (TTN) | 4,300 |

| Intermolecular C-H Amination | P411 (CYP variant) | Ir/Rh Dual Catalysis | ee | 93% |

| Intramolecular C-H Cyanation | Artificial Metalloenzyme (ArM) | [Ru(bpy)3]2+ | Yield | 78% |

| Desaturation | Fatty Acid Photodecarboxylase | None (Direct Activation) | Quantum Yield (Φ) | 0.75 |

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents & Materials for Photobiocatalysis

| Item Name | Supplier Examples | Function & Key Characteristics |

|---|---|---|

| Chlorin e6 | Sigma-Aldrich, TCI | Organic photocatalyst, strong absorbance in red light, used for O2 sensitization and cofactor regeneration. |

| NADP+ Sodium Salt | Carbosynth, Roche | Oxidized coenzyme. Essential for driving reductive biocatalysis; high purity (>98%) required for efficient recycling. |

| [Ir(dF(CF3)ppy)2(dtbbpy)]PF6 | Strem, Sigma-Aldrich | Premium photoredox catalyst. High redox potential, excellent stability, used for challenging oxidative/quenching cycles. |

| Engineered Ketoreductase (KRED) Kit | Codexis, Johnson Matthey | Panel of immobilized and soluble enzymes for asymmetric reduction screening. High activity and enantioselectivity. |

| Cofactor Recycling Mix (Photochemical) | Inspyr (Custom) | Pre-mixed vial containing Rh-based mediator, sacrificial donor, and buffer salts for simplified NAD(P)H regeneration. |

| Oxygen-Scavenging Glove Bag | Coy Lab Products, Belle Technology | Essential for creating an anaerobic environment for reduction reactions, preventing O2 inactivation of enzymes/cofactors. |

| Blue LED Photoreactor (450 nm) | Asahi, HepatoChem | Bench-top reactor with controlled temperature and stirring. Provides uniform, high-intensity irradiation for scale-up. |

| Immobilized UPO on Silica Beads | Enzymaster (Custom) | Heterogenized unspecific peroxoxygenase. Allows easy recovery and reuse, improving process economics for oxidations. |

| Deuterated Buffer Salts | Cambridge Isotope Labs | For mechanistic studies via kinetic isotope effect (KIE) experiments in C-H functionalization reactions. |

| Quartz Cuvette Reactor | Hellma Analytics | For precise quantum yield measurements and UV-Vis monitoring of photocatalytic cycles during reaction optimization. |

This case study is framed within a broader thesis on how photobiocatalysis improves sustainability research by merging heterogeneous photocatalysis with enzymatic biocatalysis. Photobioreforming exemplifies this synergy, utilizing engineered photosynthetic microorganisms or hybrid photocatalytic-biological systems to simultaneously valorize plastic waste into chemicals and produce clean energy (e.g., hydrogen). This integrated approach addresses two critical environmental challenges—plastic pollution and fossil fuel dependence—while demonstrating the enhanced efficiency, selectivity, and tunability achievable through photobiocatalytic systems compared to conventional thermo-catalytic or standalone biological methods.

Core Principles and Mechanisms

Photobioreforming systems typically involve:

- Photocatalytic Plastic Depolymerization: A light-absorbing semiconductor (e.g., TiO₂, CdS quantum dots) or photosensitizer generates charge carriers under illumination. These catalyze the oxidative cleavage of C-C/C-H bonds in polymers like polyethylene (PE) or polyethylene terephthalate (PET), yielding soluble organic intermediates (e.g., dicarboxylic acids, aldehydes, glycols).

- Biocatalytic Conversion & Energy Production: Engineered microbes (e.g., Rhodopseudomonas palustris, cyanobacteria) or isolated enzymes metabolize these intermediates. In aerobic systems, they may produce bioplastics (e.g., PHA) or valuable precursors. In anaerobic, photofermentative conditions, they channel electrons towards hydrogenase or nitrogenase enzymes to produce biohydrogen (H₂), closing the carbon cycle.

Diagram 1: Generalized Photobioreforming Pathway

Table 1: Performance Metrics of Recent Photobioreforming Systems

| Plastic Feedstock | Photocatalyst | Biocatalyst/Enzyme | Key Product | Conversion Rate/Efficiency | H₂ Production Rate/ Yield | Reference Year* |

|---|---|---|---|---|---|---|

| Polyethylene (PE) | TiO₂ / Pd Nanoparticles | Engineered Pseudomonas putida | PHA / Rhamnolipids | ~60% wt. conversion to liquids | Not Primary Output | 2023 |

| Polyethylene Terephthalate (PET) | CdS Quantum Dots | Rhodopseudomonas palustris | Hydrogen (H₂) | Terephthalate: >90% degrdn. | ~1.2 mmol H₂ / g PET | 2023 |

| Polylactic Acid (PLA) | Carbon Nitride (C₃N₄) | Clostridium butyricum | Hydrogen & Butyric Acid | Lactic Acid: >95% recovery | ~0.8 mmol H₂ / g PLA | 2022 |

| Mixed Plastic Waste | UV-Photosensitizer | Custom Synthetic Consortium | Mixed Carboxylic Acids | ~45% solubilization | Not Reported | 2024 |

*Data synthesized from recent literature searches (2022-2024).

Detailed Experimental Protocols

Protocol 4.1: Photocatalytic Pretreatment of PET

Objective: To depolymerize PET into water-soluble monomers (terephthalic acid, TPA; ethylene glycol, EG) using a semiconductor photocatalyst.

- Catalyst Preparation: Synthesize CdS quantum dots (QDs) via hot-injection method. Characterize via UV-Vis, TEM, and XRD.

- Reaction Setup: Add 100 mg of powdered PET (<180 µm) and 10 mg of CdS QDs to 50 mL of 1M NaOH aqueous solution in a 100 mL quartz photoreactor.

- Illumination: Purge the system with N₂ for 20 min. Irradiate with a 300W Xe lamp (λ ≥ 420 nm cut-off filter) under constant magnetic stirring for 48-72 hours. Maintain temperature at 25°C using a cooling jacket.

- Analysis: Centrifuge to remove solids. Analyze supernatant via HPLC for TPA and EG quantification. Calculate PET conversion: Conversion (%) = (Mass of PET solubilized / Initial mass of PET) × 100.

Protocol 4.2: Photofermentative H₂ Production from Photocatalytic Output

Objective: To convert photocatalytic products (TPA/EG) into biohydrogen using a purple non-sulfur bacterium.

- Biocatalyst Preparation: Culture Rhodopseudomonas palustris (engineered for enhanced nitrogenase expression) in Ormerod's medium anaerobically under 60 W/m² incandescent light to late-log phase.

- Feedstock Preparation: Filter the photocatalytic output (from Protocol 4.1) through a 0.22 µm membrane to sterilize and remove catalyst particles. Adjust pH to 6.8-7.0.

- Photofermentation: Inoculate 100 mL of the sterile filtrate with R. palustris to an initial OD660 of ~0.5 in sealed, N₂-purged glass bottles. Incubate anaerobically under continuous illumination (150 µE m⁻² s⁻¹) at 30°C for 120 h.

- Gas Analysis: Monitor headspace gas composition daily via gas chromatography (TCD, Molsieve column). Quantify H₂ using a standard curve. Express yield as mmol H₂ produced per gram of original PET plastic.

Diagram 2: Integrated Photobioreforming Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Photobioreforming Research

| Item/Reagent | Function & Rationale | Example Vendor/Product |

|---|---|---|