Microwave-Assisted Organic Synthesis: Enhancing Reaction Yields and Efficiency in Drug Development

This article explores the transformative impact of Microwave-Assisted Organic Synthesis (MAOS) as a green and efficient methodology for chemical research and drug development.

Microwave-Assisted Organic Synthesis: Enhancing Reaction Yields and Efficiency in Drug Development

Abstract

This article explores the transformative impact of Microwave-Assisted Organic Synthesis (MAOS) as a green and efficient methodology for chemical research and drug development. Targeting researchers and pharmaceutical professionals, it covers the foundational principles of microwave heating, including dielectric mechanisms and thermal effects. The scope extends to practical methodologies for synthesizing nitrogen and oxygen heterocycles—crucial scaffolds in medicinal chemistry—alongside optimization strategies using factorial design. A critical comparative analysis demonstrates the superior performance of MAOS over conventional heating, highlighting significant reductions in reaction time, improvements in product yield, and enhanced energy efficiency. The article concludes by synthesizing key evidence and discussing future implications for accelerating sustainable pharmaceutical development.

Understanding Microwave Synthesis: Core Principles and Green Chemistry Advantages

Microwave-Assisted Organic Synthesis (MAOS) has emerged as a revolutionary tool in modern chemical research, particularly for drug development professionals seeking improved reaction yields and efficiency. The core principle underlying this technology is the unique conversion of electromagnetic energy into thermal energy through two fundamental mechanisms: dipolar polarization and ionic conduction [1] [2]. These mechanisms enable rapid, volumetric heating that often leads to significantly reduced reaction times, enhanced yields, and cleaner reaction profiles compared to conventional thermal methods [3].

When materials are exposed to microwave irradiation (typically at 2.45 GHz), their component molecules interact directly with the oscillating electric field, resulting in energy absorption and heat generation [1]. This direct energy transfer differentiates microwave heating from conventional conduction-based heating, where energy must transfer from the vessel surface inward. For researchers working on synthetic methodology development, understanding these fundamental mechanisms is crucial for optimizing reaction conditions, selecting appropriate solvents and catalysts, and designing novel synthetic routes with improved efficiency [2].

Theoretical Foundations

Dipolar Polarization

Dipolar polarization represents the primary heating mechanism for polar molecules subjected to microwave irradiation [4]. Molecules possessing a permanent dipole moment attempt to align themselves with the rapidly oscillating electric field (approximately 4.9 × 10^9 times per second at 2.45 GHz) [1]. This continuous reorientation creates molecular friction through collisions between neighboring molecules, generating heat throughout the material volume [5] [6].

The efficiency of dipolar polarization depends on several factors, including the dipole moment magnitude, molecular mobility, and the applied electric field frequency [1]. For a reagent to be effectively heated via this mechanism, it must possess a significant dipole moment and be sufficiently polarizable to respond to the field oscillations [4]. Common polar solvents such as water, methanol, DMF, and DMSO exhibit strong microwave absorption primarily through this mechanism [2].

Ionic Conduction

Ionic conduction provides a complementary heating mechanism that occurs when ionic species are present in the reaction mixture [5]. Under the influence of the microwave's electric field, dissolved charged particles (cations and anions) oscillate back and forth, accelerating through the medium and colliding with neighboring molecules [1] [6]. These collisions convert kinetic energy into thermal energy, effectively heating the solution [5].

This mechanism is particularly significant in reactions involving ionic reagents, salts, or ionic liquids [4]. The conduction mechanism typically generates heat more efficiently than dipolar polarization alone, which explains why electrolyte solutions often heat more rapidly than pure polar solvents under microwave irradiation [5] [6]. The intensity of this effect depends on factors such as ion charge, size, concentration, and mobility within the solution [5].

Combined Effects and Mathematical Relationships

In practical synthetic applications, both mechanisms often operate simultaneously, contributing to the overall heating effect [6]. The total microwave power dissipation per unit volume (P) can be described by the following equation, which incorporates contributions from both mechanisms [1] [6]:

P = ω·ε″eff·ε0·E²rms

Where:

- ω = angular frequency of microwave radiation

- ε″eff = effective dielectric loss factor

- ε0 = permittivity of free space

- E_rms = root mean square value of the electric field

The effective dielectric loss factor (ε″eff) encompasses both polarization and conduction effects, and can be expressed as [6]:

ε″eff = ε″dipolar + ε″interfacial + σ/ωε0

Where σ represents the ionic conductivity.

The interaction between these mechanisms and the resulting heating efficiency can be visualized through the following conceptual diagram:

Quantitative Analysis of Heating Effects

Ionic Concentration Effects

The relationship between ionic concentration and microwave heating efficiency has been systematically investigated [5]. Contrary to some assumptions, increasing ionic concentration does not always enhance heating; beyond certain thresholds, heating efficiency may actually decrease due to restricted molecular mobility and reduced penetration depth [5]. The following table summarizes experimental data obtained from exposing various chloride solutions to 2.45 GHz microwave radiation at 900 W for 40 seconds:

Table 1: Temperature Profiles of Alkali Metal Chloride Solutions (1M) After 40-Second Microwave Exposure

| Compound | Ionic Radius (Å) | Final Temperature (°C) | Temperature Difference from Water (°C) |

|---|---|---|---|

| H₂O (reference) | - | 40.0 | 0.0 |

| LiCl | 0.76 | 37.2 | -2.8 |

| NaCl | 1.02 | 34.5 | -5.5 |

| KCl | 1.38 | 32.8 | -7.2 |

| CsCl | 1.67 | 30.2 | -9.8 |

Data adapted from experimental results published by Shafique et al. [5]

The data demonstrates an inverse relationship between ionic size and final temperature, suggesting that larger ions with greater hydration spheres restrict water molecule mobility more effectively, thereby reducing heating efficiency [5].

Table 2: Temperature Profiles of Alkaline Earth Metal Chloride Solutions (1M)

| Compound | Ionic Radius (Å) | Final Temperature (°C) | Temperature Difference from Water (°C) |

|---|---|---|---|

| H₂O (reference) | - | 40.0 | 0.0 |

| MgCl₂ | 0.72 | 36.9 | -3.1 |

| CaCl₂ | 1.00 | 34.2 | -5.8 |

| SrCl₂ | 1.18 | 33.1 | -6.9 |

| BaCl₂ | 1.35 | 31.7 | -8.3 |

Data adapted from experimental results published by Shafique et al. [5]

The more pronounced temperature depression observed with divalent cations compared to monovalent cations highlights the significant influence of ion charge on heating efficiency, with higher charge densities leading to greater restriction of solvent dipole rotation [5].

Experimental Protocols

Protocol 1: Investigating Ionic Effects on Microwave Heating

Objective: To quantitatively evaluate the effect of different ions and concentrations on microwave heating efficiency.

Materials and Equipment:

- Modified domestic microwave oven (900 W, 2.45 GHz) with rotating turntable

- Polystyrene (PS) cups (100 mL capacity)

- Digital thermometers (2 units)

- Analytical balance

- Deionized water

- Chloride salts (LiCl, NaCl, KCl, CsCl, MgCl₂, CaCl₂, SrCl₂, BaCl₂)

- Volumetric flasks (100 mL)

- Pipettes and graduated cylinders

Procedure:

- Prepare aqueous solutions of each chloride salt at concentrations of 0.01, 0.025, 0.05, 0.1, 0.25, 0.5, and 1.0 mol/dm³ using deionized water.

- Place 100 mL of each test solution in a PS cup and position it on one arm of the rotating turntable.

- Simultaneously, place 100 mL of deionized water (reference) in an identical PS cup on the opposing turntable arm.

- Initiate turntable rotation (60 rpm recommended to ensure uniform exposure and eliminate hot spots).

- Expose both samples to full microwave power (900 W) for precisely 40 seconds.

- Immediately measure and record temperatures of both solutions using separate digital thermometers.

- Repeat each measurement in triplicate to ensure statistical significance.

- Calculate average temperature values and standard deviations for each concentration.

- Plot concentration versus temperature relationships for each salt to visualize heating trends.

Safety Considerations:

- Use thermal protection when handling heated samples

- Ensure proper ventilation in the workspace

- Avoid microwave operation with empty containers

- Use appropriate chemical handling procedures for salt solutions

Protocol 2: Solvent-Free Quinoline Synthesis via Microwave Irradiation

Objective: To demonstrate the application of microwave irradiation in the efficient synthesis of pharmaceutically relevant quinoline derivatives under solvent-free conditions.

Materials and Equipment:

- Dedicated microwave reactor with temperature and pressure monitoring capabilities

- YbCl₃ (catalyst)

- Propargylated-flavone or coumarin derivatives

- Various aldehydes and anilines

- Reaction vessels appropriate for microwave use

- Vacuum filtration apparatus

- Recrystallization equipment

- Analytical instruments (TLC, NMR, HPLC)

Procedure:

- Charge the microwave reaction vessel with propargylated-flavone or coumarin (1.0 mmol), aldehyde (1.0 mmol), aniline (1.0 mmol), and YbCl₃ catalyst (5 mol%).

- Secure the vessel in the microwave reactor and program the following method:

- Temperature: 100°C

- Time: 4 minutes

- Stirring: Continuous, high speed

- Initiate the microwave irradiation protocol.

- Upon completion and cooling, purify the crude product via recrystallization.

- Characterize the quinoline derivatives using appropriate analytical techniques (TLC, NMR, MS).

- Compare yield and purity with conventional thermal methods (typically 60 minutes at 100°C).

Expected Outcomes:

- Reaction time reduction from 60 minutes (conventional) to 4 minutes (microwave)

- Yield improvement typically ranging from 80-95%

- Enhanced atom economy (95%) and catalyst recyclability

- Cleaner reaction profile with reduced byproduct formation [3]

Research Reagent Solutions

Table 3: Essential Materials for Microwave-Assisted Organic Synthesis Experiments

| Reagent/Chemical | Function/Application | Specific Considerations |

|---|---|---|

| YbCl₃ (Ytterbium(III) chloride) | Lewis acid catalyst | Particularly effective for domino reactions under microwave conditions; recyclable [3] |

| Ionic liquids (e.g., [BMIM][BF₄]) | Green solvent/ catalyst | Excellent microwave absorbers via ionic conduction mechanism; low vapor pressure [4] |

| Polar solvents (DMF, DMSO, MeOH) | Reaction media | Effective for dipolar polarization heating; high dielectric loss factors [2] |

| Aqueous electrolyte solutions (NaCl, KCl) | Model systems for mechanism studies | Enable investigation of ionic conduction effects; concentration-dependent heating [5] |

| Propargylated flavones/coumarins | Substrates for heterocycle synthesis | Enable construction of complex molecular architectures under microwave conditions [3] |

| Various aldehydes and anilines | Building blocks for multicomponent reactions | Provide structural diversity in library synthesis for drug discovery [3] |

Applications in Drug Development

The fundamental understanding of dipolar polarization and ionic conduction mechanisms enables drug development professionals to strategically design synthetic routes that leverage the unique advantages of microwave irradiation [3] [2]. Specific applications include:

Rapid Library Synthesis: The dramatic reduction in reaction times (from hours to minutes) facilitates rapid generation of structure-activity relationship (SAR) data during lead optimization phases [3].

Green Chemistry Implementation: Solvent-free protocols and reduced energy consumption align with pharmaceutical industry initiatives toward sustainable manufacturing [2] [7].

Oxygen- and Nitrogen-Containing Heterocycles: Efficient synthesis of biologically relevant scaffolds including quinolines, pyrazolopyrimidines, coumarins, and isatin derivatives with demonstrated anti-cancer, anti-malarial, and anti-viral activities [3].

Challenging Transformations: Enhanced reaction rates and selectivity for transformations typically requiring harsh conditions or prolonged reaction times under conventional heating [3] [2].

The integration of microwave-assisted synthesis into drug discovery workflows represents a significant advancement in synthetic methodology, with the fundamental mechanisms of dipolar polarization and ionic conduction providing the theoretical foundation for continued innovation in this field.

Dielectric Heating vs. Conventional Conductive Heat Transfer

In the pursuit of efficiency and sustainability in organic synthesis, the heating methodology employed plays a pivotal role in determining reaction outcomes, energy consumption, and procedural safety. While conventional conductive heating has been the traditional mainstay of chemical laboratories for centuries, dielectric heating—encompassing microwave and radiofrequency techniques—has emerged as a transformative technology, particularly within the context of microwave-assisted organic synthesis (MAOS) for improved yields [8] [4]. This application note provides a detailed comparison of these two fundamental heat transfer mechanisms, offering structured quantitative data, executable experimental protocols, and practical guidance to enable researchers to leverage dielectric heating for enhanced synthetic efficiency.

Fundamental Mechanisms: A Comparative Analysis

Principles of Energy Transfer

Conventional Conductive Heating: This process relies on the superficial application of thermal energy and its inward propagation via conduction, convection, and radiation [9]. An external heat source (e.g., an oil bath or heating mantle) transfers thermal energy to the walls of the reaction vessel. This energy then migrates inward through the vessel material and into the reaction mixture by means of a temperature gradient, where the vessel surface is hotter than the reaction core [9]. The process is governed by the laws of conductive heat transfer, such as Fourier's law for a flat surface: ( Q = k \cdot \frac{A}{D} (TA - TB) ), where ( Q ) is the heat flow, ( k ) is the thermal conductivity of the material, ( A ) is the area, ( D ) is the thickness, and ( TA - TB ) is the temperature difference [10]. This method is characteristically slow and inefficient as it depends on the thermal conductivity of successive materials and often creates localized overheating at the vessel walls [9] [4].

Dielectric Heating: This mechanism involves the direct coupling of electromagnetic energy with materials capable of interacting with the electric field component [11] [9]. In the context of organic synthesis, the two primary mechanisms are:

- Dipolar Polarization: Molecules possessing a permanent dipole moment (e.g., water, DMF, ethanol) attempt to align themselves with a rapidly oscillating electric field (e.g., 2.45 GHz, corresponding to billions of oscillations per second). This molecular rotation causes intermolecular friction and collisions, resulting in volumetric heat generation [11] [9] [4].

- Ionic Conduction: Charged ions present in the reaction mixture accelerate under the influence of the electric field, colliding with neighboring molecules and converting their kinetic energy into heat [9]. The efficiency of this process increases with temperature [9].

Table 1: Fundamental Comparison of Heating Mechanisms

| Feature | Conventional Conductive Heating | Dielectric (Microwave) Heating |

|---|---|---|

| Energy Transfer | Indirect, via vessel walls | Direct, to the reaction mixture |

| Penetration Depth | Shallow, creates a temperature gradient | Deep, enables volumetric core heating [11] |

| Heating Rate | Slow (minutes to hours) | Rapid (seconds to minutes) [9] |

| Energy Efficiency | Lower (significant heat loss to surroundings) | Higher (focused energy absorption) [2] |

| Process Control | Inertial; slow to respond to changes | "Instant on-instant off"; precise and responsive [9] |

| Molecular Selectivity | Non-selective | Selective for polar molecules and ions [2] |

Quantitative Energy and Reaction Kinetics

The dramatic enhancement in reaction rates observed under microwave irradiation is primarily a kinetic phenomenon explained by the Arrhenius equation (( k = A e^{-Ea/RT} )) [9]. Microwave energy does not lower the activation energy (( Ea )) but provides rapid and efficient energy input to overcome it. This leads to a significant increase in the effective reaction temperature (( T )) instantaneously at the molecular level, far exceeding the measured bulk temperature [9].

Table 2: Impact of Instantaneous Temperature on Theoretical Reaction Rate Enhancement Assumptions: Bulk Temperature = 150°C, Activation Energy (Ea) = 50 kcal/mol [9]

| Instantaneous Temperature Increase | Final Instantaneous Temperature | Theoretical Rate Enhancement Factor |

|---|---|---|

| +17°C | 167°C | 10-fold |

| +35°C | 185°C | 100-fold |

| +56°C | 206°C | 1000-fold |

The energy provided by a standard 300 W microwave reactor (≈72 cal/sec) is vastly greater than the caloric requirement to drive a typical small-scale molecular transformation (≈5 calories), enabling these extreme rate accelerations [9].

Experimental Protocols for Microwave-Assisted Synthesis

The following protocol exemplifies the application of dielectric heating in a multi-component reaction, a common transformation in pharmaceutical research.

Protocol: Microwave-Assisted One-Pot Synthesis of Tetrahydro-pyrazoloquinolinones

This procedure, adapted from a published organic synthesis, demonstrates the synthesis of a complex N-heterocyclic scaffold relevant to drug discovery [12].

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Specification | Function/Rationale |

|---|---|---|

| Microwave Reactor | Single-mode (e.g., Biotage Initiator/Optimizer or CEM Discover) [12] | Provides controlled temperature/pressure monitoring and even field distribution for reproducibility. |

| Reaction Vials | 20 mL sealed Pyrex vials with pressure-resistant septa [12] | Withstand elevated temperatures and pressures generated during microwave irradiation. |

| Solvent: Anhydrous Ethanol | <0.2% water [12] | Polar solvent that efficiently couples with microwave energy via dipolar polarization. |

| Reagents | 5-Phenyl-1H-pyrazol-3-amine, 5,5-Dimethyl-1,3-cyclohexanedione, p-Tolualdehyde, Triethylamine [12] | Building blocks for the multi-component cascade reaction. |

| Safety Equipment | Lab coat, gloves, safety glasses, crimper/decapper | Mandatory for handling sealed vessels under pressure. |

Step-by-Step Workflow:

Charging the Vessel: In a dedicated 20 mL microwave process vial containing a magnetic stir bar, combine dry ethanol (10 mL), triethylamine (7.04 mmol, 1.6 equiv), 5-phenyl-1H-pyrazol-3-amine (4.40 mmol, 1.0 equiv), and 5,5-dimethyl-1,3-cyclohexanedione (4.40 mmol, 1.0 equiv). Stir vigorously for 2 minutes at room temperature to form a homogeneous solution [12].

Initiating the Reaction: Add p-tolualdehyde (4.40 mmol, 1.0 equiv) to the stirring solution [12].

Sealing and Securing: Tightly seal the vial with a Teflon septum and an aluminum crimp cap using a dedicated crimper [12].

- CAUTION: Sealed-vessel technology generates high internal pressure (7-15 bar). Use only vendor-approved vials and seals [12].

Microwave Irradiation: Transfer the sealed vial to the microwave reactor. Process the mixture at 150°C for 30 minutes with high absorption setting and active stirring [12]. The internal pressure will typically reach 10-12 bar.

Cooling and Depressurization: After irradiation, allow the instrument's gas-jet cooling system to bring the vial to below 50°C (approx. 5 minutes) before removing it from the cavity. Only decrimp and open the vial once it is safe to do so [12].

Work-up and Isolation: Transfer the reaction mixture to water and acidify to ~pH 2 with 6M HCl to precipitate the crude product. Isolate the solid via suction filtration, wash with water, and dry. Further purification is achieved via trituration and recrystallization from hot ethanol to yield the desired product as yellow crystals (46-50% yield) [12].

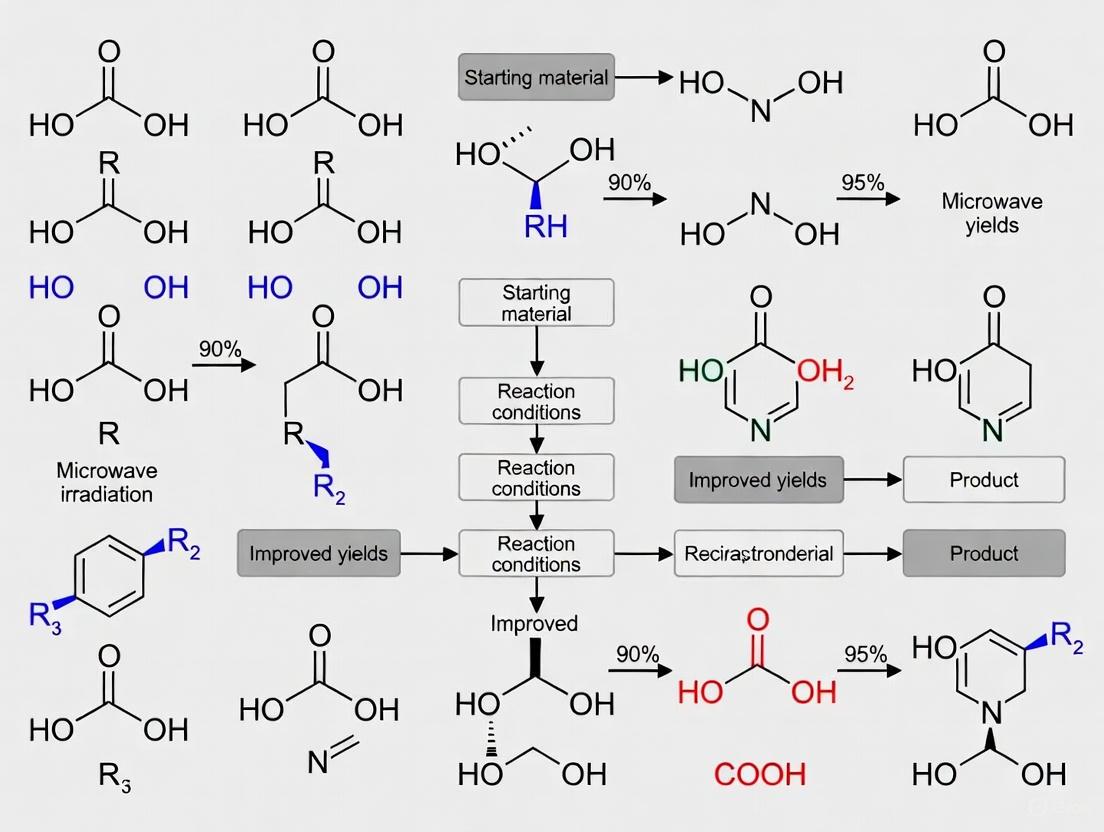

Figure 1: Experimental workflow for the microwave-assisted synthesis protocol.

Applications and Synergies in Organic Synthesis and Drug Discovery

Dielectric heating has proven particularly effective in accelerating a wide range of synthetic transformations critical to modern research.

Transition-Metal-Catalyzed Couplings: Reactions such as Suzuki, Heck, and Buchwald-Hartwig aminations often require hours or days under conventional heating. Microwave irradiation can reduce these times to minutes while frequently improving yields and allowing the use of less reactive aryl chlorides [8]. The inverted temperature gradient (core hotter than walls) may also reduce catalyst decomposition via "wall effects" [8].

Multi-Component Reactions (MCRs): The ability to rapidly and uniformly heat a mixture of reagents makes MAOS ideal for one-pot MCRs like the Mannich and Ugi reactions. This combination minimizes synthetic steps, reduces solvent consumption, and accelerates the generation of complex molecular libraries for drug discovery [8] [4].

Green Chemistry and Sustainability: MAOS aligns with multiple principles of green chemistry [2] [4]. It enables:

- Dramatic reduction in reaction times, lowering energy consumption.

- Improved atom economy through higher yields and fewer by-products.

- Use of solvent-free conditions or safer solvents like water.

- Prevention of waste by facilitating cleaner reaction profiles [2].

Strategic Implementation Guide

Choosing the appropriate heating method is critical for experimental success. The following diagram and table aid in this decision-making process.

Figure 2: Decision tree for selecting a heating methodology.

Table 3: Suitability Assessment of Heating Methods for Common Scenarios

| Synthetic Context or Goal | Recommended Method | Rationale |

|---|---|---|

| Rapid Reaction Screening & Optimization | Dielectric Heating | Unmatched speed enables testing of a vast parameter space (solvent, catalyst, temp) in a short time [8]. |

| Scaling Up Well-Understood Reactions | Conventional Heating | Established infrastructure and processes; capital cost of large-scale microwave reactors can be prohibitive. |

| Reactions with Polar/Ionic Intermediates | Dielectric Heating | Intermediates can couple directly with microwaves, providing a potential "specific microwave effect" [9]. |

| Reactions in Non-Polar Solvents (e.g., hexane) | Conventional Heating | Non-polar solvents are microwave-transparent, leading to inefficient heating unless polar reagents are present [2]. |

| Minimizing Environmental Impact | Dielectric Heating | Reduced energy consumption, less solvent use, and fewer by-products align with green chemistry principles [2] [4]. |

Dielectric heating represents a paradigm shift in synthetic methodology, moving beyond simple thermal acceleration to offer a fundamentally different mode of energy input. Its capacity for volumetric and selective heating translates into unparalleled reductions in reaction times, frequent improvements in yield and product purity, and the ability to perform previously inaccessible transformations. For researchers in drug development and organic synthesis, integrating microwave protocols as a standard tool—guided by the comparative data, experimental procedures, and strategic framework provided here—can significantly accelerate research cycles and contribute to more sustainable laboratory practices. While conventional heating remains suitable for many applications, dielectric heating is unequivocally the superior technology for enhancing synthetic efficiency and achieving improved yields in modern chemical research.

Microwave-assisted organic synthesis (MAOS) has emerged as a cornerstone of modern green chemistry, directly supporting its core principles through enhanced atom economy and significant reduction of chemical waste [2] [4]. This synergistic combination addresses two of the most critical environmental challenges in conventional synthesis: inefficient material utilization and substantial waste generation [13]. By enabling rapid, selective heating through dielectric mechanisms, microwave irradiation transforms traditional reaction kinetics and pathways [2]. The resultant processes demonstrate superior sustainability profiles, achieving faster reaction rates, higher yields, and cleaner product profiles while minimizing energy consumption and hazardous byproducts [14]. This application note details how MAOS specifically advances atom economy and waste prevention, providing researchers with quantitative metrics, validated protocols, and practical implementation frameworks to integrate these green advantages into pharmaceutical and fine chemical development.

Quantitative Green Metrics in MAOS

Systematic evaluation using standardized green metrics demonstrates the significant advantages of microwave-assisted synthesis over conventional methods. The data, derived from fine chemical synthesis case studies, provides measurable evidence for improved sustainability [15].

Table 1: Comparative Green Metrics for Fine Chemical Synthesis

| Synthetic Process | Method | Atom Economy (AE) | Reaction Yield (ɛ) | Reaction Mass Efficiency (RME) | Overall Sustainability |

|---|---|---|---|---|---|

| Epoxidation of R-(+)-limonene | Conventional | 0.89 | 0.65 | 0.415 | Moderate |

| Florol via Isoprenol Cyclization | MAOS | 1.0 | 0.70 | 0.233 | Improved |

| Dihydrocarvone from Limonene-1,2-epoxide | MAOS | 1.0 | 0.63 | 0.63 | Excellent |

These metrics reveal that MAOS consistently achieves perfect atom economy (AE = 1.0), indicating that all reactant atoms are incorporated into the final product with minimal wasted material [15]. The enhanced reaction mass efficiency (RME) values, particularly for dihydrocarvone synthesis (RME = 0.63), demonstrate superior material utilization and reduced waste generation compared to conventional approaches [15].

Table 2: Green Chemistry Principles Addressed by MAOS

| Green Chemistry Principle | MAOS Implementation | Experimental Evidence |

|---|---|---|

| Waste Prevention | Sealed-vessel reactions eliminate cooling water waste; reduced byproducts [13]. | Zero wastewater from reflux cooling; 50-90% reduction in chemical waste [13] [4]. |

| Atom Economy | Shorter reaction times and improved yields maximize reactant incorporation [13]. | Perfect atom economy (AE=1.0) achieved in multiple catalytic processes [15]. |

| Reduced Energy Demand | Direct molecular heating vs. convective surface heating [2]. | Energy consumption reduced by factors of 10-100x compared to conventional heating [13]. |

| Safer Solvents & Auxiliaries | Enables solvent-free conditions or use of water, ethanol [2] [4]. | Successful synthesis of quinolines, coumarins in aqueous media or solvent-free [2]. |

| Catalysis | Enhanced catalyst efficiency and screening capabilities [13]. | Parallel screening of 96 catalysts in single experiment; reduced catalyst loading [13]. |

Experimental Protocols for MAOS

General Workflow for Microwave-Assisted Reactions

The following diagram illustrates the standardized workflow for performing microwave-assisted organic synthesis, highlighting key decision points and optimization parameters.

Protocol 1: Microwave-Assisted Esterification with Improved Atom Economy

Objective: Demonstrate efficient ester synthesis with enhanced atom economy and reduced waste compared to conventional Fischer esterification [14].

Reaction: Esterification of benzoic acid with n-butanol Green Chemistry Focus: Atom economy improvement, waste reduction, energy efficiency

Table 3: Research Reagent Solutions for Esterification Protocol

| Reagent/Material | Function | Green Chemistry Advantage |

|---|---|---|

| Benzoic Acid | Core carboxylic acid reactant | High purity minimizes byproducts |

| n-Butanol | Alcohol reactant & reaction medium | Serves dual purpose as reactant and solvent, reducing waste |

| p-Toluene Sulfonic Acid (PTSA) | Acid catalyst | Enables lower loading vs. conventional H₂SO₄ |

| Microwave Reactor Vessel | Sealed reaction container | Enables high-temperature operation without solvent loss |

Experimental Procedure:

- Reaction Mixture Preparation: Charge a 10-mL microwave vessel with benzoic acid (1.22 g, 10 mmol), n-butanol (7.4 mL, 80 mmol), and PTSA (0.17 g, 1 mmol) [14].

- Parameter Setup: Seal the vessel and place in the microwave reactor. Program the system for 140°C with dynamic power control (maximum 300 W) and vigorous stirring (600 rpm) [14].

- Reaction Execution: Irradiate for 5 minutes with real-time temperature and pressure monitoring. The rapid heating achieves completion in minutes versus hours under conventional reflux.

- Workup: Cool the reaction mixture to room temperature using compressed air. Dilute with ethyl acetate (15 mL) and wash with saturated NaHCO₃ solution (2 × 10 mL) to remove catalyst.

- Purification: Dry over anhydrous MgSO₄, filter, and concentrate under reduced pressure.

Green Metrics Analysis:

- Atom Economy: 88% (theoretical maximum for esterification)

- Experimental Yield: 95% vs. 64% conventional method [14]

- Time Savings: 5 minutes vs. 4-8 hours conventional

- Energy Reduction: >80% compared to conventional reflux

Protocol 2: Solvent-Free Heterocyclic Synthesis

Objective: Demonstrate waste-minimized synthesis of nitrogen heterocycles using solvent-free microwave conditions [16].

Reaction: Synthesis of 2-pyrazolines from chalcones Green Chemistry Focus: Solvent elimination, atom economy, reduced hazard

Table 4: Research Reagent Solutions for Heterocyclic Synthesis

| Reagent/Material | Function | Green Chemistry Advantage |

|---|---|---|

| Chalcone Derivative | Michael acceptor & reaction scaffold | Enables one-pot cyclization |

| Hydrazine Hydrate | Nitrogen source for heterocycle formation | Atom-economical incorporation into product |

| Polyethylene Glycol (PEG-400) | Green reaction medium & phase-transfer catalyst | Biodegradable, non-toxic alternative to organic solvents [16] |

| Microwave Vessel | Open or sealed container for neat reaction | Facilitates solvent-free conditions |

Experimental Procedure:

- Reaction Setup: In a microwave vessel, combine chalcone derivative (2.5 mmol) with hydrazine hydrate (3.0 mmol) and PEG-400 (2 mL) as green media [16].

- Optimized Conditions: Heat at 120°C for 3-5 minutes in the microwave reactor with medium stirring.

- Process Monitoring: Observe reaction progress through color change from yellow to colorless upon pyrazoline formation.

- Product Isolation: After cooling, add cold water (10 mL) to precipitate the product. Collect by filtration and wash with cold water.

- Purification: Recrystallize from ethanol-water mixture to obtain pure 2-pyrazoline derivatives.

Green Metrics Analysis:

- Solvent Waste Reduction: 100% elimination of volatile organic solvents

- Atom Economy: >90% for cyclization process

- Reaction Mass Efficiency: 70-85% range achieved

- Time Efficiency: 5 minutes vs. 2-6 hours conventional

Mechanisms of Green Improvement in MAOS

Scientific Basis for Enhanced Atom Economy

The following diagram illustrates the fundamental mechanisms through which microwave irradiation enhances atom economy and reduces waste at the molecular level.

Dielectric Heating and Selectivity

The green advantages of MAOS originate from its unique heating mechanism based on dipolar polarization and ionic conduction [2] [4]. Unlike conventional heating that relies on surface conduction, microwave energy penetrates and directly excites polar molecules throughout the reaction volume. This selective activation enables:

- Precise Energy Targeting: Polar reaction intermediates receive energy preferentially, driving desired pathways while minimizing decomposition side reactions [2].

- Suppressed Byproduct Formation: The rapid, uniform heating prevents localized hot spots that typically cause decomposition and byproduct generation [4].

- Enhanced Molecular Collisions: Increased molecular rotation and ion migration significantly elevate productive collision frequency without increasing thermal degradation [2].

Implementation Strategies

Reaction Selection and Optimization

Successful implementation for green chemistry outcomes requires strategic reaction selection and systematic optimization:

Ideal Candidate Reactions:

- Polar mechanisms with ionic or dipolar intermediates

- Reactions requiring elevated temperatures but sensitive to conventional heating gradients

- Processes hampered by slow kinetics under conventional conditions

- Transformations currently employing large solvent volumes or generating significant byproducts [2]

Optimization Framework:

- Dielectric Analysis: Evaluate solvent and reactant polarity through dielectric constant (ε') and loss tangent (tan δ) [2].

- Temperature Profiling: Identify optimal temperature range balancing reaction rate and selectivity.

- Time Reduction: Systematically reduce reaction time from conventional baseline while monitoring yield.

- Solvent Minimization: Evaluate solvent-free, aqueous, or green solvent alternatives [13].

Scaling Considerations

Translating laboratory-scale green metrics to industrial implementation requires strategic approaches:

Continuous Flow Systems: Microwave-assisted continuous-flow organic synthesis (MACOS) addresses penetration depth limitations while maintaining the green advantages of MAOS [14]. Continuous flow systems enable:

- Consistent Product Quality: Uniform reaction conditions throughout the process

- Improved Safety: Smaller reaction volumes at any given time

- Scale-Up Efficiency: Linear scaling through numbered-up parallel reactors [14]

Industrial Reactor Design: Advanced microwave cavity designs, including transmission-line short-circuited waveguide units, combine features of mono- and multimode systems for larger-scale applications while preserving energy efficiency [14].

Microwave-assisted organic synthesis represents a paradigm shift in sustainable chemical production, providing measurable improvements in atom economy and waste reduction while maintaining synthetic efficiency [2] [13]. The protocols and metrics detailed in this application note demonstrate that MAOS consistently delivers superior environmental performance across multiple reaction classes, from simple esterifications to complex heterocyclic formations [14] [16]. By implementing the standardized workflows and optimization strategies outlined, researchers can reliably achieve the dual green chemistry objectives of maximizing reactant incorporation into valuable products while minimizing waste generation [15]. As microwave reactor technology continues to advance, particularly in continuous-flow systems, these green advantages will become increasingly accessible at production scales, further establishing MAOS as an essential technology for sustainable pharmaceutical and fine chemical development [17] [14].

Microwave-Assisted Organic Synthesis (MAOS) has emerged as a revolutionary green chemistry approach that addresses significant limitations of conventional synthetic methods. Traditional organic synthesis techniques often involve excessive reaction times, high energy consumption, substantial solvent usage, and significant chemical waste generation [4]. In contrast, MAOS utilizes microwave irradiation to directly deliver energy to reaction mixtures, enabling more efficient molecular transformations that align with the twelve principles of green chemistry [4] [2]. This paradigm shift offers substantial improvements in energy efficiency, reaction speed, and safer chemical design, making it particularly valuable for pharmaceutical research and drug development where rapid, efficient, and environmentally benign synthesis is increasingly prioritized [2] [18]. The technique has evolved significantly since its first reported applications in 1986, with modern dedicated microwave reactors providing precise control over temperature, pressure, and power parameters [2].

Fundamental Mechanisms and Advantages

Principles of Microwave Heating

Microwave-assisted synthesis operates through fundamentally different heating mechanisms compared to conventional methods. Microwave energy, occupying the electromagnetic spectrum between 0.3-300 GHz, interacts with materials through two primary mechanisms:

- Dipolar Polarization: Molecules with permanent dipole moments align themselves with the oscillating electric field of microwave radiation, resulting in molecular rotation, collisions, and rapid heat generation through molecular friction [4].

- Ionic Conduction: Charged particles in solution undergo accelerated migration under the influence of the microwave electric field, converting kinetic energy into heat through increased collision frequency [4].

These mechanisms enable volumetric heating, where energy penetrates and heats the entire reaction mixture simultaneously rather than relying on conductive heat transfer from vessel walls [17] [19]. This direct energy delivery to molecular targets facilitates more efficient activation barriers and often reduces the overall activation energy (Ea) required for reactions [19].

Quantitative Advantages Over Conventional Methods

Table 1: Quantitative Comparison of Microwave-Assisted vs. Conventional Synthesis

| Parameter | Microwave-Assisted Synthesis | Conventional Methods | Improvement Factor |

|---|---|---|---|

| Reaction Time | Seconds to minutes [20] [21] | Hours to days [22] [19] | Up to 1000× faster [4] |

| Energy Consumption | Up to 75% reduction [22] | High (prolonged heating) | Significant reduction [19] |

| Reaction Yield | Often 84-90% or higher [21] | Typically lower | 10-30% improvement common |

| Solvent Usage | Minimal; often solvent-free or aqueous [2] | Substantial organic solvents | Drastic reduction [4] |

Table 2: Specific Examples of Microwave Synthesis Performance

| Application | Reaction Time (MW) | Conventional Time | Key Outcome |

|---|---|---|---|

| MOF-801 Synthesis | 45 seconds [20] | Several hours | Phase-pure nanocrystals [20] |

| MXene Production | 90 minutes [22] | Up to 40 hours | 75% energy reduction [22] |

| Schiff Base-Urea Hybrids | 10-17 minutes [21] | Several hours | 84-90% yield [21] |

| TaC Nanorods | 20 minutes [23] | Several hours | High-quality EMW absorbers [23] |

Experimental Protocols and Methodologies

General Microwave Synthesis Workflow

Protocol 1: Microwave-Assisted Synthesis of MOF-801

Application: Rapid synthesis of metal-organic frameworks for gas storage and separation [20].

Materials:

- Zirconium precursor (ZrCl₄ or ZrOCl₂·8H₂O)

- Fumaric acid (linker)

- N,N-Dimethylformamide (DMF) or formic acid

- Deionized water

- Teflon-lined microwave reaction vessel

Procedure:

- Reagent Preparation: Dissolve zirconium precursor (1 mmol) and fumaric acid (1.5 mmol) in a mixture of DMF (10 mL) and deionized water (1 mL) with sonication for 5 minutes.

- Vessel Loading: Transfer the homogeneous solution to a Teflon-lined microwave vessel, ensuring the fill level does not exceed 70% of total capacity.

- Reaction Parameters: Secure the vessel in the microwave reactor and program the system for:

- Temperature: 110°C

- Hold time: 45 seconds

- Stirring: Continuous at medium speed

- Irradiation: Initiate the microwave program at fixed frequency of 2.45 GHz.

- Post-processing: After automatic cooling to room temperature, carefully open the vessel and collect the white crystalline product by centrifugation.

- Purification: Wash the product three times with fresh DMF, then with methanol, and activate under vacuum at 120°C for 12 hours.

Key Advantages: This protocol demonstrates a remarkable reduction in synthesis time from conventional hydrothermal methods (typically 24 hours) to just 45 seconds while maintaining high phase purity, nanocrystal size (22 nm range), and excellent surface area (739.7 m²/g) [20].

Protocol 2: Microwave-Assisted Synthesis of Schiff Base-Urea Hybrids

Application: Efficient synthesis of pharmaceutical intermediates with anti-inflammatory activity [21].

Materials:

- 1-(2-(2-hydrazinyl-2-oxoethoxy)phenyl)-3-propylurea (1) (key intermediate)

- Substituted isatins or aromatic aldehydes

- Absolute ethanol (green solvent)

- Microwave-transparent glass vial (10-20 mL capacity)

- Silica gel for chromatography

Procedure:

- Reaction Setup: Combine intermediate 1 (1.0 mmol) with substituted isatin or aromatic aldehyde (1.1 mmol) in absolute ethanol (5 mL) in a microwave vial.

- Parameter Optimization: Cap the vial and place in the microwave reactor. Program the system with the following parameters:

- Temperature: 80°C

- Irradiation time: 10-17 minutes (monitor by TLC)

- Power: 150 W with continuous stirring

- Reaction Monitoring: Monitor reaction progress by TLC (ethyl acetate/hexane, 3:7) at 5-minute intervals.

- Workup Procedure: After completion, cool the reaction mixture to room temperature and concentrate under reduced pressure.

- Purification: Purify the crude product by silica gel column chromatography using gradient elution (ethyl acetate/hexane, 1:4 to 1:1).

- Characterization: Characterize the pure Schiff base-urea hybrids (compounds 2-13) by NMR, IR, and mass spectrometry.

Key Advantages: This green protocol achieves high yields (84-90%) in dramatically reduced time (10-17 minutes) compared to conventional heating, which typically requires several hours. The method demonstrates excellent selectivity and produces compounds with significant COX-2 inhibitory activity for anti-inflammatory applications [21].

The Researcher's Toolkit: Essential Reagents and Materials

Table 3: Essential Research Reagent Solutions for Microwave-Assisted Synthesis

| Reagent/Material | Function | Application Examples | Green Chemistry Considerations |

|---|---|---|---|

| Ionic Liquids | Microwave-absorbing solvents; catalysts | Nanomaterial synthesis, organic transformations [17] | Reusable, low vapor pressure, replace volatile organic compounds |

| Water | Green polar solvent | Organic synthesis, nanoparticle fabrication [2] | Non-toxic, renewable, inexpensive |

| Plant Extracts | Natural reducing/capping agents | Metallic nanoparticle synthesis [17] | Biodegradable, renewable feedstocks |

| Polar Solvents (EtOH, MeOH) | Efficient microwave absorption | General organic synthesis, condensation reactions [21] | Prefer ethanol over methanol for reduced toxicity |

| Solid-Supported Reagents | Heterogeneous catalysts | Various organic transformations [4] | Recyclable, easy separation from products |

| Metal-Organic Precursors | Nanomaterial building blocks | MOF synthesis, nanoparticle fabrication [20] [23] | Enable rapid crystallization at lower temperatures |

Sustainability and Green Chemistry Alignment

The alignment of microwave-assisted synthesis with green chemistry principles extends beyond laboratory efficiency to address broader sustainability goals. The technique directly supports multiple UN Sustainable Development Goals, including SDG 7 (Affordable and Clean Energy), SDG 9 (Industry, Innovation and Infrastructure), and SDG 12 (Responsible Consumption and Production) [17]. The significant reduction in energy consumption (up to 75% in MXene synthesis) and substantial decreases in reaction times contribute to a lower carbon footprint for chemical manufacturing processes [22]. Furthermore, the ability to use water, ionic liquids, or solvent-free conditions dramatically reduces the environmental impact associated with volatile organic solvents [2] [18]. The combination of rapid synthesis, improved yields, and reduced waste generation positions MAOS as a transformative technology for sustainable pharmaceutical development and industrial chemical production.

Microwave-assisted organic synthesis represents a paradigm shift in sustainable chemical methodology that effectively addresses the core advantages of energy efficiency, speed, and safer chemical design. The dramatic reductions in reaction time (up to 1000× faster) and energy consumption (up to 75% reduction), coupled with improved yields and selectivity, make this approach particularly valuable for drug discovery and development pipelines where rapid iteration is essential [22] [21]. The compatibility with green solvents, including water, ionic liquids, and bio-based solvents, along with opportunities for solvent-free reactions, aligns with the principles of safer chemical design [2] [18].

Future developments in MAOS will likely focus on scaling up the technology for industrial applications through continuous-flow microwave reactors, integrating artificial intelligence for reaction optimization, and further exploring non-thermal microwave effects that may enable previously inaccessible transformations [17] [19]. The integration of microwave synthesis with other sustainable technologies, such as biocatalysis and photocatalysis, presents exciting opportunities for developing hybrid systems with enhanced selectivity and efficiency [2] [18]. As the global chemical industry faces increasing pressure to adopt greener manufacturing processes, microwave-assisted synthesis stands poised to play a pivotal role in the transition toward more sustainable chemical production.

Microwave-assisted organic synthesis (MAOS) has revolutionized modern chemical research by providing a powerful tool for accelerating reaction rates, improving yields, and enhancing reproducibility. Within the framework of green chemistry, MAOS aligns with sustainable practices by reducing energy consumption, minimizing solvent use, and decreasing reaction times significantly compared to conventional heating methods [2]. The technology leverages microwave irradiation to deliver energy directly and volumetrically to reactants through dielectric heating mechanisms, primarily dipolar polarization and ionic conduction [4]. This direct energy transfer enables reactions to proceed at markedly accelerated rates—often reducing processes that require hours under conventional heating to mere minutes [2] [14].

The foundation of effective microwave chemistry lies in selecting appropriate reactor technology, with the primary distinction being between monomode and multimode systems. Monomode reactors feature compact cavities where microwave irradiation is focused directly onto a single reaction vessel, creating a high microwave field density that enables exceedingly fast heating rates [24]. In contrast, multimode reactors utilize larger cavities where microwaves reflect chaotically off the walls, creating multiple modes that interact with the cavity load, making them suitable for parallel reactions and larger-scale synthesis [24]. Understanding the operational characteristics, advantages, and limitations of each system is crucial for researchers aiming to optimize synthetic protocols within drug development and materials science applications.

Comparative Analysis: Monomode vs. Multimode Reactors

The selection between monomode and multimode microwave reactors represents a critical decision point in experimental design for microwave-assisted organic synthesis. Each system offers distinct advantages tailored to specific research applications and scalability requirements. The comparative performance characteristics of these systems are quantified in Table 1, providing researchers with objective data to inform equipment selection.

Table 1: Performance Comparison Between Monomode and Multimode Microwave Reactors

| Parameter | Monomode Reactors | Multimode Reactors |

|---|---|---|

| Cavity Design | Small, compact; irradiation focused on single vessel [24] | Large; chaotic microwave field distribution [24] |

| Maximum Scale | Typically up to 20 mL [24] | Up to 100 mL per vessel; parallel processing possible [24] |

| Heating Efficiency | High microwave field density for fast heating rates [24] | Lower power density; requires more power [25] |

| Field Uniformity | Well-defined, homogeneous field [14] | Less uniform; potential for hot/cold spots [25] |

| Primary Applications | Method development, reaction optimization, kinetic studies [24] | High-throughput screening, scale-up to multigram scale [24] |

| Throughput | Sequential reactions; often equipped with autosamplers [24] | Parallel synthesis; multiple vessels simultaneously [24] |

| Reproducibility | High due to controlled field distribution [25] | Variable in conventional systems; improved in modern reactors [14] |

The data reveals a clear application-based distinction between reactor types. Monomode systems excel in method development and reaction optimization where precise control, rapid heating, and reproducibility are paramount. The focused energy delivery in monomode reactors enables superior performance for investigating reaction kinetics and mechanism studies [14]. The high field density allows for efficient heating of small volume reactions (typically 0.3-20 mL), making them ideal for precious compounds or expensive catalysts during early-stage research [24].

Multimode reactors offer distinct advantages in applications requiring higher throughput or larger reaction scales. Their capacity to accommodate multiple vessels simultaneously makes them particularly valuable for reaction screening and parallel synthesis campaigns [24]. Modern multimode instruments can facilitate scale-up to multigram quantities (up to 100 mL per vessel), providing a crucial bridge between discovery and development phases [24]. However, this scalability comes with potential challenges in field uniformity, as the chaotic microwave distribution in larger cavities can create hot and cold spots, potentially affecting reproducibility if not properly managed [25]. Advanced multimode systems address this limitation through improved cavity design and mode stirrers to enhance field homogeneity [14].

Decision Framework for Reactor Selection

The choice between monomode and multimode microwave technology represents a strategic decision that significantly impacts research efficiency and outcomes. The following decision pathway provides a systematic approach for researchers to select the optimal reactor configuration based on specific experimental requirements and objectives.

Figure 1: Reactor Selection Decision Pathway. This flowchart provides a systematic approach for selecting between monomode and multimode microwave reactors based on research objectives, scale, and throughput requirements.

Application-Specific Selection Guidelines

The decision pathway in Figure 1 illustrates how research objectives should drive reactor selection. For method development and reaction optimization where precise control and reproducibility are critical, monomode reactors are unequivocally superior. Their focused energy delivery enables rapid heating and exact temperature control, facilitating efficient parameter optimization [24]. This makes them particularly valuable for establishing kinetic models and investigating reaction mechanisms where consistent, uniform heating is essential [14].

For applications demanding high-throughput screening or parallel synthesis, multimode reactors offer significant advantages. Their capacity to process multiple reactions simultaneously dramatically increases productivity during compound library generation [24]. When research objectives require scale-up to multigram quantities for further testing or development, multimode systems provide the necessary vessel capacity (up to 100 mL) while maintaining the benefits of microwave acceleration [24]. Modern multimode instruments have addressed historical limitations in reproducibility through improved cavity design and advanced temperature monitoring systems [14].

Experimental Protocols for Enhanced Synthesis

General Microwave-Assisted Reaction Setup

The following protocol outlines a standardized procedure for executing microwave-assisted organic synthesis, with specific considerations for both monomode and multimode platforms. This methodology is particularly applicable to the synthesis of heterocyclic compounds, which represent crucial scaffolds in pharmaceutical development [2].

Table 2: Essential Research Reagent Solutions for Microwave-Assisted Synthesis

| Reagent/Material | Function | Green Chemistry Considerations |

|---|---|---|

| Deep Eutectic Solvents (DES) | Green reaction medium [26] | Non-volatile, non-flammable, low toxicity, biodegradable |

| Polar Solvents (Water, DMSO, DMF) | Efficient microwave absorption [2] | Water is preferred for green synthesis; use minimal amounts of DMSO/DMF |

| Dimethyl Carbonate (DMC) | Green methylating agent [16] | Non-toxic, biodegradable alternative to methyl halides |

| Polyethylene Glycol (PEG) | Phase-transfer catalyst and solvent [16] | Reusable, non-toxic, environmentally benign |

| Ionic Liquids | Reaction medium and catalyst [16] | Negligible vapor pressure, recyclable, tunable properties |

| Solid-Supported Reagents | Heterogeneous catalysis [2] | Easy separation, recyclability, reduced waste |

Materials and Equipment:

- Monomode or multimode microwave reactor with temperature and pressure monitoring capabilities

- Appropriate microwave reaction vessels (sealed for high-pressure, open for atmospheric)

- Polar solvents or green alternatives (refer to Table 2 for recommendations)

- Magnetic stir bars compatible with microwave irradiation

- Personal protective equipment (heat-resistant gloves, safety glasses)

Procedure:

- Reaction Preparation: Weigh reagents and transfer to an appropriate microwave reaction vessel. For a typical optimization reaction in a monomode reactor, use 2-20 mL of solvent. Add a microwave-compatible stir bar to ensure efficient mixing during irradiation.

Solvent Selection: Prioritize green solvents from Table 2. Deep Eutectic Solvents (DES) are particularly recommended as they enable efficient microwave absorption while offering superior environmental profiles [26]. The polarity of the solvent system directly impacts microwave absorption efficiency—select solvents with high dielectric constants for optimal results [2].

Vessel Sealing: For reactions above the solvent boiling point, seal the reaction vessel according to manufacturer specifications. Ensure proper pressure seal integrity to prevent vessel failure during operation.

Parameter Programming: Input reaction parameters into the microwave reactor interface. For initial screening, program a temperature gradient method (e.g., 50°C to 150°C) with fixed irradiation time (5-10 minutes) to determine optimal conditions.

Reaction Execution: Start the irradiation protocol with simultaneous stirring. Modern instruments automatically adjust power output to maintain the desired temperature profile. Monitor temperature and pressure in real-time throughout the reaction.

Post-Reaction Processing: After completion and cooling, carefully vent sealed vessels if necessary. Transfer the reaction mixture for workup and analysis.

Reaction Analysis: Utilize appropriate analytical techniques (TLC, HPLC, NMR) to determine conversion and purity. Compare results against conventional thermal methods to quantify microwave enhancement.

Key Considerations:

- Scale-Up Strategy: When transferring from monomode (method development) to multimode (scale-up), maintain constant temperature and time parameters while adjusting power and vessel geometry accordingly [24].

- Safety Protocols: Never microwave metal containers or incompatible materials. Always operate within the prescribed temperature and pressure limits of the reaction vessels.

- Reproducibility: For consistent results in multimode systems, ensure consistent vessel positioning and load distribution within the cavity [25].

Case Study: Synthesis of 2-Aminobenzoxazoles via Metal-Free Microwave Conditions

This protocol demonstrates the application of microwave technology to metal-free organic synthesis, aligning with green chemistry principles for sustainable pharmaceutical development [16].

Traditional Method: Conventional synthesis employs Cu(OAc)₂ and K₂CO₃ to catalyze the reaction between o-aminophenol and benzonitrile, yielding approximately 75% with significant hazards to skin, eyes, and respiratory system [16].

Microwave-Optimized Method: The metal-free approach employs tetrabutylammonium iodide (TBAI) as catalyst with aqueous H₂O₂ or TBHP as co-oxidants at 80°C under microwave irradiation [16].

Procedure:

- Charge a microwave vessel with o-aminophenol (1.0 equiv), benzonitrile derivative (1.2 equiv), TBAI (10 mol%), and TBHP (1.5 equiv) in ethanol-water (3:1) mixture.

Seal the vessel and place in the microwave reactor. Heat at 80°C for 15 minutes with high stirring.

After cooling, dilute the mixture with water and extract with ethyl acetate. Concentrate the organic layer under reduced pressure.

Purify the crude product by recrystallization to afford 2-aminobenzoxazole derivatives in 82-97% yield [16].

Microwave Advantage: The microwave protocol completes the transformation in 15 minutes compared to several hours required by conventional methods, with significantly improved yields (82-97% vs. 75%) and eliminated transition metal contaminants [16].

Advanced Reactor Technologies and Future Directions

The evolution of microwave reactor technology continues to address limitations in heating uniformity, scalability, and energy efficiency. Recent innovations in planar microwave heating structures represent significant advancements beyond conventional cavity-based systems [27]. These technologies employ complementary split ring resonators (CSRRs) designed to operate at multiple frequencies (2, 4, 6, and 8 GHz), enabling frequency-specific optimization based on the dielectric properties of reaction mixtures [27]. This approach allows researchers to select heating frequencies that match the highest dielectric losses of specific solvents, dramatically improving heating efficiency compared to standard 2.45 GHz systems [27].

The scalability challenge inherent in microwave chemistry is being addressed through innovative reactor designs that maintain efficiency across different scales. The scalability of planar microwave heaters has been successfully demonstrated using power dividers and microwave switches, enabling parallel processing while conserving the benefits of focused microwave energy [27]. This numbering-up approach, rather than traditional scaling-up, provides a practical pathway for implementing microwave technology in industrial applications without sacrificing the kinetic advantages observed at laboratory scale [27].

Continuous-flow microwave reactors represent another significant advancement, particularly for industrial applications. These systems combine the benefits of microwave irradiation with continuous processing, overcoming the penetration depth limitations associated with batch systems [14]. Continuous-flow microreactors confine reactions to low-volume microfluidic structures, resulting in high mixing and heating rates while improving safety, controllability, and efficiency [27]. This technology has enabled the development of "kilolab" scale continuous-flow microwave systems that bridge the gap between laboratory research and industrial production [14].

Future directions in microwave reactor technology include enhanced integration with process analytical technologies (PAT) for real-time reaction monitoring, adaptive control systems that automatically optimize reaction parameters, and hybrid approaches combining microwave irradiation with other energy sources such as ultrasound or photochemistry [14]. These advancements will further establish microwave-assisted organic synthesis as an indispensable tool for sustainable chemical research and development across pharmaceutical, materials, and fine chemical industries.

Practical MAOS Strategies for Bioactive Heterocycle Synthesis

Nitrogen-containing heterocycles represent a cornerstone of modern organic chemistry, particularly in the development of pharmaceuticals and agrochemicals. Among these, triazoles, imidazoles, and quinolines stand out for their prevalence in biologically active molecules and materials science. This article details advanced protocols for the synthesis of these valuable heterocycles, framed within a thesis investigating microwave-assisted organic synthesis for improved reaction efficiency and yield. The application of microwave irradiation has revolutionized synthetic approaches to these compounds, typically offering dramatic reductions in reaction time alongside improvements in yield and purity compared to conventional thermal methods [28] [29] [30]. These protocols are designed for researchers, scientists, and drug development professionals seeking efficient, reproducible synthetic methods.

Application Notes & Protocols

Triazoles

Background and Significance: Triazoles, existing as 1,2,3- and 1,2,4-isomers, are five-membered heterocycles whose derivatives are invaluable in pharmaceutical chemistry, notably as antifungal agents [28] [31]. They are classified as "fine chemicals" and are often synthesized via "click chemistry," a powerful approach involving cycloaddition between azides and alkynes [32]. Microwave-assisted synthesis has emerged as a green and sustainable approach, offering benefits such as atom economy, reduced use of hazardous chemicals, and enhanced energy efficiency [28].

Quantitative Data Summary:

Table 1: Recent Advances in Microwave-Assisted Synthesis of Triazoles

| Triazole Type | Key Synthetic Feature | Comparative Advantage over Conventional Methods | Representative Yield | Reference |

|---|---|---|---|---|

| 1,2,3-Triazoles | Click Chemistry (CuAAC) | Shorter reaction times, high regioselectivity (1,4-disubstituted) | High Yields | [32] |

| 1,2,4-Triazoles | Microwave-assisted cyclization | Reduced reaction times, improved energy efficiency | High Yields | [28] |

| General Triazoles | Green synthesis approaches | Reduced hazardous chemicals, safer design, better atom economy | Not Specified | [28] |

Detailed Protocol: Microwave-Assisted Click Synthesis of 1,4-Disubstituted 1,2,3-Triazoles

This procedure is adapted from established methods in green chemistry [32].

- Reaction Setup: In a dedicated microwave vial, combine the organic azide (1.0 mmol) and the terminal alkyne (1.0 - 1.2 mmol).

- Catalyst and Solvent Addition: Add a mixture of tert-butanol and water (1:1, ~4 mL) as solvent. Introduce copper(II) sulfate pentahydrate (5 mol%) and sodium ascorbate (10 mol%) to the reaction mixture.

- Microwave Irradiation: Cap the vial and place it in the microwave reactor. Irradiate the mixture at a power of 100-150 W and a temperature of 80-100 °C for 5-15 minutes.

- Reaction Monitoring: Monitor reaction completion by TLC or LC-MS.

- Work-up Procedure: After cooling, pour the reaction mixture into water (15 mL) and extract with ethyl acetate (3 x 20 mL). Combine the organic layers, dry over anhydrous magnesium sulfate, and concentrate under reduced pressure.

- Purification: Purify the crude product by recrystallization or flash column chromatography to obtain the pure 1,4-disubstituted 1,2,3-triazole.

Imidazoles

Background and Significance: The imidazole scaffold is a fundamental structural unit in many therapeutic agents, exhibiting a wide range of biological activities including antibacterial, antifungal, and anti-inflammatory properties [29] [33]. Conventional synthesis often suffers from long reaction times and harsh conditions. Microwave irradiation has been successfully applied to overcome these limitations, particularly in multi-component reactions like the Debus-Radziszewski synthesis [29] [30].

Quantitative Data Summary:

Table 2: Optimized Conditions for Microwave-Assisted Synthesis of Polysubstituted Imidazoles

| Parameter | Protocol A: Green Cr₂O₃ NPs [29] | Protocol B: Factorial Design [30] |

|---|---|---|

| Catalyst | Ginger-synthesized Cr₂O₃ nanoparticles (15 mmol) | Not Specified |

| Solvent | H₂O | Not Specified |

| Microwave Power | 400 W | 720 W |

| Reaction Time | 4 – 9 minutes | 7 minutes |

| Yield Range | 89 – 98% | Up to 87% (optimized) |

Detailed Protocol: Green Synthesis of Polysubstituted Imidazoles using Cr₂O₃ Nanoparticles

This protocol utilizes bio-synthesized nanoparticles as a catalyst in water, representing an excellent example of a sustainable methodology [29].

- Reaction Mixture: In a microwave vessel, combine the aromatic aldehyde (1 mmol), benzil (1 mmol), ammonium acetate (3 mmol), and Cr₂O₃ nanoparticles (15 mmol) in water (2 mL).

- Microwave Irradiation: Subject the mixture to microwave irradiation at 400 W for 4-9 minutes (monitor by TLC).

- Work-up: After irradiation, cool the mixture in an ice bath. Filter the resulting solid under reduced pressure.

- Washing and Purification: Wash the solid thoroughly with water and dry. Recrystallize from ethanol to obtain the pure polysubstituted imidazole product.

The following workflow diagrams the experimental setup and optimization process for microwave-assisted imidazole synthesis:

Quinolines

Background and Significance: Quinoline derivatives are privileged structures in medicinal chemistry with demonstrated antimalarial, antiviral, and anticancer activities. They also find applications in material science due to their chemical stability and electronic properties [34]. Microwave-assisted protocols have been developed to streamline their synthesis, offering efficient pathways to polysubstituted frameworks.

Quantitative Data Summary:

Table 3: Methods for the Synthesis of Quinoline Derivatives

| Synthetic Method | Catalyst/System | Conditions | Key Outcome | Reference |

|---|---|---|---|---|

| Dimerization of 2-Aminoacetophenone | NaOH/DMSO Superbase | Room Temperature, 24h | 82% Yield | [34] |

| Skraup-type Reaction | Ni/Beta Zeolite | Microwave Irradiation | High Efficiency | [35] |

Detailed Protocol: Superbase-Promoted Synthesis of Polysubstituted Quinolines

This energy-efficient protocol operates at room temperature [34].

- Reaction Setup: In a round-bottom flask, dissolve 2-aminoacetophenone derivative (1 mmol) in anhydrous dimethyl sulfoxide (DMSO, 2 mL).

- Base Addition: Add sodium hydroxide (NaOH, 1 mmol) to the solution.

- Stirring: Stir the reaction mixture at room temperature for approximately 24 hours.

- Reaction Monitoring: Monitor the reaction progress by TLC.

- Work-up: Upon completion, quench the reaction by adding a saturated aqueous ammonium chloride solution.

- Extraction and Purification: Extract the aqueous mixture with ethyl acetate (3 x 20 mL). Combine the organic extracts, wash with brine, dry over anhydrous sodium sulfate, and concentrate. Purify the residue by flash column chromatography to isolate the desired polysubstituted quinoline.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents and Materials for Nitrogen Heterocycle Synthesis

| Reagent/Material | Function/Application | Example/Note |

|---|---|---|

| Cr₂O₃ Nanoparticles | Green Lewis Acid Catalyst | Synthesized via Zingiber officinal (ginger) extract; used in imidazole synthesis [29]. |

| Copper(II) Sulfate / Sodium Ascorbate | Catalytic System for Click Chemistry | Enables the Cu(I)-catalyzed Azide-Alkyne Cycloaddition (CuAAC) for 1,2,3-triazoles [32] [31]. |

| NaOH/DMSO System | Superbase Medium | Facilitates room-temperature dimerization of 2-aminoacetophenones to quinolines [34]. |

| Ammonium Acetate | Nitrogen Source | Key reactant in the Debus-Radziszewski synthesis of imidazoles [29] [30]. |

| Polar Aprotic Solvents (DMSO, DMF) | Reaction Medium | Essential for reactions like quinoline synthesis where solvent polarity influences yield [34]. |

| Beta Zeolite | Heterogeneous Catalyst | Used in high-efficiency, microwave-assisted quinoline synthesis [35]. |

The integration of microwave irradiation into the synthesis of nitrogen heterocycles provides a powerful tool for enhancing synthetic efficiency. The protocols outlined for triazoles, imidazoles, and quinolines demonstrate significant advantages, including drastically reduced reaction times, improved yields, and the facilitation of greener chemical processes. These Application Notes provide researchers with validated, detailed methodologies to advance their work in drug discovery and development, underscoring the critical role of microwave-assisted organic synthesis in modern chemical research.

The synthesis of oxygen heterocycles, particularly coumarins and pyran derivatives, represents a significant area of research in organic and medicinal chemistry due to their widespread presence in biologically active molecules and natural products. This document details application notes and protocols framed within a broader thesis on microwave-assisted organic synthesis (MAOS) for improved yields. Microwave irradiation has emerged as a powerful tool in synthetic chemistry, offering dramatic reductions in reaction times, enhanced reaction rates, improved yields, and superior purity profiles compared to conventional heating methods [36] [37]. The focus on coumarins and pyran derivatives is warranted by their privileged structures found in numerous pharmaceuticals, fragrances, and materials, exhibiting a broad spectrum of biological activities including antitumor, antimicrobial, anti-inflammatory, and antioxidant properties [38] [37] [39]. These protocols are designed for researchers, scientists, and drug development professionals seeking efficient, sustainable, and high-yielding synthetic routes.

Quantitative Data on Microwave-Assisted Synthesis

The advantages of microwave-assisted synthesis over conventional methods are quantitatively demonstrated in the tables below, highlighting enhanced efficiency and yield.

Table 1: Comparative Analysis: Microwave vs. Conventional Synthesis of Coumarin-Purine Hybrids [36]

| Compound Code | R-Substituent | Conventional Yield (%) | Microwave Yield (%) | Conventional Time (hours) | Microwave Time (minutes) |

|---|---|---|---|---|---|

| 3a | 6-CH₃ | 85 | 97 | 6.00 | 5 |

| 3b | 7-CH₃ | 84 | 96 | 6.00 | 6 |

| 3c | 5,6-benzo | 80 | 94 | 7.00 | 5 |

| 3f | 6-OCH₃ | 80 | 90 | 7.50 | 8 |

| 3g | 6-Cl | 75 | 90 | 8.00 | 9 |

| 3i | 7-OH | 74 | 90 | 7.50 | 5 |

Table 2: Microwave-Assisted Pechmann Condensation for Coumarin Synthesis using FeF₃ Catalyst [39]

| Phenol Substrate | Product Coumarin | Microwave Time (min) | Yield (%) | MP (°C, Observed) |

|---|---|---|---|---|

| Resorcinol | 7-hydroxy-4-methyl-2H-chromen-2-one | 7 | 95 | 185-188 |

| 1-Naphthol | 4-methyl-2H-benzo[h]chromen-2-one | 7 | 94 | 258-260 |

| 2-Naphthol | 4-methyl-2H-benzo[f]chromen-2-one? | 8 | 89 | 135-138 |

| m-Cresol | 5-methyl-4-methyl-2H-chromen-2-one? | 8 | 85 | 153-156 |

Table 3: Optimization of Microwave Power for Pechmann Condensation [39]

| Microwave Power (W) | Reaction Yield (%) |

|---|---|

| 0 (Conventional) | 26 |

| 100 | Data Not Specified |

| 250 | Data Not Specified |

| 300 | Data Not Specified |

| 450 | 95 |

| 600 | No Significant Change |

Experimental Protocols

Protocol 1: Microwave-Assisted Synthesis of Coumarin-Purine Hybrids

This protocol describes the nucleophilic substitution reaction for synthesizing 1,3-dimethyl-7-((substituted)-2-oxo-2H-chromen-4-yl)methyl)-1H-purine-2,6(3H,7H)-dione hybrids [36].

Reagents:

- 4-Bromomethylcoumarins (1, 1 mmol)

- 1,3-Dimethylpurine-2,6-dione (2, 1 mmol)

- Anhydrous potassium carbonate (K₂CO₃)

- Anhydrous acetone

Procedure:

- Reaction Mixture Preparation: In a dedicated microwave reaction vessel, combine the 4-bromomethylcoumarin derivative (1 mmol), 1,3-dimethylpurine-2,6-dione (1 mmol), and anhydrous potassium carbonate (acting as a base) in anhydrous acetone.

- Microwave Irradiation: Seal the vessel and place it in the microwave reactor. Irradiate the mixture at a power of 450 W for 5–9 minutes, monitoring the reaction by TLC. The specific time depends on the coumarin substituent (see Table 1).

- Work-up: After completion, allow the reaction mixture to cool to room temperature. Filter the mixture to remove inorganic salts.

- Isolation: Concentrate the filtrate under reduced pressure to obtain the crude product.

- Purification: The crude product typically possesses high purity and may be used directly without further complex purification. If necessary, recrystallization from a suitable solvent (e.g., ethanol) can be performed.

Protocol 2: Solvent-Free Microwave Pechmann Condensation for 4-Methylcoumarins

This protocol outlines a green chemistry approach for synthesizing 4-methylcoumarin derivatives using FeF₃ as a catalyst under solvent-free conditions [39].

Reagents:

- Phenol derivative (e.g., resorcinol, 1-naphthol, 1 mmol)

- Ethyl acetoacetate (1 mmol)

- Iron(III) Fluoride (FeF₃, 0.05 g)

Procedure:

- Grinding and Mixing: In a mortar, thoroughly mix the phenol substrate (1 mmol) and ethyl acetoacetate (1 mmol) with iron(III) fluoride (FeF₃, 0.05 g) until a homogeneous mixture is obtained.

- Microwave Irradiation: Transfer the mixture to a microwave-compatible reaction vessel. Irradiate the mixture at 450 W and 110 °C for 6–9 minutes (see Table 2 for specific times per phenol).

- Reaction Monitoring: Monitor the reaction progress by TLC.

- Work-up: After cooling, dilute the solid reaction mixture with ethyl acetate (~10-15 mL).

- Catalyst Recovery: Separate the catalyst by filtration. The FeF₃ catalyst can be regenerated by washing with ethyl acetate, drying under vacuum, and reused for up to four cycles with minimal loss of activity.

- Product Isolation: Concentrate the ethyl acetate filtrate under reduced pressure. The resulting solid crude product can be purified by recrystallization from ethanol to afford the pure coumarin derivative.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Reagents for Microwave-Assisted Synthesis of Oxygen Heterocycles

| Reagent / Material | Function / Role in Synthesis | Example Use Case |

|---|---|---|

| FeF₃ (Iron(III) Fluoride) | Lewis acid catalyst; activates carbonyl groups for condensation. | Pechmann condensation under solvent-free microwave conditions [39]. |

| Anhydrous K₂CO₃ (Potassium Carbonate) | Base; promotes deprotonation and nucleophile generation. | Nucleophilic substitution in coumarin-purine hybrid synthesis [36]. |

| 4-Bromomethylcoumarins | Key electrophilic building block; contains a good leaving group for substitution. | Core intermediate for constructing coumarin-heterocycle hybrids [36]. |

| Ethyl Acetoacetate | β-Ketoester; provides the 4-methyl-2-oxo-2H-chromen skeleton in Pechmann reactions. | Condensation with phenols to form 4-methylcoumarins [39]. |

| Phenol Derivatives (Resorcinol, Naphthols) | Nucleophilic partners; determine the substitution pattern on the final coumarin ring. | Substrates in Pechmann condensation [39]. |

| Polar Solvents (Acetone) | Reaction medium for homogeneous heating under microwave irradiation. | Solvent for nucleophilic substitution reactions [36]. |

Workflow and Pathway Visualizations

Experimental Workflow for Coumarin Hybrid Synthesis

The diagram below illustrates the general experimental workflow for the microwave-assisted synthesis of coumarin-based hybrids, integrating the protocols described above.

Simplified Biosynthetic Pathway of Coumarins in Plants

Understanding the natural biosynthetic pathway of coumarins provides context for the structural diversity and bioactivity of these compounds. The following diagram outlines the key enzymatic steps in plants.

Multicomponent Reactions and One-Pot Syntheses under Microwave Irradiation