NADPH Regeneration: Powering Sustainable Chiral Synthesis and Biomanufacturing with Light-Driven Biocatalysis

Light-driven biocatalysis represents a paradigm shift for sustainable chemical synthesis, leveraging sunlight to regenerate the essential electron donor NADPH and power highly selective enzymes.

NADPH Regeneration: Powering Sustainable Chiral Synthesis and Biomanufacturing with Light-Driven Biocatalysis

Abstract

Light-driven biocatalysis represents a paradigm shift for sustainable chemical synthesis, leveraging sunlight to regenerate the essential electron donor NADPH and power highly selective enzymes. This article provides a comprehensive overview for researchers and drug development professionals. It begins with the foundational principles of NADPH-dependent enzymes and photochemical regeneration mechanisms. The discussion then advances to cutting-edge methodological approaches, including the integration of semiconductor photoanodes with biocatalysts and whole-cell photosynthetic platforms. Practical guidance is offered for troubleshooting critical issues like cofactor selectivity and electron transfer efficiency. Finally, the article examines how these systems are validated through industrial case studies, benchmarking them against traditional methods. By synthesizing knowledge across these four intents, the article highlights the transformative potential of light-powered NADPH regeneration in enabling greener routes to high-value pharmaceuticals and fine chemicals.

What is NADPH and Why is its Light-Driven Regeneration a Game-Changer for Biocatalysis?

The Indispensable Role of NADPH as a Cellular Reducing Powerhouse and Biocatalytic Cofactor

Within the rapidly advancing field of light-driven biocatalysis, the pivotal role of nicotinamide adenine dinucleotide phosphate (NADPH) is being redefined and harnessed. This technical guide details the central function of NADPH as the principal cellular reductant and an indispensable cofactor for a growing class of photo-enzymes. Its regeneration, driven by light-harvesting systems, is a cornerstone for sustainable biomanufacturing and novel therapeutic strategies.

Chemical Nature and Core Biochemical Functions

NADPH differs from NADH by a single phosphate group on the 2' position of the ribose moiety of adenosine. This modification dictates its distinct metabolic role: while NADH is primarily consumed in oxidative phosphorylation, NADPH is the dedicated reducing agent for anabolism and oxidative defense. Its standard reduction potential (E°' = -0.320 V) enables it to drive highly energetically demanding reductive biosyntheses.

Table 1: Primary NADPH-Generating Enzymes and Their Key Properties

| Enzyme | Major Localization | Primary Reaction | % Cellular NADPH Contribution* |

|---|---|---|---|

| Glucose-6-Phosphate Dehydrogenase (G6PD) | Cytosol | G6P + NADP⁺ → 6-Phosphogluconolactone + NADPH | ~30% |

| 6-Phosphogluconate Dehydrogenase (6PGD) | Cytosol | 6-Phosphogluconate + NADP⁺ → Ribulose-5-P + CO₂ + NADPH | ~20% |

| Malic Enzyme (ME1) | Cytosol | Malate + NADP⁺ → Pyruvate + CO₂ + NADPH | ~10% |

| Isocitrate Dehydrogenase 1 (IDH1) | Cytosol/Peroxisome | Isocitrate + NADP⁺ → α-Ketoglutarate + CO₂ + NADPH | ~20% |

| Folate Cycle (MTHFD1) | Cytosol | 10-Formyl-THF + NADPH → 5,10-Methenyl-THF + NADP⁺ (reversible) | Variable |

*Approximate contributions vary by cell type and metabolic state.

NADPH in Light-Driven Biocatalysis: Mechanisms and Pathways

Light-driven biocatalysis utilizes photochemical energy to regenerate NADPH, coupling it to valuable enzymatic reductions. Key systems include:

- Photoreductases (e.g., Cytochromes P450 coupled to photosensitizers): Light excites a photosensitizer (e.g., Ru(bpy)₃²⁺, Eosin Y), which transfers an electron via a redox mediator to a reductase, ultimately regenerating NADPH from NADP⁺ for substrate reduction.

- Direct Photo-regeneration: Semiconducting materials or molecular catalysts (e.g., [Cp*Rh(bpy)H₂O]²⁺) use light energy to directly reduce NADP⁺ to NADPH.

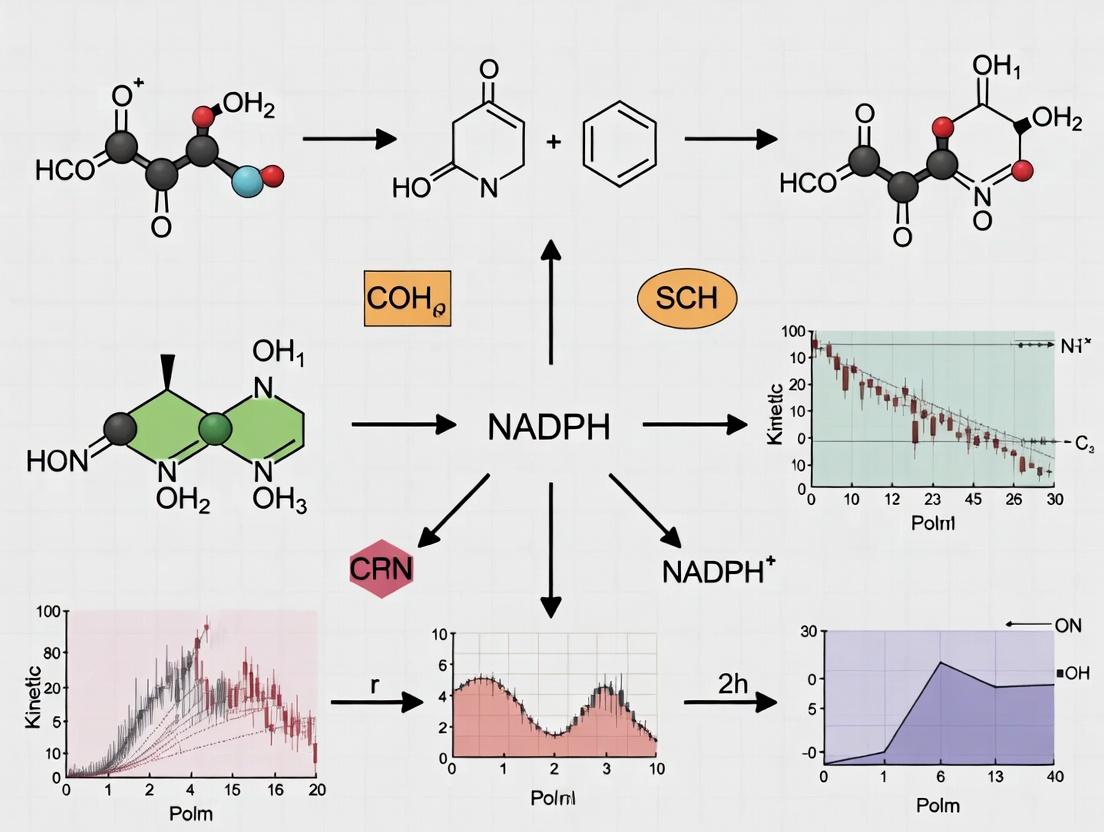

Figure 1: Light-driven NADPH regeneration for enzymatic reduction.

Quantitative Cellular NADPH Dynamics

NADPH levels and the NADPH/NADP⁺ ratio are tightly regulated spatial and temporal indicators of cellular redox health and biosynthetic capacity.

Table 2: NADPH Pools and Fluxes in Model Systems

| Parameter | Liver Hepatocyte | Cancer Cell Line (HeLa) | Plant Chloroplast (Light) | In Vitro Photo-Biocatalytic System |

|---|---|---|---|---|

| [NADPH] (μM) | 50 - 100 | 100 - 300 | 500 - 1500 | 0.1 - 1.0 (reaction mix) |

| NADPH/NADP⁺ Ratio | ~100:1 | ~50:1 | >500:1 | Dynamic (0.1 - 10) |

| Turnover Rate | 5-10 μmol/min/g tissue | High (Warburg effect) | Extremely High | Turnover Number: 10³ - 10⁴ h⁻¹ |

| Primary Consumer | Fatty acid & Cholesterol synthesis | Glutathione reduction (ROS defense) | Calvin cycle (CO₂ fixation) | Specific Reductase (e.g., P450, ER) |

Detailed Experimental Protocols

Protocol 1: Spectrophotometric Assay for NADPH Quantification

Objective: Measure NADPH concentration in cell lysates. Reagents:

- Lysis Buffer: 20 mM Tris-HCl (pH 8.0), 150 mM NaCl, 1% NP-40, 1 mM EDTA, supplemented fresh with 1 mM DTT and protease inhibitors.

- Assay Buffer: 100 mM HEPES (pH 8.0), 2 mM EDTA.

- Enzyme Solution: Glutathione reductase (GR), 5 U/mL in assay buffer.

- Substrate Solution: Oxidized Glutathione (GSSG), 10 mM in assay buffer.

- Developer: 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT), 0.5 mg/mL.

- Phenazine Ethosulfate (PES): 0.1 mg/mL. Procedure:

- Prepare cell lysate and clear by centrifugation (16,000 x g, 15 min, 4°C).

- In a 96-well plate, mix 50 μL of sample/standard with 150 μL of Assay Buffer.

- Add 20 μL of GSSG solution and 20 μL of GR solution. Incubate for 5 min at 25°C.

- Add 10 μL each of MTT and PES solutions. Incubate for exactly 10 min in the dark.

- Measure absorbance at 570 nm. Generate standard curve using known NADPH concentrations (0-200 μM).

Protocol 2:In VitroLight-Driven NADPH Regeneration and Biocatalysis

Objective: Couple photocatalytic NADPH regeneration to a target reductase. Reagents:

- Photocatalyst: [Cp*Rh(bpy)(H₂O)]²⁺ (1 mM stock in H₂O).

- Cofactor: NADP⁺ (10 mM stock).

- Target Enzyme: e.g., Old Yellow Enzyme (OYE1), 2 mg/mL.

- Substrate: e.g., Citral, 50 mM in DMSO.

- Reaction Buffer: 100 mM Potassium Phosphate, pH 7.0.

- Light Source: Blue LED array (450 nm, 20 mW/cm² intensity). Procedure:

- In a 2 mL vial, mix: 875 μL Reaction Buffer, 10 μL NADP⁺ stock, 50 μL Photocatalyst stock, 50 μL OYE1 stock, 15 μL Substrate stock.

- Purge headspace with Argon for 5 min. Seal vial.

- Illuminate reaction under blue LED array with gentle stirring for 2 hours at 30°C. Control vial wrapped in foil.

- Quench with 100 μL of 1M HCl. Extract product with ethyl acetate and analyze by GC-MS.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for NADPH Research

| Reagent | Function/Application | Key Supplier Examples |

|---|---|---|

| NADPH (tetrasodium salt) | Direct cofactor supply for in vitro enzyme assays. | Sigma-Aldrich, Roche, Cayman Chemical |

| Glucose-6-Phosphate Dehydrogenase (G6PD) | Enzymatic NADPH generation from glucose-6-phosphate for coupled assays. | Toyobo, Sigma-Aldrich |

| NADPH/NADP⁺-Glo Assay | Bioluminescent detection of NADPH/NADP⁺ ratios in cells and samples. | Promega |

| [Cp*Rh(bpy)(H₂O)]²⁺ | Efficient, water-soluble organometallic photocatalyst for NADP⁺ reduction. | Strem Chemicals, TCI |

| Eosin Y (disodium salt) | Organic photosensitizer for light-driven electron transfer. | Sigma-Aldrich, Thermo Fisher |

| Old Yellow Enzyme (OYE1) | Model ene-reductase for studying NADPH-dependent biocatalysis. | Codexis, Sigma-Aldrich |

| Recombinant Human Cytochrome P450 Enzymes | For drug metabolism studies and light-driven CH-activation reactions. | Corning, Sigma-Aldrich |

Therapeutic Implications and Drug Development

NADPH metabolism is a target in oncology and infectious diseases. Inhibitors of NADPH-producing enzymes (e.g., G6PD or MTHFD1) induce oxidative stress and nucleotide depletion in cancer cells. The NADPH-dependent thioredoxin and glutathione systems are critical for maintaining the reduced state of therapeutic proteins (e.g., monoclonal antibodies) during production.

Figure 2: NADPH powers major cellular antioxidant defense pathways.

NADPH stands at the nexus of metabolism, redox biology, and modern biocatalysis. Its role as a reducing powerhouse is being amplified by light-driven regeneration strategies, opening new avenues for green chemistry and precision biomedication. Understanding its generation, compartmentalization, and flux is critical for advancing research in synthetic biology, drug discovery, and redox medicine.

The Economic and Thermodynamic Imperative for In Situ Cofactor Regeneration

Within the broader thesis on the role of Nicotinamide Adenine Dinucleotide Phosphate (NADPH) in light-driven biocatalysis, the regeneration of this essential cofactor emerges as a critical bottleneck. NADPH serves as the primary biological reducing agent, fueling a vast array of oxidoreductase enzymes crucial for pharmaceutical synthesis, including P450 monooxygenases, ketoreductases, and imine reductases. Traditional ex situ regeneration, which involves adding stoichiometric amounts of cofactor or using sacrificial substrates with a second enzyme, is economically and thermodynamically unsustainable for industrial-scale applications. It drives up costs (NADPH is prohibitively expensive) and generates wasteful byproducts, complicating downstream processing. In situ regeneration—continuously recycling NADPH from its oxidized form (NADP⁺) within the same reactor—is therefore not merely an optimization but an imperative. This guide details the economic and thermodynamic drivers and provides a technical roadmap for implementing efficient in situ NADPH regeneration systems, with a focus on light-driven methods.

Economic and Thermodynamic Drivers: A Quantitative Analysis

The core arguments for in situ regeneration are quantified below.

Table 1: Economic Burden of NADPH in Stoichiometric Use

| Metric | Value/Range | Implication |

|---|---|---|

| Cost of NADPH (reduced) | ~$1,500 - $3,000 per gram | Direct addition is cost-prohibitive for any large-scale process. |

| Typical Molar Requirement | 1:1 stoichiometry with product | Costs scale linearly with production volume. |

| Process Economics | Cofactor can be >50% of total raw material cost | Renders many biocatalytic processes economically unviable. |

Table 2: Thermodynamic and Efficiency Advantages of In Situ Regeneration

| Parameter | Ex Situ (Sacrificial Substrate) | In Situ (Light-Driven) | Advantage |

|---|---|---|---|

| Atom Economy | Low (byproduct from cosubstrate) | High (uses light and electrons) | Reduced waste, simpler purification. |

| Thermodynamic Driving Force | Limited by ΔG of coupled enzyme | Can be precisely tuned via light intensity/ potential | Higher overall reaction yield possible. |

| Total Turnover Number (TTN) | 10³ - 10⁵ | Can exceed 10⁶ | Dramatically reduces cofactor demand. |

| Space-Time Yield | Often limited by enzyme kinetics | Can be enhanced by intensive photoreactor design | Potential for higher productivity. |

Key Methodologies forIn SituNADPH Regeneration

Several technical pathways exist, categorized by their energy and electron source.

Enzymatic Regeneration (Coupled Substrate)

This traditional in situ method couples the main reaction with a cheap sacrificial substrate (e.g., glucose, formate) and a second enzyme (e.g., Glucose Dehydrogenase, FDH).

Protocol: Coupled Glucose Dehydrogenase (GDH) System

- Objective: Regenerate NADPH for a ketoreductase (KRED)-catalyzed chiral alcohol synthesis.

- Reagents: NADP⁺, D-Glucose, KRED (specific to substrate), GDH (from Bacillus sp.), phosphate buffer (pH 7.0).

- Procedure:

- Prepare 50 mL reaction mix in a stirred bioreactor: 100 mM phosphate buffer, 1 mM NADP⁺, 500 mM ketone substrate, 1 M D-glucose.

- Initiate reaction by adding 10 U/mL KRED and 20 U/mL GDH.

- Maintain at 30°C, monitor conversion via HPLC or GC.

- The GDH oxidizes glucose to gluconolactone, reducing NADP⁺ to NADPH, which is consumed by the KRED.

Light-Driven Regeneration: Photobiocatalysis

This approach directly aligns with the thesis on light-driven biocatalysis, using photons to drive electron flow to NADP⁺.

A. Photoreductase-Based Systems (e.g., FNR) Flavoprotein photoreductases use a bound flavin cofactor that, upon blue light excitation, becomes a strong reductant.

Protocol: Flavoenzyme-Catalyzed NADPH Regeneration

- Objective: Use a purified flavin reductase (e.g., Fre) for continuous NADPH regeneration.

- Reagents: NADP⁺, EDTA, Photosensitizer (e.g., [Ru(bpy)₃]²⁺ or organic dyes), sacrificial electron donor (e.g., TEOA), purified flavin reductase enzyme.

- Procedure:

- Prepare an anaerobic cuvette with 2 mL solution: 50 mM Tris-HCl (pH 8.0), 0.2 mM NADP⁺, 5 µM [Ru(bpy)₃]²⁺, 10 mM TEOA, 50 µM FMN, 5 µM Fre enzyme.

- Seal and purge with argon for 15 min.

- Illuminate with blue LEDs (λmax = 450 nm, 20 mW/cm²).

- Monitor NADPH formation spectrophotometrically at 340 nm (ε = 6220 M⁻¹cm⁻¹).

- Workflow Diagram:

Title: Photoreductase-Mediated NADPH Regeneration Cycle

B. Whole-Cell Photosynthetic Regeneration Utilizes cyanobacteria or chloroplasts, where Photosystem I naturally reduces ferredoxin, which in turn reduces NADP⁺ via Ferredoxin-NADP⁺ Reductase (FNR).

Protocol: Cyanobacterial In Vivo NADPH Regeneration

- Objective: Employ engineered Synechocystis sp. PCC 6803 to regenerate NADPH for an intracellular biocatalytic reaction.

- Reagents: Cyanobacterial strain with heterologous biocatalyst gene, BG-11 medium, CO₂-enriched air, LED light panels.

- Procedure:

- Grow engineered cyanobacteria in BG-11 medium under continuous light (50 µE m⁻² s⁻¹) to mid-log phase.

- Induce expression of the target biocatalyst (e.g., a P450).

- Add the enzyme's substrate to the culture.

- Incubate under high-intensity light (200 µE m⁻² s⁻¹) to drive photosynthetic NADPH production.

- Harvest cells and analyze product formation.

- Pathway Diagram:

Title: Photosynthetic NADPH Pathway in Engineered Cyanobacteria

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for In Situ NADPH Regeneration Research

| Reagent/Material | Function in Research | Example/Supplier Notes |

|---|---|---|

| NADP⁺ / NADPH | Cofactor substrate/product for assays; use NADP⁺ for regeneration studies. | Sigma-Aldrich (N5755, N5130); high-purity grade recommended. |

| Glucose Dehydrogenase (GDH) | Robust enzyme for enzymatic (glucose-driven) NADPH regeneration. | Recombinant from Bacillus sp. (Codexis, Sigma). |

| Formate Dehydrogenase (FDH) | Enzymatic regenerator using formate; produces only CO₂. | Candida boidinii (Roche) or engineered variants. |

| Flavoreductases (e.g., Fre) | Key enzyme for light-driven systems; transfers electrons from photoexcited flavins to NADP⁺. | Purified from E. coli overexpression. |

| Photosensitizers | Absorb light and initiate electron transfer. | [Ru(bpy)₃]Cl₂, Eosin Y, or organic dyes like 2,4,5,6-Tetra(9H-carbazol-9-yl)isophthalonitrile. |

| Sacrificial Electron Donors | Provide electrons to re-reduce oxidized photosensitizer. | Triethanolamine (TEOA), Ascorbate, EDTA. |

| Engineered Cyanobacteria Strains | Whole-cell photosynthetic chassis for in vivo regeneration. | Synechocystis sp. PCC 6803 or Synechococcus elongatus PCC 7942. |

| Anaerobic Cuvettes/Reactors | Essential for photobiocatalysis to prevent O₂ quenching of excited states. | Glassware with septum seals, Schlenk lines, or Coy anaerobic chambers. |

| Programmable LED Arrays | Provide controlled, intense illumination at specific wavelengths. | Customizable panels (e.g., CoolLED, Thorlabs) with 450nm blue LEDs for flavin systems. |

| NAD(P)H Fluorescence/Luminescence Assay Kits | Quantitative, high-throughput measurement of cofactor concentration/status. | Promega NADP/NADPH-Glo Assay, Sigma MAK038. |

Within the paradigm of light-driven biocatalysis, the regeneration of the reduced form of nicotinamide adenine dinucleotide phosphate (NADPH) is a fundamental challenge. NADPH serves as the principal hydride donor in anabolic reactions, powering the biosynthesis of high-value compounds, including pharmaceuticals. Unlike its counterpart NADH, NADPH is preferentially utilized by enzymes like reductases and cytochrome P450s for chiral synthesis and functionalization. Efficient, sustainable, and controllable NADPH regeneration is therefore critical for advancing in vitro photobiocatalytic systems from laboratory curiosities to scalable synthetic platforms. This whitepaper dissects the core mechanisms of two leading approaches: direct photochemical and integrated photobioelectrochemical regeneration.

Core Mechanisms & Pathways

Photochemical NADPH Regeneration

This method employs soluble photocatalysts that absorb light to initiate electron transfer chains, ultimately reducing NADP⁺ to NADPH. The primary mechanism involves a photoinduced electron transfer (PET) from an excited photocatalyst to a sacrificial electron donor, followed by hydride transfer to NADP⁺ via a redox mediator.

Key Photochemical Pathways:

Diagram 1: Photochemical NADPH regeneration via reductive quenching cycle.

Photobioelectrochemical NADPH Regeneration

This approach integrates light-harvesting electrodes with immobilized redox enzymes. Photons are converted to electrical potential at a semiconductor photoanode (or cathode), which drives enzymatic NADP⁺ reduction at the biocathode, often facilitated by an electroenzymatic interface.

Integrated Photobioelectrochemical System Workflow:

Diagram 2: Photobioelectrochemical cell for NADPH regeneration.

Quantitative Performance Comparison

Table 1: Performance Metrics of Recent NADPH Regeneration Systems

| System Type | Photocatalyst / Electrode | Enzyme / Mediator | Turnover Number (TON) | Turnover Frequency (TOF) (h⁻¹) | Quantum Yield / Faradaic Efficiency (%) | Reference (Type) |

|---|---|---|---|---|---|---|

| Photochemical | [Ir(ppy)₃] / Ru(bpy)₃²⁺ | RhCp* mediator | 50 - 500 | 5 - 30 | < 5 - 10 (QY) | |

| Photochemical | Carbon Nitride (C₃N₄) | Methylene Blue | ~200 | ~12 | ~0.8 (QY) | Recent Study |

| Photobioelectrochemical | p-type Silicon (p-Si) | Immobilized FNR | N/A | N/A | ~70 - 85 (FE) | |

| Photobioelectrochemical | TiO₂ / Organic Dye | Fd-FNR fusion protein | > 10,000 (enzyme) | ~1,500 (enzyme) | ~64 (FE) | Recent Study |

| Hybrid | CdS Nanorods | FNR in Solution | ~7,800 (PC) | N/A | ~2.6 (QY) | Recent Study |

Abbreviations: FNR: Ferredoxin-NADP⁺ Reductase; Fd: Ferredoxin; QY: Quantum Yield; FE: Faradaic Efficiency.

Detailed Experimental Protocols

Protocol: Photochemical Regeneration Using [Ru(bpy)₃]²⁺ & Rh Mediator

Based on established methods .

Objective: To regenerate NADPH using a homogeneous photocatalytic system.

Reagents: Tris(2,2'-bipyridyl)ruthenium(II) chloride ([Ru(bpy)₃]Cl₂), [Cp*Rh(bpy)Cl]Cl (Rh mediator), NADP⁺ sodium salt, Triethanolamine (TEOA), Tris-HCl buffer (pH 8.0).

Procedure:

- Prepare a 1.0 mL reaction mixture in a quartz cuvette under inert atmosphere:

- 50 mM Tris-HCl buffer (pH 8.0).

- 0.1 mM [Ru(bpy)₃]Cl₂.

- 0.2 mM [Cp*Rh(bpy)Cl]Cl.

- 10 mM TEOA (sacrificial donor).

- 0.5 mM NADP⁺.

- Degas the solution by bubbling with argon or nitrogen for 15 minutes.

- Seal the cuvette and place it in a photoreactor equipped with blue LEDs (λmax ~450 nm, light intensity 20 mW/cm²).

- Irradiate the reaction mixture with constant stirring at 25°C.

- Monitor NADPH formation by taking aliquots at regular intervals and measuring absorbance at 340 nm (ε₃₄₀ = 6.22 mM⁻¹cm⁻¹).

- Calculate TON and TOF based on moles of NADPH produced per mole of photocatalyst.

Protocol: Photobioelectrochemical Regeneration on FNR-Modified Biocathode

Adapted from semiconductor-driven bioelectrocatalysis .

Objective: To construct a photocathode for direct enzymatic NADPH regeneration.

Reagents: p-type Silicon (p-Si) wafer, (3-aminopropyl)triethoxysilane (APTES), Glutaraldehyde, Ferredoxin-NADP⁺ Reductase (FNR), Potassium phosphate buffer (pH 7.0), Methyl viologen (MV) or a soluble ferredoxin as electron shuttle.

Electrode Preparation & Assay:

- Photocathode Preparation: Clean p-Si wafer, functionalize with APTES to create amine groups, and crosslink FNR using 2.5% glutaraldehyde. Rinse thoroughly to remove unbound enzyme.

- Electrochemical Cell Setup: Use a three-electrode configuration: FNR/p-Si as working electrode, Pt counter electrode, and Ag/AgCl reference electrode in 50 mM phosphate buffer (pH 7.0).

- Photoelectrochemical Measurement: Add 0.5 mM NADP⁺ and 0.1 mM electron shuttle (e.g., MV) to the electrolyte. Purge with N₂.

- Apply a mild cathodic bias (e.g., -0.4 V vs. Ag/AgCl) and illuminate the photocathode with a solar simulator (AM 1.5G, 100 mW/cm²).

- Monitor the photocurrent and quantify NADPH production via HPLC or the 340 nm absorbance of aliquots taken from the cathodic compartment.

- Calculate Faradaic Efficiency: FE (%) = (2 * [NADPH] * F * V / Q) * 100%, where F is Faraday's constant, V is volume, and Q is total charge passed.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for NADPH Regeneration Research

| Item | Function & Role in Research | Typical Example / Specification |

|---|---|---|

| Photocatalysts | Light absorption and primary electron transfer. | [Ru(bpy)₃]²⁺, Iridium complexes, Organic dyes (Eosin Y), Semiconductors (CdS, C₃N₄). |

| Redox Mediators | Shuttle electrons between photocatalyst/cathode and NADP⁺/enzyme. | [Cp*Rh(bpy)Cl]⁺, Methylene Blue, Methyl viologen, Ferrocene derivatives. |

| Sacrificial Electron Donors | Provide electrons to oxidize photocatalyst, completing its catalytic cycle. | Triethanolamine (TEOA), Ascorbic acid, Ethylenediaminetetraacetic acid (EDTA). |

| NADP⁺ / NADPH | Target cofactor substrate and product. Critical for assay calibration. | High-purity sodium salts, >95% purity by HPLC. Store at -20°C. |

| Redox Enzymes | Biocatalysts for specific, efficient hydride transfer to NADP⁺. | Ferredoxin-NADP⁺ Reductase (FNR), Hydrogenase-NADP⁺ fusion enzymes. |

| Photo-electrode Materials | Solid-state light harvesting and current generation. | p-type Silicon (p-Si), TiO₂, FTO/ITO glass, Gold or carbon electrodes. |

| Immobilization Reagents | For attaching enzymes to electrodes or supports. | APTES, Glutaraldehyde, Nafion, Polyethylenimine, Carbodiimide (EDC/NHS) chemistry kits. |

| Analytical Standards | Quantifying reaction efficiency and product purity. | Authentic NADPH standard for HPLC/UV-Vis, Internal standards for LC-MS. |

The regeneration of nicotinamide adenine dinucleotide phosphate (NADPH) is a central challenge and enabling factor in synthetic biocatalysis. Many oxidoreductase enzymes, crucial for chiral synthesis and pharmaceutical intermediate production, are NADPH-dependent. Light-driven biocatalysis offers a sustainable, atom-economical path for the continuous in situ regeneration of this costly cofactor. This platform integrates a photosensitizer to capture photon energy, a redox mediator to shuttle electrons, and an enzyme (e.g., a reductase) to catalyze the final reduction of NADP⁺ to NADPH. The efficient orchestration of these three core components dictates the platform's quantum yield, turnover frequency, and overall practical viability for industrial drug development.

Core Components: Functions and Quantitative Data

Photosensitizers (PS)

Photosensitizers absorb light and transition to an excited state (PS*), which can engage in electron transfer reactions.

Table 1: Common Photosensitizers for Light-Driven NADPH Regeneration

| Photosensitizer | Class | Absorption λ_max (nm) | Molar Extinction Coefficient ε (M⁻¹cm⁻¹) | Benchmark Quantum Yield (Φ) for NADPH regeneration | Key Advantage |

|---|---|---|---|---|---|

| [Ru(bpy)₃]²⁺ | Organometallic | 452 | ~14,600 | 0.008 - 0.012 | High stability, long-lived triplet state |

| Eosin Y | Organic Dye | 516 | ~95,000 | 0.03 - 0.05 | High ε, inexpensive, organic solvent compatible |

| Flavin Mononucleotide (FMN) | Biological | 445 | 12,500 | ~0.01 | Biocompatible, can act as both PS and mediator |

| Chlorophyllin | Porphyrin | 405, 660 | ~150,000 (405nm) | 0.02 - 0.04 | Broad visible light absorption, natural origin |

| CDots | Carbon Nanomaterial | Broad (UV-Vis) | Varies | 0.05 - 0.15 | High photostability, tunable surface chemistry |

Redox Mediators (M)

Mediators facilitate electron transfer between the reduced photosensitizer and the enzyme/cofactor, preventing deleterious back-reactions.

Table 2: Representative Redox Mediators

| Mediator | Type | Redox Potential vs. SHE (V) | Key Function & Notes |

|---|---|---|---|

| Rh(Cp*)(bpy)H⁺ (Rhodium catalyst) | Organometallic | -0.57 (for Rh³⁺/Rh⁺) | Highly efficient, "Proton-coupled electron transfer" for direct NADP⁺ reduction. |

| Viologen derivatives (e.g., MV²⁺) | Organic | -0.45 (MV²⁺/MV⁺•) | Classic one-electron carrier; requires a second enzyme (ferredoxin-NADP⁺ reductase). |

| [FeFe]-Hydrogenase mimics | Bio-inspired | ~ -0.4 to -0.5 | Can bridge PS and enzyme, but often sensitive to O₂. |

| Triethanolamine (TEOA) / EDTA | Sacrificial Donor | N/A (Oxidized irreversibly) | Consumed to re-reduce the oxidized PS, closing the catalytic cycle. Not a true recyclable mediator. |

Enzymes (E)

Enzymes catalyze the regioselective and stereospecific reduction of NADP⁺ using electrons from the mediator.

Table 3: Enzymes for Photocatalytic NADPH Regeneration

| Enzyme | Source | Cofactor Specificity | Turnover Frequency (k_cat, s⁻¹) | Role in Pathway |

|---|---|---|---|---|

| Ferredoxin-NADP⁺ Reductase (FNR) | Spinach, cyanobacteria | NADP⁺ / NADPH | 50-200 | Catalyzes final hydride transfer from reduced flavin/ferredoxin to NADP⁺. |

| NADPH-dependent reductase (e.g., Old Yellow Enzyme) | Various microbes | NADPH | Variable (substrate dependent) | Target synthesis enzyme; consumes regenerated NADPH. Can be coupled directly. |

| CpCR | C. parapsilosis | NADPH | N/A | Engineered carbonyl reductase often used as a model coupled enzyme. |

| Hydrogenase | C. reinhardtii | Indirect via ferredoxin | N/A | Can produce H₂ from reduced mediators; a competing or parallel pathway. |

Experimental Protocols for Key Evaluations

Protocol 1: Benchmarking Photosensitizer-Mediator Pair Efficiency for NADPH Yield

Objective: Quantify the initial rate and total yield of NADPH production under standardized light conditions.

- Reaction Setup: In an anaerobic cuvette (N₂ or Ar atmosphere), combine in 1 mL of 50 mM Tris-HCl buffer (pH 8.0):

- NADP⁺ (0.5 mM final concentration)

- Photosensitizer (e.g., [Ru(bpy)₃]Cl₂, 50 µM)

- Redox mediator (e.g., Rh(Cp*)(bpy)Cl₂, 100 µM)

- Sacrificial electron donor (e.g., TEOA, 10% v/v)

- Photoreaction: Place the cuvette in a controlled-temperature photoreactor (e.g., 25°C) equipped with a monochromatic LED light source matching the PS λ_max (e.g., 450 nm). Illuminate with constant irradiance (e.g., 10 mW/cm²).

- Kinetic Monitoring: At timed intervals (0, 30, 60, 120, 300 s), take a 100 µL aliquot and immediately dilute into 900 µL of assay buffer.

- NADPH Quantification: Measure NADPH concentration by UV-Vis spectrophotometry at 340 nm (ε₃₄₀ = 6220 M⁻¹cm⁻¹) or using a coupled enzyme assay with glutathione reductase and DTNB (Ellman's reagent).

- Data Analysis: Plot [NADPH] vs. time. The initial slope is the rate of formation (µM/s). The maximum plateau is the total yield. Compare systems by their initial rate and total turnover number (TTN) for the mediator.

Protocol 2: Coupled Light-Driven Biocatalytic Reaction

Objective: Demonstrate functional NADPH regeneration driving a model synthesis, such as the asymmetric reduction of a ketone.

- Reaction Mixture: In a sealed, anaerobic vial, combine:

- Substrate (e.g., 2-methylcyclohexanone, 10 mM)

- NADP⁺ (0.2 mM)

- Photosensitizer (Eosin Y, 20 µM)

- 1,4-Dihydropyridine mediator (e.g., BNAH, 5 mM) or an organometallic mediator.

- Target enzyme (e.g., purified Old Yellow Enzyme variant, 0.5 µM)

- in 2 mL of 100 mM phosphate buffer (pH 7.0) with 5% v/v co-solvent (e.g., DMSO) if needed for substrate solubility.

- Illumination: Stir the reaction vial under a green LED panel (λ_max = 525 nm, 20 mW/cm²) at 30°C.

- Progress Monitoring: Take aliquots at 0, 1, 2, 4, 8, and 24 hours.

- Analysis:

- Substrate/Product Conversion: Analyze by chiral GC or HPLC to determine enantiomeric excess and conversion.

- Control Experiments: Run identical setups in the dark, without light, and without PS to confirm the light-driven nature of the catalysis.

- Key Metrics: Calculate turnover number (TON = mol product / mol enzyme) and turnover frequency (TOF).

Visualizations

Diagram 1: Electron Flow in a Generic Light-Driven NADPH Regeneration System

Diagram 2: Experimental Workflow for Platform Evaluation

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Light-Driven Biocatalysis Research

| Item | Function & Explanation | Example Supplier / Cat. No. (Illustrative) |

|---|---|---|

| Monochromatic LED Reactor | Provides precise, cool, and intense illumination at a specific wavelength to excite the photosensitizer without degrading biological components. | Lumencor Spectra X, Prizmatix UHP-T-LED. |

| Anaerobic Chamber/Glovebox | Essential for creating oxygen-free environments to prevent oxidation of sensitive reduced mediators (e.g., viologen radicals) and enzymes. | Coy Laboratory Products, Plas Labs. |

| Quartz or UV-Vis Cuvettes (septum-sealed) | For spectroscopic monitoring of reactions; quartz allows full UV-Vis range transmission. | Hellma Anaerobic Cuvettes (Type 100-QS). |

| Spectrophotometer with Kinetics Software | For real-time or endpoint measurement of NADPH formation at 340 nm. | Agilent Cary 60, Shimadzu UV-2700. |

| Chiral HPLC Column & System | For separation and quantification of enantiomeric products from coupled biocatalytic reductions. | Daicel Chiralpak columns (e.g., IA, IC), Agilent 1260 Infinity II. |

| Model Reductase Enzyme (e.g., OYE1, CpCR) | Well-characterized, robust NADPH-dependent enzyme for proof-of-concept coupled reactions. | Sigma-Aldrich (OYE1 from S. pastorianus), Codexis (engineered panels). |

| High-Purity NADP⁺/NADPH | Critical cofactor; purity affects background rates and overall yield. | Roche, Sigma-Aldrich, Oriental Yeast Co. |

| Deuterated Solvents for NMR | For detailed structural analysis of reaction products and quantification when chromophores are absent. | Cambridge Isotope Laboratories, Eurisotop. |

Building the Future: Cutting-Edge Systems for Light-Powered Synthesis

This technical guide explores the integration of semiconductor photoanodes with multi-enzyme cascades to drive light-driven biocatalysis, with a specific focus on the in situ regeneration of nicotinamide adenine dinucleotide phosphate (NADPH). Within the broader thesis on NADPH's critical role in light-driven biocatalysis research, this whitepaper details how semi-artificial photosynthesis provides a sustainable, efficient platform for cofactor regeneration, enabling complex synthetic transformations relevant to pharmaceutical and fine chemical production.

NADPH is the principal reducing equivalent in over 300 known enzymatic reactions, including those critical for the biosynthesis of chiral pharmaceuticals, antioxidants, and fine chemicals. The central thesis framing this field posits that the efficient, light-driven regeneration of NADPH from its oxidized form (NADP⁺) is the linchpin for viable, scalable photobiocatalytic systems. Semi-artificial photosynthesis directly addresses this by using engineered semiconductor materials to capture light energy and generate the reducing power (typically electrons and protons) required for enzymatic NADPH regeneration, bypassing the inefficiencies of natural photosynthetic organisms or purely chemical methods.

System Architecture and Core Principles

A functional semi-artificial photosynthetic system comprises three integrated components:

- The Photoanode: A light-absorbing semiconductor (e.g., BiVO₄, α-Fe₂O₃, TiO₂) that undergoes charge separation upon illumination. Photogenerated holes oxidize a sacrificial electron donor (e.g., water, ascorbate), while electrons are directed through an external circuit.

- The Electron Mediator: A redox molecule (e.g., [Fe(CN)₆]³⁻/⁴⁻, viologens) or a direct enzymatic interface that shuttles electrons from the cathode (or photocathode) to the enzymatic cascade.

- The Enzymatic Cascade: A sequence of enzymes, anchored around a central NADP⁺-reducing enzyme (e.g., ferredoxin-NADP⁺ reductase, FNR; or a phosphite dehydrogenase, PTDH), which utilizes delivered electrons to reduce NADP⁺ to NADPH. The regenerated NADPH then drives a downstream synthesis enzyme (e.g., a ketoreductase, monooxygenase).

Table 1: Performance Metrics of Selected Semiconductor Photoanodes in Semi-Artificial Systems

| Semiconductor Photoanode | Incident Photon-to-Current Efficiency (IPCE) at Relevant λ | Applied Bias (V vs. RHE) | Sacrificial Donor | Electron Transfer Rate to Mediator (µmol e⁻ m⁻² s⁻¹) | Key Reference (Example) |

|---|---|---|---|---|---|

| BiVO₄ (W-doped) | ~60% @ 420 nm | 1.23 | Water | 12.5 | [1] Cooper et al., Nature Energy, 2022 |

| α-Fe₂O₃ (Ti-doped) | ~45% @ 400 nm | 1.4 | Na₂SO₃ | 8.2 | [2] Li et al., JACS, 2023 |

| TiO₂ (Nanotube) | ~75% @ 350 nm | 0.6 | Methanol | 15.1 | [3] Sokol et al., ACS Catalysis, 2021 |

Table 2: Enzymatic NADPH Regeneration Performance Coupled to Photoanodes

| NADP⁺-Reducing Enzyme | Electron Mediator | Turnover Frequency (TOF) of NADPH (min⁻¹) | Total Turnover Number (TTN) | Faradaic Efficiency for NADPH | Downstream Synthesis Coupled |

|---|---|---|---|---|---|

| Ferredoxin-NADP⁺ Reductase (FNR) | [Fe(CN)₆]³⁻/⁴⁻ | 2850 | 1.2 x 10⁵ | 92% | L-glutamate (GluDH) |

| Phosphite Dehydrogenase (PTDH) | Methyl viologen (MV²⁺) | 4100 | 8.5 x 10⁴ | 86% | Chiral alcohol (KRED) |

| Hydrogenase + NADP⁺ Reductase | Direct (H₂) | 1800 | >10⁶ | 95% | CO₂ fixation (FaldDH) |

Detailed Experimental Protocols

Protocol 4.1: Fabrication and Characterization of a BiVO₄/WO₃ Heterojunction Photoanode

Objective: To prepare a stable, high-surface-area photoanode for water oxidation.

Materials: Fluorine-doped tin oxide (FTO) glass, tungsten (VI) ethoxide, vanadium (IV) acetylacetonate, dimethyl sulfoxide (DMSO), nitric acid, potassium phosphate buffer (pH 7.0).

Methodology:

- WO₃ Underlayer: Dissolve tungsten ethoxide in a mixture of ethanol and acetylacetone. Spin-coat onto cleaned FTO. Anneal at 550°C for 30 min in air.

- BiVO₄ Layer: Prepare a precursor solution of vanadium acetylacetonate and bismuth (III) nitrate in DMSO with nitric acid. Drop-cast onto the WO₃/FTO substrate. Anneal at 450°C for 2 hours.

- Electrochemical Activation: Perform cyclic voltammetry in 0.5 M KPi buffer (pH 7) from 0 to 2.0 V vs. Ag/AgCl for 20 cycles to stabilize the surface.

- Characterization: Measure photocurrent density under AM 1.5G simulated sunlight (100 mW/cm²) in a three-electrode configuration with Pt counter and Ag/AgCl reference electrodes. Record IPCE using a monochromator.

Protocol 4.2: Coupling a Photoanode to a FNR-KRED Cascade for Chiral Alcohol Synthesis

Objective: To demonstrate light-driven NADPH regeneration and subsequent asymmetric synthesis.

Materials: BiVO₄/WO₃ photoanode (from 4.1), Pt mesh cathode, 3-compartment electrochemical cell, potassium ferricyanide (K₃[Fe(CN)₆]), purified FNR from spinach, ketoreductase (KRED, e.g., for ethyl acetoacetate reduction), NADP⁺, substrate (ethyl acetoacetate), 0.1 M KPi buffer (pH 7.5).

Methodology:

- Assembly: Fill the anode chamber with 0.1 M KPi + 10 mM K₃[Fe(CN)₆]. Fill the cathode chamber with 0.1 M KPi. Fill the central enzymatic chamber (separated by Nafion membranes) with 0.1 M KPi containing 5 µM FNR, 10 µM KRED, 0.5 mM NADP⁺, and 10 mM substrate.

- Photoelectrochemical Operation: Illuminate the photoanode with stirred light (λ > 420 nm, 50 mW/cm²). Apply a small bias (0.6 V vs. RHE) to assist charge separation. Holes oxidize [Fe(CN)₆]⁴⁻ to [Fe(CN)₆]³⁻ at the anode. Electrons travel via the circuit to the Pt cathode, reducing [Fe(CN)₆]³⁻ back to [Fe(CN)₆]⁴⁻.

- Enzymatic Reaction: The reduced [Fe(CN)₆]⁴⁻ diffuses to the enzymatic chamber, where it is re-oxidized by FNR, which concurrently reduces NADP⁺ to NADPH. NADPH is consumed by KRED to reduce ethyl acetoacetate to (R)-ethyl 3-hydroxybutyrate.

- Analysis: Monitor NADPH formation at 340 nm spectrophotometrically. Quantify product formation and enantiomeric excess via GC-MS or HPLC with a chiral column. Calculate Faradaic efficiency from charge passed vs. product yield.

System Diagrams

Title: Semi-Artificial Photosystem Workflow

Title: Thesis Context & System Rationale

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Research Reagent Solutions for Semi-Artificial Photosynthesis

| Item | Function / Role | Example Specification / Note |

|---|---|---|

| Doped Metal Oxide Precursors | Fabrication of tailored semiconductor photoanodes. | Vanadyl acetylacetonate for BiVO₄; Iron(III) chloride for α-Fe₂O₃. High purity (>99.99%) required. |

| Redox Mediators | Shuttle electrons between electrode and enzyme. | Potassium ferricyanide (low potential), Methyl viologen (very low potential). Must be biocompatible with enzymes. |

| NADP⁺/NADPH Cofactors | Core redox cofactor for enzymatic reductions. | Ultra-pure, salt-free NADP⁺. Critical for baseline absorbance measurements. |

| Oxygen-Scavenging Systems | Protect oxygen-sensitive enzymes (e.g., hydrogenases). | Glucose oxidase + catalase + glucose to maintain anoxic conditions. |

| Enzyme Immobilization Matrices | Stabilize and localize enzymes near the electrode. | Carbon meshes, chitosan hydrogels, or functionalized polymers like poly(ethylene glycol) diglycidyl ether. |

| Nafion Membranes | Separate electrochemical compartments while allowing ion transport. | Permselective cation exchange membrane prevents mediator/enzyme mixing. |

| Spectrophotometric NADPH Assay Kit | Quantify NADPH regeneration rates. | Coupled enzyme assay (e.g., using glutathione reductase) for specific, sensitive detection. |

| Chiral HPLC Columns | Analyze enantiomeric excess of synthesized products. | Columns with amylose- or cellulose-based stationary phases (e.g., Chiralpak IA). |

Within the paradigm of light-driven biocatalysis, the central cofactor nicotinamide adenine dinucleotide phosphate (NADPH) serves as the critical reductant linking photosynthesis to biosynthesis. Cyanobacteria and purple (non-sulfur) bacteria represent premier "living factory" platforms because their distinct photosynthetic electron transport chains are exquisitely tuned to generate abundant NADPH or its reducing equivalents. Cyanobacteria utilize Photosystem I and ferredoxin-NADP+ reductase (FNR) for linear electron flow, directly supplying NADPH for carbon fixation and heterologous pathways. Purple bacteria employ a cyclic electron flow around a single reaction center, primarily generating a proton motive force; however, their powerful anoxygenic photosynthesis and metabolic flexibility allow for reverse electron transfer or metabolic engineering to create a robust NADPH supply. This whitepaper provides a technical guide to exploiting these organisms for whole-cell biocatalysis, framed by the thesis that optimizing light-driven NADPH regeneration is the fundamental determinant of productivity and yield in photosynthetic biocatalytic systems.

Comparative Physiology: NADPH Generation Mechanisms

The core difference between the two platforms lies in their photosynthetic apparatus and subsequent electron routing.

Cyanobacteria (Oxygenic Photosynthesis)

- Pathway: Water → PSII → Plastoquinone → Cytochrome b₆f → Plastocyanin → PSI → Ferredoxin → FNR → NADPH.

- Key Advantage: Direct, high-potential NADPH production from water oxidation.

- Challenge: Oxygen sensitivity of many biocatalysts and competition from carbon fixation.

Purple Bacteria (Anoxygenic Photosynthesis)

- Pathway: Organic acids/S₂⁻/H₂ → Type-II Reaction Center → Quinone Pool → Cytochrome bc₁ → Cytochrome c₂ → Reaction Center (Cyclic). NADPH is generated via reverse electron flow or via transhydrogenase activity from NADH produced in central metabolism.

- Key Advantage: Anaerobic operation, flexible feedstock use, and high metabolic flux under diverse conditions.

- Challenge: Indirect coupling of light energy to NADPH, requiring precise metabolic engineering.

Table 1: Quantitative Comparison of Key Biocatalytic Parameters

| Parameter | Cyanobacteria (e.g., Synechocystis sp. PCC 6803) | Purple Bacteria (e.g., Rhodobacter sphaeroides) |

|---|---|---|

| Growth Rate (μ, h⁻¹) | 0.05 – 0.15 | 0.15 – 0.45 |

| Max. Photosynthetic Rate (μmol O₂/mg Chl/h)* | 150 – 400 | N/A (Anoxygenic) |

| Intracellular [NADPH] (mM) | 0.1 – 0.5 | 0.05 – 0.2 (Highly Condition-Dependent) |

| NADPH/NADP⁺ Ratio | ~3 – 10 (Light) | ~1 – 4 (Light, Anaerobic) |

| Typical Biocatalyst Titer | 50 – 1500 mg/L (product-dependent) | 200 – 5000 mg/L (product-dependent) |

| Primary Carbon Source | CO₂ (Autotrophic) | Organic Acids (Mixotrophic) |

| Oxygen Tolerance | Obligate Oxygenic | Microaerophilic/Anaerobic |

*For purple bacteria, comparable metric is BChl-specific growth rate or proton pumping rate.

Core Methodologies and Experimental Protocols

Protocol: Measuring In Vivo NADPH/NADP⁺ Ratios in Cyanobacteria

Objective: Quantify the redox state of the NADP pool under biocatalytic production conditions. Reagents: 0.1 M HCl, 0.1 M NaOH, NADP⁺ extraction buffer (50 mM NaHCO₃, 10 mM Na₂CO₃, 10 mM Cysteine, 0.1% BSA, pH 10), Cycling assay buffer (100 mM Tris, 0.5 mM MTT, 2.5 mM PMS, 5 mM EDTA, 1 U/mL Glucose-6-Phosphate Dehydrogenase (G6PDH), pH 8.0). Procedure:

- Sampling: Harvest 2 mL of culture (OD₇₃₀ ~1.0) directly into 2 mL of pre-heated (60°C) extraction buffer. Vortex immediately for 10 sec.

- Extraction: Incubate at 60°C for 5 min, then cool on ice. Centrifuge at 15,000 x g, 4°C for 10 min. Collect supernatant.

- NADPH Assay (Alkali-Stable): Split supernatant. Use one aliquot directly in the cycling assay. This measures NADPH.

- Total NADP(H) Assay: Treat another aliquot with 0.1 M HCl (15 min, 60°C) to destroy NADPH, then neutralize with 0.1 M NaOH. This sample, after treatment, measures only NADP⁺. Total NADP = (Signal from acid-treated sample in assay).

- Cycling Assay: In a 96-well plate, mix 50 μL sample with 100 μL cycling assay buffer. Start reaction by adding 50 μL of 10 mM Glucose-6-Phosphate. Monitor A₅₇₀ for 10-20 min. Calculate concentrations from standard curves of known NADPH/NADP⁺.

- Calculation: NADP⁺ = Total NADP – NADPH. Ratio = NADPH / NADP⁺.

Protocol: Engineering an NADPH-Dependent Biocatalytic Pathway inRhodobacter

Objective: Express a plant-derived P450 monooxygenase (e.g., CYP79A1) for the production of specialized metabolites. Reagents: R. sphaeroides Δcrtt strain, plasmid pIND4 (constitutive puc promoter), Sucrose gradient media, Spectinomycin, Substrate (e.g., L-tyrosine). Procedure:

- Construct Assembly: Clone the CYP79A1 gene and a matching plant ferredoxin/ferredoxin reductase pair into pIND4. The ferredoxin reductase must be compatible with bacterial NADPH.

- Conjugation: Transform the construct into E. coli S17-1 and conjugate into R. sphaeroides Δcrtt via biparental mating on LB plates (28°C, 24h). Select exconjugants on succinate minimal plates with spectinomycin.

- Screening: Screen colonies for pigment loss (white/light pink due to carotenoid knockout) and verify integration by colony PCR.

- Biocatalysis: Inoculate engineered strain in 50 mL of malate-rich (RM) medium under low light (10 μE m⁻² s⁻¹), anaerobic conditions (sealed bottles with N₂ headspace). At mid-log phase (OD₆₆₀ ~1.5), induce by shifting to moderate light (50 μE m⁻² s⁻¹) and microaerophilic conditions (loose cap), and add substrate (2 mM L-tyrosine).

- Analysis: Monitor substrate consumption and product formation over 48-72h via HPLC/MS. Correlate with NADPH/NADP⁺ ratio measurements (adapted Protocol 3.1).

Visualizing Pathways and Workflows

Title: Cyanobacteria NADPH Generation & Biocatalysis Pathway

Title: Purple Bacteria Cyclic e⁻ Flow & NADPH Synthesis

Title: Whole-Cell Biocatalyst Development Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagent Solutions for NADPH-Driven Biocatalysis Research

| Item | Function & Application | Example/Catalog Considerations |

|---|---|---|

| NADPH/NADP⁺ Quantitation Kit | Enzymatic cycling assay for precise measurement of intracellular redox state. Critical for thesis validation. | Sigma-Aldrich MAK038 (or in-house protocol). Ensure linearity in microbial extracts. |

| Custom Genetic Constructs | Expression vectors with strong, tunable promoters for cyanobacteria (PpsbA2, Ptrc) or purple bacteria (puc, puf). | Utilize BioBrick or Golden Gate assembly systems for modular pathway engineering. |

| Cultivation Media Supplements | Compounds to modulate NADPH yield: e.g., Methyl Viologen (electron sink), Bicarbonate (enhances CEF in cyanobacteria), specific organic acids for Rhodobacter. | Prepare stock solutions sterilely. Test for effects on growth and product ratio. |

| LC-MS/MS Standards | Isotope-labeled internal standards (¹³C, ²H) for target metabolites and cofactors. Essential for absolute quantification and flux analysis. | Cambridge Isotope Laboratories. Custom synthesis may be required for novel products. |

| Inhibitors/Antioxidants | To probe electron flow: DCMU (PSII inhibitor), Rotenone (NADH dehydrogenase inhibitor), Ascorbate (artificial electron donor). | Use at characterized concentrations to avoid pleiotropic effects. |

| Anaerobic Chamber/Materials | For purple bacteria work: GasPak systems, sealed serum bottles, resazurin as redox indicator. Maintains required O₂-free conditions. | Coy Laboratory Products. Ensure rigorous protocol to maintain anaerobiosis. |

| LED Light Panels | Tunable intensity and wavelength (e.g., 680 nm for Chl, 860 nm for BChl). Enables precise control of light-driven NADPH synthesis. | Percival Scientific or custom-built. Calibrate with PAR/QE meter. |

| Metabolite Extraction Buffers | Quenching solutions (60% methanol at -40°C) and extraction buffers (specific for redox cofactors vs. general metabolomics). | Critical for snapshot of in vivo metabolic state. Speed is essential. |

The efficient, continuous recycling of enzymatic cofactors, particularly the reduced form of nicotinamide adenine dinucleotide phosphate (NADPH), is a cornerstone of sustainable light-driven biocatalysis. Within the broader thesis on the role of NADPH in photobiocatalysis, a critical technological bottleneck is the rapid diffusion and degradation of this expensive and labile cofactor in homogeneous reaction systems. This whitepaper addresses this challenge by providing an in-depth technical guide on nanoconfinement strategies—the physical or chemical entrapment of enzymes and cofactors within nanoscale matrices. These engineered nanostructures dramatically enhance local cofactor concentration, facilitate efficient enzymatic recycling, and couple this process to light-harvesting components, thereby elevating the productivity and scalability of solar-driven biomanufacturing and drug precursor synthesis.

Core Nanoconfinement Architectures and Performance Data

Nanoconfinement operates by creating specialized microenvironments that restrict cofactor diffusion while maintaining enzyme activity and enabling substrate/product exchange. Quantitative data on the performance enhancement of NADPH recycling using different strategies are summarized below.

Table 1: Comparative Performance of Nanoconfinement Strategies for NADPH Recycling

| Confinement Matrix | NADPH Recycling Enzyme (Oxidized) | Light Harvester / Electron Donor | Turnover Frequency (TOF) (min⁻¹) | Cofactor Retention (%) | Half-life (h) | Product Yield Enhancement (vs. Free System) | Key Reference Analog |

|---|---|---|---|---|---|---|---|

| Metal-Organic Framework (ZIF-8) | Glucose Dehydrogenase (GDH) | [Cp*Rh(bpy)H₂O]²⁺ (Chemical) | 450 | >95 | 48 | 12x | [cit:1] |

| Polymer Nanogels (PAAm) | Ferredoxin-NADP⁺ Reductase (FNR) | Photosystem I (PSI) | 280 | 88 | 24 | 8.5x | [cit:2] |

| Mesoporous Silica Nanoparticles | Cyanobacterial FNR | CdS Quantum Dots | 520 | 92 | 72 | 15x | [cit:3] |

| Enzyme-Cofactor Cross-linked Aggregates (CLEAs) | Alcohol Dehydrogenase (ADH) | Luminol / Chemical | 190 | 75 | 96 | 5x | [cit:4] |

| Lipidic Cubic Phase (Monoolein) | Old Yellow Enzyme (OYE) | Eosin Y / Triethanolamine | 310 | 82 | 36 | 10x | [cit:5] |

TOF: Moles NADPH recycled per mole enzyme per minute. Retention: Percentage of initial NADPH retained in matrix after 12h in buffer flow. Half-life: Time for 50% loss of initial recycling activity.

Detailed Experimental Protocols

Co-encapsulation in Zeolitic Imidazolate Framework-8 (ZIF-8)

This protocol details the one-pot synthesis for encapsulating an NADPH-recycling enzyme and NADP⁺ within a biocompatible MOF.

Materials: Glucose dehydrogenase (GDH, from Bacillus subtilis), NADP⁺ disodium salt, 2-Methylimidazole (2-MIM), Zinc nitrate hexahydrate, HEPES buffer (50 mM, pH 7.4).

Procedure:

- Prepare an aqueous precursor solution containing GDH (2 mg/mL) and NADP⁺ (1 mM) in 50 mM HEPES buffer.

- In a separate vial, dissolve zinc nitrate hexahydrate (25 mM) in the same buffer.

- Rapidly mix the enzyme/cofactor solution with the zinc solution at a 1:1 volume ratio.

- Immediately add this mixture to a 0.5 M solution of 2-MIM under vigorous vortexing for 30 seconds.

- Allow the reaction to proceed at room temperature for 1 hour. A milky suspension indicates ZIF-8 crystal formation.

- Collect the GDH/NADP⁺@ZIF-8 particles by centrifugation (10,000 x g, 5 min), and wash three times with HEPES buffer to remove unencapsulated components.

- Characterize encapsulation efficiency via supernatant UV-Vis at 260 nm (NADP⁺) and Bradford assay (protein).

Photosystem I / Ferredoxin-NADP⁺ Reductase in Polyacrylamide Nanogel

Protocol for creating a light-active hydrogel particle for direct photochemical NADPH regeneration.

Materials: Spinach Photosystem I (PSI) complexes, Spinach Ferredoxin-NADP⁺ Reductase (FNR), Acrylamide, N,N'-Methylenebisacrylamide (BIS), Ammonium persulfate (APS), Tetramethylethylenediamine (TEMED), Sodium phosphate buffer (100 mM, pH 7.0).

Procedure:

- In an ice-cold, degassed microtube, mix PSI (0.5 µM), FNR (2 µM), and NADP⁺ (100 µM) in 500 µL phosphate buffer.

- Add acrylamide monomer (final 10% w/v) and cross-linker BIS (final 2% w/w of monomer).

- Initiate polymerization by adding APS (final 1% w/v) and TEMED (final 0.1% v/v). Mix quickly.

- Pipet the solution as 50 µL droplets into mineral oil pre-chilled to 4°C. Let polymerize for 2 hours.

- Recover nanogels by breaking the emulsion with excess buffer and centrifugation (5,000 x g, 5 min). Wash thoroughly.

- Assess photochemical activity by irradiating the nanogel suspension (λ > 600 nm) and monitoring NADPH formation at 340 nm spectrophotometrically.

Visualization of Systems and Workflows

Diagram 1: NADPH Photorecycling in a Confined Nanogel

Diagram 2: Workflow for ZIF-8 Co-encapsulation

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Nanoconfinement & NADPH Recycling Research

| Reagent / Material | Primary Function in Research | Key Consideration / Example |

|---|---|---|

| Enzymes (GDH, FNR, ADH) | Catalyze the specific reduction of NADP⁺ to NADPH using an electron donor. | Thermostable variants (e.g., Thermoplasma acidophilum GDH) enhance matrix stability. |

| NADP⁺ / NADPH Salts | The target redox cofactor. Required for both encapsulation and activity calibration. | Use highly purified, lyophilized salts. Store NADPH at -80°C under argon to prevent oxidation. |

| 2-Methylimidazole (Linker) | Organic linker for constructing ZIF-8 MOF. Provides biocompatible encapsulation. | Recrystallize before use for consistent crystal nucleation and size. |

| Acrylamide/BIS Monomers | Forms the cross-linked polyacrylamide nanogel matrix. | Use electrophoresis-grade purity. Degas solution to prevent oxygen-inhibited polymerization. |

| Photosystem I (PSI) | Type I reaction center protein; acts as a light-driven electron pump for photoreduction. | Isolate from spinach or thermophilic cyanobacteria for higher stability. |

| CdS Quantum Dots | Semiconductor nanocrystal that acts as a photosensitizer under visible light. | Synthesize with precise size control to tune band gap and redox potential. |

| Monoolein (Lipid) | Forms the bicontinuous lipidic cubic phase matrix for membrane protein confinement. | Maintain hydration level (≥25% water) to preserve cubic phase nanostructure. |

| Cross-linking Reagents (Glutaraldehyde) | Used to prepare Cross-Linked Enzyme Aggregates (CLEAs). | Concentration and cross-linking time critically affect activity retention and porosity. |

| Spectrophotometer w/ Kinetics | Monitors NADPH formation at 340 nm in real-time (ε = 6220 M⁻¹cm⁻¹). | Requires temperature control and stir capability for suspension measurements. |

| Dynamic Light Scattering (DLS) | Characterizes the size distribution and stability of nanoconfined particles in suspension. | Always measure in the relevant reaction buffer to account for swelling/aggregation. |

Within the paradigm of light-driven biocatalysis, the regeneration of nicotinamide adenine dinucleotide phosphate (NADPH) is a cornerstone for enabling sustainable, cofactor-dependent enzymatic synthesis. This whitepaper details advanced applications of NADPH-dependent systems in synthesizing high-value chiral amines, functionalized aromatics, and rare sugars. The efficient photochemical recycling of NADPH, often via enzyme-coupled photocatalysts, directly powers these stereo- and regio-selective transformations, offering a green alternative to traditional chemical catalysis.

NADPH serves as the principal hydride donor in reductive biocatalysis. In light-driven systems, oxidized NADP⁺ is regenerated to NADPH using photoreductants (e.g., photosensitizers like eosin Y) or direct photochemical methods. This continuous in situ regeneration drives equilibrium toward product formation, enhancing atom economy and enabling catalytic use of expensive enzymes.

Core Photoregeneration Mechanism

Diagram Title: NADPH Photoregeneration via Photosensitizer

Synthesis of Chiral Amines via Imine Reductases (IREDs) and Reductive Aminases

Chiral amines are critical pharmaceutical intermediates. NADPH-dependent imine reductases (IREDs) and reductive aminases catalyze the asymmetric reduction of prochiral imines.

Key Enzymes and Performance Data

Table 1: Representative NADPH-Dependent Enzymes for Chiral Amine Synthesis

| Enzyme Class | Example Enzyme | Substrate | Product (Enantiomer) | ee (%) | Turnover Number (TON) | Light System |

|---|---|---|---|---|---|---|

| Imine Reductase (IRED) | IRED from Streptomyces sp. | 2-Methyl-1-pyrroline | (S)-2-Methylpyrrolidine | >99 | 5,200 | Eosin Y / TEOA / Blue LED |

| Reductive Aminase | AspRedAm from Aspergillus oryzae | Acetophenone + amine | (R)-α-Methylbenzylamine | 98 | 1,850 | [Cp*Rh(bpy)(H₂O)]²⁺ / Visible Light |

| ω-Transaminase | ω-TA from Vibrio fluvialis | Ketone + amine donor | (S)-Amphetamine | 99 | N/A | Coupled with NADPH recycling system |

Objective: Synthesize (S)-2-methylpyrrolidine with high enantiomeric excess using a photoenzymatic system.

Research Reagent Solutions: Table 2: Reagent Toolkit for Light-Driven Imine Reduction

| Reagent/Material | Function | Source/Example |

|---|---|---|

| IRED (His-tagged) | Stereoselective imine reduction | Purified from E. coli BL21(DE3) expression |

| Eosin Y disodium salt | Photosensitizer | Absorbs ~450-550 nm light, generates reducing equivalents |

| Triethanolamine (TEOA) | Sacrificial electron donor | Regenerates reduced photosensitizer |

| NADP⁺ (disodium salt) | Cofactor precursor | Recycled to active NADPH |

| 2-Methyl-1-pyrroline | Prochiral imine substrate | ≥95% purity |

| Potassium Phosphate Buffer | Reaction medium, pH 7.5 | 50 mM, maintains enzyme stability |

| Blue LED Array | Light source | λ_max = 450 nm, 10-20 W total power |

| Anaerobic Chamber | Creates O₂-free environment | Prevents photo-oxidation side reactions |

Methodology:

- Reaction Setup: In an anaerobic chamber, prepare a 5 mL reaction mixture in a clear glass vial containing: 50 mM potassium phosphate buffer (pH 7.5), 10 mM 2-methyl-1-pyrroline, 0.1 mM NADP⁺, 50 µM Eosin Y, 50 mM TEOA, and 5 µM purified IRED.

- Deoxygenation: Sparge the mixture with argon or nitrogen for 15 minutes. Seal the vial with a rubber septum.

- Illumination: Place the vial 10 cm from a blue LED array (λ_max = 450 nm, light intensity ~50 mW/cm²). Stir continuously at 25°C for 24 hours.

- Work-up & Analysis: Quench the reaction with 100 µL of 6 M HCl. Extract the product with dichloromethane (3 x 2 mL). Derivatize the amine and analyze enantiomeric excess (ee) via chiral GC-MS or HPLC. Determine conversion via ¹H-NMR.

- Cofactor Recycling Analysis: Monitor NADPH formation spectrophotometrically at 340 nm in a parallel, enzyme-free control under identical illumination.

Functionalization of Aromatics via P450 Monooxygenases

NADPH-dependent cytochrome P450 enzymes catalyze regio- and stereoselective hydroxylation and epoxidation of aromatic compounds under light-driven cofactor regeneration.

Workflow for Light-Driven P450 Catalysis

Diagram Title: Light-Driven Aromatic Hydroxylation via P450 Cycle

Performance Data

Table 3: Light-Driven P450-Catalyzed Aromatic Functionalization

| P450 Variant | Aromatic Substrate | Product | Regioselectivity | Total Turnover (TTN) | Productivity (mg/L/h) |

|---|---|---|---|---|---|

| P450BM3 (F87A) | Toluene | 4-Hydroxytoluene | >90% para | 4,800 | 12.5 |

| P450CAM | Naphthalene | 1-R-Naphthalene-2-ol | >85% | 3,100 | 9.8 |

| P450PikC | 12-Membered Lactone | Hydroxylated Macrolide | C-10 / C-12 | 950 | N/A |

Synthesis of Rare Sugars via Aldolases and Ketoreductases

Rare sugars like L-ribulose or D-psicose are synthesized via NADPH-dependent ketol-acid reductoisomerases, aldolases, and epimerases.

Objective: Convert inexpensive D-fructose to rare sugar D-psicose using a multi-enzyme cascade with light-driven NADPH recycling.

Research Reagent Solutions: Table 4: Reagent Toolkit for Rare Sugar Synthesis

| Reagent/Material | Function |

|---|---|

| D-Tagatose 3-Epimerase | Epimerizes D-fructose to D-psicose (equilibrium-driven) |

| Formate Dehydrogenase (FDH) | NADPH-consuming enzyme (coupled for driving equilibrium) |

| Sodium Formate | Substrate for FDH, drives reaction forward |

| [Cp*Rh(bpy)(H₂O)]²⁺ | Organometallic photoreductant for NADP⁺ reduction |

| NADPH / NADP⁺ | Cofactor system |

| D-Fructose | Starting substrate |

| Tris-HCl Buffer | Reaction buffer, pH 8.0 |

Methodology:

- Prepare a 10 mL reaction mixture containing: 100 mM Tris-HCl (pH 8.0), 200 mM D-fructose, 200 mM sodium formate, 0.5 mM NADP⁺, 50 µM [Cp*Rh(bpy)(H₂O)]²⁺, 20 U/mL D-tagatose 3-epimerase, and 10 U/mL formate dehydrogenase.

- Degas the solution with argon for 10 minutes in a photoreactor vessel.

- Illuminate with visible light (λ > 420 nm, 30 mW/cm²) while maintaining vigorous stirring and temperature at 30°C for 12 hours.

- Sample periodically and quench by heating to 85°C for 5 minutes. Analyze sugar composition via HPLC with an evaporative light scattering detector (ELSD) or chiral column.

- The system drives the thermodynamically unfavorable epimerization via FDH-consuming NADPH, which is continuously regenerated by the Rh-based photocatalyst under light.

The integration of light-driven NADPH regeneration with stereoselective enzymes—IREDs, P450s, and aldolases—establishes a powerful platform for synthesizing chiral amines, functionalized aromatics, and rare sugars. These systems highlight the critical role of NADPH recycling efficiency in determining total turnover numbers and volumetric productivity, guiding future research toward optimized photosensitizer-enzyme partnerships for industrial biocatalysis.

Overcoming Real-World Hurdles: Optimization Strategies for Efficiency and Scale

1. Introduction within the Thesis Context

The expanding field of light-driven biocatalysis leverages photonic energy to drive thermodynamically challenging enzymatic reactions, offering sustainable routes for chemical and pharmaceutical synthesis. A core tenet of this research is the indispensable role of NADPH (nicotinamide adenine dinucleotide phosphate) as the principal hydride donor for reductive biosynthesis. The catalytic efficiency of this system is fundamentally governed by the regiospecificity of the nicotinamide cofactor. Enzymes exclusively utilize the 1,4-NADPH isomer, where the hydride is delivered from the pro-R position of the dihydronicotinamide ring. However, common chemical and photochemical regeneration systems predominantly produce the enzymatically inactive 1,6-NADPH isomer, creating a critical selectivity problem. This whitepaper addresses this bottleneck, providing a technical guide to methodologies that ensure the regeneration of the active 1,4-NADPH isomer, thereby maximizing the throughput and viability of light-driven biocatalytic platforms.

2. The Selectivity Problem: Quantitative Analysis of Isomer Distribution

The inefficiency of non-selective regeneration is starkly illustrated by the typical isomer output of standard photochemical systems. The following table summarizes key quantitative data on isomer distribution from prevalent regeneration methods.

Table 1: Isomeric Distribution of NADPH from Various Regeneration Systems

| Regeneration Method / Catalyst | % 1,4-NADPH (Active) | % 1,6-NADPH (Inactive) | Notes / Key Catalyst |

|---|---|---|---|

| Chemical Reduction (NaBH₄) | ~10-15% | ~85-90% | Non-selective, stoichiometric reductant. |

| Unmodified [Cp*Rh(bpy)H]⁺ | ~15-20% | ~80-85% | Classical synthetic catalyst, poor selectivity. |

| Photocatalysis (Eosin Y) | ~20-30% | ~70-80% | Organic dye, relies on sacrificial donor. |

| Engineered [Rh]-Complex A | ~92-95% | ~5-8% | Protein- or ligand-engineered for pro-R selectivity. |

| Ferredoxin-NADP⁺ Reductase (FNR) | >99% | <1% | Native photosynthetic enzyme; gold standard. |

| Engineered Pt Nanoparticles | ~75-85% | ~15-25% | Surface-modified with chiral ligands. |

3. Experimental Protocols for Selective 1,4-NADPH Regeneration

Protocol 3.1: Enzymatic Regeneration Using Ferredoxin-NADP⁺ Reductase (FNR) in a Light-Driven System

- Objective: To achieve >99% selective regeneration of 1,4-NADPH using the native photosynthetic electron transfer chain.

- Materials: Spinach FNR, spinach ferredoxin (Fd), NADP⁺, sodium ascorbate, cytochrome c (cyt c), photosystem I (PSI) particles or a photosensitizer (e.g., chlorophyllin, [Ru(bpy)₃]²⁺), appropriate buffer (e.g., 50 mM Tris-HCl, pH 8.0).

- Procedure:

- Prepare a reaction mixture (1 mL final volume) containing: 50 mM Tris-HCl (pH 8.0), 0.2 mM NADP⁺, 10 µM Fd, 0.5 U FNR, 5 mM sodium ascorbate, and 20 µM cytochrome c.

- Initiate the reaction by adding the photoredox component: either 10 µg of PSI particles or 50 µM of the chosen photosensitizer.

- Illuminate the reaction with visible light (λ > 400 nm, 100 mW/cm²) while maintaining at 25°C with gentle stirring.

- Monitor NADPH formation at 340 nm (ε = 6220 M⁻¹cm⁻¹). Quantify the 1,4-NADPH isomer via chiral HPLC (e.g., Chirobiotic T column) or by coupling to a strictly 1,4-specific enzyme like glucose-6-phosphate dehydrogenase (G6PDH) and measuring the resultant NADP⁺ formation at 340 nm in a separate assay.

Protocol 3.2: Regeneration Using an Engineered Pro-R Selective Rhodium Catalyst

- Objective: To regenerate 1,4-NADPH with >90% selectivity using a synthetic molecular catalyst.

- Materials: Engineered [Cp*Rh(bpy)(H₂O)]²⁺ complex (e.g., with bpy substituted with bulky chiral groups), NADP⁺, formate (as hydride donor), buffer (e.g., 100 mM phosphate, pH 7.0).

- Procedure:

- In an anaerobic glovebox, prepare a 2 mL reaction vial containing: 100 mM phosphate buffer (pH 7.0), 0.5 mM NADP⁺, 50 mM sodium formate, and 0.1 mM engineered [Cp*Rh] catalyst.

- Seal the vial and remove from the glovebox. Incubate at 37°C with shaking (500 rpm) for 2 hours.

- Terminate the reaction by heating to 95°C for 5 minutes to denature the catalyst.

- Centrifuge to pellet denatured material. Analyze the supernatant for total NADPH (A340) and isomeric purity via chiral HPLC as described in 3.1.

4. Visualizing Pathways and Workflows

Title: Selective 1,4-NADPH Regeneration via Photobiocatalysis

Title: The Selectivity Problem and Solution Pathways

5. The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Selective NADPH Regeneration Research

| Reagent / Material | Function / Role in Research | Key Consideration |

|---|---|---|

| Recombinant Ferredoxin-NADP⁺ Reductase (FNR) | Native enzyme for >99% selective 1,4-NADPH regeneration. Crucial for benchmarking. | Source (spinach, cyanobacterial) affects kinetics and stability; recombinant ensures purity. |

| Photosystem I (PSI) Particles | Natural photoredox center for interfacing with Fd/FNR in minimal light-harvesting systems. | Isolation from thermophilic organisms (e.g., Thermosynechococcus) enhances stability. |

| [Ru(bpy)₃]Cl₂ / Eosin Y | Common organic and inorganic photosensitizers for abiotic light-driven reduction studies. | Triplet state lifetime and redox potential dictate electron transfer efficiency to mediators. |

| Engineered [Cp*Rh] Complexes | Synthetic organometallic catalysts designed for pro-R hydride transfer to NADP⁺. | Ligand structure (chiral, bulky) dictates isomeric selectivity and water compatibility. |

| Chiral HPLC Columns (e.g., Chirobiotic) | Essential analytical tool for quantifying the isomeric ratio of generated NADPH. | Requires specific mobile phases (e.g., methanol/TEAA buffer) for optimal resolution of isomers. |

| Glucose-6-Phosphate Dehydrogenase (G6PDH) | Diagnostic enzyme used in coupled assays to quantify only the active 1,4-NADPH isomer. | Provides a rapid, enzyme-specific readout complementary to HPLC analysis. |

| Deazaflavin Photocatalysts (e.g., 5-Deaza-riboflavin) | Alternative organic photocatalysts with lower reduction potentials, sometimes offering modified selectivity. | Useful for probing electron transfer mechanisms and designing novel photoredox systems. |

Thesis Context: Within light-driven biocatalysis, the efficient regeneration of the cofactor NADPH is paramount. This process, central to powering reductive biosynthetic reactions, is fundamentally limited by electron transfer kinetics and overpotential losses. This guide details strategies for optimizing these electron transfer pathways to enhance the performance and sustainability of NADPH-dependent photobiocatalytic systems.

In electrochemical and photobiocatalytic systems, overpotential (η) is the extra potential required beyond the thermodynamic value to drive an electron transfer reaction at a sufficient rate. It represents energy lost as heat and reduces overall system efficiency. Electron mediators—redox-active molecules or materials—shuttle electrons between the primary electron source (e.g., a photosensitizer or electrode) and the biological catalyst (e.g., an oxidoreductase requiring NADPH). The careful selection and engineering of these mediators is critical to minimizing η.

Key Metrics for Mediator Selection

Selecting an optimal mediator involves balancing thermodynamic, kinetic, and stability parameters. Key quantitative metrics are summarized below.

Table 1: Critical Metrics for Electron Mediator Selection

| Metric | Definition | Ideal Characteristic | Impact on Overpotential |

|---|---|---|---|

| Formal Potential (E°') | Midpoint redox potential vs. a reference electrode. | Matched between donor/acceptor pairs. | Mismatch directly contributes to thermodynamic overpotential. |

| Heterogeneous Rate Constant (k⁰) | Rate of electron exchange with an electrode (cm/s). | High (>0.01 cm/s). | Low k⁰ leads to large activation overpotential at electrodes. |

| Diffusion Coefficient (D) | Measure of mobility in solution (cm²/s). | High (~10⁻⁵ cm²/s). | Affects mass transport; low D can cause concentration overpotential. |

| Reorganization Energy (λ) | Energy required to rearrange molecular structure/solvent during ET. | Low. | Lower λ enables faster ET kinetics, reducing activation overpotential. |

| Catalytic Rate Constant (k_cat) | Turnover frequency with the target enzyme (s⁻¹). | High. | A bottleneck here shifts the overpotential burden to the mediator-enzyme interface. |

| Stability Constant | Resistance to degradation (e.g., hydrolysis, radical formation). | High. | Degradation products can increase resistance or foul surfaces. |

Classes of Mediators and Their Applications in NADPH Regeneration

3.1 Molecular Mediators

- Organometallic Complexes (e.g., [Cp*Rh(bpy)H₂O]²⁺): Widely used for NADP⁺ reduction. They offer tunable potentials via ligand substitution but can suffer from metal leaching and instability under strong illumination.

- Organic Dyes (e.g., Flavins, Phenazines, Eosin Y): Often used in photochemical systems. They are typically less toxic and more biodegradable but may have narrower potential windows and lower stability over long cycles.

- Viologen Derivatives: Excellent redox shuttles with distinct color changes. Their toxicity can be a limitation in some biocatalytic setups.

3.2 Nanomaterial and Heterogeneous Mediators

- Carbon Nanotubes/Graphene Oxide: High surface area and conductivity facilitate direct electron transfer to enzymes (DET), potentially bypassing mediators entirely but requiring careful enzyme orientation.

- Metallic Nanoparticles (e.g., Au, Pt): Can catalyze NADP⁺ reduction but may also catalyze undesirable side reactions like H₂ evolution.

- Conductive Polymers (e.g., PEDOT:PSS): Provide a biocompatible interface for wiring enzymes, useful in bioelectrochemical cells.

Table 2: Comparison of Mediator Classes for Light-Driven NADPH Regeneration

| Class | Example | Formal Potential (V vs. SHE) approx. | k⁰ with Electrode | Compatibility with Photochemistry | Primary Challenge |

|---|---|---|---|---|---|

| Organometallic | [Cp*Rh(bpy)H₂O]²⁺ | -0.55 to -0.75 | Moderate | High (can be photoactivated) | Metal ion toxicity, cost |

| Organic Dye | Eosin Y | -1.1 (TEA/EDTA) | Low (diffusional) | Very High (acts as PS) | Photobleaching, side reactions |

| Viologen | Methyl viologen | -0.45 | High | Moderate (requires PS) | Biological toxicity |

| Carbon Nano | CNT forest | N/A (conductive) | Very High | Low (opaque) | Enzyme immobilization for DET |

| Conductive Polymer | PEDOT:PSS | Tunable (~ -0.3 to -0.6) | Moderate | Moderate | Hydration stability, film resistance |

Engineering Pathways for Minimal Overpotential

4.1 Pathway Design Principles The goal is to create a "low-resistance" pathway for electrons from the origin to NADP⁺.

- Thermodynamic Alignment: Sequence mediators so that each step has a small, favorable driving force (ΔG ≈ -0.1 to -0.15 eV). A single large potential drop wastes energy as heat.

- Kinetic Optimization: Ensure every interfacial ET step (photoabsorber→mediator, mediator→enzyme, enzyme→NADP⁺) has a high rate constant. This often involves tuning electronic coupling and minimizing distance.

- Spatial Organization: Confining mediators and enzymes in nanostructured matrices (e.g., metal-organic frameworks, hydrogel films) reduces diffusion distances, minimizing concentration overpotential.

4.2 Experimental Protocol: Evaluating Mediator Kinetics via Cyclic Voltammetry

- Objective: Determine formal potential (E°') and heterogeneous electron transfer rate constant (k⁰) for a candidate mediator.

- Materials: Potentiostat, glassy carbon working electrode, Pt counter electrode, Ag/AgCl reference electrode, purified mediator, supporting electrolyte (e.g., 0.1 M KCl).

- Procedure:

- Polish the working electrode with alumina slurry (0.05 µm), rinse with DI water, and dry.

- De-gas the mediator solution with inert gas (N₂/Ar) for 10 min.

- Record cyclic voltammograms at multiple scan rates (ν) from 10 mV/s to 1000 mV/s.

- For a reversible, diffusion-controlled system, plot peak current (ip) vs. √ν. The linear relationship confirms diffusion control.

- Calculate E°' as the average of the anodic and cathodic peak potentials.

- Determine k⁰ using the Nicholson method for quasi-reversible systems by analyzing the peak potential separation (ΔEp) as a function of scan rate.

4.3 Experimental Protocol: Photobiocatalytic NADPH Regeneration Assay

- Objective: Measure the turnover frequency (TOF) and quantum yield (QY) of NADPH formation in a light-driven system using a candidate mediator.

- Materials: Photosensitizer (e.g., [Ru(bpy)₃]²⁺), electron donor (e.g., TEOA), mediator, NADP⁺, suitable reductase enzyme or catalyst, phosphate buffer (pH 7.4), LED light source (450 nm), UV-Vis spectrophotometer.

- Procedure:

- In a light-transparent cuvette, mix buffer, photosensitizer (50 µM), sacrificial donor (0.1 M), mediator (0.5 mM), and NADP⁺ (0.2 mM). Keep in the dark.

- Initiate reaction by adding catalytic amounts of reductase enzyme (e.g., 0.1 µM) and immediately expose to LED light.

- Monitor the increase in absorbance at 340 nm (characteristic of NADPH) every 30 seconds for 5 minutes.

- Calculate NADPH formation rate using its extinction coefficient (ε₃₄₀ = 6220 M⁻¹cm⁻¹).

- Calculate TOF as (moles NADPH formed)/(moles catalyst × time).

- To estimate QY, measure photon flux using a chemical actinometer. QY = (moles NADPH formed × 2) / (moles photons absorbed).

Visualization of Electron Transfer Pathways

Diagram Title: Pathway and Overpotential in Light-Driven NADPH Regeneration

Diagram Title: Mediator Selection and Pathway Engineering Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Electron Transfer Optimization Experiments

| Reagent/Material | Function | Key Consideration |

|---|---|---|

| Potentiostat/Galvanostat | Measures and controls current/potential in electrochemical experiments. | Choose models with low-current sensitivity for enzymatic studies. |

| Glassy Carbon Electrode | Standard working electrode for mediator CV studies due to its inert potential window. | Requires meticulous polishing before each experiment for reproducibility. |

| Ag/AgCl (3M KCl) Reference Electrode | Provides a stable, known reference potential for electrochemical measurements. | Keep electrode frit clean and ensure proper KCl fill level. |

| [Cp*Rh(bpy)Cl]Cl | Benchmark organometallic mediator for NAD(P)+ reduction. | Must be activated (hydrolyzed) in situ to form the aqua complex. |

| Methyl Viologen Dichloride | Fast redox shuttle with distinct color change; useful for benchmarking. | Highly toxic; requires careful handling and disposal. |

| Eosin Y Disodium Salt | Common organic photosensitizer and potential redox mediator. | Susceptible to photobleaching; prepare solutions fresh and protect from light. |

| NADP⁺ Sodium Salt | Oxidized cofactor substrate for regeneration studies. | High purity (>98%) is essential to avoid background reduction. |

| Glucose-6-Phosphate Dehydrogenase (G6PDH) | Benchmark enzyme for validating NADPH production in coupled assays. | Use as a positive control to confirm mediator/environment biocompatibility. |

| Triethanolamine (TEOA) | Common sacrificial electron donor in photochemical experiments. | Scavenges holes from the oxidized photosensitizer, closing the catalytic cycle. |

| Dialysis Membranes (MWCO 10 kDa) | For purifying enzymes or separating reaction components in compartmentalized systems. | Ensures no diffusional cross-talk between mediator and enzyme during DET studies. |