Optimizing Multi-Directional LED Arrays for Photoredox Catalysis in Drug Discovery

This comprehensive guide explores the design, implementation, and validation of multi-directional LED array configurations for photoredox illumination in biomedical research.

Optimizing Multi-Directional LED Arrays for Photoredox Catalysis in Drug Discovery

Abstract

This comprehensive guide explores the design, implementation, and validation of multi-directional LED array configurations for photoredox illumination in biomedical research. It provides a foundational understanding of photoredox principles, detailed methodologies for constructing and applying bespoke illumination systems, strategies for troubleshooting and optimizing performance, and comparative validation techniques. Tailored for researchers, scientists, and drug development professionals, the article addresses the critical need for reproducible, uniform, and high-throughput photochemical irradiation to advance photocatalysis in drug synthesis, chemical biology, and therapeutic development.

Fundamentals of Photoredox Catalysis and Multi-Directional Illumination

Photoredox catalysis (PRC) utilizes light-absorbing molecules (photocatalysts) to initiate single-electron transfer (SET) events under mild conditions, enabling novel bond formations critical in drug discovery. The mechanism operates within a cycle of photoexcitation and redox events.

The Photoredox Cycle

The catalytic cycle involves four core steps:

- Photon Absorption & Excitation: A ground-state photocatalyst (PC) absorbs a photon of specific wavelength, promoting an electron from the highest occupied molecular orbital (HOMO) to the lowest unoccupied molecular orbital (LUMO), forming the excited-state photocatalyst (*PC).

- Quenching & SET: *PC is both a stronger reductant and oxidant than its ground state. It can undergo oxidative quenching (electron transfer to a substrate, forming PC⁺) or reductive quenching (electron transfer from a substrate, forming PC⁻).

- Product Formation & Catalyst Regeneration: The radical species generated via SET engage in bond-forming steps. The oxidized or reduced photocatalyst intermediate returns to its ground state via a second SET event with a sacrificial donor/acceptor or a substrate, completing the cycle.

Key Experimental Protocols for Photoredox Studies

Protocol 1: Standard Screening of Photoredox Reactions Under LED Illumination

Objective: To evaluate the efficiency of a photoredox-catalyzed C–N cross-coupling reaction.

Materials:

- Photoredox catalyst (e.g., Ir(ppy)₃, 1 mol%)

- Substrate A (aryl halide, 1.0 equiv)

- Substrate B (amine, 1.5 equiv)

- Base (e.g., DIPEA, 2.0 equiv)

- Anhydrous solvent (e.g., DMSO or MeCN, 0.1 M concentration)

- Schlenk tube or vial equipped with a magnetic stir bar

- Appropriate LED light source (e.g., 450 nm blue LED array)

Procedure:

- In a nitrogen-filled glovebox, charge the Schlenk tube with Substrate A (0.1 mmol), Substrate B (0.15 mmol), base (0.2 mmol), and photocatalyst (0.001 mmol).

- Add anhydrous solvent (1.0 mL) and seal the tube.

- Remove the tube from the glovebox and place it at a fixed distance (e.g., 5 cm) from the LED array. Ensure uniform illumination of the reaction vessel.

- Stir the reaction mixture vigorously under LED illumination at ambient temperature for 16-24 hours.

- Monitor reaction progress by TLC or LCMS.

- Upon completion, dilute the mixture with ethyl acetate (10 mL) and wash with water (3 x 5 mL). Dry the organic layer over anhydrous MgSO₄, filter, and concentrate in vacuo.

- Purify the crude product via flash column chromatography to obtain the desired coupled product.

Protocol 2: Quantum Yield Measurement for Photocatalyst Evaluation

Objective: To determine the quantum yield (Φ) of a model photoredox reaction, assessing catalyst efficiency.

Materials:

- Calibrated integrating sphere coupled to a spectrometer.

- Monochromatic LED light source at λex.

- Potassium ferrioxalate actinometry solution.

- Photoredox reaction mixture in a quartz cuvette.

Procedure:

- Actinometry: Measure the photon flux (I0, einstein s⁻¹) of the LED using potassium ferrioxalate actinometry, following established procedures (e.g., Hatchard & Parker, 1953).

- Reaction Setup: Prepare a dilute, air-free solution of the photoreaction in a sealed quartz cuvette.

- Irradiation & Analysis: Irradiate the sample with the calibrated monochromatic LED. At regular intervals, use the integrating sphere to measure the absolute number of photons absorbed by the reaction mixture.

- Quantification: Simultaneously, quantify product formation (e.g., via GC or HPLC with a calibration curve).

- Calculation: Calculate the quantum yield using the formula: Φ = (moles of product formed) / (moles of photons absorbed by the photocatalyst).

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Iridium & Ruthenium Complexes (e.g., [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆, Ru(bpy)₃Cl₂) | Noble metal polypyridyl complexes with long-lived triplet excited states, high redox potentials, and tunable photophysics. Workhorses for exploratory studies. |

| Organic Dyes (e.g., Eosin Y, 4CzIPN) | Cost-effective, metal-free photocatalysts with strong visible light absorption. Useful for large-scale or sustainable chemistry applications. |

| Sacrificial Electron Donors (e.g., DIPEA, TEA, Hantzsch ester) | Provide electrons to regenerate the photocatalyst after oxidative quenching, often participating in the hydrogen atom transfer (HAT) steps. |

| Sacrificial Electron Acceptors (e.g., Oxygen, persulfates (S₂O₈²⁻)) | Accept electrons from the reduced photocatalyst to complete the catalytic cycle, generating reactive oxygen or sulfate radical species. |

| Single-Electron Transfer (SET) Agents (e.g., [Ni], [Cu] complexes) | Dual catalytic partners that intercept radical intermediates from PRC cycles to enable cross-coupling (e.g., Ni-catalyzed C–O, C–N bond formation). |

| Deuterated Solvents (e.g., CD₃CN, D₂O) | For mechanistic studies via NMR or MS to track hydrogen/deuterium exchange and radical pathways. |

Table 1: Key Photophysical & Electrochemical Properties of Common Photocatalysts

| Photocatalyst | E1/2 (PC*/PC⁻) [V vs SCE] (Reducing Power) | E1/2 (PC⁺/PC*) [V vs SCE] (Oxidizing Power) | Excited-State Lifetime (τ, ns) | λabs max (nm) |

|---|---|---|---|---|

| Ru(bpy)₃Cl₂ | -0.81 | +0.77 | ~1000 | 452 |

| Ir(ppy)₃ | -1.73 | +0.31 | ~1900 | 375 |

| 4CzIPN | -1.21 | +1.35 | ~5800 | 380, 420 |

| Eosin Y | -1.06 | +0.83 | ~2700 | 530 |

Table 2: Representative Photoredox Reaction Optimization Data (C-N Coupling Yield vs. Variables)

| LED Wavelength (nm) | Photocatalyst (1 mol%) | Solvent | Base | Yield (%)* |

|---|---|---|---|---|

| 390 | Ir(ppy)₃ | DMSO | DIPEA | 72 |

| 450 | Ir(ppy)₃ | DMSO | DIPEA | 95 |

| 525 | Ir(ppy)₃ | DMSO | DIPEA | 15 |

| 450 | Ru(bpy)₃Cl₂ | DMSO | DIPEA | 88 |

| 450 | 4CzIPN | DMSO | DIPEA | 81 |

| 450 | Ir(ppy)₃ | MeCN | DIPEA | 89 |

| 450 | Ir(ppy)₃ | DMF | DIPEA | 91 |

| 450 | Ir(ppy)₃ | DMSO | TEA | 63 |

| 450 | Ir(ppy)₃ | DMSO | K₂CO₃ | 45 |

*Isolated yield after 18h irradiation.

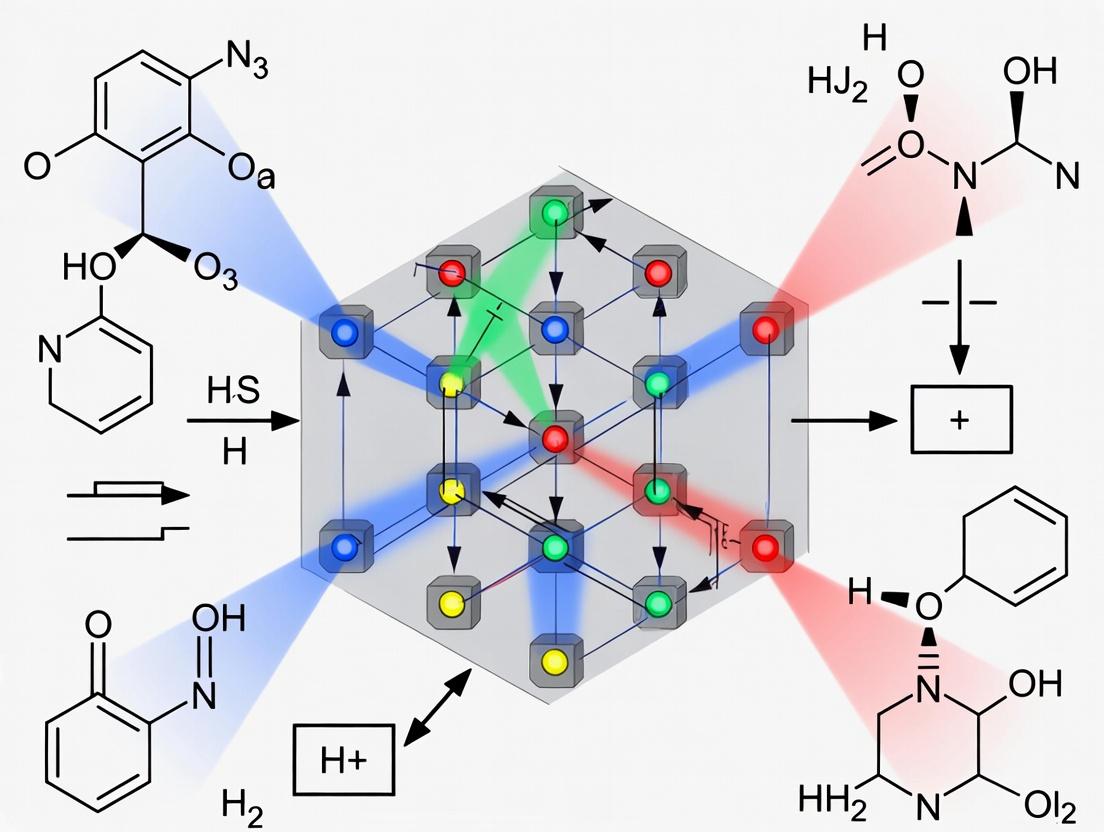

Visualization of Mechanisms and Workflows

Title: Photoredox Catalytic Cycle: Quenching Pathways

Title: LED-Driven Photoredox Experimental Workflow

Application Notes

The pursuit of precise, scalable, and reproducible photoredox catalysis in pharmaceutical research is fundamentally limited by traditional single-point light sources (e.g., bench-top LEDs, lasers). These sources create heterogeneous photon flux, leading to inconsistent reaction yields, poor scalability, and irreproducible kinetic data. This note details how programmable LED array configurations—enabling multi-directional and tunable illumination geometries—overcome these barriers by providing uniform irradiance, temporal control, and spatial selectivity. This is critical for advancing photoredox methodologies in high-throughput screening and eventual scale-up.

Quantitative Comparison of Illumination Systems

Table 1: Performance Metrics of Single-Point vs. Array-Based Illumination

| Parameter | Single-Point LED/Laser | Programmable Multi-Directional LED Array | Impact on Photoredox Research |

|---|---|---|---|

| Irradiance Uniformity | Low (Gradient >50% across sample) | High (Gradient <10% across sample) | Enables reproducible kinetics and yield data. |

| Photon Flux Density (Typical Range) | 10-100 mW/cm² (peak center) | 5-50 mW/cm² (uniform) | Precise, sample-wide control of reaction driving force. |

| Spectral Tuning | Fixed wavelength per device. | Real-time multi-wavelength combos (e.g., 450nm + 525nm). | Facilitates dual catalytic cycles and mechanistic studies. |

| Temporal Control (Pulsing) | Millisecond on/off possible. | Microsecond programmable patterning. | Allows study of radical lifetimes and sequential catalysis. |

| Sample Throughput Format | Single vial or well. | Parallel illumination of microtiter plates (96/384-well). | Enables high-throughput reaction condition screening. |

| Scalability (Volume) | Poor; requires costly flow cells. | Excellent via linear scaling of array dimensions. | Direct path from µL screening to mL preparative scale. |

Table 2: Photoredox Reaction Outcomes Under Different Geometries

| Reaction Type | Single-Point Yield (±SD) | LED Array Yield (±SD) | Key Improvement |

|---|---|---|---|

| Aryl Amination | 65% (±22%) | 88% (±5%) | Yield reproducibility increased 4-fold. |

| Decarboxylative Alkylation | 72% (±18%) | 91% (±4%) | Eliminates hot-spot driven side-products. |

| Dual Catalysis (Ir/Ru) | 45% (±30%) | 82% (±6%) | Precise wavelength ratio control optimizes synergy. |

Experimental Protocols

Protocol 1: Assessing Irradiance Uniformity for Reaction Vessel Mapping

Objective: To quantify the photon flux distribution within a standard reaction vessel (e.g., a 20 mL vial or a 96-well plate) under different illumination setups.

- Calibrate Sensor: Use a flat-response silicon photodiode connected to a optical power meter. Calibrate at relevant wavelengths (e.g., 450 nm).

- Single-Point Source Setup: Position a high-power 450nm LED (collimated) 5 cm above the center of an empty vessel.

- Array Source Setup: Position a 4x4 LED array (450nm) to provide concentric illumination from sides and top. Use a diffuser layer.

- Map Flux: Secure the photodiode sensor to a 3D translation stage. Program a raster scan to measure power (mW) at a grid of points (e.g., 5mm spacing) covering the vessel's base and volume.

- Data Analysis: Normalize all readings to the maximum point measurement. Calculate the coefficient of variation (CV) across all points for each setup. Acceptance Criterion: Array geometry should achieve CV < 10%.

Protocol 2: High-Throughput Screening of Photoredox Conditions

Objective: To reliably screen catalyst, ligand, and substrate scope in a 96-well plate format.

- Plate Preparation: In a 96-well optical bottom plate, use an automated liquid handler to dispense varying catalysts (0.5-2 mol%) and substrates (0.1 mmol in 100 µL solvent) into wells.

- Illumination: Place the plate in a custom chamber with a bottom-facing 12x8 LED array. Program the array for uniform irradiance (e.g., 20 mW/cm² at 450 nm).

- Environmental Control: Purge the chamber with inert gas (N₂) and maintain temperature at 25°C via a Peltier stage.

- Reaction Initiation & Quenching: Start all reactions simultaneously by initiating illumination. After a fixed time (e.g., 2 hours), automatically inject a quenching agent (e.g., 20 µL of saturated NH₄Cl) via a robotic arm.

- Analysis: Use UPLC-MS with an autosampler to analyze conversion and yield for each well. Correlate results with illumination maps from Protocol 1.

Protocol 3: Kinetics Study Under Pulsed Multi-Wavelength Illumination

Objective: To probe radical intermediate lifetimes using temporally patterned light.

- Reaction Setup: In a stirred cuvette, prepare a reaction mixture for a known radical chain process (e.g., a Giese addition). Include an internal standard.

- Array Programming: Configure a dual-wavelength array (e.g., 450nm and 525nm LEDs) facing the cuvette. Program a sequence: a) 450nm pulse (100 ms) to initiate radical formation, b) a variable dark delay (1-1000 ms), c) a 525nm pulse (500 ms) to activate a radical trap.

- In-Line Monitoring: Use a flow cell connected to the cuvette outlet, leading into a benchtop NMR or IR spectrometer for real-time concentration monitoring.

- Data Fitting: Plot product yield vs. dark delay time. Fit the curve to a kinetic model to estimate the lifetime of the key radical intermediate.

Visualizations

Title: Basic Photoredox Catalysis Pathway

Title: Experimental Workflow for LED Array Photoredox Research

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item | Function & Relevance to Multi-Directional Illumination |

|---|---|

| Programmable LED Array Reactor | Core illumination device. Allows spatial and temporal control of wavelength/intensity. Essential for uniform, scalable photochemistry. |

| Silicon Photodiode & 3D Translation Stage | For mapping photon flux (irradiance) within reaction vessels (Protocol 1). Critical for quantifying illumination uniformity. |

| Optical Bottom Multi-Well Plates (e.g., 96-well) | Enable parallel photoredox screening with bottom-up illumination from an array, ensuring consistent path length for all wells. |

| Inert Atmosphere Chamber/Glovebox | Many photoredox catalysts and intermediates are oxygen-sensitive. Uniform illumination must be paired with controlled environment. |

| In-Line Spectroscopic Flow Cell (NMR/IR/UV-Vis) | For real-time reaction monitoring under dynamic illumination patterns (Protocol 3). Links kinetics to light parameters. |

| Diffuser Plates (e.g., Ground Glass, Opal Glass) | Placed between LED array and sample to scatter light, reducing sharp intensity gradients and creating a more homogeneous field. |

| Spectral & Quantum Yield Calibration Kit | Includes actinometers (e.g., potassium ferrioxalate) and calibrated spectrometers to measure absolute photon flux delivered by the array. |

| Temperature-Controlled Peltier Stage | Photoreactions are exothermic; uniform cooling is as vital as uniform light to prevent thermal gradients and side-reactions. |

Application Notes: Multi-Directional Photoredox Illumination Research

Within photoredox catalysis research for drug development, the precise configuration of LED arrays is critical for replicating and probing reaction kinetics. Multi-directional illumination systems, designed to provide homogeneous photon flux across complex reactor geometries, require an integrated understanding of four core components. Their synergistic operation dictates the spectral purity, temporal stability, and spatial uniformity of light delivery—key parameters influencing photocatalytic cycle efficiency and side-product formation.

Light-Emitting Diodes (LEDs)

LEDs are the photon source, with selection directly impacting the reaction's quantum yield. Key metrics include peak wavelength (λmax), spectral half-width (FWHM), and radiant flux (mW/nm).

Table 1: Quantitative Metrics for High-Power Photoredox LEDs

| Parameter | Typical Value/ Range | Impact on Photoredox Experiment |

|---|---|---|

| Peak Wavelength (λmax) | 365 nm, 450 nm, 525 nm | Must match catalyst absorption cross-section (e.g., Ir(ppy)3 ~ 450 nm). |

| Spectral FWHM | 15 - 25 nm | Narrow bandwidth ensures selective excitation of target photocatalyst. |

| Optical Output Power | 500 mW to 10 W per diode | Determines achievable photon flux and irradiance at the sample. |

| Viewing Angle | 120° - 140° | Influences design of secondary optics for beam collimation in arrays. |

| Forward Voltage (Vf) | 2.8 V (Blue) to 3.6 V (UV) | Critical for series/parallel driver configuration. |

| Junction Temp. (Tj) Max | +150°C | Exceeding Tj causes wavelength shift and accelerated decay. |

Protocol 1: LED Spectral Calibration and Matching Objective: To characterize and bin LEDs for uniform spectral output within an array.

- Setup: Use an integrating sphere coupled to a calibrated spectrometer. Mount LED on a temperature-controlled heatsink (25°C).

- Power: Drive LED at constant current (e.g., 700 mA) using a precision DC source.

- Measurement: Record emission spectrum from 350-750 nm. Integrate for 1s, average 10 readings.

- Analysis: Calculate λmax and FWHM. Bin LEDs into groups where λmax varies by ≤ ±1 nm and FWHM by ≤ ±2 nm for array assembly.

LED Drivers

Drivers provide regulated electrical power. Constant current (CC) drivers are essential to prevent thermal runaway and maintain stable optical output, as LED intensity is current-dependent.

Table 2: Driver Specifications for Photoredox Arrays

| Driver Type | Current Ripple | Modulation Capability | Best Use Case |

|---|---|---|---|

| Switching CC | <±5% | PWM up to 1 kHz | Static illumination, basic pulsed experiments. |

| Linear CC | <±1% | Analog (DC) only | High-stability, low-noise applications. |

| High-Speed CC | <±2% | Analog/PWM to 100 kHz | Advanced kinetic studies requiring microsecond pulses. |

Protocol 2: Driver Output Stability & Ripple Test Objective: Quantify current stability, a critical factor in maintaining constant photon flux.

- Setup: Connect driver output to a precision 1Ω sense resistor in series with a dummy load (resistor mimicking LED Vf).

- Measurement: Use an oscilloscope with high-resolution (≥12-bit) ADC. Probe voltage across the sense resistor.

- Analysis: Measure peak-to-peak ripple voltage (Vripple). Calculate current ripple: Iripple = Vripple / 1Ω. Express as percentage of set DC current.

Heat Sinks & Thermal Management

LED efficacy and lifetime are inversely related to junction temperature. Effective heat sinking maintains Tj within limits, preserving spectral output and preventing catastrophic failure.

Protocol 3: Thermal Characterization of an LED Array Module Objective: Measure thermal resistance from LED junction to ambient (RθJA).

- Setup: Attach a thermocouple to the heatsink's thermal interface near the LED mount. Operate LED in a temperature-stable environment.

- Procedure: Drive LED at rated current until thermal equilibrium (~30 min). Record heatsink temperature (Ths). Simultaneously, use the LED's forward voltage (Vf) as a temperature-sensitive parameter (TSP) with a pre-calibrated Vf-Tj curve.

- Calculation: Calculate RθJA = (Tj - Tambient) / Powerdissipated. Powerdissipated = (Vf * If) - Optical Power.

Controllers

Controllers govern timing, intensity, and synchronization of multiple array segments, enabling complex illumination protocols essential for studying reaction intermediates and kinetics.

Protocol 4: Programmed Multi-Vector Illumination for Kinetic Analysis Objective: Execute a timed sequence from different array facets to probe reaction diffusion limits.

- Controller Programming: Use a microcontroller (e.g., Arduino Due) or FPGA. Write sequence: Illuminate North vector (450 nm, 50 mW/cm²) for 10 ms, delay 2 ms, illuminate South-East and South-West vectors simultaneously for 20 ms.

- Synchronization: Trigger a high-speed spectrometer or quenching agent injector at the 5 ms mark of the second pulse via the controller's digital output.

- Validation: Verify timing and irradiance with a fast photodiode and oscilloscope at the reaction vessel position.

Diagrams

Diagram Title: LED Array Control and Data Acquisition Workflow

Diagram Title: Primary Heat Dissipation Pathway in an LED

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Photoredox LED Array Experiments

| Item | Function / Relevance |

|---|---|

| Precision Spectrometer (e.g., Ocean Insight FLAME-S) | Measures LED spectral output and irradiance at the reaction plane. |

| Thermal Camera (FLIR ONE Pro) | Visualizes thermal gradients across the LED array heatsink to identify hotspots. |

| LabVIEW or Python DAQ Suite | Custom software for controlling illumination protocols and synchronizing data acquisition from multiple sensors. |

| Neutral Density Filter Kit | Attenuates LED intensity in a calibrated manner for studying photon flux-dependent reaction kinetics. |

| Optical Integrating Sphere | Collects and homogenizes light for accurate total radiant flux measurement of individual LEDs. |

| Thermal Interface Paste (Arctic MX-6) | Fills microscopic air gaps between LED package and heatsink, minimizing thermal resistance (Rθ). |

| Bench Power Supply (Keysight) | Provides stable, ripple-free DC input to LED drivers during characterization. |

| Fast Photodiode Sensor (Thorlabs) | Validates microsecond-scale illumination pulses and measures transient light intensity. |

| Custom Reactor Vessel (Quartz/Glass) | Allows multi-angular illumination with minimal photon scattering and spectral distortion. |

| Irradiance Standard (Calibrated) | Enables absolute photon flux calibration (mW/cm²/nm) at the sample location. |

This application note details the critical photonic parameters governing reaction efficiency in photoredox catalysis, directly supporting the broader thesis on "LED Array Configuration for Multi-Directional Photoredox Illumination." Optimizing these parameters is essential for translating small-scale photoreactions to robust, scalable protocols applicable in pharmaceutical research and development. This document provides actionable protocols and data frameworks for researchers.

Table 1: Key Photonic Parameters and Their Impact on Photoredox Efficiency

| Parameter | Definition | Unit | Role in Reaction Efficiency | Typical Optimization Range (Visible Light) |

|---|---|---|---|---|

| Wavelength (λ) | Energy per photon; must match catalyst absorption. | nm (nanometers) | Determines if a photon is absorbed by the photocatalyst. Mismatch leads to zero efficiency. | 365 - 460 nm (Common for Ir/Ru catalysts) |

| Irradiance (Ee) | Radiant power incident per unit area. | mW/cm² | Governs the rate of photon delivery. Higher irradiance increases reaction rate, but can cause side-reactions or degradation. | 10 - 100 mW/cm² |

| Photon Flux (q_p) | Number of photons incident per unit area per unit time. | mol/(m²·s) or einstein/(m²·s) | Directly proportional to the maximum possible rate of photon absorption. The fundamental driver of photokinetics. | 10⁻⁷ - 10⁻⁵ einstein/(m²·s) |

| Photon Flux Density (PFD) | Number of photons incident per unit area per unit time per unit wavelength interval. | mol/(m²·s·nm) | Used for polychromatic sources to describe spectral distribution. | N/A - Source dependent |

| Total Photon Dose | Cumulative photon flux over reaction time. | mol/m² or einstein/m² | Ensures sufficient photons are delivered to complete the reaction. | Product of Photon Flux × Time |

Table 2: Representative Photocatalyst Absorption & Corresponding Optimal Wavelength

| Photocatalyst Class | Common Example | Primary Absorption Peak (nm) | Recommended LED Wavelength (nm) | Molar Extinction Coefficient (ε, M⁻¹cm⁻¹) |

|---|---|---|---|---|

| Iridium (III) | [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | ~380, ~425 | 390 ± 5, 450 ± 5 | ~15,000 @ 380 nm |

| Ruthenium (II) | [Ru(bpy)₃]Cl₂ | ~452 | 450 ± 5 | ~14,600 @ 452 nm |

| Organic Dye | Eosin Y | ~525 | 530 ± 5 | ~95,000 @ 525 nm |

| Acridinium | Mes-Acr⁺ | ~430, ~455 | 450 ± 5 | ~5,000 @ 455 nm |

Experimental Protocols

Protocol 1: Determining Reaction-Appropriate Wavelength

Objective: To identify the effective wavelength range for a given photocatalyst/substrate system. Materials: LED light sources (narrow-band, e.g., 385, 405, 450, 525 nm), photoreactor vials, spectrophotometer. Procedure:

- Prepare a standard reaction mixture with photocatalyst and substrate.

- Aliquot equal volumes into multiple identical reaction vials.

- Irradiate each vial with a different, monochromatic LED source, keeping irradiance constant (e.g., 20 mW/cm²) and reaction time fixed.

- Quench reactions simultaneously and analyze conversion/yield via HPLC or GC.

- Plot yield vs. wavelength to identify the action spectrum. The optimal λ aligns with the catalyst's absorption profile but must be empirically verified for side reactions.

Protocol 2: Quantifying Irradiance and Photon Flux for Reaction Scaling

Objective: To measure and standardize light delivery for reproducible scaling. Materials: Calibrated thermopile or silicon photodiode power sensor, spectrometer (for spectral confirmation), ruler. Procedure for Irradiance Measurement:

- Power Measurement: Place the sensor at the exact position of the reaction vessel. Measure total radiant power (P) in watts (W) from the light source.

- Beam Area Calculation: Illuminate a piece of graph paper to define the lit area (A) in cm². For uniform arrays, calculate the illuminated vessel area.

- Irradiance Calculation: Ee = P / A (mW/cm²). Procedure for Photon Flux Calculation:

- Obtain the source's spectral output data (from manufacturer or spectrometer).

- Calculate photon flux:

q_p = (Ee * ∫(λ / (N_A * h * c)) dλ), where the integral is over the spectrum. For a narrow-band LED centered at λ0 (in meters), a useful approximation is:q_p (mol m⁻² s⁻¹) ≈ [Ee (W m⁻²) * λ0 (m)] / (N_A * h * c). - Key Scaling Step: Maintain constant photon flux, not just irradiance, when changing wavelengths or source geometry to ensure consistent photon delivery rates.

Protocol 3: LED Array Configuration for Multi-Directional Illumination

Objective: To construct an array ensuring uniform photon flux within a multi-vessel reactor. Materials: Multiple LED modules, heat sinks, current drivers, multi-well reactor block, light diffuser sheet, photometer. Procedure:

- Array Geometry: Arrange LEDs symmetrically around the reactor block (e.g., 4-sided or overhead ring array). The thesis emphasizes this to eliminate photon flux gradients.

- Calibration: Measure irradiance at the center of each vessel position. Adjust LED orientation/drive current until variance is <5%.

- Thermal Management: Use heat sinks and active cooling to maintain LED junction temperature, preventing wavelength drift and intensity drop.

- Validation: Run a control photoreaction in all vessel positions simultaneously. Analyze yield variance to confirm uniformity of the photonic field.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Narrow-Bandwidth LED Modules (e.g., 450 ± 5 nm) | Provides monochromatic light matching common photocatalyst absorptions, minimizing thermal load and side-reactions from unwanted wavelengths. |

| Calibrated Integrating Sphere Spectrometer | Measures the absolute spectral irradiance (mW/cm²/nm) of a light source, essential for accurate photon flux calculation. |

| Silicon Photodiode Power Sensor | Robust, easy-to-use tool for routine measurement of total irradiance (mW/cm²) at the reaction plane for reproducibility checks. |

| Aerobic/Anaerobic Sealed Reaction Vials (e.g., crimp vials) | Allows reactions under controlled atmosphere (inert or oxygen), critical for many photoredox mechanisms involving radicals or sensitive intermediates. |

| Benchmark Photocatalysts (e.g., [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆) | High-potential, robust catalyst used as a positive control to validate light setup efficiency before testing novel systems. |

| Chemical Actinometry Solution (e.g., Potassium Ferrioxalate) | A chemical method to absolutely determine photon flux within a reaction vessel by measuring the photochemical yield of a calibrated reaction. |

Visualizations

Diagram 1: Photoredox Cycle & Light Parameter Intervention Points

Title: Photoredox Cycle with Key Light-Dependent Steps

Diagram 2: LED Array Config Workflow for Uniform Illumination

Title: LED Array Design and Calibration Workflow

Current Applications in Medicinal Chemistry and Chemical Biology

This work is presented within the framework of a broader thesis investigating novel LED array configurations for multi-directional photoredox illumination in chemical synthesis. A primary goal is to demonstrate how programmable, spatially controlled light delivery can overcome traditional limitations in photochemical reaction scale-up and throughput, enabling new applications in medicinal chemistry and chemical biology. The following application notes and protocols highlight key areas where advanced photoredox catalysis is driving innovation.

Application Note 1: Photoredox-Catalyzed Late-Stage Functionalization (LSF) of Pharmaceuticals

Late-stage functionalization diversifies drug candidates without de novo synthesis. Photoredox catalysis, particularly with precise light control, enables the installation of diverse functional groups onto complex scaffolds under mild conditions.

Key Quantitative Data:

Table 1: Performance of Selected Photoredox LSF Protocols

| Target Scaffold | Reaction Type | Catalyst (mol%) | Light Source (nm) | Reported Yield (%) | Key Reference (Year) |

|---|---|---|---|---|---|

| Artesunate | C–H trifluoromethylation | Ir(ppy)₃ (1) | 450 nm LEDs | 85 | Zhu et al. (2023) |

| Diazepam | C–H alkylation (decarboxylative) | [Ru(bpy)₃]²⁺ (0.5) | 455 nm Blue LEDs | 78 | Le et al. (2022) |

| Verubecestat | C–H borylation | Ir[dF(CF₃)ppy]₂(dtbbpy)PF₆ (2) | 427 nm LEDs | 65 (site-selectivity >20:1) | Koniarczyk et al. (2023) |

| Sertraline | C–H amination | 4CzIPN (5) | 456 nm LEDs | 72 | Shen et al. (2024) |

Detailed Protocol: C–H Trifluoromethylation of Artesunate Analogs

Objective: To install a CF₃ group onto the artemisinin core using a scalable, LED-driven photoredox protocol.

Materials:

- Substrate: Artesunate (1.0 equiv, 0.2 mmol scale)

- Photocatalyst: Ir(ppy)₃ (1 mol%)

- CF₃ Source: Umemoto's Reagent (1.5 equiv)

- Solvent: Anhydrous DMF/DCE (1:1, 0.05 M)

- Base: K₂HPO₄ (2.0 equiv)

- Light Source: Custom 450nm LED array (see Thesis Context for configuration details).

- Reaction Vessel: 10 mL screw-cap vial with magnetic stir bar.

Procedure:

- In a glovebox (N₂ atmosphere), charge the vial with artesunate (71.2 mg), Ir(ppy)₃ (1.5 mg), and K₂HPO₄ (69.6 mg).

- Add solvent mixture (4 mL) and stir until fully dissolved.

- Add Umemoto's reagent (84.3 mg) and seal the vial.

- Place the vial in the center of the multi-directional LED array chamber. The array should be configured for uniform irradiance from three axes ( Thesis Parameter: 15 mW/cm² per axis).

- Stir and irradiate the reaction mixture for 18 hours at room temperature.

- Monitor reaction completion by TLC or LC-MS.

- Quench by adding saturated aqueous NaHCO₃ (5 mL). Extract with EtOAc (3 x 10 mL).

- Dry combined organic layers over Na₂SO₄, filter, and concentrate in vacuo.

- Purify the crude residue by flash column chromatography (SiO₂, hexanes/EtOAc gradient).

Application Note 2: Photochemical Proteolysis-Targeting Chimeras (PROTACs) Assembly

PROTACs are heterobifunctional molecules that recruit E3 ubiquitin ligases to target proteins for degradation. Photoredox catalysis facilitates the efficient, modular construction of these complex molecules, especially using metallaphotoredox cross-couplings.

Key Quantitative Data:

Table 2: Photoredox Protocols for PROTAC Linker Coupling

| Coupling Partner A | Coupling Partner B | Key Bond Formed | Catalyst System | Light Conditions | Yield in PROTAC Synthesis (%) | Degradation Efficiency (DC₅₀) |

|---|---|---|---|---|---|---|

| VHL Ligand-alkyl bromide | Thalidomide analog-aryl pinacol boronate | C(sp²)–C(sp³) | Ni(dtbbpy)Br₂ / Ir[dF(CF₃)ppy]₂(dtbbpy)PF₆ | 450 nm LEDs, 24h | 58 (over 3 steps) | 50 nM (BRD4) |

| CRBN Ligand-aryl iodide | BET inhibitor-alkyl carboxylic acid | C(sp²)–C(sp³) (decarboxylative) | NiCl₂•glyme / 4CzIPN / Hantzsch ester | 427 nm LEDs, 12h | 41 (direct) | 120 nM (BRD4) |

Detailed Protocol: Metallaphotoredox Synthesis of a VHL-BRD4 PROTAC

Objective: To couple a VHL-targeting alkyl bromide to a BRD4-targeting aryl boronic ester via a Ni/Ir dual catalytic, light-driven cross-coupling.

Materials:

- VHL Ligand-Br: (S,R,S)-AHPC-alkyl bromide (1.0 equiv, 0.1 mmol)

- BRD4 Ligand-Bpin: JQ1-pinacol boronate (1.5 equiv)

- Dual Catalyst: Ni(dtbbpy)Br₂ (10 mol%), Ir[dF(CF₃)ppy]₂(dtbbpy)PF₆ (2 mol%)

- Base: Cs₂CO₃ (3.0 equiv)

- Solvent: Degassed DMA (0.05 M)

- Additive: 4Å molecular sieves (powdered)

- Light Source: Programmable 450nm LED array with alternating 5s on/off pulses to manage heat (Thesis Parameter: Axial illumination mode).

Procedure:

- In a glovebox (N₂), add both catalysts, Cs₂CO₃ (97.8 mg), and molecular sieves (~50 mg) to a dry vial.

- Add degassed DMA (2 mL) and stir for 5 minutes.

- Add the VHL Ligand-Br (54.3 mg) and JQ1-Bpin (68.1 mg).

- Seal vial and transfer to the LED array chamber.

- Irradiate with pulsed blue light (450 nm, 20 mW/cm²) while stirring vigorously for 24 hours.

- Filter the reaction mixture through a celite pad to remove sieves and salts, washing with DCM.

- Concentrate the filtrate and purify the crude product by preparative HPLC (C18 column, water/ACN + 0.1% TFA).

- Lyophilize the pure fractions to obtain the PROTAC as a solid. Confirm identity by HRMS and ¹H NMR.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Photoredox Applications in Medicinal Chemistry

| Reagent / Material | Primary Function | Key Considerations for Use |

|---|---|---|

| Ir(ppy)₃ (Tris(2-phenylpyridine)iridium(III)) | Strong reducing photocatalyst (oxidative quenching cycle). | Air-stable solid. Excited state reductant. Best for reductive quenching cycles with amines or with oxidants. |

| [Ru(bpy)₃]Cl₂ | Classic, versatile oxidant/reductant photocatalyst. | Water-soluble, good for mechanistic studies. Lower cost than Ir complexes but less potent excited state reductant. |

| 4CzIPN (1,2,3,5-Tetrakis(carbazol-9-yl)-4,6-dicyanobenzene) | Organic, metal-free, strongly reducing photocatalyst. | Avoids metal contamination in final APIs. High triplet energy. Requires degassed solvents for optimal performance. |

| Ni(dtbbpy)Br₂ | Earth-abundant transition metal co-catalyst for cross-coupling. | Used in dual catalytic metallaphotoredox. Must be rigorously paired with appropriate photocatalyst and light. |

| Hantzsch Ester (HE) | Organic reductant and hydrogen atom donor. | Common stoichiometric reductant in decarboxylative couplings. Replaces toxic tin or silane reagents. |

| Umemoto's Reagent (S-(Trifluoromethyl)dibenzothiophenium tetrafluoroborate) | Source of CF₃⁺ for radical trifluoromethylation. | Powerful electrophilic trifluoromethylating agent. Handle with care in inert atmosphere. |

| 4Å Molecular Sieves (powdered) | Scavenges trace water in sensitive photoredox reactions. | Essential for nickel-catalyzed steps. Must be activated (heated) before use. |

Visualization: Pathways and Workflows

Diagram Title: Photoredox C-H Trifluoromethylation Mechanism

Diagram Title: Metallaphotoredox PROTAC Synthesis Workflow

Diagram Title: PROTAC MoA and Synthesis via Photoredox

Design and Implementation: Building Your Multi-Directional LED Photoreactor

This document details the integrated design and fabrication workflow for constructing a multi-directional LED array system, a core hardware component for advanced photoredox catalysis research. The system's design is framed within a broader thesis investigating spatially controlled illumination to manipulate reaction kinetics and selectivity in pharmaceutical precursor synthesis. Precise optical output, thermal management, and modular configurability are paramount for generating reproducible, high-quality experimental data in drug development.

System Design Workflow

The following diagram outlines the comprehensive, iterative workflow from conceptual design to functional prototype assembly.

Application Notes & Protocols

Phase 1: 3D Optical & Thermal Modeling

Objective: To create a virtual prototype predicting irradiance distribution at the reaction vessel and junction temperatures of LEDs.

Protocol 1.1: Ray Tracing for Irradiance Profile

- Software: Utilize optical design software (e.g., TracePro, FRED, or open-source Blender with ray-tracing add-ons).

- Model Import/Construction:

- Import CAD model of the target multi-well reactor or vial holder.

- Construct solid models of LEDs using manufacturer-supplied lens geometry files (STEP format) or Lambertian approximations.

- Source Definition:

- Define each LED as a ray source with the spectral power distribution (SPD) corresponding to the target wavelength (e.g., 450 nm ± 20 nm FWHM).

- Set ray count to >1e6 for statistical significance.

- Surface Property Assignment:

- Assign reflective properties (e.g., Spectralon-like, >98% diffuse reflectance) to the interior surfaces of the custom illumination chamber.

- Assign the reactor vial material properties (e.g., borosilicate glass, ~92% transmission per surface).

- Execution & Analysis:

- Run Monte Carlo ray trace.

- Output: Irradiance map (W/cm²) across the reactor's working volume. Optimize LED placement and angle to achieve uniformity >85% or targeted gradient profiles.

Protocol 1.2: Finite Element Analysis (FEA) for Thermal Management

- Software: Use engineering FEA software (e.g., ANSYS Icepak, COMSOL Multiphysics, or SimScale).

- Geometry & Mesh:

- Import the PCB and heatsink assembly model.

- Generate a conformal mesh, refining at interfaces between LED packages, PCB, and heatsink.

- Material Properties:

- Define thermal conductivity (k): PCB (FR4, k ~0.3 W/m·K; or metal-core, k >1 W/m·K), aluminum heatsink (k ~200 W/m·K), thermal interface material (TIM, k = 2-8 W/m·K).

- Boundary Conditions & Loads:

- Apply heat generation load (Q) to each LED die: Q = IF * VF * (1 - ηE), where ηE is the typical wall-plug efficiency (see Table 1).

- Set convective boundary condition at heatsink fins (e.g., natural convection, h ~5-10 W/m²·K; forced convection if fan is used).

- Solve & Validate:

- Solve for steady-state temperature.

- Critical Output: Ensure LED junction temperature (T_j) remains below manufacturer-specified maximum (often 85-125°C) to prevent wavelength shift and accelerated lumen decay.

Phase 2: Circuit Design & Assembly

Objective: To translate the validated model into a reliable, controllable printed circuit board (PCB) assembly.

Protocol 2.1: PCB Schematic and Layout Design

- Schematic Capture:

- Driver Selection: Choose constant current LED drivers (e.g., Texas Instruments TLC59116) based on forward current (IF) requirement and dimming method (PWM or I²C).

- Current Setting: Calculate current-setting resistor: Rset = Vref / IF (refer to driver datasheet).

- Decoupling: Place 100nF and 10µF capacitors near each driver IC power pin.

- PCB Layout:

- Stack-up: For power levels >10W total, use a 2-layer metal-core PCB (MCPCB) for optimal heat spreading.

- Routing: Use thick traces (>1mm) for high-current paths. Keep PWM/dimming signal lines away from analog feedback lines.

- Thermal Vias: If using a standard FR4 PCB with a separate heatsink, populate LED pads with an array of thermal vias (filled and capped) to transfer heat to the backside copper plane/heatsink.

Protocol 2.2: Component Soldering & Assembly Protocol

- Materials Preparation:

- Soldering: Use lead-free solder paste (SAC305) and a precision stencil.

- Thermal Interface: Apply a uniform, thin layer of thermal grease (e.g., Arctic MX-4) or pre-cut thermal pad to the back of the MCPCB/heatsink interface.

- Pick-and-Place & Reflow:

- For surface-mount LEDs (e.g., 3535 package), use a manual or automated pick-and-place tool.

- Follow the LED manufacturer's specific reflow profile. A typical lead-free profile: Preheat (150-180°C, 60-90s), Reflow (peak 245°C for 30-60s), Cooling.

- CRITICAL: Avoid exceeding the LED's maximum package temperature during reflow (often 260°C for 10s).

- Post-Assembly Inspection:

- Visually inspect for solder bridges or misalignment.

- Perform electrical continuity test to check for shorts.

- Power the array at low current and use a thermal camera to identify any anomalous hot spots indicating poor solder joints.

Table 1: Representative High-Power LED Parameters for Photoredox Catalysis

| LED Wavelength (nm) | Typical Forward Voltage (V) @ 350mA | Radiant Flux (mW) @ 350mA | Wall-Plug Efficiency (η) | Key Application in Photoredox |

|---|---|---|---|---|

| 365 (UV-A) | 3.4 - 3.8 | 400 - 550 | 30 - 40% | Direct substrate/catalyst excitation |

| 385 (UV-A) | 3.4 - 3.8 | 450 - 600 | 35 - 45% | Photoinitiator activation |

| 450 (Blue) | 2.9 - 3.4 | 650 - 900 | 50 - 65% | Common for Ir(III) & Ru(II) polypyridyl complexes |

| 525 (Green) | 3.0 - 3.6 | 400 - 600 | 40 - 55% | Selective excitation in multi-catalyst systems |

| 625 (Red) | 1.9 - 2.2 | 350 - 500 | 55 - 70% | Reducing photocatalyst zones, deep-tissue analogs |

| 850 (NIR) | 1.4 - 1.6 | 600 - 800 | 60 - 75% | Deep penetration studies, heat control experiments |

Table 2: Thermal Resistance (Rθ) Analysis for Common Packages

| Component / Interface | Typical Thermal Resistance (Rθ) | Notes for Design |

|---|---|---|

| High-Power LED (3535 Package), Junction-to-Case (Rθ_JC) | 2 - 8 °C/W | Check specific datasheet. Lower is better. |

| Solder Joint (LED to MCPCB) | ~0.5 °C/W | Assumes proper reflow. |

| MCPCB (1.5mm Al base), Dielectric Layer | 0.3 - 1.5 °C/W | Primary bottleneck in MCPCB. |

| Thermal Grease Interface (TIM) | 0.1 - 0.3 °C/W per interface | Apply thin, uniform layer. |

| Extruded Aluminum Heatsink (Natural Conv.) | 3 - 10 °C/W | Depends heavily on surface area and orientation. |

The Scientist's Toolkit: Research Reagent Solutions & Essential Materials

| Item | Function/Description | Example/Catalog No. (if applicable) |

|---|---|---|

| Metal-Core PCB (MCPCB) | Provides structural support and critical heat spreading away from LED junctions. Dielectric layer electrically isolates circuits. | Bergquist HT Series (Al base), Laird Thermal Systems MCPCBs |

| Constant Current LED Driver | Provides stable, flicker-free current to LEDs regardless of forward voltage variations. Enables precise PWM dimming for intensity control. | Texas Instruments TLC59116, Analog Devices LT3922-1 |

| Thermal Interface Material (TIM) | Fills microscopic air gaps between PCB and heatsink, drastically improving heat conduction. | Arctic MX-4 (grease), Bergquist SIL-PAD 1500ST (pad) |

| Spectral Power Distribution (SPD) Meter | Measures absolute irradiance (W/cm²/nm) and integrated photon flux (μmol/s). Critical for dose-controlled reactions. | Ocean Insight FX Spectrometer, Apogee Instruments MQ-500 |

| Photoredox Catalyst - [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₶ | A standard, highly oxidizing photocatalyst with strong absorption in the blue region (~450 nm). | Common research reagent, e.g., Sigma-Aldrich 901893 |

| Custom 3D-Printed Reactor Holder | Positions vials or multi-well plates at the optimal focal plane within the illumination array. Ensures experimental reproducibility. | Designed in Fusion 360/SolidWorks, printed in black PETG (light-absorbing). |

| Neutral Density (ND) Filter Set | Attenuates light intensity in known, calibrated steps without shifting wavelength, used for kinetic studies of photon flux. | Thorlabs NEK series (e.g., NEK01 for OD 0.1) |

Photoredox Illumination Experiment Signaling Pathway

The following diagram illustrates the core photophysical and chemical pathway enabled by the described LED array system.

Within the broader thesis on optimizing LED arrays for multi-directional photoredox illumination in chemical synthesis and drug development, the physical geometry of the light source is a critical, often underexplored variable. Photoredox catalysis, particularly in complex reaction setups like parallel synthesis or flow chemistry, requires uniform, controllable photon delivery. This application note details the configuration, comparative advantages, and implementation protocols for three core array geometries: Radial, Spherical, and Parallel Plate. These setups directly influence photon flux uniformity, reaction scalability, and experimental reproducibility in photopharmacology and photocatalytic library synthesis.

The performance of each geometry is characterized by key photometric and practical parameters. The following table synthesizes current data on typical configurations used in research settings.

Table 1: Comparative Analysis of LED Array Geometries for Photoredox Research

| Parameter | Radial (Cylindrical) Array | Spherical Array | Parallel Plate Array |

|---|---|---|---|

| Primary Use Case | Single vessel, batch reactions (e.g., round-bottom flasks) | Ultra-uniform irradiation of small, central samples | High-throughput, multi-well plate photoredox screening |

| Typical Power Density | 10-50 mW/cm² at vial surface (varies with radius) | 5-30 mW/cm² (highly uniform across central volume) | 20-100 mW/cm² per well (configurable) |

| Uniformity (Typical) | Moderate (gradient along radius) | Excellent (within central 60% of sphere volume) | Good to Excellent (per well, depends on collimation) |

| Scalability | Limited by vessel size; scaling up requires power increase | Poor; primarily for small-scale, high-precision irradiation | Excellent; scales linearly with plate size and LED count |

| Cooling Requirement | Moderate | High (enclosed space) | Low to Moderate (open design) |

| Relative Cost | Low | High | Medium |

| Key Advantage | Simple adaptation to standard glassware | Maximizes photon capture for small volume, isotropic light | Compatibility with HTS workflows, independent well control |

| Key Disadvantage | Non-uniform irradiance, hot spots possible | Complex construction, limited sample access | Directional illumination, potential shadowing |

Detailed Experimental Protocols

Protocol 1: Constructing & Calibrating a Radial Array for Batch Photoredox

Objective: To assemble a radial LED array for photocatalytic screening in standard 10 mL round-bottom flasks and calibrate irradiance. Materials: See "Scientist's Toolkit" Section 5. Procedure:

- Assembly: Mount 12-16 high-power 450 nm LEDs onto an aluminum ring heatsink (inner diameter ~8 cm). Wire in series with a constant current LED driver. Enclose with a diffuser sleeve.

- Thermal Management: Attach heatsink to a 12V DC fan. Apply thermal paste at LED-heatsink interfaces.

- Calibration: Place a calibrated silicon photodiode sensor at the center of the array (simulating vial position). Secure.

- Power Measurement: Power the array at desired current (e.g., 350 mA). Record sensor reading in mW/cm². Use a manual or motorized stage to map irradiance radially from center to 3 cm offset in 0.5 cm increments.

- Validation: Perform a benchmark photoredox reaction (e.g., Ru(bpy)3²⁺-catalyzed oxidative hydroxylation of phenylboronic acid) in triplicate. Compare conversion (via HPLC) at center vs. edge position to quantify uniformity impact.

Protocol 2: Implementing a Parallel Plate Array for 96-Well Plate Illumination

Objective: To configure a bottom-illumination parallel plate system for high-throughput photoredox reaction screening. Materials: See "Scientist's Toolkit" Section 5. Procedure:

- Array Configuration: Align a 8x12 matrix of surface-mount LEDs (λ=365 nm) on a PCB to match the spacing of a 96-well microtiter plate. Use a microlens array or diffuser plate ~5 mm above LEDs to homogenize light.

- Driver Configuration: Connect each column of 8 LEDs to an independent channel of a multi-channel constant current driver to allow for column-wise intensity control.

- Irradiance Calibration per Well: Using a micro-probe optical sensor, measure irradiance at the bottom center of every well in an empty plate. Record values. Adjust driver currents column-wise to achieve ≤10% coefficient of variation across all wells.

- Experimental Workflow: Prepare reaction master mixes in a separate plate. Using a multichannel pipette, aliquot 200 µL per well into the assay plate. Seal plate with optically clear sealing tape.

- Illumination & Kinetics: Place plate on the array. Initiate illumination and monitor reaction progress via in-plate absorbance (if applicable) or quench samples at timed intervals for LC-MS analysis.

Protocol 3: Characterizing a Spherical Array for Isotropic Irradiation

Objective: To validate the irradiance uniformity within a custom spherical LED array for fundamental photophysical studies. Materials: Small spherical array (e.g., 10 cm inner diameter), motorized 3D micromanipulator, optical power sensor. Procedure:

- Sensor Positioning: Mount a small-area sensor on the micromanipulator arm. Precisely position the sensor at the geometric center of the sphere.

- Volumetric Mapping: Program the manipulator to move the sensor through a 3D grid (1 cm steps) within a 4x4x4 cm cube centered in the sphere.

- Data Acquisition: At each grid point, record the irradiance. For each XY plane, calculate the average irradiance and standard deviation.

- Uniformity Calculation: Determine the overall uniformity (U) as: U = [1 - (Max - Min)/(Max + Min)] x 100%, where Max and Min are the extreme irradiance values within the central 2 cm diameter spherical volume. Target U > 85% for isotropic studies.

Diagram: Workflow for Geometry Selection & Experimental Implementation

Diagram Title: Workflow for Selecting and Using Photoredox LED Array Geometries

The Scientist's Toolkit: Essential Research Reagent Solutions & Materials

Table 2: Key Materials for Configuring LED Photoredox Arrays

| Item/Category | Example Product/Specification | Function in Experiment |

|---|---|---|

| High-Power LEDs | 450 nm (Royal Blue), 365 nm (UV-A), 525 nm (Green); >1 W output | Primary photon source. Wavelength chosen to match catalyst absorption (e.g., Ru/Ir complexes for blue). |

| Constant Current Driver | Programmable LED Driver (e.g., 0-2000 mA, multi-channel) | Provides stable, flicker-free current to LEDs, crucial for reproducible photon flux and longevity. |

| Thermal Management | Aluminum Heatsink, Thermal Paste, 12V DC Fan | Prevents LED efficiency drop (lumen depreciation) and failure due to junction overheating. |

| Optical Diffuser | Engineered Diffuser Film (e.g., holographic, ground glass) | Homogenizes raw LED output, reducing hot spots and improving irradiance uniformity across the sample plane. |

| Calibration Sensor | Benchtop Optical Power Meter with Silicon Photodiode Probe | Quantifies irradiance (mW/cm²) at sample plane. Essential for dose control and reproducibility between labs. |

| Photoredox Catalyst | [Ru(bpy)₃]Cl₂, Ir(ppy)₃, 4CzIPN | Absorbs light, undergoes redox cycles, and drives the catalytic transformation. Standard for benchmarking. |

| Microtiter Plate | 96-Well, Clear Bottom, Chimney Well, Non-Binding Surface | Standardized vessel for parallel plate array screening. Clear bottom allows for transmittance illumination. |

| Optical Seal | Thermally Stable, Optically Clear Adhesive Seal | Seals reaction wells in plates to prevent evaporation and oxygen ingress while transmitting light. |

| Benchmark Substrate | Phenylboronic Acid, or similar | Used in a well-studied photoredox reaction (e.g., hydroxylation) to validate array performance and uniformity. |

Selecting Optimal LED Wavelengths (365nm, 450nm, 525nm) for Common Photocatalysts

This document provides application notes and protocols for selecting monochromatic LED wavelengths (365 nm, 450 nm, 525 nm) to activate common photocatalysts. This work is situated within a broader thesis investigating configurable LED arrays for multi-directional photoredox illumination, enabling precise control over reaction kinetics and selectivity in complex chemical synthesis, including pharmaceutical development.

Photocatalyst-LED Wavelength Compatibility

The efficacy of a photoredox catalyst is contingent upon the spectral overlap between the LED emission and the catalyst's absorption profile. The following table summarizes key quantitative data for common photocatalysts relevant to these three wavelengths.

Table 1: Photocatalyst Properties & Optimal LED Wavelength Pairing

| Photocatalyst Class | Example Catalysts | Absorption Maxima (nm) | Recommended LED (nm) | Molar Extinction Coefficient (ε) at LED λ | Common Applications |

|---|---|---|---|---|---|

| Inorganic Semiconductors | TiO₂ (P25), ZnO | ~380 (TiO₂), ~370 (ZnO) | 365 (Excellent match) | High at 365nm | Environmental remediation, oxidation reactions. |

| Classic Organic Dyes | Eosin Y, Rose Bengal | ~525 (Eosin Y), ~550 (Rose Bengal) | 525 (Good match) | ~80,000 M⁻¹cm⁻¹ at 525nm (Eosin Y) | ATRA reactions, coupling reactions. |

| Transition Metal Complexes | [Ru(bpy)₃]²⁺, Ir(ppy)₃ | ~450 ([Ru(bpy)₃]²⁺), ~375, 450 (Ir(ppy)₃) | 450 (Primary match) | ~14,000 M⁻¹cm⁻¹ at 450nm ([Ru(bpy)₃]²⁺) | Reductive quenching cycles, C-H functionalization. |

| Organic Acridinium | 9-Mesityl-10-methylacridinium | ~365, 450 (dual bands) | 365 or 450 (Dual excitation) | High at 365nm, moderate at 450nm | Strongly oxidizing reactions, arylations. |

| PC Organocatalysts | 4CzIPN, 2CzPN | ~370-380, 420-450 | 450 (Optimal for visible), 365 (UV) | Varies; strong in blue region | Energy transfer, metal-free cross-couplings. |

Core Experimental Protocols

Protocol 1: Screening LED Wavelength Efficacy for a Given Reaction

Objective: To determine the most efficient LED wavelength (365, 450, or 525 nm) for a photoredox-catalyzed model reaction.

Materials:

- LED Photoreactor (equipped with interchangeable 365, 450, 525 nm modules).

- Reaction vials (e.g., 8 mL clear glass vials with septa).

- Photocatalyst stock solutions.

- Substrates and reagents.

- Inert atmosphere setup (N₂/Ar glovebox or Schlenk line).

- Analytical tools (GC, HPLC, NMR).

Procedure:

- Setup: Inside an inert atmosphere, prepare three identical reaction mixtures in separate vials. Each mixture contains the photocatalyst, substrates, and solvent at predetermined concentrations.

- Illumination: Place each vial under a dedicated, calibrated LED module (λ = 365, 450, or 525 nm). Ensure photon flux (measured in mW/cm²) is normalized across all wavelengths using a radiometer.

- Control: Prepare a fourth identical vial to be kept in the dark under otherwise identical conditions.

- Reaction Monitoring: Irradiate the vials for a set time period. Periodically withdraw aliquots from each vial under inert conditions.

- Analysis: Quantify conversion and yield for each aliquot using calibrated analytical methods (e.g., HPLC with internal standard).

- Calculation: Plot conversion vs. time for each wavelength. Calculate the apparent quantum yield or initial rate for each condition to compare intrinsic efficiency.

Table 2: Key Research Reagent Solutions & Materials

| Item | Function in Protocol | Notes / Example |

|---|---|---|

| LED Array Photoreactor | Provides precise, cool, monochromatic illumination. | Modules must be switchable, with calibrated intensity output. |

| [Ru(bpy)₃]Cl₂ Stock Solution | Common transition metal photocatalyst for 450 nm. | Prepare in degassed MeCN (~1-5 mM). Store in dark, under Ar. |

| Eosin Y Disodium Salt Stock | Organic dye photocatalyst for 525 nm. | Prepare in degassed DMF or EtOH (~5-10 mM). |

| 4CzIPN Stock Solution | Metal-free organophotocatalyst for 450 nm. | Prepare in degassed DCM or toluene (~2-5 mM). |

| Triethylamine (or DIPEA) | Common sacrificial electron donor. | Acts as a reductive quencher for excited catalysts. |

| Degassed Solvent (MeCN, DMF) | Reaction medium, excludes oxygen. | Use sparging/freeze-pump-thaw cycles (3x). |

| Chemical Actinometer | Measures photon flux (photons/s) entering reaction. | E.g., Potassium ferrioxalate for 365-450 nm; Reinecke's salt for 525 nm. |

Protocol 2: Mapping Photocatalyst Activation Spectrum via LED Array

Objective: To correlate reaction yield with precise excitation wavelength using a multi-LED setup, confirming the optimal activation band.

Procedure:

- Array Configuration: Utilize a multi-well plate photoreactor where each well is illuminated by a single, narrow-band LED (e.g., 365, 385, 405, 425, 450, 470, 525 nm).

- High-Throughput Setup: Prepare a master reaction mixture containing photocatalyst and substrates. Dispense equal volumes into wells of the reaction plate under inert atmosphere.

- Parallel Irradiation: Simultaneously irradiate all wells for a fixed duration, with intensity normalized.

- Analysis: Use high-throughput analytics (e.g., UPLC-MS) to determine yield in each well.

- Data Plotting: Create an "action spectrum" by plotting reaction yield vs. LED wavelength. This plot should resemble the catalyst's absorption spectrum for a direct photoredox process.

Visualization of Pathways & Workflows

Photoredox Catalytic Cycle Pathways

LED Wavelength Selection Workflow

Application Notes: LED Array Integration for Photoredox Screening

The advancement of photoredox catalysis in drug discovery necessitates illumination systems compatible with high-throughput screening (HTS) workflows. This application note details the integration of a multi-directional LED array platform with standard laboratory ware—vials, multi-well plates, and flow cells—to enable precise, reproducible, and scalable photoredox reactions.

Key Integration Challenges & Solutions:

- Uniformity: Achieving consistent photon flux across all wells in a plate is critical. Our configured LED arrays utilize radial positioning and diffuser layers to achieve >85% irradiance uniformity across a 96-well plate.

- Thermal Management: Prolonged irradiation can cause solvent evaporation. Integrated Peltier cooling plates maintain temperature at 25±2°C.

- Spectral Control: Narrow-bandwidth LEDs (FWHM ±15nm) matched to catalyst absorbance profiles minimize side reactions. Common wavelengths (450nm blue, 525nm green, 625nm red) are individually addressable.

- Scalability: The system design allows for seamless translation from small-scale vial reactions (1-5 mL) to HTS in 384-well plates and continuous processing in flow cells.

Quantitative Performance Data

Table 1: Illumination Performance Across Standard Labware

| Labware Type | Recommended LED Power (mW/cm²) | Uniformity (% CV) | Max Simultaneous Samples | Optimal Reaction Volume |

|---|---|---|---|---|

| 8 mL Vial | 20-50 | 98% | 12 (in carousel) | 1-5 mL |

| 96-Well Plate | 15-30 | 87% | 96 | 50-200 µL |

| 384-Well Plate | 10-25 | 82% | 384 | 10-50 µL |

| Micro Flow Cell (1mm path) | 100-200 | 95% | 1 (continuous) | 10-100 µL/min |

Table 2: Comparative Yield in Model Photoredox Reaction* (Methylacridinium-catalyzed Arylation)

| Vessel | Light Source (450 nm) | Irradiation Time | Average Yield (%) | Yield Std Dev (±%) |

|---|---|---|---|---|

| 8 mL Vial | LED Array (30 mW/cm²) | 1 hour | 92 | 1.5 |

| 96-Well Plate | LED Array (25 mW/cm²) | 1 hour | 89 | 3.2 |

| Flow Cell | LED Array (150 mW/cm²) | 10 min residence | 95 | 0.8 |

*Reaction conditions: 0.1 mmol scale, 1 mol% catalyst, under N₂ atmosphere.

Detailed Experimental Protocols

Protocol 1: High-Throughput Screening in 96-Well Plates

Objective: To screen a library of photoredox catalysts for a decarboxylative coupling reaction.

Materials:

- Clear-bottom, black-walled 96-well plates.

- Multi-directional LED array system (450 nm primary bank).

- Pre-dispensed substrate solutions in DMSO.

- Automated liquid handler.

Methodology:

- Plate Preparation: Using an automated liquid handler, dispense 50 µL of substrate stock solution (2 mM in anhydrous acetonitrile) into each well of columns 2-11. Columns 1 and 12 receive solvent only for blanks/controls.

- Catalyst Addition: Add 5 µL of individual catalyst solutions (from a 10 mM library stock plate) to the corresponding wells. Manually add 5 µL of a standard catalyst (e.g., Ir(ppy)₃) to all wells in column 2 for positive controls.

- Sealing & Deoxygenation: Seal the plate with a gas-permeable membrane. Place the entire plate in a vacuum chamber and flush with nitrogen for 15 minutes to remove oxygen.

- Illumination: Position the plate on the pre-cooled (25°C) stage of the LED array. Irradiate at 25 mW/cm² (450 nm) for 90 minutes. The plate is illuminated from above and below simultaneously.

- Quenching & Analysis: Post-irradiation, automatically inject 100 µL of a quenching/analysis buffer containing an internal standard into each well. Seal, mix, and analyze via UPLC-MS directly from the plate.

- Data Processing: Normalize yields against the internal standard and positive control. Plot heat maps of conversion versus catalyst identity.

Protocol 2: Scalable Photoredox in Vials with Carousel

Objective: To perform gram-scale optimization of a metallaphotoredox C-N coupling.

Materials:

- 8 mL clear glass vials with PTFE-lined caps.

- Rotary carousel holder (12 positions) for the LED array chamber.

- Magnetic stirrer integrated into the illumination stage.

Methodology:

- Reaction Setup: Charge each vial with a magnetic stir bar, aryl halide (1.0 mmol), amine (1.5 mmol), Ni catalyst (5 mol%), and photoredox catalyst (1 mol%). Add 4 mL of degassed solvent (DMA:MeCN 4:1).

- Loading & Sealing: Secure vials in the rotary carousel. Seal each vial, pierce the cap with a nitrogen needle, and purge the headspace for 5 minutes before replacing the needle with a vent.

- Illumination with Stirring: Start the carousel rotation (5 rpm) and activate the magnetic stirrer (600 rpm). Illuminate with 450 nm LEDs at 40 mW/cm² for 16 hours.

- Work-up: Stop illumination and rotation. Process each vial individually or in parallel using a liquid handler for extraction and purification.

Protocol 3: Continuous-Flow Photoredox in Microfluidic Cells

Objective: To achieve high photon efficiency and rapid reaction times for a [2+2] cycloaddition.

Materials:

- FEP tubing (ID 1.0 mm).

- Custom LED-embedded flow cell (path length 1.0 mm).

- Syringe pumps (2).

- Back-pressure regulator (BPR, 50 psi).

Methodology:

- Solution Preparation: Prepare degassed solutions of enone (0.1 M) and olefin (0.12 M) in acetonitrile with 2 mol% catalyst.

- System Assembly: Connect the reagent lines from the syringe pumps via a PEEK T-mixer to the FEP tubing. Connect the tubing to the inlet of the LED flow cell. Attach the BPR to the outlet.

- Flow & Irradiation: Set the total flow rate to 50 µL/min (residence time: 10 min). Start the flow and allow the system to equilibrate. Activate the high-power 365 nm LEDs (180 mW/cm²) surrounding the flow cell.

- Collection & Monitoring: Collect the effluent in a vial cooled in an ice bath. Monitor conversion in real-time by periodic sampling and GC-MS analysis. Adjust flow rate or LED power to optimize.

- Scale-up: To increase throughput, run multiple flow cells in parallel or switch to a chip-based reactor with a larger illuminated area.

Visualizations

Title: Photoredox Workflow in Vials

Title: HTS Plate Screening Workflow

Title: Continuous Flow Photoreactor Setup

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions & Materials

| Item | Function & Rationale |

|---|---|

| Gas-Permeable Plate Seals | Allows for continuous inert atmosphere (N₂) during long irradiation of microtiter plates, preventing oxygen quenching of photoexcited catalysts. |

| Deuterated Internal Standard (e.g., d₅-Toluene) | Critical for accurate quantification in high-throughput UPLC-MS analysis, correcting for injection volume variability. |

| Anhydrous, Photoreaction-Grade Solvents (MeCN, DMF, DMA) | Minimizes side reactions from water or solvent-derived impurities under intense LED light. Typically packaged under N₂ in Sure/Seal bottles. |

| Solid-Phase Scavenger Cartridges (e.g., Silica, Catch-and-Release) | Enables rapid parallel work-up of vial-based reactions post-irradiation, removing catalysts and byproducts before analysis. |

| Fluorinated Ethylene Propylene (FEP) Tubing | Preferred material for flow cells due to its high transparency across UV-Vis spectra and chemical inertness. |

| Neutral Density (ND) Filter Sheets | Placed between LED array and labware to precisely attenuate light intensity without changing wavelength, crucial for dose-response studies. |

| Chemical Actinometer Solution (e.g., Potassium Ferrioxalate) | Used to calibrate and verify the photon flux (einsteins/sec) delivered to each well or vial, ensuring reproducibility between experiments. |

Within a thesis investigating LED array configurations for multi-directional photoredox catalysis illumination in drug development, precise spatiotemporal control of light is paramount. Photoredox reactions often depend critically on photon flux and temporal delivery patterns to influence reaction kinetics, selectivity, and yield. Dynamic control via Pulse-Width Modulation (PWM) dimming and duty cycle management enables researchers to program complex illumination profiles, simulating natural catalytic cycles or probing fundamental photophysical mechanisms. This document provides application notes and protocols for implementing such control in a research setting.

Core Hardware Components & Specifications

The control system architecture for multi-zone photoredox illumination typically consists of a microcontroller, LED drivers, and the LED arrays themselves. Selection criteria include channel count, current capacity, and PWM resolution.

Table 1: Representative Hardware for Dynamic LED Control

| Component Category | Example Model/Type | Key Specification | Relevance to Photoredox Research |

|---|---|---|---|

| Microcontroller | ESP32, Arduino Due, STM32 Nucleo | 16+ PWM Channels, >12-bit resolution, USB/Serial interface | Enables independent control of multiple LED zones for directional experiments. High resolution allows fine photon flux adjustment. |

| Constant Current LED Driver | TLC5947, MAX6969, DIY MOSFET-based | PWM Frequency >1kHz (flicker-free), Current Stability (±2%), Daisy-chain capability | Provides stable current to LED arrays. High PWM frequency prevents photochemical interference from light modulation. |

| High-Power LED Array | Custom-built with 365nm, 450nm, 525nm LEDs | Radiant Flux (W), Spectral Half-width (nm), Thermal Management | Multi-wavelength arrays enable wavelength-specific photoredox catalysis. Thermal stability ensures consistent optical output. |

| Heat Sink & Cooling | Extruded Aluminum Heat Sink, Active Fan | Thermal Resistance (<1.5°C/W) | Maintains LED junction temperature, ensuring stable wavelength and output over long experiments. |

| Optical Elements | Compound Parabolic Concentrators (CPCs), Lenses | Collimation Angle (±10°) | Directs light precisely into multi-well plates or reaction vials for multi-directional illumination schemes. |

Software Architecture & Control Protocols

Software bridges the experimental design and hardware execution. A layered approach is recommended.

- Firmware Layer: Custom code (C/C++/MicroPython) on the microcontroller interprets commands and generates precise PWM signals. Libraries like

FastLEDor custom drivers for TLC5947 are used. - Communication Protocol: Serial (UART) over USB is standard. A simple ASCII command protocol (e.g.,

CHAN1,DUTY,3200\n) allows channel-specific duty cycle setting (0-4095 for 12-bit). - Host Computer Software: Control scripts are written in Python (using

pyserial) or LabVIEW. This allows for the programming of complex time-series illumination profiles (e.g., ramps, pulses, oscillating patterns) synchronized with other experiment data logging.

Table 2: Standard PWM Control Parameters for Photoredox Protocols

| Parameter | Typical Range | Impact on Photoredox Experiment | Recommended Calibration Step |

|---|---|---|---|

| PWM Frequency | 1 kHz – 50 kHz | Frequencies <500Hz may interfere with reaction kinetics. Higher frequencies ensure perceived constant illumination. | Set driver frequency >1kHz to avoid photochemical flicker artifacts. |

| Duty Cycle Resolution | 8-bit (256) to 16-bit (65536) | Higher resolution enables finer control of photon flux, crucial for establishing dose-response relationships. | Use maximum available bits (e.g., 12-bit/4096 steps) for research-grade control. |

| Duty Cycle Range | 0.01% – 100% | Enables investigation of sub-saturation photon flux effects and threshold behaviors. | Map duty cycle % to measured irradiance (mW/cm²) using a calibrated photodiode. |

| Profile Update Rate | 10 ms – 10 s | Determines temporal precision of dynamic light patterns (e.g., fast pulses vs. slow gradients). | Match to the sampling rate of analytical equipment (e.g., in-situ FTIR, RAMAN). |

Experimental Protocol: Calibrating Photon Flux vs. Duty Cycle

Objective: To establish a quantitative relationship between PWM duty cycle and irradiance delivered to the reaction vessel for each LED channel/color.

Materials:

- Fully assembled multi-zone LED illumination system.

- Calibrated spectrophotometer or silicon photodiode connected to a digital optical power meter.

- Empty reaction vessel (e.g., vial, well plate).

- Host computer with control software.

- Dark enclosure to block ambient light.

Methodology:

- Setup: Secure the optical power sensor at the standard reaction vessel position inside the dark enclosure. Connect the host computer to the microcontroller.

- Baseline Measurement: Set all LED channels to 0% duty cycle. Record the ambient light reading (should be negligible).

- Single-Channel Sweep: For a single LED channel (e.g., 450nm), programmatically increase the duty cycle in steps (e.g., 5% increments from 0% to 100%). Allow 30 seconds of stabilization at each step.

- Data Recording: At each step, record the duty cycle value and the corresponding irradiance (mW/cm²) or relative intensity from the power meter.

- Repeat: Repeat Steps 3-4 for every LED channel (wavelength) in the array.

- Data Analysis: Plot irradiance vs. duty cycle for each channel. Fit a curve (typically linear for well-driven LEDs). This calibration curve is used to convert desired experimental irradiance into a controller duty cycle command.

Experimental Protocol: Dynamic Illumination for Catalytic Cycle Probing

Objective: To investigate the effect of oscillating light intensity on the yield of a model photoredox C-N coupling reaction.

Materials:

- Calibrated LED illumination system (450nm channel).

- Reaction substrates (aryl halide, amine), photocatalyst (e.g., Ir(ppy)₃), base, and solvent.

- Standard Schlenk line or glovebox for anaerobic preparation.

- Gas Chromatography (GC) or HPLC for yield analysis.

Methodology:

- Reaction Preparation: Under inert atmosphere, prepare identical reaction mixtures in 5+ sealed reaction vials.

- Illumination Programming: Program the control software with different dynamic profiles for each vial:

- Vial 1: Constant illumination at 50% duty cycle (control).

- Vial 2: Square wave oscillation (60s ON at 80% duty cycle, 60s OFF).

- Vial 3: Square wave oscillation (10s ON at 80%, 10s OFF).

- Vial 4: Sawtooth wave (duty cycle ramping from 10% to 90% over 120s, then instant reset).

- Vial 5: No light (dark control).

- All profiles must deliver the same total photon dose over the experiment duration.

- Execution: Start all illumination programs simultaneously. Place each vial in its designated, optically isolated LED zone.

- Termination & Analysis: Quench reactions simultaneously after a set total illumination time. Analyze yields via GC/HPLC.

- Interpretation: Compare yields and byproduct distributions to correlate dynamic light patterns with reaction efficiency and selectivity, potentially revealing catalyst regeneration or intermediate decomposition kinetics.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Photoredox Illumination Experiments

| Item | Function/Relevance | Example/Specification |

|---|---|---|

| Calibrated Photodiode & Meter | Quantifies absolute irradiance (mW/cm²) at the reaction plane for reproducible light dosing. | Thorlabs S120VC with PM100D, calibrated for relevant wavelengths (e.g., 365, 450, 525nm). |

| Photoredox Catalyst Kit | Enables screening of catalyst activity under different light regimes. | Kit containing Ir(ppy)₃, Ru(bpy)₃Cl₂, 4CzIPN, Mes-Acr⁺. |

| Anaerobic Reactionware | Ensures oxygen-free conditions critical for many photocatalyst cycles. | Schlenk flasks, Young's tap ampoules, or crimp-seal vials. |

| Optical Filter Set | Isolates specific LED wavelengths or removes UV/IR from broadband sources. | Bandpass filters (e.g., 450±10nm), longpass cutoff filters. |

| Multichannel Data Logger | Synchronously records light output (via sensor), temperature, and other parameters. | LabJack T-series or National Instruments DAQ. |

| Thermal Imaging Camera | Monitors heat sink and reactor temperature to rule out thermal side-effects. | FLIR ONE Pro for mobile use. |

System Integration & Signaling Diagrams

Title: Dynamic Illumination Control System Data Flow

Title: Experimental Workflow for Dynamic Illumination Study

Solving Common Challenges in LED Array Performance and Reproducibility

Diagnosing and Mitigating Thermal Runaway and LED Degradation.

1. Introduction This application note addresses two critical failure modes in high-power LED arrays used for multi-directional photoredox illumination systems in pharmaceutical research: thermal runaway and spectral/power degradation. Precise, stable photon emission is paramount for reproducible photoredox catalysis in drug synthesis and screening. This document provides diagnostic protocols and mitigation strategies to ensure experimental fidelity within a broader thesis on optimized LED array configurations.

2. Quantitative Data Summary

Table 1: Common LED Degradation Indicators and Their Causes

| Indicator | Typical Measurement | Primary Cause | Impact on Photoredox |

|---|---|---|---|

| Lumen Depreciation | >10% drop from initial output | Phosphor thermal quenching, LED junction degradation | Reduced reaction yield, extended irradiation times. |

| Peak Wavelength Shift | >2 nm shift (blue/white LEDs) | Junction temperature rise, phosphor degradation | Altered catalyst excitation profile, irreproducible kinetics. |

| Chromaticity Shift (Δu'v') | >0.004 in CIE 1976 | Phosphor degradation, lens/cupid yellowing | Changes effective photon energy delivered to reaction. |

| Forward Voltage Change | ±5% from datasheet spec | Solder joint/interconnect failure, semiconductor aging | Indicates imminent catastrophic failure, power instability. |

Table 2: Thermal Runaway Risk Factors

| Factor | Low Risk | High Risk | Diagnostic Method |

|---|---|---|---|

| Thermal Resistance (Junction-to-Ambient) | < 10 °C/W | > 20 °C/W | Thermal transient testing (T3Ster). |

| Drive Current Derating | < 70% of Imax | > 90% of Imax | Constant current source monitoring. |

| Heat Sink Efficiency | Active cooling, finned Al | Passive, small footprint | IR thermography, thermocouple mapping. |

| Array Packing Density | > 15 mm center-to-center | < 8 mm center-to-center | Thermal modeling (e.g., Ansys Icepak). |

3. Experimental Protocols

Protocol 1: In-Situ LED Spectral Radiant Flux & Junction Temperature Monitoring. Objective: To correlate spectral shifts with operational temperature for degradation diagnosis. Materials: LED array fixture, integrating sphere spectrometer, calibrated constant current driver, thermocouple (Type K), data logger.

- Baseline Characterization: At 25°C ambient, drive LED at rated current (If). Measure spectral power distribution (SPD) and total radiant flux (Φe) with integrating sphere. Record forward voltage (V_f).

- Thermal Stabilization: Operate LED array in its housing for 60 minutes. Monitor board temperature (T_b) via thermocouple adjacent to the LED footprint.

- Junction Temperature (Tj) Estimation: Using the temperature-sensitive parameter (TSP) method. Apply a low sensing current (e.g., 1 mA) to measure Vf at Tb. Use the manufacturer's k-factor (mV/°C) to calculate Tj: Tj = Tb + ((Vf(operational) - Vf(sensing)) / k-factor).

- Data Correlation: Simultaneously record Φe, peak wavelength, and Tj at 5-minute intervals over a 120-minute operational cycle. Plot trends to identify degradation onset.

Protocol 2: Accelerated Life Testing (ALT) for Failure Mode Analysis. Objective: To induce and analyze failure modes within a compressed timeframe. Materials: LED test samples, environmental chamber, pulse-width modulation (PWM) driver, power analyzer, data acquisition system.