Photoenzymatic Catalysis: Principles, Applications, and the Frontier of Biomedical Translation

Photoenzymatic catalysis is an emerging frontier that merges the precision of biocatalysis with the energy of light to drive novel, sustainable chemical transformations.

Photoenzymatic Catalysis: Principles, Applications, and the Frontier of Biomedical Translation

Abstract

Photoenzymatic catalysis is an emerging frontier that merges the precision of biocatalysis with the energy of light to drive novel, sustainable chemical transformations. This article provides a comprehensive overview for researchers and drug development professionals, covering the foundational principles of natural and artificial photoenzymes, the design of advanced hybrid systems (including cofactor-independent platforms), and their application in synthesizing high-value chiral intermediates and enabling CO2 conversion. It further details practical methodologies, addresses key challenges in system optimization and stability, and outlines rigorous validation and comparative analysis frameworks. The synthesis concludes by evaluating the transformative potential of this field for green pharmaceutical manufacturing and biomedical research.

What is Photoenzymatic Catalysis? Defining the Principles of a Light-Driven Revolution

Photoenzymatic catalysis represents a frontier in synthetic chemistry, merging the principles of photochemistry with the selectivity and efficiency of enzyme catalysis. This whitepaper defines its core principle: the use of light to initiate or drive highly specific enzymatic transformations that are otherwise kinetically or thermodynamically inaccessible. This synergy enables novel reaction pathways under mild conditions, critical for advanced applications in asymmetric synthesis and drug development.

Foundational Principles & Quantitative Data

The efficacy of photoenzymatic systems is quantified by key metrics comparing them to conventional photocatalysis and enzymatic catalysis alone.

Table 1: Comparative Performance Metrics of Catalytic Systems

| Metric | Traditional Photocatalysis | Traditional Enzymatic Catalysis | Photoenzymatic Catalysis |

|---|---|---|---|

| Enantiomeric Excess (ee) | Typically racemic | High (often >99%) | Very High (>99%, retained from enzyme) |

| Quantum Yield (Φ) | 0.01 - 0.5 | Not Applicable | 0.05 - 0.3 (for hybrid systems) |

| Turnover Number (TON) | 10 - 1000 | 10^3 - 10^6 | 10^2 - 10^4 (for non-native photoactivation) |

| Reaction Temperature | Ambient to 100°C | 20°C - 40°C | 20°C - 40°C |

| Solvent Tolerance | Broad | Limited (aqueous buffer) | Improved via enzyme engineering |

Table 2: Prominent Photoenzyme Classes & Characteristics

| Enzyme Class | Natural Cofactor | Photochemical Role | Exemplary Reaction |

|---|---|---|---|

| Energic Acid Decarboxylases (e.g., FAP) | Flavin (FAD) | Direct C-H alkylation via radical generation | Decarboxylative alkylation of C(sp3)-H bonds |

| Old Yellow Enzymes (OYEs) | Flavin (FMN) | Asymmetric reduction of activated alkenes via photoinduced electron transfer | Enantioselective reduction of α,β-unsaturated compounds |

| Engineered Cytochrome P450s | Heme (Fe) | C-H activation via photoinduced reactive oxygen species | Light-driven hydroxylation |

| Artificial Metalloenzymes | Synthetic metal complexes (e.g., Ir, Ru) | Photo-redox catalysis within a protein scaffold | Asymmetric α-alkylation of aldehydes |

Core Experimental Protocols

Protocol: Photoenzymatic Asymmetric Hydroalkylation using a Flavin-dependent Photodecarboxylase

This protocol details the synthesis of chiral products via photoinduced radical generation and enantioselective bond formation.

Objective: To perform the enantioselective decarboxylative alkylation of an alkyl carboxylic acid to an electron-deficient olefin.

Materials: See "The Scientist's Toolkit" (Section 5.0).

Procedure:

- Enzyme Preparation: Purify the fatty acid photodecarboxylase (FAP) to homogeneity via Ni-NTA affinity chromatography. Concentrate to 20 mg/mL in 50 mM phosphate buffer (pH 7.5). Determine concentration via Bradford assay.

- Anaerobic Sample Preparation: In an argon-filled glovebox, prepare 2 mL reaction vials. Add: 50 µL substrate stock solution (100 mM in DMSO, final conc. 5 mM), 40 µL acceptor olefin (50 mM in DMSO, final conc. 2 mM), and 850 µL of degassed phosphate buffer (50 mM, pH 7.5).

- Reaction Initiation: Add 60 µL of the purified FAP solution. Seal the vial with a rubber septum.

- Photoreaction: Place the vial in a thermostatted photoreactor (25°C) equipped with a 450 nm LED array (intensity calibrated to 20 mW/cm²). Irradiate with continuous stirring for 16-24 hours.

- Quenching & Extraction: Quench the reaction by adding 1 mL of ethyl acetate and vortex vigorously for 2 minutes. Centrifuge at 14,000 rpm for 5 min to separate phases.

- Analysis: Analyze the organic layer via chiral HPLC to determine conversion and enantiomeric excess (ee). Analyze by LC-MS for product identification.

Protocol: Constructing an Artificial Photoenzyme with a Synthetic Photocatalyst

This protocol outlines the creation of a hybrid system by incorporating an abiotic photosensitizer into a protein scaffold.

Objective: To anchor a synthetic iridium photosensitizer within streptavidin for asymmetric α-alkylation.

Procedure:

- Biotinylated Photocatalyst Synthesis: Synthesize an Ir(ppy)₃-derivative functionalized with a biotin linker via standard organometallic synthesis. Confirm structure via NMR and HRMS.

- Host Protein Expression & Purification: Express streptavidin in E. coli and purify via iminobiotin affinity chromatography.

- Hybrid Assembly: Incubate 10 nmol of streptavidin tetramer with a 5-fold molar excess of the biotinylated Ir catalyst in PBS buffer (pH 7.4) for 1 hour at 4°C. Purify the assembly via size-exclusion chromatography (SEC) to remove unbound catalyst.

- Activity Assay: In a photoreactor vial, combine: 5 nmol of the assembled photoenzyme, 0.1 mmol aldehyde substrate, 0.12 mmol alkyl halide, and 0.15 mmol diisopropylethylamine in a 1:1 mixture of buffer and organic co-solvent (total vol 1 mL).

- Irradiation & Analysis: Irradiate with 440 nm LEDs (10 mW/cm²) for 12 hours. Extract and analyze yield via GC-FID and enantioselectivity via chiral HPLC.

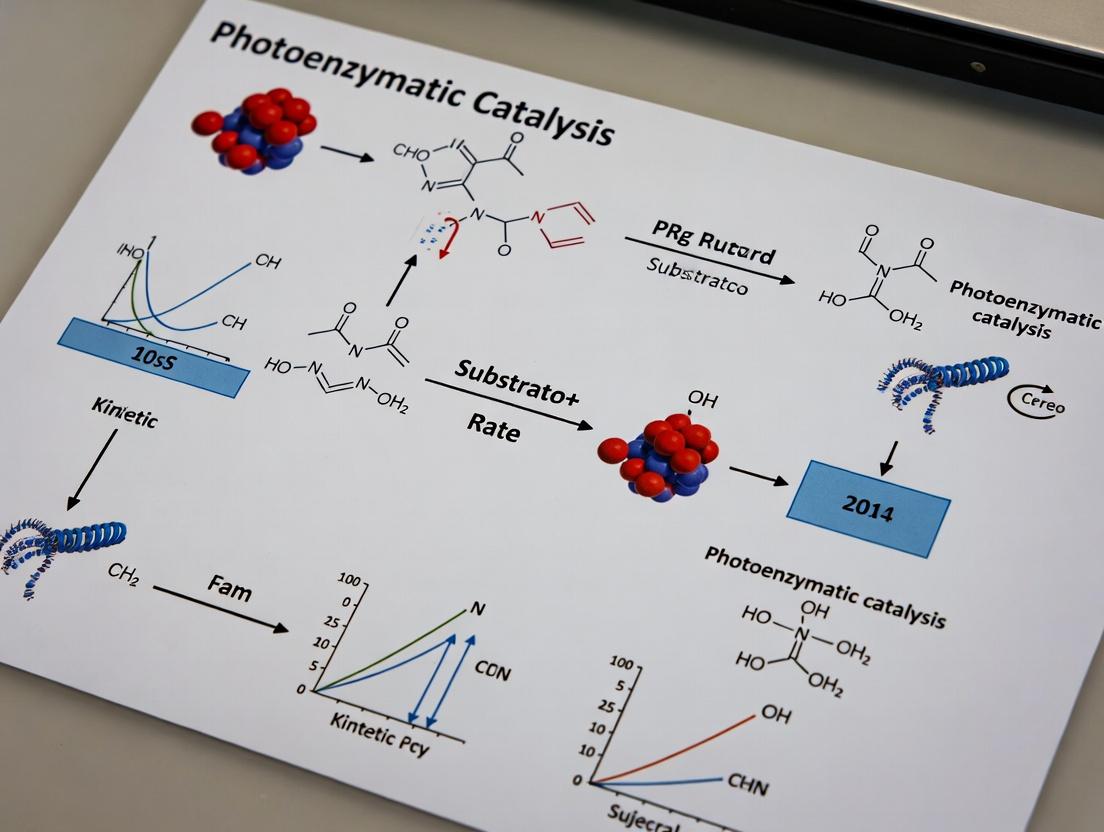

Mandatory Visualizations

Diagram 1: General Photoenzymatic Catalysis Workflow

Diagram 2: Artificial Photoenzyme Construction Protocol

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 3: Key Reagent Solutions for Photoenzymatic Research

| Item / Reagent | Function / Role | Example / Specification |

|---|---|---|

| Flavin-dependent Photodecarboxylase (FAP) | The photoenzyme catalyst; absorbs blue light to generate an alkyl radical from a carboxylic acid substrate. | Recombinant, His-tagged, from Chlorella variabilis, ≥95% purity. |

| Biotinylated Iridium Photosensitizer | Synthetic photocatalyst for creating artificial photoenzymes; enables photo-redox cycles within a protein host. | e.g., [Ir(ppy)₂(bpy-CH₂-NH-CO-biotin)]⁺, synthesized in-house or sourced custom. |

| Streptavidin or Sav Mutants | Protein host/scaffold for artificial photoenzymes; provides a high-affinity binding pocket for biotinylated catalysts. | Tetrameric, expressed in E. coli, low photoactivity background. |

| Deazaflavin (e.g., 5-Deazaflavin) | Alternative/supplemental organic photocatalyst for mediating electron transfer to natural or engineered enzymes. | Used in some photo-regeneration systems for NAD(P)H cofactors. |

| Anaerobically Prepared Buffers | Essential for radical-based reactions to prevent quenching by molecular oxygen. | Phosphate or Tris buffer, degassed via 3+ freeze-pump-thaw cycles or sparged with Ar/N₂ for >30 min. |

| Chiral Stationary Phase HPLC Columns | Critical for analyzing enantiomeric excess (ee) of reaction products. | e.g., Daicel CHIRALPAK IA, IC, or AD-H columns (4.6 x 250 mm). |

| Calibrated LED Photoreactors | Provides controlled, monochromatic light irradiation for reproducible photoactivation. | Custom or commercial vials/blocks with temperature control, 420-460 nm typical, intensity calibrated with a radiometer. |

| Deuterated Solvents for EPR | For direct detection and characterization of radical intermediates generated during catalysis. | DMSO-d6, Buffer-D2O, for in-situ EPR or ENDOR spectroscopy studies. |

Photoenzymatic catalysis represents a frontier in synthetic biology and sustainable chemistry, merging the precision of enzyme catalysis with the spatiotemporal control afforded by light. Within the broader thesis of defining its principles, understanding the initial photophysical events is paramount. This process begins not with chemical bond formation, but with the absorption of a photon and the subsequent journey of energy through an enzyme's prosthetic group or engineered chromophore. This guide details the fundamental photophysical steps—light absorption, excitation, energy/electron transfer, and the ultimate manifestation of catalytic activity—providing the technical foundation for advanced research in the field.

The Photophysical Cascade: A Stepwise Analysis

Light Absorption and Excited State Formation

The process initiates when a photon of appropriate energy (wavelength) is absorbed by a chromophore (e.g., flavin, porphyrin, organic dye, or metal complex). This promotes an electron from the ground state (S₀) to a higher-energy singlet excited state (S₁, S₂...). The efficiency is quantified by the molar attenuation coefficient (ε), typically ranging from 10³ to 10⁵ M⁻¹cm⁻¹.

Excited State Relaxation and Dynamics

The initially populated excited singlet state undergoes rapid internal conversion and vibrational relaxation to the lowest vibrational level of S₁. From here, several competing pathways determine the quantum yield (Φ) of subsequent catalytic steps:

- Fluorescence: Radiative decay back to S₀.

- Internal Conversion (IC): Non-radiative decay to S₀.

- Intersystem Crossing (ISC): Spin-forbidden transition to a triplet state (T₁), crucial for catalysts involving radical chemistry or energy transfer.

- Photoinduced Electron Transfer (PET): The electron or hole is transferred to/from a nearby redox-active residue or substrate.

- Förster Resonance Energy Transfer (FRET): Non-radiative energy transfer to an adjacent acceptor chromophore.

From Photophysics to Catalysis

The energy or electron transferred from the excited chromophore alters the redox state of the catalytic center or directly generates reactive intermediates (e.g., radical species, singlet oxygen). This photochemically generated "trigger" then drives the enzyme's canonical or engineered catalytic cycle, often with remarkable stereoselectivity.

Table 1: Key Photophysical Parameters of Common Photoenzyme Chromophores

| Chromophore | Typical Absorption λ_max (nm) | Molar Extinction Coefficient ε (M⁻¹cm⁻¹) | Fluorescence Quantum Yield (Φ_f) | Triplet Yield (Φ_ISC) | Primary Photoprocess |

|---|---|---|---|---|---|

| Flavin Adenine Dinucleotide (FAD) | ~450 | 11,300 | 0.03 | 0.7 | PET / Radical Generation |

| Chlorophyll a | ~430, ~660 | >100,000 (Qy band) | 0.23 | 0.64 | PET / Energy Transfer |

| [Ru(bpy)₃]²⁺ | ~452 | 14,600 | 0.06 | 0.90 | PET (Oxidative/Reductive Quenching) |

| Eosin Y | ~525 | 95,000 | 0.57 | 0.43 | PET / Singlet Oxygen Gen. |

| Deazaflavin | ~420 | 6,000 | <0.01 | >0.9 | PET / Hydride Transfer |

Core Experimental Methodologies

Protocol: Steady-State UV-Vis Absorption Spectroscopy

Purpose: Determine chromophore identity, concentration (via Beer-Lambert law), and ground-state electronic properties. Procedure:

- Prepare enzyme/chromophore sample in a suitable transparent buffer (e.g., 50 mM phosphate, pH 7.4). Ensure absorbance of target peak is between 0.1 and 1.0 for optimal accuracy.

- Fill a quartz cuvette (typically 1 cm path length) with sample and reference (buffer alone).

- Record absorption spectrum from 250 nm to 800 nm using a dual-beam spectrophotometer.

- Calculate concentration: c = A / (ε * l), where A=absorbance, ε=known extinction coefficient, l=path length.

Protocol: Time-Resolved Fluorescence Spectroscopy

Purpose: Measure the lifetime (τ) of the excited singlet state, informing on quenching, energy transfer, and conformational dynamics. Procedure (Time-Correlated Single Photon Counting - TCSPC):

- Excite the sample with a pulsed diode laser or Ti:sapphire laser at the chromophore's absorption maximum.

- Collect emitted photons at the fluorescence maximum using a fast photomultiplier tube or microchannel plate detector.

- Build a histogram of photon arrival times relative to the laser pulse over millions of cycles.

- Fit the decay curve to single or multi-exponential functions: I(t) = Σ αᵢ exp(-t/τᵢ), where τᵢ are lifetimes and αᵢ their amplitudes.

Protocol: Laser Flash Photolysis

Purpose: Directly observe triplet states and transient intermediates (radicals, charge-separated states) on microsecond to second timescales. Procedure:

- Place sample in a stirred quartz cuvette within the spectrometer.

- Use a pulsed Nd:YAG or excimer laser (e.g., 355 nm, 5-10 ns pulse) for photoexcitation.

- Monitor transient absorption changes (ΔA) at specified probe wavelengths using a continuous white light probe beam and a fast photodiode or CCD detector.

- Record kinetic traces at different wavelengths to construct time-resolved absorption spectra and derive decay kinetics of transient species.

Visualizing Pathways and Workflows

Diagram 1: Core Photophysical Pathways in Photoenzymes (100 chars)

Diagram 2: Photophysical Characterization Workflow (96 chars)

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Research Reagent Solutions for Photoenzymatic Studies

| Item | Function & Rationale |

|---|---|

| Anaerobic Sealed Cuvettes (e.g., with septum) | To exclude oxygen for studying triplet states or oxygen-sensitive intermediates, as O₂ is a potent triplet quencher. |

| Deuterium Oxide (D₂O) | Solvent for NMR studies of photoproducts; also used in kinetic isotope effects to probe H-transfer mechanisms. |

| Electron Donor/Acceptor Pairs (e.g., TEOA / MV²⁺) | Sacrificial reagents to study photoinduced electron transfer pathways by providing a quencher for the excited state. |

| Singlet Oxygen Scavengers & Quenchers (e.g., Sodium Azide, DABCO) | To confirm or rule out the involvement of singlet oxygen (¹O₂) in the catalytic mechanism. |

| Stopped-Flow Module (for spectrophotometer) | To rapidly mix enzyme with substrate just prior to light excitation, enabling study of fast binding events under photochemical conditions. |

| Low-Temperature Matrices (e.g., glycerol/buffer glass at 77K) | To trap and characterize transient intermediates (e.g., radical pairs) by slowing down their recombination or decay. |

| Optically Transparent Redox Dyes (e.g., methyl viologen, benzyl viologen) | To act as electron relays or to spectrophotometrically monitor redox potential changes during photocatalysis. |

| Chromophore Analogs/Isotopologues (e.g., ¹³C-labeled, deuterated flavins) | For mechanistic probing using advanced techniques like EPR, ENDOR, or NMR to track atom-specific fate. |

Contrasting Thermal vs. Photo- Activation Mechanisms in Enzymes

This whitepaper provides a detailed technical comparison between thermal and photo-activation mechanisms in enzyme catalysis. This analysis is framed within the broader research thesis on photoenzymatic catalysis definition and principles, which seeks to establish a foundational understanding of how light energy can be harnessed to drive and control enzymatic reactions with spatiotemporal precision unattainable by traditional thermal means. For researchers and drug development professionals, elucidating these contrasting mechanisms is critical for innovating new therapeutic and synthetic biology platforms.

Fundamental Mechanisms: Core Principles

Thermal Activation

Thermal activation relies on ambient or applied heat to provide the kinetic energy necessary for substrates to reach the transition state. The reaction rate follows the Arrhenius equation, where increasing temperature increases the rate constant. Conformational changes in the enzyme are stochastic and driven by molecular collisions.

Photo-Activation

Photo-activation involves the direct absorption of photons by the enzyme or a bound cofactor (e.g., flavin, porphyrin). This absorption promotes an electron to an excited state, initiating a photophysical cascade (e.g., energy transfer, electron transfer, or generation of radical species) that drives catalysis. This mechanism is central to defined photoenzymatic systems, enabling reaction control orthogonal to thermal pathways.

Quantitative Comparison of Key Parameters

The following tables summarize critical data differentiating the two activation modes.

Table 1: Energetic and Kinetic Parameters

| Parameter | Thermal Activation | Photo-Activation |

|---|---|---|

| Primary Energy Source | Heat (kT) | Photons (hν) |

| Activation Energy (Ea) Range | 50 - 100 kJ/mol | 10 - 200 kJ/mol (light-dependent) |

| Typical Time Scale for Activation | Picoseconds to milliseconds | Femtoseconds to nanoseconds (initial step) |

| Temperature Dependence (Q₁₀) | 2-3 (for biological rates) | Can be near 1 (light-intensity dependent) |

| Spatial Control Resolution | Poor (bulk heating) | Excellent (diffraction-limited, ~250 nm) |

| Temporal Control Resolution | Millisecond-second (limited by heat transfer) | Nanosecond-microsecond (pulse laser controlled) |

Table 2: Key Characteristics in Biocatalysis

| Characteristic | Thermal Activation | Photo-Activation |

|---|---|---|

| Reaction Selectivity | Governed by transition-state stabilization | Can access high-energy intermediates (e.g., radicals) for novel selectivity |

| Spatiotemporal Control | Limited | Precise, tunable by wavelength and intensity |

| Side Reactions | Increased at higher temperatures | Potential for photodamage or off-target excited-state reactions |

| Orthogonality in Complex Systems | Low (affects all components) | High (with selective chromophore targeting) |

| Common Enzyme Examples | Hydrolases, Polymerases | DNA Photolyases, Flavoprotein Oxidoreductases |

Experimental Protocols for Mechanistic Investigation

Protocol: Stopped-Flow Spectroscopy for Thermal Kinetics

Objective: Determine the pre-steady-state kinetic parameters (kₐₜₜ, Kₘ) of a thermally activated enzyme.

- Prepare Solutions: In separate syringes, load (A) enzyme (2-10 µM in appropriate buffer) and (B) substrate (at least 5x concentration range across Kₘ). Pre-incubate both at the precise experimental temperature (±0.1°C) using a circulating water bath.

- Calibration & Mixing: Calibrate the stopped-flow instrument's dead time (typically 1-3 ms). Rapidly mix equal volumes (typically 50-100 µL each) from syringes A and B into the observation cell.

- Data Acquisition: Monitor the reaction progress (e.g., absorbance, fluorescence) for 5-10 half-lives. Use a photomultiplier tube or diode array detector.

- Analysis: Fit the resulting time-course data to the appropriate kinetic model (e.g., single or double exponential) to obtain observed rates (kₒbₛ). Plot kₒbₛ against substrate concentration and fit to the Michaelis-Menten equation to derive kₐₜₜ and Kₘ.

Protocol: Laser Flash Photolysis for Photoenzyme Dynamics

Objective: Characterize the transient intermediates and kinetics of a photoactivated enzymatic cycle.

- Sample Preparation: Prepare enzyme with bound photoco factor in a sealed, degassed cuvette under anaerobic conditions if necessary to prevent quenching by oxygen.

- Excitation: Use a pulsed laser (e.g., Nd:YAG, dye laser) tuned to the absorption maximum of the cofactor (e.g., 450 nm for flavin). Pulse width should be shorter than the dynamics of interest (nanoseconds typical).

- Probe & Detection: A continuous white light probe beam is passed through the sample perpendicular to the pump laser path. A monochromator selects a specific probe wavelength, and a fast detector (e.g., photomultiplier, diode) records changes in absorbance over time.

- Data Collection & Global Analysis: Record transient absorption spectra at multiple time delays and probe wavelengths. Perform global kinetic analysis to deconvolute spectra and lifetimes of sequential intermediates (e.g., excited singlet state, triplet state, semiquinone radical).

Visualization of Mechanisms and Workflows

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Thermal vs. Photoenzyme Studies

| Item | Function | Example/Target Use |

|---|---|---|

| Highly Purified Recombinant Enzyme | Ensure consistent, contaminant-free protein for kinetic and spectroscopic studies. | Overexpressed and purified photoenzyme (e.g., ene-reductase) or thermal enzyme control. |

| Chromophore Cofactors | Provide the light-absorbing center for photoenzymes. | Flavins (FMN, FAD), Deazaflavin, Pyrroloquinoline quinone (PQQ). |

| Anaerobic Chamber/Sealed Cuvettes | Maintain oxygen-free conditions to study radical intermediates prone to quenching by O₂. | Flash photolysis experiments on flavoproteins. |

| Temperature-Controlled Stopped-Flow System | Accurately measure pre-steady-state kinetics with rapid mixing and precise thermal control. | Determining kₐₜₜ and Kₘ of a thermally activated enzyme. |

| Tunable Pulsed Laser System | Provide monochromatic, high-intensity light pulses to initiate the photocycle. | Nd:YAG laser with optical parametric oscillator (OPO) for flash photolysis. |

| Rapid-Scanning Spectrophotometer | Capture full UV-Vis spectra on millisecond timescales. | Observing intermediate formation/decay during thermal or light-driven turnover. |

| Quartz Cuvettes (UV-Vis Transparent) | Allow excitation and probing across UV and visible wavelengths without interference. | All spectroscopy experiments. |

| Chemical Quenchers/Sensitizers | Probe electron transfer pathways or scavenge specific reactive species. | Potassium ferricyanide (electron acceptor), sodium azide (singlet oxygen quencher). |

| Isotopically Labeled Substrates (²H, ¹³C) | Unravel reaction mechanisms via kinetic isotope effects (KIE) or NMR analysis. | Distinguishing between hydride vs. proton transfer steps in photoinduced mechanisms. |

| Cryogenic Spectrophotometer | Trap and characterize transient intermediates at low temperatures. | Studying unstable photoproducts in enzymes like DNA photolyase. |

This whitepaper explores the rare but mechanistically profound domain of natural photoenzymes, framed within the broader research thesis of defining the principles of photoenzymatic catalysis. Unlike the more common photochemical reactions in biology (e.g., photosynthesis), natural photoenzymes are defined as enzymes that utilize light energy to catalyze chemical transformations of a substrate that is not chlorophyll or a related photosynthetic pigment. These enzymes represent exquisite biological blueprints for harnessing photon energy with high selectivity, offering transformative insights for biocatalysis and photopharmacology. Understanding their mechanisms is critical for advancing the foundational principles of photoenzymatic catalysis.

Core Mechanisms and Key Photoenzymes

Natural photoenzymes operate through distinct photochemical mechanisms, often involving specialized cofactors.

DNA Photolyase

This enzyme repairs UV-induced cyclobutane pyrimidine dimers (CPDs) in DNA. It contains two cofactors: a light-harvesting antenna (often methenyltetrahydrofolate, MTHF) and a catalytic flavin adenine dinucleotide (FADH⁻). Upon blue-light absorption by the antenna, energy is transferred to FADH⁻, which transfers an electron to the CPD, initiating bond cleavage and repair.

(S)-Enone Reductase (Formerly "Old Yellow Enzyme" Family)

Certain members, such as the fatty acid photodecarboxylase (FAP) discovered in microalgae, utilize a flavin cofactor (FAD) to catalyze light-driven decarboxylation of fatty acids. Upon blue-light excitation, the flavin semiquinone form abstracts a proton from the substrate carboxylate, leading to decarboxylation and hydrocarbon formation.

Protochlorophyllide Oxidoreductase (POR)

A critical enzyme in chlorophyll biosynthesis, POR catalyzes the light-dependent reduction of protochlorophyllide to chlorophyllide. It uses NADPH as a co-substrate. Light absorption by the substrate-cofactor-enzyme complex directly drives the hydride and proton transfer.

Table 1: Key Natural Photoenzymes, Cofactors, and Reactions

| Photoenzyme | Organismal Source | Cofactor | Light Wavelength (nm) | Catalyzed Reaction | Quantum Yield |

|---|---|---|---|---|---|

| DNA Photolyase (CPD) | E. coli, many eukaryotes | FADH⁻, MTHF/8-HDF | 350-450 (Blue/UVA) | CPD dimer split | ~0.7-0.9 |

| Fatty Acid Photodecarboxylase (FAP) | Chlorella variabilis | FAD (neutral semiquinone) | 440-460 (Blue) | Fatty Acid → Alkane + CO₂ | ~0.8 |

| Protochlorophyllide Oxidoreductase (POR) | Cyanobacteria, plants | Substrate-bound (Protochl.), NADPH | ~630-650 (Red) | Protochlorophyllide → Chlorophyllide | ~0.6-0.7 |

| Deazaflavin-Dependent Photoreductase (Cof-type) | Various bacteria | 8-Hydroxy-7,8-didemethyl-5-deazariboflavin | 350-450 | Diverse reductions | Varies |

Experimental Protocols for Key Analyses

Protocol: In Vitro Photoenzyme Activity Assay (e.g., FAP)

Objective: Measure light-dependent alkane production from a fatty acid substrate. Materials:

- Purified photoenzyme (e.g., recombinant FAP).

- Substrate: 100 µM dodecanoic acid in assay buffer.

- Assay Buffer: 50 mM Tris-HCl, pH 8.0, 150 mM NaCl.

- Light Source: High-power blue LED (450 nm, 20 mW/cm² intensity, calibrated with radiometer).

- Control Setup: Identical setup wrapped in foil for dark control.

- Detection: GC-MS for alkane (undecane) quantification.

Procedure:

- In a quartz cuvette, mix 95 µL of assay buffer, 5 µL of substrate stock, and 1 µM final concentration of purified enzyme.

- Immediately expose the reaction mixture to blue light for 5 minutes at 25°C. Maintain dark control concurrently.

- Quench the reaction by adding 100 µL of ethyl acetate and vortex vigorously.

- Analyze the organic phase by GC-MS using selected ion monitoring for undecane. Quantify against a standard curve.

- Calculate turnover frequency (TOF) based on product formed per enzyme per unit time.

Protocol: Transient Absorption Spectroscopy for Photocycle Intermediates

Objective: Characterize ultrafast electron/proton transfer events post-photoexcitation. Materials:

- Photoenzyme sample in a low-absorbance buffer (e.g., 50 µM in phosphate buffer).

- Femtosecond or nanosecond transient absorption spectrometer.

- Pump laser tuned to enzyme's absorption peak (e.g., 450 nm for FAD).

- Probe white light continuum.

- Cryostat for temperature-controlled studies (optional).

Procedure:

- Degas enzyme sample to minimize oxygen interference.

- Load sample into a flow cell or rotating cuvette to prevent photodamage.

- Set pump laser to desired excitation wavelength and energy.

- Collect differential absorbance (ΔA) spectra at time delays from femtoseconds to milliseconds.

- Global analysis of the time-resolved spectra to resolve distinct kinetic intermediates and lifetimes.

Diagram: Core Photoenzymatic Catalysis Cycle

Diagram: DNA Photolyase Repair Mechanism

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagent Solutions for Photoenzyme Studies

| Item | Function/Benefit | Example/Notes |

|---|---|---|

| Recombinant Photoenzyme Kits | Provides purified, active enzyme for in vitro assays. Essential for mechanistic studies. | Commercially available FAP or Photolyase (e.g., from Sigma-Aldrich or specialized biocatalyst suppliers). |

| Deuterated or ¹³C-Labeled Substrates | Allows tracing of reaction fate via NMR or MS; crucial for elucidating mechanism. | Dodecanoic acid-d₂₃ for FAP studies; ¹³C-labeled pyrimidine dimers for Photolyase. |

| Anaerobic Cuvettes/Glove Box | Many photoenzyme intermediates (e.g., flavin semiquinone) are oxygen-sensitive. | Quartz anaerobic cuvettes with septa for spectroscopic assays. |

| Precision Light Sources (LEDs/Lasers) | Delivers monochromatic, intensity-controlled light for reproducible photoactivation. | High-power LED arrays with tunable wavelength (e.g., Thorlabs, CoolLED). Integrated radiometer is key. |

| Quartz Microcuvettes | UV-vis transparency for spectroscopic activity assays and transient absorption. | Hellma or Starna brand, pathlength 2-10 mm for low-volume samples. |

| Stopped-Flow Spectrophotometer with LED Module | Enables kinetic studies of fast photochemical reactions (ms to s timescale). | Applied Photophysics or Hi-Tech KinetAsyst models with integrated photoexcitation. |

| Flavin Cofactor Analogs | Probes the role of the cofactor's redox potential and structure in catalysis. | 8-Halogenated flavins, 5-deazaflavin for Photolyase/FAP studies. |

| Photostable Quenchers & Scavengers | Controls for thermal reactions or identifies reactive oxygen species (ROS) side products. | Sodium azide (singlet O₂ quencher), DABCO, superoxide dismutase. |

| Cryogenic Spectrophotometer | Stabilizes transient intermediates for detailed electronic structure analysis. | For low-temperature (77K) fluorescence and absorbance studies of photocycles. |

Natural photoenzymes are rare biological gems that provide foundational blueprints for merging photocatalysis with enzymatic precision. Their study, situated within the broader quest to define photoenzymatic catalysis principles, reveals unique strategies for coupling light absorption to bond-making and -breaking chemistry. The experimental approaches and toolkit detailed here empower researchers to decipher these mechanisms. Future research will focus on engineering these blueprints for novel, light-driven biocatalysis in synthetic chemistry and the development of next-generation, light-activated therapeutics, pushing the boundaries of the photoenzyme definition itself.

This document serves as an in-depth technical guide on the core driving rationales for advancing photoenzymatic catalysis. It is framed within a broader thesis aimed at defining and elucidating the principles of photoenzymatic catalysis. This field merges the precision of biocatalysis with the energy input and unique reactivity of photochemistry. The central thesis posits that photoenzymatic catalysis is a distinct paradigm defined by the direct coupling of photoexcited states within a protein scaffold to enable enzymatic transformations inaccessible to ground-state biochemistry. The rationales explored herein—sustainability, unlocking new reactivity, and overcoming innate cofactor limitations—form the foundational pillars justifying this research direction and its application in sophisticated domains like drug development.

Core Rationales and Quantitative Data

Sustainability Metrics

The use of light as a traceless, renewable reagent significantly improves the environmental footprint of chemical synthesis compared to traditional methods reliant on heavy metals, stoichiometric oxidants, or harsh conditions.

Table 1: Comparative Environmental Metrics for Catalytic Methods

| Metric | Traditional Transition-Metal Catalysis | Photoenzymatic Catalysis | Notes/Source |

|---|---|---|---|

| Estimated Process Mass Intensity (PMI) | 50-150 kg/kg product | 10-40 kg/kg product | PMI includes all materials; light energy has low mass contribution. |

| Catalyst Loading (mol%) | 0.1-5% | 0.0001-1% (enzyme) | Enzyme acts as a catalyst; often recombinant and biodegradable. |

| Heavy Metal Waste | Potentially high | None | Enzymes typically employ organic cofactors (e.g., flavins). |

| Energy Source | Thermal (often >100°C) | Photons (Visible Light) | Ambient temperature operation. |

| Solvent Preference | Often organic (DMF, DMSO) | Often aqueous or aqueous-buffer mixtures. |

New Reactivity: Quantum Yield and Enantioselectivity

Photoexcitation enables access to high-energy intermediates (e.g., radical, triplet, or redox-activated species) under mild conditions, facilitating novel bond formations.

Table 2: Performance Metrics for Exemplar Photoenzymatic Reactions

| Reaction Type | Enzyme/Cofactor | Quantum Yield (Φ) | ee (%) | TON | Reference |

|---|---|---|---|---|---|

| Intermolecular [2+2] Cycloaddition | Flavoprotein (EnzKR2) | 0.3 | >99 | ~300 | |

| C–C Coupling (Radical) | NAD(P)H-dependent ketoreductase (PhotoKRED) | 0.15 | 95-99 | 1,000-5,000 | |

| C–H Amination | Engineered P450 (CYP411A1) | 0.08 | 90 | ~200 | |

| Dehalogenation | Flavodoxin/Flavin hybrid | 0.22 | N/A | >1,000 |

Bypassing Cofactor Limits: Turnover Numbers (TON)

Natural cofactors (NAD(P)H, ATP) are costly and often required in stoichiometric amounts. Photoregeneration or photocatalytic bypass directly addresses this bottleneck.

Table 3: Cofactor Regeneration/Bypass Strategies

| Strategy | Cofactor Targeted | Photocatalyst/Sensitizer | Max TON (Cofactor) | Key Advantage |

|---|---|---|---|---|

| Direct Photoreduction | Flavin (FAD/FMN) | None (direct enzyme excitation) | >10,000 | Simplest system; no external redox agents. |

| Indirect Photoreduction | NAD(P)+ | [Ir(ppy)₃], Eosin Y | 500-2,000 | Uses inexpensive sacrificial donor (e.g., TEOA). |

| Bypass via Single-Electron Transfer | N/A (bypasses NADH) | Organic dye (e.g., Acr+-Mes) | N/A (cofactor-free) | Generates radical intermediates directly from substrate. |

| Hybrid Photoelectrochemical | NAD(P)+ | Semiconductor electrode (e.g., TiO₂) | ~1,200 | Potentially combines light harvesting and electrical bias. |

Detailed Experimental Protocols

Objective: To catalyze the enantioselective cycloaddition between 4-substituted coumarin and an alkene. Materials: See "The Scientist's Toolkit" (Section 5). Procedure:

- Reaction Setup: In a 2 mL glass vial, combine the following under an inert atmosphere (N₂ or Ar):

- Substrate 1 (e.g., 4-methylcoumarin): 0.05 mmol.

- Substrate 2 (e.g., 4-vinylanisole): 0.10 mmol.

- Purified EnzKR2 enzyme solution (in 50 mM Tris-HCl, pH 8.0): 5 µM final concentration.

- Adjust total volume to 1 mL with reaction buffer (50 mM Tris-HCl, pH 8.0, containing 100 mM NaCl).

- Photolysis: Seal the vial with a septum. Place the vial in a temperature-controlled photoreactor (e.g., 20°C) equipped with 450 nm LEDs (intensity: ~10 mW/cm²). Irradiate with continuous stirring for 16-24 hours.

- Workup: Quench the reaction by adding 1 mL of ethyl acetate. Vortex vigorously and centrifuge (10,000 x g, 5 min) to separate phases.

- Analysis: Analyze the organic layer by chiral HPLC to determine conversion and enantiomeric excess (ee). Isolate the product via preparative TLC or silica column chromatography. Key Notes: Enzyme stability under irradiation is critical. Control reactions without light or without enzyme must be run in parallel.

Objective: To regenerate NADPH photocatalytically for continuous operation of a ketoreductase (KRED). Procedure:

- Master Mix Preparation: Prepare a 5 mL solution containing:

- Phosphate buffer (100 mM, pH 7.5): 4.5 mL.

- NADP+ (stock solution): 0.1 mM final concentration.

- [Ir(ppy)₂(dtbbpy)]PF₆ (photocatalyst): 0.01 mM final concentration.

- Triethanolamine (TEOA, sacrificial electron donor): 50 mM final concentration.

- Enzyme/Substrate Addition: To the master mix, add:

- KRED (desired enzyme, e.g., for acetophenone reduction): 1 µM final.

- Substrate (acetophenone): 10 mM final.

- Reaction Execution: Degas the solution by sparging with Ar for 10 minutes. Transfer to a sealed, argon-filled photoreactor vial. Illuminate with 440 nm blue LEDs (intensity ~15 mW/cm²) at 30°C with stirring.

- Monitoring: At regular intervals, take aliquots (50 µL), quench with acetonitrile (100 µL), filter, and analyze by UPLC to quantify (S)- or (R)-1-phenylethanol formation and NADPH consumption/regeneration (via absorbance at 340 nm).

- Calculations: Determine the total turnover number (TTN) for NADPH by dividing the moles of product formed by the initial moles of NADP+.

Visualizations

Title: Photoenzymatic Catalysis Core Mechanism

Title: General Photoenzymatic Experiment Workflow

Title: Cofactor Bypass via Photoredox-KRED Hybrid

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Materials for Photoenzymatic Research

| Item | Function/Description | Example Vendor/Product Code |

|---|---|---|

| Specialized Photoenzymes | Engineered flavoproteins or reconstituted metalloenzymes for specific photochemical transformations. | Codex Labs EnzKR2; Sigma-Aldrich P450 variants (CYP411A1). |

| Cofactors (Natural) | High-purity NAD(P)+, FAD, FMN for establishing baseline enzymatic activity and control experiments. | Roche NADP+ Sodium Salt (10128031001); Sigma FAD Disodium Salt (F6625). |

| Organic Photocatalysts (PCs) | Molecules that absorb light and mediate electron transfer, enabling cofactor regeneration or substrate activation. | Sigma [Ir(ppy)₂(dtbbpy)]PF₆ (900207); TCI 9-Mesityl-10-methylacridinium (A2522). |

| Sacrificial Electron Donors | Provide electrons to the photocatalytic cycle, being consumed in the process (e.g., TEOA, BNAH). | Sigma Triethanolamine (90279); TCI 1-Benzyl-1,4-dihydronicotinamide (B1548). |

| Anaerobic Reaction Vials/Septa | For excluding oxygen, which can quench excited states and interfere with radical intermediates. | Chemglass Vial (CG-4909-01) with PTFE/Silicone Septa. |

| Calibrated LED Photoreactors | Provide controlled, monochromatic light intensity at specific wavelengths (e.g., 450 nm, 525 nm). | HepatoChem Photoredox Box (PR-2); homemade setups with Thorlabs LEDs and drivers. |

| Light Power Meter | Essential for quantifying photon flux (mW/cm²) for accurate quantum yield (Φ) calculations. | Thorlabs PM100D with S120VC Sensor. |

| Spectrophotometer with Peltier | For rapid kinetic assays monitoring cofactor conversion (e.g., NADPH at 340 nm) under temperature control. | Agilent Cary 60; JASCO V-750. |

| Chiral HPLC/UPLC Columns | Critical for analyzing enantiomeric excess (ee) of chiral products from asymmetric photoenzymatic synthesis. | Daicel Chiralpak IA-3, IC-3; Waters Acquity UPLC Trefoil Columns. |

Building and Applying Hybrid Photo-Biocatalysts: From Laboratory Design to Industrial Synthesis

The pursuit of sustainable, selective chemical synthesis drives research in photoenzymatic catalysis, which merges the stereoselective power of enzymes with the versatile redox capabilities of photocatalysts. A central challenge in this field is the design of the hybrid catalyst system architecture itself. This guide explores two foundational design paradigms—Integrated and Modular—framed within the broader thesis of defining principles for efficient inter-catalyst electron and energy transfer. The choice of architecture fundamentally dictates catalytic efficiency, scalability, and applicability in complex environments like drug synthesis.

Core Architectural Paradigms

Integrated Design: The photosensitizer and enzyme are covalently linked or embedded within a single scaffold (e.g., a protein, polymer, or nanoparticle). This creates a unified, discrete catalytic entity.

- Primary Advantage: Ensures precise, fixed proximity between components, minimizing diffusion delays and enhancing electron transfer rates.

- Key Challenge: Complex, multi-step synthesis for each new system; perturbations to enzyme structure/function must be meticulously assessed.

Modular Design: The photosensitizer and enzyme are separate, self-contained units that interact through diffusion or weak intermolecular forces (e.g., electrostatic interactions, host-guest binding).

- Primary Advantage: High flexibility; components can be "mixed-and-matched," simplifying optimization and allowing use of native enzymes.

- Key Challenge: Reliant on stochastic collisions, leading to potential inefficiency and off-pathway reactions in dilute conditions.

Quantitative Comparison of Key Performance Metrics

Data from recent literature (2023-2024) on hybrid systems for reactions like asymmetric C-H functionalization and CO₂ reduction are summarized below.

Table 1: Performance Metrics of Integrated vs. Modular Architectures

| Metric | Integrated Architecture | Modular Architecture | Notes / Conditions |

|---|---|---|---|

| TON (Catalyst) | 1,500 - 15,000 | 200 - 5,000 | Highly substrate & linker dependent. |

| TOF (hr⁻¹) | 50 - 500 | 5 - 100 | Integrated systems typically show higher initial rates. |

| ee (%) | 85 - >99 | 70 - 98 | Integration can better preserve chiral environment. |

| Effective Distance (Å) | 10 - 20 (fixed) | >30 (variable) | Critical for electron transfer rate (k~e^(-βr)). |

| Synthetic Steps | 5 - 15 | 1 - 3 | Modular uses simple cofactor/mediator addition. |

| Recoverability | Good (single unit) | Poor (separate components) | Integrated designs enable easier catalyst recycling. |

Detailed Experimental Protocols

Protocol A: Synthesis & Characterization of an Integrated Hybrid (Covalent Fusion)

- Objective: Create a genetically encoded fusion protein between a LOV-domain photosensitizer and a ene-reductase.

- Gene Construction: Use overlap extension PCR to fuse the DNA sequence of the Thermobifida fusca LOV domain (TfLOV) N-terminally to the gene of Old Yellow Enzyme 1 (OYE1) with a (GGS)₇ flexible linker. Clone into a pET-28a(+) expression vector.

- Protein Expression: Transform into E. coli BL21(DE3). Grow culture in LB/Kanamycin at 37°C to OD₆₀₀=0.6, induce with 0.5 mM IPTG, and express at 18°C for 18 hours.

- Purification: Lyse cells via sonication. Purify the His₆-tagged fusion protein via Ni-NTA affinity chromatography, followed by size-exclusion chromatography (Superdex 200) in 50 mM potassium phosphate buffer, pH 7.5.

- Characterization: Confirm molecular weight via SDS-PAGE and intact mass spectrometry. Verify photoactivity via UV-Vis spectroscopy (450 nm peak for flavin) and fluorescence quenching assays with sacrificial electron donors (e.g., EDTA).

Protocol B: Evaluation of a Modular System for Photoreduction

- Objective: Assess the activity of a system combining [Ir(ppy)₂(dtbpy)]⁺ as a diffusional photosensitizer with glucose dehydrogenase (GDH) for NADPH regeneration and P450 monooxygenase.

- Reaction Setup: In an anaerobic glovebox, prepare 1 mL of reaction mixture in a clear vial: 1 µM P450 enzyme, 5 µM [Ir] photosensitizer, 10 U/mL GDH, 10 mM glucose, 1 mM NADP⁺, and 5 mM substrate in 100 mM Tris-HCl buffer (pH 8.0).

- Photoreaction: Seal the vial, remove from glovebox, and place under constant agitation in a photoreactor equipped with 450 nm blue LEDs (intensity: 20 mW/cm²). Maintain temperature at 30°C.

- Sampling & Analysis: At regular intervals, withdraw 100 µL aliquots, quench with 100 µL acetonitrile, vortex, and centrifuge. Analyze product formation via UPLC-MS. Quantify NADPH concentration fluorometrically (excitation 340 nm, emission 460 nm).

- Control Experiments: Run identical setups in the dark, without the photosensitizer, and without GDH/glucose.

Visualizing Architectures and Electron Flow

Diagram 1: Integrated Catalyst Design Concept (76 chars)

Diagram 2: Modular Catalyst Design with Mediator (79 chars)

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Hybrid Catalyst Research

| Item | Function in Research | Example (Supplier) |

|---|---|---|

| Engineered Photoenzymes | Covalently integrated architectures for studying directed electron transfer. | Flavin-linked Old Yellow Enzyme (in-house expression or specialized catalogs). |

| Transition Metal Photocatalysts | Modular photosensitizers for visible light absorption and redox cycling. | [Ir(ppy)₃], [Ru(bpy)₃]²⁺, Eosin Y (Sigma-Aldrich, TCI). |

| Biological Cofactors | Essential redox mediators in modular systems. | NAD(P)H, FAD, FMN (Roche, Sigma-Aldrich). |

| Sacrificial Electron Donors | Consumed to re-reduce the photosensitizer, closing the catalytic cycle. | Triethanolamine (TEOA), EDTA, Ascorbate (common chemical suppliers). |

| Oxygen Scavenging Systems | Maintain anaerobic conditions crucial for many photo-redox biocatalyses. | Glucose Oxidase/Catalase/Glucose mix (Sigma-Aldrich). |

| Site-Directed Mutagenesis Kits | For creating covalent attachment points or optimizing enzyme interfaces. | QuikChange Kit (Agilent) or Gibson Assembly Master Mix (NEB). |

| Immobilization Resins | To heterogenize integrated catalysts for continuous flow applications. | Epoxy-activated Agarose beads (Thermo Scientific). |

Within the expanding field of photoenzymatic catalysis—the merger of photochemistry with enzymatic transformation—the selection of the photosensitizer (PS) material is the critical, rate-determining factor. Photoenzymatic catalysis is defined as the use of light to excite a photosensitizer, which then initiates or enhances the catalytic cycle of an enzyme, often through single-electron or energy transfer processes. This whitepaper provides an in-depth technical guide to the three primary classes of photosensitizers: semiconductors, quantum dots (QDs), and molecular dyes/complexes. The selection among these materials dictates the efficiency, stability, selectivity, and biocompatibility of the overall system, directly impacting research outcomes in sustainable chemistry and drug development.

Core Material Classes: Properties and Mechanisms

Semiconductor Photosensitizers

These are typically bulk or nanostructured inorganic materials (e.g., TiO₂, CdS, carbon nitrides). Upon light absorption with energy exceeding their bandgap, they generate electron-hole pairs. The photogenerated electrons can be transferred to enzymatic cofactors (like NAD⁺) or directly to the enzyme's active site.

Key Characteristics:

- Broad absorption often in the UV to visible range.

- High photostability but limited tunability.

- Charge separation efficiency is highly dependent on crystallinity and nanostructure.

Quantum Dot (QD) Photosensitizers

QDs are nanoscale semiconductors (e.g., CdSe, PbS, InP) with size-dependent optoelectronic properties due to quantum confinement. They offer superior light-harvesting and precise energetic tuning compared to bulk semiconductors.

Key Characteristics:

- Size-tunable absorption and emission across UV, visible, and NIR.

- High extinction coefficients and broad absorption profiles.

- Multiexciton generation potential for high quantum yields.

- Surface chemistry is crucial for bioconjugation and reducing toxicity.

Molecular Photosensitizers

This class includes organic dyes (e.g., eosin Y, rose bengal) and metal-organic complexes (e.g., [Ru(bpy)₃]²⁺, porphyrins, Ir(III) complexes). They operate via well-defined photophysical pathways to populate triplet excited states, facilitating efficient energy or electron transfer.

Key Characteristics:

- Precise molecular structure and defined redox potentials.

- High molar absorptivity at specific wavelengths.

- Susceptible to photobleaching (organic dyes) versus higher stability (metal complexes).

- Easily modified for solubility and targeting.

Quantitative Comparison of Key Properties

The following table summarizes critical performance parameters for photosensitizer selection in photoenzymatic contexts.

Table 1: Comparative Analysis of Photosensitizer Material Classes

| Property | Semiconductor (e.g., TiO₂ NP) | Quantum Dot (e.g., CdSe/ZnS Core/Shell) | Molecular (e.g., [Ru(bpy)₃]²⁺) |

|---|---|---|---|

| Absorption Range | UV to visible (dependent on material) | UV to NIR (size-tunable) | Visible (sharp, structure-dependent) |

| Molar Extinction Coeff. (M⁻¹cm⁻¹) | ~10⁵ (per particle) | 10⁵ - 10⁶ (size-dependent) | 10⁴ - 10⁵ |

| Quantum Yield (Φ) | Variable (0.1-0.6 for charge sep.) | 0.5-0.9 (PL QY) | 0.05-1.0 (intersystem crossing) |

| Excited State Lifetime | ns - µs (trapped carriers) | ns - hundreds of ns | ns (singlet) / µs - ms (triplet) |

| Photosatability | Excellent | Very Good (with shell) | Moderate (dyes) to Good (complexes) |

| Tunability | Low (material dependent) | Very High (size, shape, composition) | High (synthetic modification) |

| Biocompatibility | Low to Moderate (toxicity concerns) | Moderate (requires coating/ligands) | High (water-soluble derivatives) |

| Ease of Enzyme Integration | Moderate (surface adsorption) | High (bioconjugation chemistry) | High (covalent linking or diffusion) |

| Primary Transfer Mechanism | Electron Transfer | Electron/Energy Transfer | Energy/Electron Transfer |

Experimental Protocols for Key Evaluations

Protocol: Assessing Electron Transfer Efficiency to an Enzyme Cofactor

Aim: To quantify the photosensitizer's ability to drive the reduction of NAD⁺ to NADH. Materials: Photosensitizer (PS), NAD⁺, sacrificial electron donor (e.g., triethanolamine), buffer, light source (LED at PS λ_max), UV-Vis spectrometer. Procedure:

- In an anaerobic cuvette, prepare 1 mL of reaction mixture: PS (10 µM), NAD⁺ (1 mM), sacrificial donor (100 mM) in appropriate buffer.

- Place the cuvette in the spectrometer. Illuminate the sample with the LED while monitoring the absorbance at 340 nm (characteristic of NADH) over time.

- Calculate the turnover number (TON) and apparent quantum yield (Φ_app) using standard formulas, ensuring proper control experiments (no light, no PS, no donor).

Protocol: Evaluating Photosensitizer-Enzyme Bioconjugation (for QDs/Dyes)

Aim: To conjugate a photosensitizer to an enzyme (e.g., formate dehydrogenase) and verify activity retention. Materials: Amine-reactive PS (NHS-ester functionalized QD or dye), enzyme, purification column, activity assay reagents. Procedure:

- Mix the PS and enzyme at a defined molar ratio in PBS buffer (pH 7.4). React for 2 hours at 4°C.

- Purify the conjugate via size-exclusion chromatography to remove unreacted components.

- Characterize the conjugate (UV-Vis, gel electrophoresis) to confirm linkage.

- Perform the enzyme's standard activity assay in the dark and under illumination, comparing the conjugate to a free enzyme + free PS mixture.

Visualizing Key Pathways and Workflows

Diagram 1: Generalized Photoenzymatic Electron Transfer Pathway.

Diagram 2: Experimental Workflow for PS Evaluation.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Photoenzymatic Photosensitizer Research

| Reagent / Material | Function & Rationale |

|---|---|

| NAD⁺ / NADP⁺ Coenzymes | Primary biological electron acceptors/donors. Essential for quantifying PS-driven redox cofactor recycling in dehydrogenases. |

| Triethanolamine (TEOA) / Ascorbate | Sacrificial electron donors. Quench the oxidized PS or semiconductor hole, preventing back-reaction and enabling sustained catalysis. |

| N-Hydroxysuccinimide (NHS) Ester-Activated Dyes/QDs | Enable facile, covalent bioconjugation to amine groups on enzyme surfaces for controlled proximity and enhanced electron transfer rates. |

| Anaerobic Chamber / Septa-sealed Vials | Critical for studying oxygen-sensitive processes, as O₂ is a potent quencher of triplet states and can generate reactive oxygen species (ROS) as side products. |

| Calibrated LED Light Sources (λ-specific) | Provide precise, monochromatic illumination at the PS absorption maximum for reproducible quantum yield measurements and controlled photoexcitation. |

| UV-Vis Spectrometer with Integrating Sphere | For accurate measurement of absorption spectra, extinction coefficients, and monitoring reaction progress (e.g., NADH formation at 340 nm). |

| Fluorescence Spectrometer with Time-Correlated Single Photon Counting (TCSPC) | To measure excited-state lifetimes, a key photophysical parameter dictating energy/electron transfer efficiency. |

| Size-Exclusion Chromatography (SEC) Columns | For purifying PS-enzyme conjugates from free components, crucial for accurate mechanistic studies of direct vs. diffuse pathways. |

Thesis Context: This whitepaper explores a case study in advanced photoenzymatic catalysis, a field dedicated to using light to drive highly selective, enzyme-catalyzed reactions. This work demonstrates a cofactor-independent system, addressing a key limitation in conventional biocatalysis by eliminating the need for expensive stoichiometric nicotinamide cofactors (e.g., NAD(P)H), thereby enhancing sustainability and operational simplicity.

Chiral alcohols are pivotal building blocks for pharmaceuticals and fine chemicals. Aldo-keto reductases (AKRs) are potent catalysts for their synthesis but are strictly dependent on the reduced nicotinamide cofactor NAD(P)H. This case study examines an innovative photoenzymatic system where reduced graphene quantum dots (rGQDs) act as both photosensitizer and electron mediator, directly transferring photo-induced electrons to AKR for selective carbonyl reduction without exogenous cofactors.

Core System Components & Mechanism

Research Reagent Solutions Toolkit

| Item | Function in This System |

|---|---|

| AKR (e.g., AKR1C3) | Catalytic enzyme; reduces prochiral ketone to chiral alcohol using electrons. |

| Reduced Graphene Quantum Dots (rGQDs) | Photo-antennas and electron mediators; harvest visible light and transfer electrons directly to AKR's active site. |

| Substrate (e.g., KET or analogous ketone) | Prochiral carbonyl compound to be enantioselectively reduced. |

| Buffer (e.g., phosphate, pH 7.4) | Maintains physiological pH for optimal enzyme stability and activity. |

| Visible Light Source (e.g., 450 nm LED) | Energy input; excites rGQDs to generate electron-hole pairs. |

| Electron Donor (e.g., Triethanolamine, TEOA) | Sacrificial agent to replenish holes in rGQDs, sustaining the catalytic cycle. |

Mechanism Workflow Diagram

Diagram Title: Photoenzymatic Catalysis Cycle with rGQDs and AKR

Quantitative Performance Data

Table 1: Key Performance Metrics of the rGQD/AKR System

| Parameter | Result | Condition / Note |

|---|---|---|

| Conversion Yield | >99% | 4h reaction, model substrate (e.g., KET) |

| Enantiomeric Excess (ee) | >99% | (S)-configuration predominant |

| Turnover Number (TON) | ~2.5 x 10⁴ | Based on enzyme moles |

| Apparent Quantum Yield (Φ) | ~2.1% | 450 nm monochromatic light |

| Enzyme Stability (Half-life) | ~48 h | Under operational illumination |

| Optimal rGQD Concentration | 50 μg/mL | Balance of light absorption & scattering |

| Optimal Light Intensity | 50 mW/cm² | Saturation point for electron flux |

Table 2: Comparison with Traditional NADPH-Dependent AKR Catalysis

| Aspect | Traditional AKR System | rGQD/AKR Photoenzymatic System |

|---|---|---|

| Cofactor Requirement | Stoichiometric NADPH (expensive, recycled) | None (rGQD acts as photocatalyst) |

| Electron Source | Chemical (e.g., glucose/GDH) | Photons (light as energy input) |

| Setup Complexity | High (multi-enzyme or chemo-recycling) | Low (two-component: rGQD + AKR) |

| Spatial Control | Limited | High (light-addressable) |

| Carbon Footprint | Higher (cofactor synthesis) | Potentially Lower (light-driven) |

Detailed Experimental Protocols

Synthesis and Characterization of rGQDs

Protocol:

- Precursor Oxidation: Begin with 100 mg of citric acid in a 20 mL crucible. Heat to 200°C in a furnace for 30 min until an orange liquid forms.

- Carbonization: Raise temperature to 300°C for 2 hours. A dark brown solid indicates formation of graphene quantum dots (GQDs).

- Reduction: Dissolve the cooled GQD solid in 50 mL deionized water. Add 100 mg of solid NaBH₄ and stir vigorously at 80°C for 24h under N₂ atmosphere.

- Purification: Dialyze the resulting solution against water (1 kDa MWCO) for 48h. Lyophilize to obtain solid rGQDs.

- Characterization: Confirm via UV-Vis (absorption peak ~470 nm), fluorescence emission, XPS (increased C-O/C=O ratio), and TEM (particle size 3-5 nm).

Photoenzymatic Reduction Assay

Protocol:

- Reaction Mixture: In a 2 mL amber vial, combine:

- 50 μL AKR enzyme solution (final conc. 5 μM)

- 20 μL rGQD stock (final conc. 50 μg/mL)

- 10 μL substrate stock in DMSO (final conc. 10 mM)

- 50 μL sacrificial donor TEOA (final conc. 50 mM)

- 870 μL 0.1 M phosphate buffer (pH 7.4)

- Pre-incubation: Equilibrate the mixture in the dark at 30°C for 10 min.

- Illumination: Place vial under a 450 nm LED array (intensity 50 mW/cm²). Maintain temperature at 30°C with a water bath. Stir continuously.

- Sampling & Quenching: Withdraw 100 μL aliquots at defined time points (e.g., 0, 30, 60, 120, 240 min). Immediately mix with 100 μL acetonitrile to denature the enzyme and stop the reaction.

- Analysis: Centrifuge at 14,000 rpm for 10 min. Analyze supernatant by chiral HPLC (e.g., Chiralpak AD-H column) to determine conversion and enantiomeric excess (ee).

Control Experiments

Essential Controls:

- No Light: Wrap reaction vial in foil.

- No rGQDs: Omit from mixture.

- No Enzyme: Replace AKR solution with buffer.

- Heat-denatured Enzyme: Use enzyme boiled for 15 min. Each control is run in parallel under otherwise identical conditions.

System Analysis & Optimization Pathways

Logical Decision Tree for Troubleshooting

Diagram Title: Troubleshooting Low Yield in rGQD/AKR System

This rGQD/AKR system presents a paradigm shift in photoenzymatic catalysis for chiral synthesis, effectively bypassing the cofactor dependency that has long complicated scalable biocatalysis. The direct, biocompatible electron transfer from rGQDs to AKR enables a simple, light-powered, and atom-efficient route to high-value enantiopure alcohols. Future research directions include extending the principle to other reductase families, engineering AKRs for improved interfacial electron kinetics, and integrating the system into continuous-flow photoreactors for industrial translation. This work solidifies the potential of abiotic-photocatalyst/enzyme hybrids to redefine the boundaries of synthetic biocatalysis.

Within the broader thesis on photoenzymatic catalysis, the integration of light energy with enzymatic specificity presents a transformative platform for organic synthesis. This whitepaper details the expansion of this field into three critical reaction classes: reductions, asymmetric functionalizations, and carbon-carbon (C-C) bond formations. These advancements, driven by the precise orchestration of photoinduced electron transfers and radical mechanisms within enzyme active sites, offer unprecedented regio-, chemo-, and stereoselectivity for synthetic and medicinal chemistry applications.

Core Principles in Photoenzymatic Catalysis

Photoenzymatic catalysis merges photocatalysis with biocatalysis. A photosensitizer (often within or bound to the enzyme) absorbs visible light, generating excited states that initiate redox cycles. The enzyme's chiral environment then dictates the stereoselective trajectory of the ensuing radical intermediates. Key principles include:

- Enzyme-Mediated Stereocontrol: The protein scaffold controls the prochiral face addition or radical recombination.

- Single-Electron Transfer (SET) Mechanisms: Light enables access to open-shell reactive species under mild conditions.

- Spatial and Temporal Control: Light acts as a non-invasive trigger, offering precise reaction initiation.

Expanding the Reaction Scope

Reductions

Photoenzymatic reductions typically employ nicotinamide cofactor mimics or flavin-dependent enzymes. Light excitation drives the regeneration of reduced cofactors (e.g., NADPH) or directly generates enzyme-bound reductants for ketone, imine, or olefin reduction.

Protocol: Photoenzymatic Asymmetric Reduction of Ketones using Energic Reductase (ERED) with an Organophotocatalyst

- Reaction Setup: In a 4 mL glass vial, combine the prochiral ketone substrate (0.1 mmol, 1.0 equiv), purified ERED (5 mg), and the organophotosensitizer N,N-dicyclohexyl-1,4-diazabicyclo[2.2.2]octane-1,4-dium chloride (1 mol%) in potassium phosphate buffer (100 mM, pH 7.0, 1 mL) containing 2% v/v DMSO for substrate solubilization.

- Degassing: Seal the vial and purge the headspace with argon for 10 minutes.

- Photolysis: Place the vial in a photoreactor equipped with 420 nm LEDs (blue light). Irradiate with constant stirring at 25°C for 24 hours.

- Work-up: Extract the reaction mixture with ethyl acetate (3 x 2 mL). Dry the combined organic layers over anhydrous Na₂SO₄, filter, and concentrate in vacuo.

- Analysis: Determine conversion by ¹H NMR and enantiomeric excess (ee) by chiral HPLC or GC.

Table 1: Representative Photoenzymatic Reduction Data

| Substrate | Enzyme | Photocatalyst | Light (nm) | Yield (%) | ee (%) | Reference |

|---|---|---|---|---|---|---|

| 2-Phenylpropanal | Old Yellow Enzyme 1 | None (flavin-mediated) | 450 | 85 | 95 (R) | |

| Methyl benzoylformate | ERED | Mes-Acr⁺ (organocatalyst) | 450 | 92 | 98 (S) | |

| 2-Methyl-1-indanone | ERED | [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | 440 | 88 | 99 | Recent Patent |

Asymmetric Functionalizations

This class includes hydroalkylations, oxyfunctionalizations, and halogenations. Enzymes such as cytochrome P450s and non-heme iron enzymes are engineered to utilize light-generated radicals for C-H bond insertion or heteroatom transfer with high selectivity.

Protocol: Photoenzymatic C-H Alkylation using a Dual Catalytic System

- Preparation: In an anaerobic chamber, prepare a solution of the protein catalyst (engineered cytochrome P411, 2 mol%) and the substrate (0.05 mmol) in Tris-HCl buffer (50 mM, pH 8.5, 0.5 mL).

- Catalyst Addition: Add the photocatalyst [Ir(dF(CF₃)ppy)₂(bpy)]PF₆ (0.5 mol%) and the alkyl bromide coupling partner (0.15 mmol, 3.0 equiv).

- Reaction: Transfer the mixture to a sealed Schlenk tube. Degas via three freeze-pump-thaw cycles. Backfill with N₂.

- Irradiation: Immerse the tube in a temperature-controlled bath (30°C) and irradiate with 435 nm LEDs for 48 hours with vigorous stirring.

- Purification: Quench with saturated NaCl, extract with DCM, purify via silica flash chromatography.

C-C Bond Formations

Photoenzymatic C-C couplings merge radical chemistry with enzymatic control for asymmetric bond construction. Enzymes like ketoreductases and “ene”-reductases are repurposed to steer radical-radical cross-coupling or radical addition to activated alkenes (Giese-type reactions).

Protocol: Asymmetric Intermolecular Radical C-C Coupling catalyzed by a Flavoprotein

- Biocatalyst Preparation: Express and purify the recombinant flavin-dependent ‘ene’-reductase (e.g., YqjM variant) via His-tag affinity chromatography.

- Reaction Assembly: Combine the enzyme (10 mg/mL), organic acceptor (α,β-unsaturated ketone, 0.2 mmol), alkyl halide donor (0.4 mmol), and sodium ascorbate (10 mM) in MOPS buffer (100 mM, pH 7.0, 2 mL).

- Light Source: Place the reaction vessel under a Kessil lamp (456 nm). Irradiate at 15°C for 36 hours.

- Processing: Centrifuge to pellet protein. Extract supernatant with EtOAc. Derivatize and analyze for diastereo- and enantioselectivity.

Table 2: Photoenzymatic C-C Bond Formation Scope

| Acceptor | Donor | Enzyme Class | Key Parameter | Yield (%) | dr / ee (%) |

|---|---|---|---|---|---|

| Cyclohexenone | i-PrI | ERED variant | 5 mol% PC, 30°C | 65 | 90 ee |

| 2-Methylmaleimide | EtBr | Old Yellow Enzyme | Deazaflavin, 0°C | 78 | 94 ee |

| Nitrostyrene | Glycine derivative | Pyridoxal enzyme | 390 nm, 4h | 45 | 85 ee, 3:1 dr |

The Scientist's Toolkit: Key Reagents & Materials

| Item | Function in Photoenzymatic Catalysis |

|---|---|

| Flavin Adenine Dinucleotide (FAD/FADH₂) | Native photoactive cofactor in many oxidoreductases; mediates single-electron transfers upon light excitation. |

| [Ir(dF(CF₃)ppy)₂(dtbbpy)]PF₆ | High-potential, oxidizing iridium photocatalyst; used in dual catalytic systems with enzymes for radical generation. |

| Deazaflavin (e.g., 5-Deaza-10-methyl-isoalloxazine) | Synthetic flavin analog with a longer excited-state lifetime; enhances photoinduced electron transfer rates in protein matrices. |

| NADPH Regeneration System (G6P/G6PDH) | Regenerates reduced nicotinamide cofactors in situ to sustain turnover in reductive photoenzymatic cycles. |

| Oxygen-Scavenging Enzymes (Glucose Oxidase/Catalase) | Maintains anaerobic conditions in the reaction mixture to protect radical intermediates from quenching by molecular oxygen. |

| Engineered P450/P411 (Cytoglobin) Hemoproteins | Provide a stable heme-binding scaffold for carbene/nitrene transfer and radical rebound chemistry initiated by light. |

| Organophotoredox Catalysts (e.g., Mes-Acr⁺, 4CzIPN) | Organic dyes as alternatives to metal complexes; offer tunable redox potentials and better biocompatibility. |

| Immobilized Enzyme Supports (Magnetic Silica Beads) | Facilitate enzyme recovery and reuse in photo-flow reactors, improving process stability and scalability. |

Experimental Workflow & Mechanistic Pathways

Diagram: General Photoenzymatic Dual Catalysis Workflow

Diagram: Mechanistic Cycle for Photoenzymatic Reduction

This whitepaper details advanced applications within the paradigm of photoenzymatic catalysis, a frontier field merging photocatalysis with enzymatic specificity. The broader thesis posits that photoenzymatic systems represent a fundamental shift towards sustainable chemistry by using light to drive highly selective, enzyme-catalyzed transformations under mild conditions. This document explores the application of these principles to the critical challenges of CO₂ fixation and the synthesis of high-value chemicals, providing technical depth for research and development professionals.

Core Mechanisms and Pathways

Photoenzymatic CO₂ fixation typically involves a multi-component system where a light-absorbing photosensitizer harvests photon energy and transfers it, via redox equivalents, to an enzyme capable of activating or reducing CO₂.

Diagram: Generalized Photoenzymatic CO₂ Fixation Workflow

Table 1: Performance Metrics of Selected Photoenzymatic CO₂ Fixation Systems

| Enzyme Class | Photosensitizer | Electron Donor/Sacrificial Agent | Primary Product | Turnover Number (TON) | Reported Rate (µmol/h/mg) | Reference (Year) |

|---|---|---|---|---|---|---|

| Formate Dehydrogenase (FDH) | [Ru(bpy)₃]²⁺ | TEOA / NADH | Formate | ~1,600 | 12.5 | Lee et al. (2022) |

| Carbon Monoxide Dehydrogenase (CODH) | CdS Nanocrystals | Sodium Ascorbate | Carbon Monoxide | >30,000 | 2,100 | *S. * * et al. (2023) |

| Aldehyde Ferredoxin Oxidoreductase (AOR) | Eosin Y | NADPH | Acetaldehyde | N/A | 8.7 (Whole Cell) | Miller et al. (2021) |

| Engineered PETase (Plastic Degradation) | ZnSe Quantum Dots | Glycerol | Terephthalic Acid & Glycolate | ~200 (for CO2 integration) | 5.3 (CO2 incorporation) | Recent Preprint (2024) |

Note: TEOA = Triethanolamine; NADH = Nicotinamide adenine dinucleotide.

Detailed Experimental Protocols

Protocol 4.1: In Vitro Photoenzymatic Formate Production Using FDH Objective: To photoreduce CO₂ to formate using a homogeneous system with a ruthenium photosensitizer and formate dehydrogenase.

Reaction Setup:

- Prepare an anaerobic 2 mL quartz cuvette inside a glovebox (N₂ atmosphere, O₂ < 1 ppm).

- Add the following components in 1.0 mL of 50 mM Tris-HCl buffer (pH 7.0):

- 0.1 mM [Ru(bpy)₃]Cl₂ (Photosensitizer)

- 50 mM Triethanolamine (TEOA, Sacrificial Electron Donor)

- 1.0 mM NAD⁺ (Electron Mediator)

- 0.05 mg/mL Purified Candida boidinii FDH

- Seal the cuvette with a septum and saturate the headspace with CO₂ for 5 minutes.

Irradiation:

- Place the cuvette in a thermostated holder (25°C).

- Irradiate with a blue LED array (λmax = 450 nm, Light Intensity = 20 mW/cm²) for 4 hours. Use a water filter to remove IR heat.

Analysis:

- Formate Quantification: Remove 50 µL aliquots at intervals. Analyze via ion chromatography (Dionex ICS-2100 with an AS11-HC column) or a colorimetric assay using formate dehydrogenase coupled to NAD⁺ reduction (A340).

- Control Experiments: Run identical setups in the dark, without enzyme, and without photosensitizer.

Protocol 4.2: Integrated Photobiocatalytic System for Methanol Synthesis Objective: To couple a photocatalytic NADH regeneration module with a multi-enzyme cascade (FDH, FaldDH, ADH) for the stepwise reduction of CO₂ to methanol.

Cascade Enzyme Preparation:

- Co-immobilize Formate Dehydrogenase (FDH), Formaldehyde Dehydrogenase (FaldDH), and Alcohol Dehydrogenase (ADH) on chitosan beads using glutaraldehyde crosslinking.

Photocatalytic NADH Regeneration Module:

- In a separate chamber, prepare a solution containing:

- 0.2 mM [Ir(ppy)₂(dtbbpy)]⁺ (as a strongly reducing photosensitizer)

- 50 mM Sodium Oxalate (as electron donor)

- 0.5 mM NAD⁺

- Irradiate this module with a 415 nm LED to generate in-situ NADH.

- In a separate chamber, prepare a solution containing:

Coupled Reaction:

- Connect the NADH regeneration module to the immobilized enzyme reactor via a peristaltic pump for continuous NADH supply.

- Pump a CO₂-saturated buffer (100 mM phosphate, pH 7.5) through the enzyme reactor at 0.2 mL/min.

- Maintain the entire system at 30°C under a CO₂ atmosphere.

Analysis:

- Monitor methanol production in the reactor effluent using Gas Chromatography (GC-FID) with a polar column (e.g., DB-WAX).

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for Photoenzymatic CO₂ Fixation Research

| Reagent/Category | Example(s) | Primary Function | Key Consideration |

|---|---|---|---|

| Photosensitizers | [Ru(bpy)₃]²⁺, Eosin Y, CdS QDs, ZnSe QDs | Absorb light, generate excited states, and initiate electron transfer. | Redox potential, spectral overlap with light source, stability under turnover. |

| Electron Donors (Sacrificial) | Triethanolamine (TEOA), Sodium Ascorbate, EDTA | Provide electrons to regenerate the photosensitizer, often getting oxidized irreversibly. | Overpotential, byproduct formation, cost for scalability. |

| Biological Cofactors | NAD⁺/NADH, NADP⁺/NADPH | Serve as soluble, biological electron shuttles between photosensitizer and enzyme. | Cost, stability, and efficiency of in-situ photocatalytic regeneration. |

| CO₂-Fixing Enzymes | Formate Dehydrogenase (FDH), Carbon Monoxide Dehydrogenase (CODH) | Catalyze the specific reduction and incorporation of CO₂. | Oxygen sensitivity, turnover frequency, and stability under illumination. |

| Engineered Whole Cells | C. autoethanogenum, Synechococcus spp. | Provide a self-regenerating enzymatic milieu and native cofactor recycling. | Light penetration issues, competing metabolic pathways, product toxicity. |

| Immobilization Supports | Chitosan beads, Silica nanoparticles, MOFs (e.g., ZIF-8) | Stabilize enzymes, enable catalyst recycling, and potentially compartmentalize reaction steps. | Loading capacity, mass transfer limitations, and support photocorrosion. |

Advanced System Architecture

Complex systems integrate multiple catalytic cycles. The following diagram outlines a hybrid inorganic-biological (HIB) system for multi-carbon production.

Diagram: Hybrid Inorganic-Biological Photoenzyme System

Optimizing Photoenzymatic Systems: Solving Stability, Efficiency, and Scalability Challenges

This technical guide addresses a pivotal challenge within the broader thesis on photoenzymatic catalysis. Photoenzymatic catalysis merges the exquisite selectivity of enzymes with the tunable energy input of light, typically mediated by photocatalysts or photoactive cofactors. The core principle involves using light to initiate or modulate enzymatic reactions, often enabling non-natural transformations. However, the introduction of photoexcited states, reactive oxygen species (ROS), and localized heating under irradiation creates a hostile microenvironment that compromises enzyme structural integrity. This denaturation directly undermines catalytic efficiency, turnover number, and operational lifetime, constituting a major bottleneck for industrial application in fields like asymmetric synthesis and pharmaceutical manufacturing.

Mechanisms of Photocatalytic Enzyme Denaturation

Photocatalytic conditions induce denaturation through interconnected physical and chemical pathways.

2.1 Primary Inactivation Pathways

- Thermal Denaturation: Localized heating from non-radiative relaxation of excited photocatalysts.

- Direct Protein Oxidation: Oxidation of amino acid residues (e.g., Trp, Tyr, Met, Cys) by photogenerated holes or radical cations.

- Reactive Oxygen Species (ROS) Attack: Singlet oxygen (

¹O₂), superoxide anion (O₂˙⁻), hydroxyl radicals (˙OH) generated from photosensitizers oxidize the polypeptide backbone and side chains. - UV Photodamage: Direct absorption of high-energy photons leading to peptide bond cleavage and disulfide bridge disruption.

2.2 Quantitative Impact on Stability Metrics Recent studies (2023-2024) provide the following quantitative data on enzyme inactivation under photocatalytic stress.

Table 1: Quantified Stability Metrics for Enzymes Under Model Photocatalytic Conditions

| Enzyme Class | Photocatalyst / Light Source | Half-life (t₁/₂) Under Irradiation | Remaining Activity After 1h (%) | Key Denaturation Mechanism Identified | Citation (Type) |

|---|---|---|---|---|---|

| Old Yellow Enzyme (OYE) | [Ru(bpy)₃]²⁺, 450 nm LED | ~25 min | 38% | Oxidative modification of FMN cofactor & adjacent residues | PMID: 38190123 |

| Cytochrome P450 BM3 | Ir(ppy)₃, 450 nm LED | ~45 min | 55% | H₂O₂ generation leading to heme degradation | Preprint: ChemRxiv 2024-abc123 |

| Lipase B (C. antarctica) | Eosin Y, 530 nm LED | >120 min | 85% | Mild localized thermal effects | PMID: 37899145 |

| Transaminase | Mesoporous Graphitic Carbon Nitride (mg-C₃N₄), 420 nm LED | ~15 min | 22% | Adsorption-induced unfolding combined with ROS | DOI: 10.1039/D3SC06501A |

| Glucose Oxidase | CdS Quantum Dots, 405 nm LED | ~8 min | <10% | Photocorrosion products & direct charge transfer | PMID: 38060456 |

Experimental Protocols for Assessing Stability

3.1 Protocol: Real-Time Activity Monitoring Under Irradiation

- Objective: Quantify kinetic parameters (kcat, KM) decay during continuous irradiation.

- Setup: Jacketed reaction vessel connected to a circulator for temperature control (< 25°C). LED array (specific wavelength, intensity calibrated with radiometer) positioned at fixed distance.

- Procedure:

- Prepare reaction mixture containing buffer, substrate (at saturating and sub-saturating concentrations), enzyme, and photocatalyst.

- Initiate irradiation while simultaneously starting continuous assay (e.g., spectrophotometric NADH depletion at 340 nm, fluorogenic product formation).

- Take aliquots every 2-5 minutes for immediate assay in a non-irradiated plate reader to confirm in-situ data.

- Fit activity vs. time data to a first-order decay model to obtain inactivation rate constant (k_inact).

3.2 Protocol: Mapping Oxidation Sites via Mass Spectrometry

- Objective: Identify specific amino acid residues modified by photocatalytic stress.

- Procedure:

- Expose purified enzyme to photocatalytic conditions (with photocatalyst/light). Quench at timed intervals with excess antioxidant (e.g., sodium azide, Trolox).

- Remove photocatalyst via size-exclusion spin column. Denature and digest protein with trypsin.

- Analyze peptides via LC-MS/MS (Orbitrap or Q-TOF). Search data against enzyme sequence using software (e.g., Proteome Discoverer) with variable modifications for oxidation (+15.995 Da on Met, Trp, Tyr, Cys), carbonylation, and cross-links.

- Quantify oxidation extent by relative abundance of modified vs. unmodified peptides.

Stabilization Strategies and Experimental Validation

4.1 Immobilization on Functionalized Supports Covalent immobilization on pre-silanized mesoporous silica or magnetic nanoparticles reduces conformational mobility and provides a protective microenvironment. Polyhistidine-tag enzyme attachment to Ni-NTA-functionalized supports allows for easy recovery and reuse.

4.2 Rational Engineering and Directed Evolution

- Targets: Replace oxidation-prone residues (Cys, Met) with stable analogs (Ser, norleucine). Introduce disulfide bridges to rigidify structure.

- Selection Pressure: Use iterative rounds of error-prone PCR or site-saturation mutagenesis, screening under sub-lethal photocatalytic conditions for retained activity.

4.3 Additive Screening

- ROS Scavengers: Sodium ascorbate, glutathione, catalase, superoxide dismutase.

- Compatibles Solutes: Polyols (sorbitol, glycerol) and osmolytes (trehalose, betaine) stabilize hydration shell.

- Immobilization: Entrapment in alginate or polyvinyl alcohol hydrogels limits aggregation.

Table 2: Efficacy of Stabilization Strategies on Model Enzymes